- Offer Profile

-

Quality, innovation and customised solution. These are the three pillars of dbds – Deutsche Biogas Dach-Systeme GmbH, which offers flexible storage systems for biogas plants. Our high standards for the quality we provide – both when it comes to advising and supporting customers, and in the quality of our products – paired with our determination to always think innovatively and strive for further progress mean that we can give our customers first-class, customised solutions that offer the best possible efficiency. This philosophy and this goal have made dbds a leading provider of gas storage systems in the agricultural and industrial biogas plant sectors.

Welcome to dbds – Deutsche Biogas Dach-Systeme GmbH

-

dbds – Deutsche Biogas Dach-Systeme GmbH is an established system provider in the biogas segment, offering double-membrane gas storage units with a focus on quality, innovation and customised solutions. Our aim at all times is to tailor optimally efficient individual solutions to our customers from the industrial, agricultural and municipal power supply sectors.

From consulting and designing roof systems and components, through production, to installation and completion, we insist on the highest quality standards. To ensure this, we rely on high quality components for PVC membranes, stainless steel elements, sensors and support air fans, as well as verifiable structural analysis in accordance with DIN EN 1991-1-4. Our membranes are joined together in our factory in Düren, near Cologne, using the high-frequency welding method for maximum durability.

To ensure continuous further development of our roof system, we focus on innovation, working on research projects and real-life tests aimed at increasing the efficiency of our roof systems. We use Low Emissivity technology (LowE) to improve the efficiency of biogas plants by reducing thermal losses through the roof system thanks to a coating of aluminium particles applied in the factory, thus saving energy costs.

As a member of the Fachverband Biogas e.V. and Biogasrat biogas associations, and the Flexperten and DWA working groups representing the biogas, cogeneration, power trading and water management sectors, we work together closely with our partners to advance and promote our industry.

Technology & expertise

-

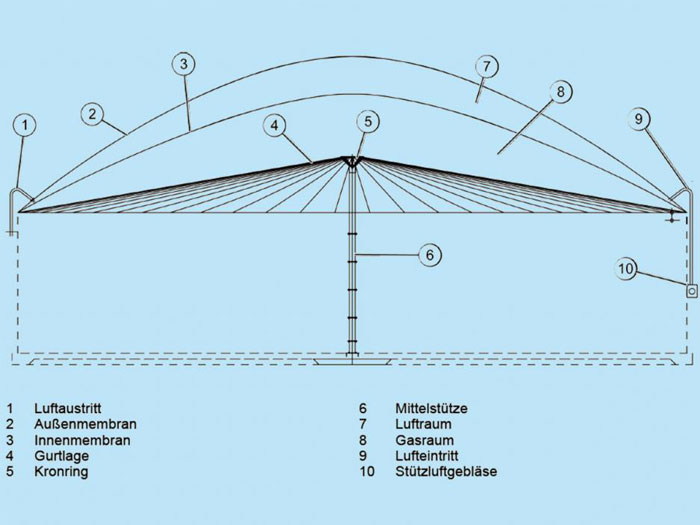

As a system provider of double-membrane gas storage units, we insist on the highest quality when it comes to designing our gas storage systems. We pay particular attention to careful and painstaking production of membranes in our two factories in Düren, and we use first-class fastening and substructural components, as well as sensors, measuring and support air technology.

Together with our long-term suppliers and partners, we believe in producing durable and long-lasting products and the most efficient implementation in each individual case.

Double Membranes

-

Our double membranes are made of a PVC-coated polyester fabric that was specifically designed and produced for use in the biogas sector. The material is flame retardant in accordance with DIN 4102 B1 and it is UV-resistant. We use materials with a grammage ranging from 800 g/m² to 1,500 g/m². Our standard colours for this are agate grey as per TRAS-120 (similar to RAL 7038) or moss green (similar to RAL 6005), but other colours are also available on request, such as silver grey (similar to RAL 7001). The gas permeability of the membranes ranges from <200 cm³/(m² d bar) to <500 cm³/(m² d bar).

The material is welded together in our two factories in Düren using the high-frequency welding method. The outer membrane has built-in air inlets and outlets and condensate drain plugs. Hemstitch seams or flaps are worked into the inner membrane as guides for the fill level measuring equipment. If desired or depending on individual needs, we can also integrate viewing windows, service platforms or other built-in parts in our double membranes. For profiles up to the size of the hemisphere, we employ parallel cutting with material webs arranged in parallel to prevent concentrations of tension in the pole area.

Double membranes for bolted fastening systems feature a reinforced piping edge to guarantee the best possible durability at the clamping edge even under unusually high pressure or extreme weather conditions.

TRAS 120

-

The TRAS-120 regulations define the technical requirements for biogas plants to minimise dangers such as fire, explosions and other safety-related risks. They include design requirements such as materials, sealing systems, tank and piping dimensions, and safety equipment. In addition, they contain operational specifications for monitoring gases and temperatures, handling substrates, pressure-relief systems and guidelines on what to do in the event of malfunctions or emergencies. Furthermore, the TRAS-120 guidelines specify regular inspection, maintenance and servicing of plant sections to ensure safe operation and avoid dangers.

For more information and editions, consult, for example, the Commission on Process Safety (KAS) at the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection.

You can download the technical rules for plant safety (TRAS 120) – technical safety requirements for biogas plants (unofficial version from 15.03.2019, official version of TRAS-120 published in the Federal Gazette) here.

Below is a list of the most important points required to comply with TRAS-120 that we at dbds cover. We will be happy to inform you about additional measures.

LowE technology for double membranes to increase the thermal efficiency of biogas plants

-

The question of energy efficiency and thermal efficiency is becoming more and more important, including in the biogas sector. To achieve significant reductions in the demand for heating and thus improve the energy efficiency of biogas plants, dbds – Deutsche Biogas Dach-Systeme GmbH uses patented Low Emissivity Technology (LowE). This involves a coating of aluminium particles applied to the PVC membranes in the factory on the outer face of the inner membrane or the inner face of the outer membrane. The principle of applying a coating with a low emmisivity is familiar from thermal insulation glazing, where it has become a tried and tested, state-of-the-art method.

The benefits to you:- Energy savings from reducing the annual heating demand (by up to -20%)

- Reduction of gas or volume losses by reflecting heat in summer and thus preventing excessive expansion

- No additional insulation in the roof system and thus no additional load on the substructure or additional work and expense during installation

- Attractive funding options from the KfW national development bank possible thanks to process-related savings for conventionally generated energy

References

-

Our mission: Customer satisfaction thanks to customer focus

Here you can find a selection of references for our double-membrane gas storage units, in Germany and elsewhere. We would be happy to provide you with further references from your local area or in different fields and for different specifications, on request.

The services and references provided by dbds range from double-membrane systems on tanks with standard or customised heights, through external gas tanks with a spherical or rectangular design, the integration of special fittings (service platforms, viewing windows, manholes etc.), to service and upgrade deployments for your biogas plant.

Cüstriner Bioenergie project

-

Project data

- Location: Küstriner Vorland, Germany

- Wind load zone: II

- Application: agricultural products

- Project implementation: 2023

BGA Bützow project

-

Project data

- Location: Bützow, Germany

- Wind load zone: II

- Application: agricultural products

- Project implementation: 2022

BGA Genthin project

-

Project data

- Location: Landkreis Genthin, Germany

- Wind load zone: II

- Application: biowaste fermentation plant

- Project implementation: 2020

External gas tank at Dolgen am See

-

Project data

- Location: Dolgen am See (Landkreis Rostock), Germany

- Wind load zone: II

- External gas tank designed as a hemisphere

- Project implementation: 2019

BGA Eberdingen project

-

Project data

Special profile with cylindrical extension of the inner membrane and undercut design of outer membrane to achieve the desired gas storage volume of 2,000 m³.

- Location: Eberdingen, Germany

- Wind load zone: I

- Application: agricultural products - flexibilisation

- Project implementation: 2020

BGA Wurzen project

-

Project data

Double membrane in compliance with TRAS-120 with two integrated service platforms

- Location: Wurzen, Germany

- Wind load zone: II

- Application: agricultural products

- Project implementation: 2019