- Offer Profile

-

ABEL develops and manufactures reciprocating positive displacement pumps for varying flow rates and pump pressures and specializes in diaphragm pumps. Depending on the design, they are suitable for abrasive, aggressive, and even shear-sensitive media. We are recognized around the world as the technological leaders in mechanical diaphragm pumps. Solids handling pumps (for paste-like and non-Newtonian media) and high pressure plunger pumps complete our range of products.

DIAPHRAGM PUMPS

-

Diaphragm pumps for difficult media and extremely tough applications

ABEL develops and manufactures reciprocating positive displacement pumps for varying flow rates and pump pressures and specializes in diaphragm pumps. Depending on the design, they are suitable for abrasive, aggressive, and even shear-sensitive media. We are recognized around the world as the technological leaders in mechanical diaphragm pumps. Solids handling pumps (for paste-like and non-Newtonian media) and high pressure plunger pumps complete our range of products.

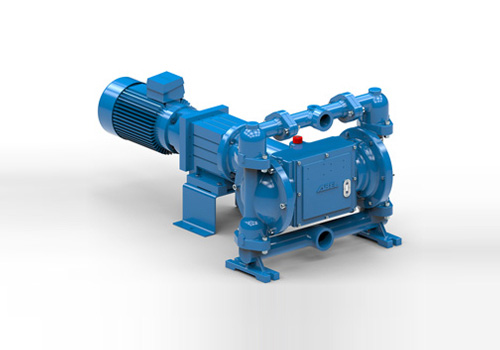

EM Electric Diaphragm Pumps Metal

-

The ABEL EM series is available in three different metal designs: ductile iron (SG), stainless steel (ED), or aluminum (AL, upon request). Using suitable, durable materials for diaphragms, valve seats and balls will give you the best possible combination of materials for your application.

Metal design- Water and waste water management

- Ceramics industry

- Surface engineering

- Marble and stone works

- Shipping, offshore

- Automobile industry

- Machine construction

- Pigment production

- Paper industry

- Mining

- Paint and lacquer industry

- Steel industry

EM Electric Diaphragm Pumps Plastic

-

In the chemical industry and in other areas of process technology, aggressive media require the use of high-quality plastics such as polypropylene (PP) or PVDF (PV), as well as explosion-proof motors. ABEL offers suitable pumps for these applications with maximum pump flows of up to 20 m3/h (90 GPM).

Plastic design- Chemical industry

- Pharmaceutical industry

- Refineries

- Power plants

ABEL EM pump applications

- As process pumps for the transport of fluids and powders

- Feeding filter presses

- Feeding centrifuges

- For dosing

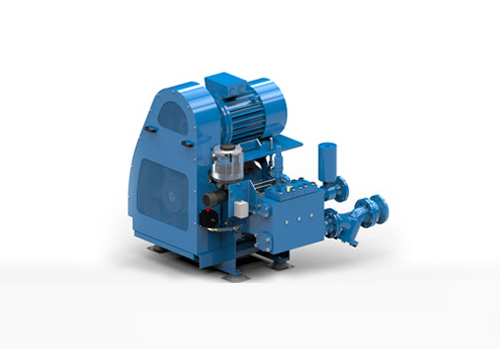

CM Compact Diaphragm Pumps

-

ABEL CM piston diaphragm pumps are single or double-action specialized pumps that are used for difficult media. They are highly resistant to wear, even when used at high pressures over an extended period of time. Their true double-diaphragm technology offers a high degree of safety. When used as a pump for feeding filter presses, the rugged, automatic flow rate control (which does not use complex electronics) is another impressive feature that makes it even more reliable.

ABEL CM pumps – specialists for difficult media- For sludge transfer

- Feeding filter presses, rotary kilns, or spray driers (spray dryer feed pump)

- Raw sewage transfer

- Transfer of abrasive, corrosive, acidic, alkaline, pigmented, viscous, and grainy media

HM Hydraulic Piston Diaphragm Pumps

-

These Piston Diaphragm Pumps are reliable under

high-pressure and increased flow rates.

The ABEL HM Piston Diaphragm Pump Range has been especially developed for operations with increased flow rates combined with high operating pressures. During the last 15 years we have constantly developed our products to comply with the latest challenges and requirements in the industry.

ABEL HM PISTON DIAPHRAGM PUMPS are available as single or double-acting models as well as assuring an increased performance, reliable functionality and especially low operating and maintenance costs. They can be utilised for flow rates up to 100 m³/h, and up to 10.0 MPa operation pressure. The ABEL HM Pumps are equipped with pre-formed diaphragm which remain stable throughout the duration of the pumping operations. The ABEL HM construction method has been tested in many various industries, as well as with very difficult media, and has been proved to be operationally secure as well as providing a very high membrane, service life time. The parts of the pump which will come into contact with the materials to be pumped are made of nodular cast iron (also rubber-coated), polypropylene, cast steel or stainless steel.

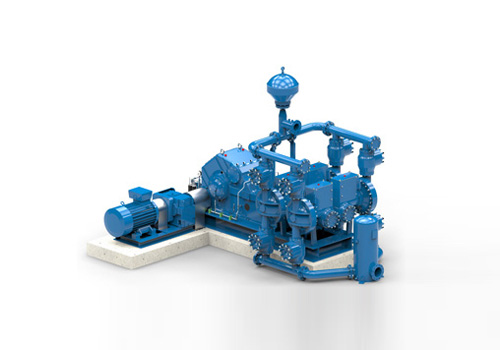

HMQ Hydraulic Piston Membrane Pumps

-

Piston diaphragm pumps for efficiently handling large volumes - that is ABEL`s strong point

The pumps which are included in the ABEL range, HMQ (Quadruplex) are easily identifiable due to their unique compactness and space-saving designs. They come to the fore when large volumes of abrasive materials need to be transferred under high-pressure conditions. This also applies when slurry with a high, mineral based content has to be transferred, in such environments as the mining and/or cement industry.

The four, pre-formed diaphragms which are incorporated in an ABEL HMQ remain stable throughout the duration of the pumping operations. A regulating-valve installed on the hydraulic side of the unit monitors not only the front diaphragm, but also the rear diaphragm position. This concept of diaphragm monitoring, which provides a high service life standard, is one of the basic reasons behind the reliability and durability of these products.

Every ABEL HMQ Pump is equipped with an integral reduction gear and can be fitted out with ball and/or API cone valves. The parts of the pump which will come into contact with the materials to be pumped are made of nodular cast iron (also rubber-coated), cast steel or stainless steel. A reverse flow design is also available for installation in cases of slurries which contain non-stable sedimentation. These multiple-application, piston diaphragm pumps are an ideal construction for transfer operations involving flows of up to 800 m³/h and pressures of up to 10.0 MPa (with special unit-sizes up to 16.0 MPa), also providing economical advantages for the user.

HMT Hydraulic Piston Membrane Pumps

-

These Triplex Piston Diaphragm Pumps transfer abrasive slurries up to 25.0 MPa.

Very high operating pressures in connection with increased flow rates create special environments for pump specifications. When abrasive materials with an increased SC-content are present, many industrial partners decide on an ABEL HMT. This simple operating, slow-running Triple Piston Diaphragm Pump operates safely, even when dry, and can be utilised in conditions where the flow rates reach 600 m³/h.

The Pumps in the HMT range are equipped with API cone valves and are also available for reverse-flow for non-stable sedimentary slurries. Parts which come into contact with slurries to be pumped are constructed of nodular cast iron, cast steel or various stainless steels. Typical applications for transfer requirements, as well as high-pressure environments, for an ABEL HMT are pipeline transfer, autoclaves and/or reactor feed and spray dryer feeding.

PISTON PUMPS

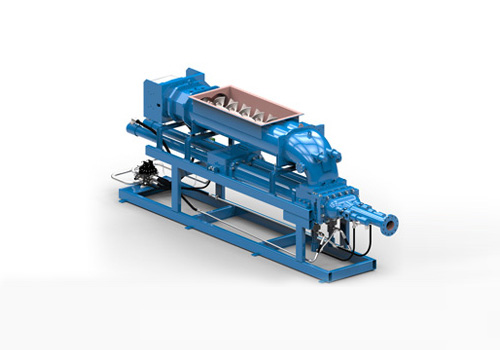

SH Solids Handling Pumps

-

Solids Handling pumps for difficult media at extremely high pressure.

ABEL SH solids handling pumps span a wide performance range and are also suited for a large number of pumping media and applications. These high pressure pumps really prove their worth when extremely abrasive, paste-like and compact media (e.g. dehydrated sewage sludge) have to be conveyed safely at high pressure. At ABEL, this high-capacity pump has extra wall thickness and a large intake valve, which, when combined with a very good filling ratio, produce a service life that is longer than the norm.

Along with the actual pump unit (consisting of sludge, hydraulic main and valve cylinders) an ABEL SH thick matter pump comprises a total of four components: the actual pump, the hydraulic drive unit, a feed screw to fill the product cylinder, and a control cabinet with PLC. The programmable logic controller is the “brain” of the system and allows for integration with complex processes and control room systems.

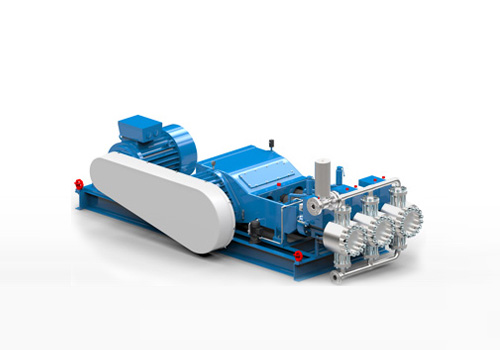

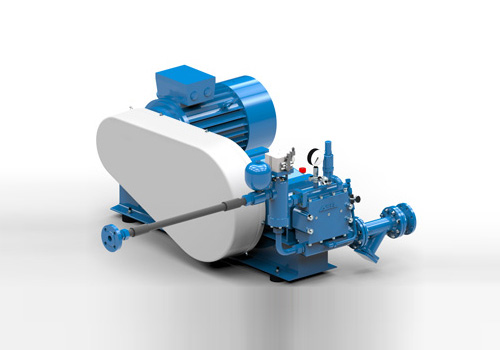

HP High Pressure Pumps

-

ABEL HP triplex plunger pumps - an efficient, solid purchase.

he HP series offers an additional triplex plunger pump for high pressure cleaning with up to 16.0 MPa (2300 psi). This series has proven its worth many times over, especially when used to clean filter cloths for chamber and membrane filter presses. With accessories that are designed to meet the specific needs of cleaning applications, such as the ABEL directional control valve, this series lives up to expectations. The ABEL Series HP pumps can be used in the oil and gas industries, and for feeding combinator in the food industry.

Very high pressure for an extended period of time – is demanding – requires: ABEL HPT

Especially in process technology, ABEL HPT high pressure plunger pumps show a technological edge when used rigorously over a longer period of time. And that applies for quite varied media, such as salt water and salt solutions, acids, margarine, chemicals, and even lightly contaminated fluids.

HPT High Pressure Pumps

-

Very high pressure for an extended period of time – is demanding – requires: ABEL HPT

Especially in process technology, ABEL HPT high pressure plunger pumps show a technological edge when used rigorously over a longer period of time. And that applies for quite varied media, such as salt water and salt solutions, acids, margarine, chemicals, and even lightly contaminated fluids.

Designed to meet the requirements of the media being pumped, various materials are used, such as high(-)quality stainless steel. Different types of valves are also used, such as cone, spherical cone, and ball valves. The plunger seal, which is adapted to meet the requirements of the application and pumping media, is made using V-rings or stuffing boxes; of course, they are also available in flushed or lubricated versions.

Built in mobile turnkey containers, HPT series pumps can be used in a number of applications, especially when you require a high degree of mobility because you need to keep changing locations.