- Offer Profile

- For over 55 years, we have planned, designed, manufactured, installed and commissioned biomass cogeneration plants worldwide. Additionally, we have been at the forefront of developing innovative technologies in biomass gasification, carbonisation and torrefaction for over 20 years.

Our technologies

- As one of the world’s leading suppliers of climate-neutral technologies for heat and power generation from biomass, we integrate sustainability with industry. Our innovative solutions also encompass biomass gasification, carbonisation and torrefaction.

PolyCombustion

-

Transforming a fossil-fueled world into a clean energy future.

As one of the world’s leading suppliers of climate-neutral technologies for heat and power generation from biomass, we integrate sustainability with industry. Additionally, we specialise in torrefaction and carbonisation plants for biochar production.

polycombustion

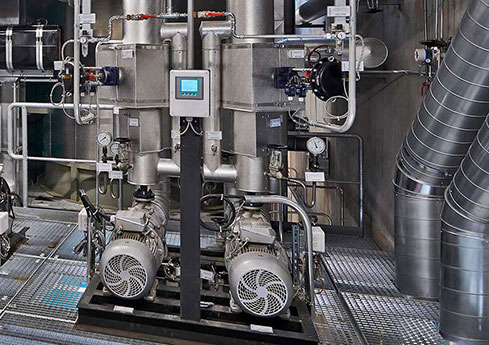

- Drawing on decades of expertise, Polytechnik provides highly efficient moving step grate furnaces, ensuring optimal combustion of various biomass types with minimal emissions. Our product portfolio includes systems with outputs ranging from 1 MW to individual boiler outputs of 30 MW thermal. We manufacture warm water and hot water boilers, hot air, steam and thermal oil boiler systems. Our combined heat and power plants primarily utilise superheated steam and thermal oil. Our extensive experience is reflected in the over 3,000 systems we have constructed worldwide.

Combustion technology

-

Our fully automatic fuel control ensures the optimal distribution of biomass throughout the combustion system. The fuel is pre-dried within the system for efficient degassing and subsequent combustion in the system. Specially adapted air and flue gas fans for each zone provide precise temperature control and effectively mix pyrolysis and combustion gases with oxygen. This results in complete burnout, minimal emissions and maximum efficiency.

Combustion systems

- Air and water-cooled reciprocating flat and step grates

- Underfeed stoker systems and combinations

Boiler technology

-

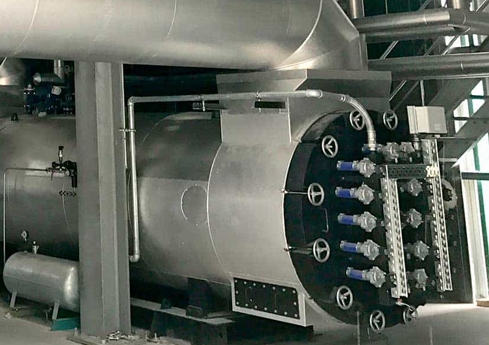

To efficiently transfer the energy of the hot flue gases in the combustion chamber to the heat utilisation system, Polytechnik offers a robust and durable range of boiler systems. Our boilers are designed to ensure maximum efficiency across the entire load range while guaranteeing low operating and maintenance costs. The heat exchangers are equipped with automatic heating surface cleaning systems to maintain optimal performance.

Boiler types

- Water and smoke tube boilers

- Thermal oil boiler

- Single, double and multi-pass design

Input Material - PolyCombustion

- We work with a diverse array of tried-and-tested fuels, enabling us to implement the most economically viable system for each fuel type.

Warm and hot water

- Polytechnik’s warm and hot water generation systems are not only used in industry (to supply drying kilns in the timber industry, for instance) but also extensively in local and district heating systems for municipalities and cities. Our domestic hot water (DHW) generation systems operate in the 90-110°C range, while our hot water (HW) systems supply temperatures from 110°C to 200°C.

Hot air

- These systems use flue gases from biomass combustion to produce hot air or hot gas. This can be achieved either directly by mixing flue gas in mixing chambers (hot gas) or indirectly by using mixing chambers and heat exchangers (hot air). Hot gas systems can reach medium temperatures between 130°C and approximately 950°C, while hot air systems achieve temperatures between approximately 100°C and 350°C.

Superheated steam

- Superheated steam is created by heating steam above its saturation temperature through additional flue gas heating in the superheater. Depending on the input material, our biomass power plants can generate superheated steam with temperatures of up to 475°C. This superheated steam is typically directed to a steam turbine to generate power.

Process steam

- Our process steam systems reliably and efficiently supply steam to steam-processing sectors ranging from the veneer, food and brewing industries to the dairy, cosmetics, aircraft and paper industries. Our process steam systems convert biogenic residues into steam of the required quality and quantity. We offer a wide range of solutions, from low-pressure steam boilers to high-pressure and hot steam boilers.

Thermal oil

- Our thermal oil systems are tailored to meet the specific requirements and operating temperatures of our customers’ processes, utilising either mineral or synthetic oils as their energy source. Polytechnik’s thermal oil systems are employed not only in combined heat and power plants but also across various industrial sectors. These sectors use thermal oil for heating, drying and other technological processes, such as veneer pressing. The thermal oil systems we offer are compatible with both mineral and syn

Combined heat and power generation

- Combined heat and power (CHP) plants are an efficient and cost-effective way to generate both heat and power from biogenic residues. This dual generation can be achieved through the use of a steam turbine or an organic Rankine cycle (ORC) turbine.

Reference - PolyCombustion

PVA Alland

- Boiler output: 800 kW

- Combustion system: Hydraulic step grate

- Input material: Hogfuel, Woodchips

- Construction: 2009

- Location: Austria

- Technology: PolyCombustion

- Technical system: Warm water

- Industry: District heating

PBS-Schreiner

-

- Combustion system: Hydraulic step grate

- Input material: Bark, Hogfuel, Woodchips

- Construction: 2014

- Location: Germany

- Technology: PolyCombustion

- Technical system: Process steam

- Industry: General industry

Naturwärme Schrems

- Boiler output: 1500 kW & 2000 kW

- Combustion system: Hydraulic step grate

- Input material: Bark, Hogfuel, Woodchips

- Construction: 2014

- Location: Austria

- Technology: PolyCombustion

- Technical system: Warm water

- Industry: District heating

PolyGasification

PolyHeld

-

is the combustion technology of the future. Extreme air staging techniques facilitate the clean and efficient combustion of various fuels while minimising emissions.

The PolyHeld system delivers an exceptionally efficient heat supply solution, catering to low output ranges from 400 kW to 3 MW. By integrating a counterflow gasifier and precision staged combustion, we attain efficiencies surpassing 92%. Its unique design eliminates the need for supplementary flue gas cleaning, leading to substantial savings in operational costs. Notably, the PolyHeld system boasts an outstanding partial load capacity of as low as 25%. The PolyHeld system is particularly suitable for generating warm water, hot water and steam as well as for heating thermal oils.

- Fuel versatility: wood and forestry residues and most woody fuels (with a moisture content of up to M45)

- Efficiency: >92% (a 5% improvement over traditional systems)

- NOx: 25% lower than conventional systems

- Dust: <20mg/Nm3; 11% O2 (without additional exhaust gas cleaning)

- Output range: 25-100%

- Low maintenance costs

KOMBI POWER SYSTEMS

-

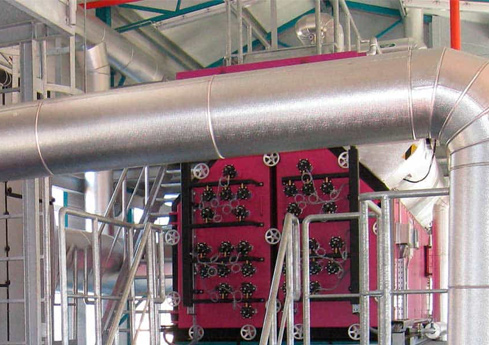

The cornerstone of the ReGaWatt-developed Kombi Power System is its counterflow gas generator, capable of delivering thermal outputs of 990 kW to 20,000 kW. Moreover, through a combined heat and power unit, it can produce an electrical output ranging from 250 kW to 5,000 kW. This robust and durable gasification technology boasts numerous advantages:

- Extensive fuel versatility: biogenic residues such as waste wood, screenings and bark

- Capable of operating at part-load (as low as 20%) and adjustable within minutes

- No pre-drying necessary (w30 – w55)

- Complete burnout = clean ash

With its modular design, the Kombi Power System offers customisable solutions tailored to each customer’s requirements, facilitating the versatile production of power, heat, cooling, steam and synthesis gas for direct gas utilisation. Additionally, it yields bio-oil with a calorific value comparable to heating oil, ideal for heat generation and temporary storage to offset peak demands (can be stored for up to 6 months).

Technical media

Warm and hot water

- Polytechnik’s warm and hot water generation systems are not only used in industry (to supply drying kilns in the timber industry, for instance) but also extensively in local and district heating systems for municipalities and cities. Our domestic hot water (DHW) generation systems operate in the 90-110°C range, while our hot water (HW) systems supply temperatures from 110°C to 200°C.

Hot air

- These systems use flue gases from biomass combustion to produce hot air or hot gas. This can be achieved either directly by mixing flue gas in mixing chambers (hot gas) or indirectly by using mixing chambers and heat exchangers (hot air). Hot gas systems can reach medium temperatures between 130°C and approximately 950°C, while hot air systems achieve temperatures between approximately 100°C and 350°C.

Superheated steam

- Superheated steam is created by heating steam above its saturation temperature through additional flue gas heating in the superheater. Depending on the input material, our biomass power plants can generate superheated steam with temperatures of up to 475°C. This superheated steam is typically directed to a steam turbine to generate power.

Process steam

- Our process steam systems reliably and efficiently supply steam to steam-processing sectors ranging from the veneer, food and brewing industries to the dairy, cosmetics, aircraft and paper industries. Our process steam systems convert biogenic residues into steam of the required quality and quantity. We offer a wide range of solutions, from low-pressure steam boilers to high-pressure and hot steam boilers.

Thermal oil

- Our thermal oil systems are tailored to meet the specific requirements and operating temperatures of our customers’ processes, utilising either mineral or synthetic oils as their energy source. Polytechnik’s thermal oil systems are employed not only in combined heat and power plants but also across various industrial sectors. These sectors use thermal oil for heating, drying and other technological processes, such as veneer pressing.

Combined heat and power generation

- Combined heat and power (CHP) plants are an efficient and cost-effective way to generate both heat and power from biogenic residues. This dual generation can be achieved through the use of a steam turbine or an organic Rankine cycle (ORC) turbine.

References - PolyGasification

Fernwärme Sulz

-

- Boiler output: 1,000 kW

- Combustion system: PolyHeld wood gasifier

- Input material: Forest woodchips

- Construction: 2020

- Location: Austria

- Technology: PolyGasification

- Technical medium: Hot water

- Industry: Energy supplier, District heating

Furudono

- Boiler output: 2x 990 kWel

- Combustion system: Poly ReGaWatt wood gasifier

- Input material: Bark, Forest woodchips

- Construction: 2024

- Location: Japan

- Technology: PolyGasification

- Technical medium: Thermal oil

- Industry: Energy supplier

Knaupp

- Boiler output: 2x 2,000 kW

- Combustion system: PolyHeld wood gasifier

- Input material: Woodchips

- Construction: 2023

- Location: Germany

- Technology: PolyGasification

- Technical medium: Hot water

- Industry: Greenhouse

PolyCarbonisation

PolyCarbonisation

-

With our proprietary technology, we design and construct production plants for biochar applications with carbon content reaching up to 97%. Our process employs pyrolysis, in which biomass is heated in the absence of air, utilising an automated batch process. The waste gases and pollutants generated during carbonisation are thermally recycled within a closed-loop system. The excess energy produced can be used thermally or converted into power. The entire production process – from raw material delivery to biochar processing – is highly automated and operates on a 24/7 shift basis. Polytechnik offers plants with annual production capacities ranging from 3,000 to 9,000 tonnes.

Torrefaction

-

Our specialised combustion unit enables the lean gas produced during torrefaction to be utilised in addition to the solid fuel.

Polytechnik’s torrefaction plants are the latest addition to our product portfolio. These plants have an annual production capacity of up to 60,000 tonnes, converting various types of solid biomass into a dimensionally stable, easily transportable and storable product through pyrolysis at around 300°C in the absence of air. The energy released during this process that is not needed for the torrefaction can be harnessed to generate hot water or steam or to heat thermal oil, depending on customer requirements.

Torrefied material can be used as a substitute for fossil coal in numerous applications, such as the steel industry. We customise our torrefaction plants to meet specific customer requirements, particularly regarding the input material. This customisation ensures an optimised performance and enhances economic efficiency for our clients.

Reference - PolyCarbonisation

Green Carbon

- Kesselleistung: 4.000 kW

- Feuerungsart: Syngas Brennkammer

- Inputmaterial: Biomasse Reststoffe

- Baujahr: 2015/2016

- Standort: Deutschland

- Technologie: PolyCarbonisation

- Technisches Medium: Heißluft

- Industrie: Biochar Produktion

Taaleri / Joensuu Biocoal

- Boiler output: 12,000 kW

- Combustion system: Syngas combustion chamber

- Input material: Forest woodchips

- Construction: 2024

- Location: Finland

- Technology: PolyCarbonisation

- Technical medium: Hot water

- Industry: Green coal production, Torrefaction

Service

- The purchase of a Polytechnik system marks the beginning of our relationship with the customer, not the end. Our numerous long-standing partnerships are a testament to the trust our clients place in our team’s expertise and innovative capabilities.

Maintenance & repair

-

Your benefits include:

- Customised maintenance plan

- Damage prevention

- Reduction and control of repair costs

- Minimised downtimes

- Maintaining the value of your system

Routine maintenance and servicing are crucial to avoiding downtime and prolonging the lifespan of your system. We provide tailored and adaptable maintenance contracts, ensuring that your system can not only be operated longer but also more cost-effectively.

With our in-house production capabilities and extensive partner network, maintenance and repairs to our systems can be carried out quickly. Moreover, preventive check-ups can substantially mitigate any repair costs associated with your system.

Spare parts procurement

-

Our services include:

- Expert consultation

- Production of customised spare parts

- Reliable procurement from trusted manufacturers

- Logistics support

You can count on our service team for expert guidance on selecting the right spare parts. Whether produced in-house or sourced from reputable manufacturers, quality and long-term availability are our top priorities. We are also happy to handle the logistics for you, ensuring prompt and reliable delivery.

Modernisation & optimisation

-

Our services include:

- Analysis and evaluation of the current situation

- Recommendation of measures to optimise and increase efficiency

- Recording of operating and status data (e.g., exhaust gas values)

- Concept development for risk minimisation and operational safety

- Modernisation through the use of innovative technologies

Maximising resource efficiency is not only crucial for sustainability but also central for the economic success of your plant. We provide the opportunity to modernise and optimise your system to align with efficiency standards.

After conducting a thorough analysis and condition assessment of all components, we will provide you with a foundation for making informed decisions regarding subsequent measures for your system.

Operator training & consulting

-

Our services include:

- Training for new staff members

- Refresher training for your company

- Advice on converting your operations

Professional operation of the system is essential for economic efficiency and a prolonged service life.

After commissioning, we offer ongoing advice and support, including further training, analysis of optimal operating parameters and guidance on adjusting the operating structures as needed.