- Offer Profile

-

Stirling Cryogenics is the international market leader in stand-alone cryogenic cooling systems. Located in the Netherlands in the town of Son, at the outskirts of Eindhoven. Originally founded by technology giant Philips more than 70 years ago and it has been the cornerstone of our cooling systems ever since.

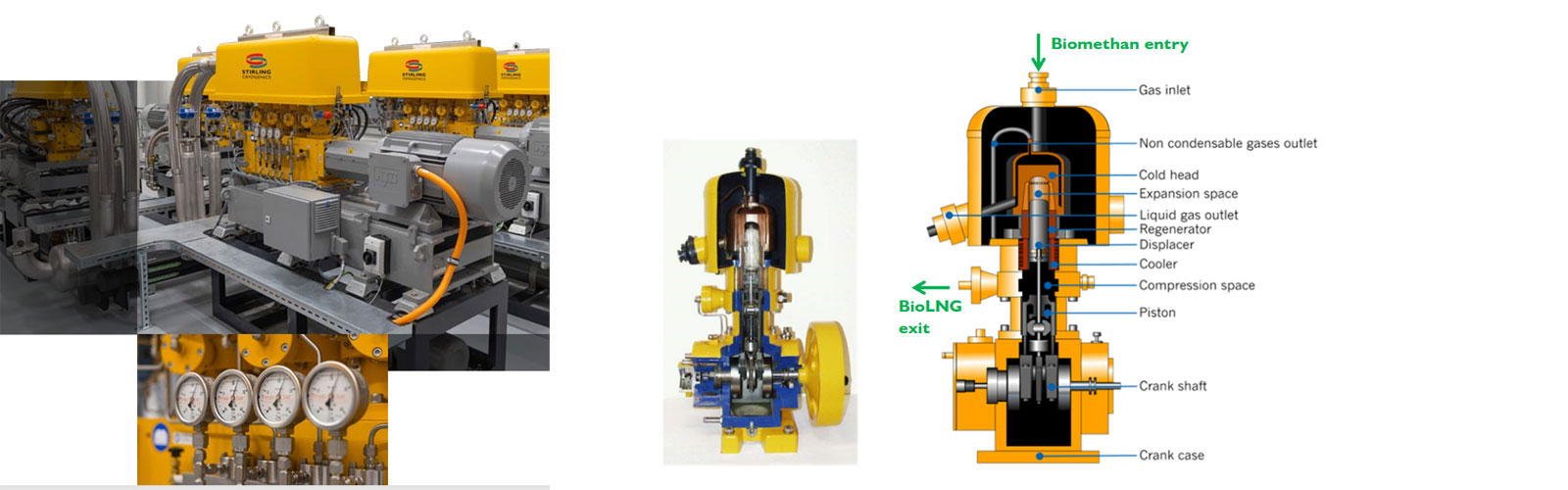

We design, build and supply cryogenic solutions based on the (reversed) Stirling thermodynamic cycle with over 4,000 installations worldwide. The Stirling cryogenerator makes it possible for our systems to produce temperatures ranging from 200 K (-73 °C) down to 15 K (-258 °C). With a Stirling Cryogenerator you've got your own reliable and efficient cold source! [Image of Stirling cryocooler diagram]

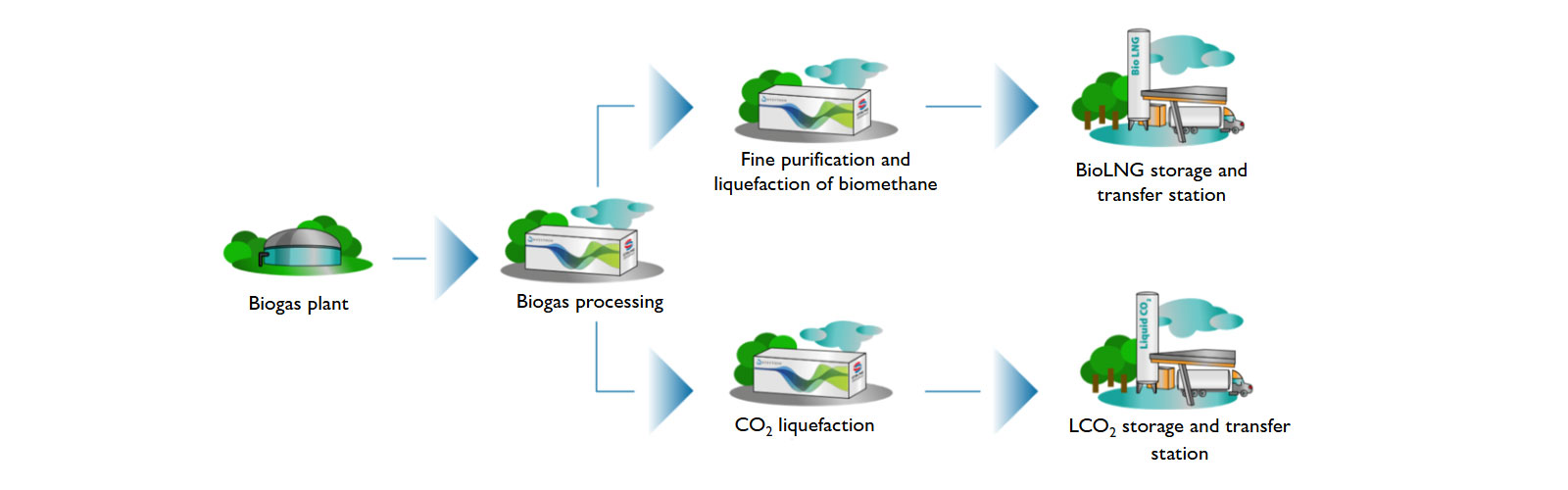

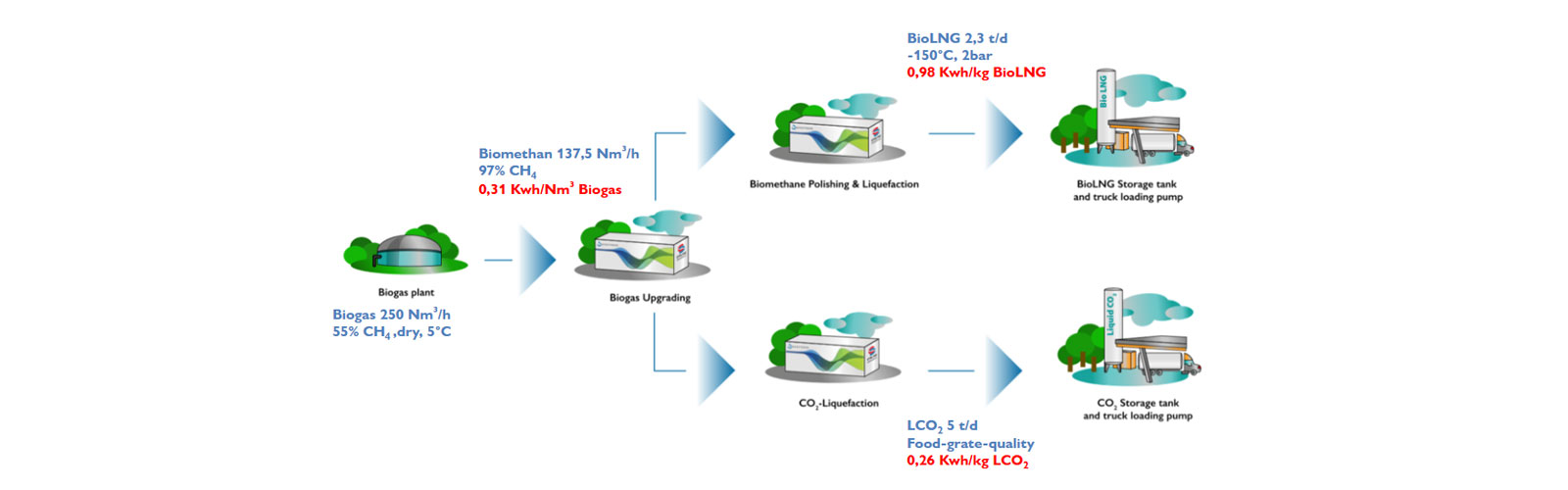

From Biogas to BioLNG (liquid biomethane)

-

Scope of delivery:

- Biogas upgrading

- Bio-LNG liquefaction

- CO2 processing

- Infrastructure for Bio-LNG and CO2 (storage tanks, transfer pumps, dispensers)

- Integration into existing plant technology

The scope of supply can be offered and installed either in full or in parts.

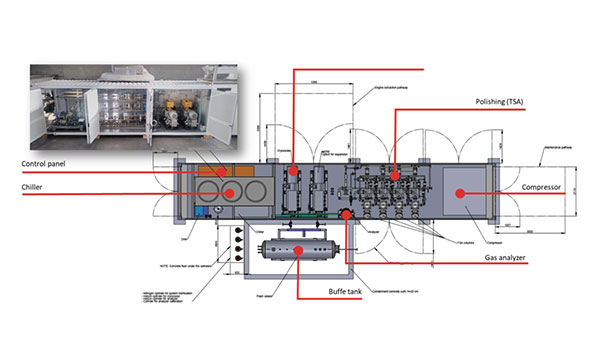

Biogas upgrading

-

The raw biogas coming from the fermenter of the biogas plant is first pre-treated and then compressed to a certain pressure. This built-up pressure causes the raw biogas to pass through hollow body membranes, where the separation of CH4 (methane) and CO2 (carbon dioxide) takes place. Using a 3-stage process, the required gas quality of up to 97% by volume CH4 is achieved. The quality of the biomethane is constantly measured using various analysers. If there are deviations in the concentration of the gases, the system is automatically adjusted to achieve a constant quality.

- Energy-efficient plant technology

- Modular design through the use of membranes

- Compatible with any biogas plant

- Plant size from 150 - 2,000 Nm³/h raw biogas

- Containerised design in our own production facility

- Hybrid gas treatment (for more contaminated gas)

- Design, installation, and commissioning by HYSYTECH

- 3-stage upgrading process

- Low power consumption for liquefaction (0.34 kWh/Nm³ biogas)

- PRISM membrane from AIR PRODUCTS

- Low maintenance requirements

Polishing and liquefaction of biomethane

-

Damit Biomethan als Kraftstoff eingesetzt werden kann, muss das Biomethan zu BioLNG umgewandelt werden. Dazu wird das aufbereitete Biogas aus der Gasaufbereitung durch eine Feinreinigung geführt und anschließend im Stirling-Kryokühler auf eine Temperatur von -155 °C gekühlt. Bei dieser Temperatur wird das Biomethan verflüssigt und kann als Kraftstoff eingesetzt werden. Das sich daraus ergebende BioLNG wird in kryogenen Lagertanks gelagert oder direkt an einer Tankstelle vertankt.

Durch den Einsatz des Stirling-Kryokühlers kann das BioLNG mit einem Druck von bis zu 0,5 barg hergestellt werden. Während des Verflüssigungsvorgangs werden aus 600 Litern gasförmigem Biomethan 1 Liter BioLNG. BioLNG ist einfach zu transportieren und dank seiner 3-mal höheren Dichte deutlich effizienter als BioCNG. Das hergestellte BioLNG wird hauptsächlich für den Fernlastverkehr eingesetzt. Die Stirling-Kryokühler wurden in den 1950er Jahren für die Verflüssigung von Stickstoff entwickelt und sind daher für Temperaturen von bis zu -196 °C ausgelegt. Nähere Informationen über das umgekehrte Stirling-Verfahren finden Sie auf unserer Website.

- Flexible, redundante und modulare Bauweise der Anlage (1 – 20 t/Tag BioLNG, bzw. 120 – 2000 Nm³/h Biogas)

- Keine weiteren Betriebsstoffe nötig

- Geringer Strombedarf

- Plug- & Play-Lösung dank containerbasierter Anlagenteile aus der eigenen Werksfertigung

- Kompatibel mit jeder Biogasanlage oder Biogasaufbereitungsanlage

- Vollautomatischer Anlagenbetrieb

CO2-liquefaction

-

CO2-Rückgewinnung leicht gemacht: Unsere hochmodernen Anlagen zur CO2-Rückgewinnung bieten eine äußerst effiziente Methode, um das aus der Biogasaufbereitung gewonnene CO2 in reinsten Rohstoff (99,998 %) zu verwandeln. Diese Anlagen werden nach höchsten Qualitätsstandards in Containerbauweise in unserer Produktionsstätte in Turin gefertigt und direkt beim Kunden installiert.

- Erfüllt EIGA-Norm

- Einsatz von ungiftigen Kühlmitteln

- Diverse Anlagengrößen verfügbar (360 Nm³/h bis 4.000 Nm³/h)

- Kompatibel mit jeder Biogasaufbereitung

Stirling Cryogenerator

-

Stirling Cryogenics is the specialist in stand-alone cryogenic cooling systems and is located in the Netherlands, on the outskirts of Eindhoven. Originally founded by technology giant Philips and since 2018 part of the HYSYTECH Group based in Turin (Italy). We design, build and supply cryogenic solutions based on the (reverse) Stirling thermodynamic cycle. Today, with over 4,000 installations in operation and 6,000 Cryogenerators across the globe, we continue to build on the legacy of innovation and reliability of our one and four cylinder Cryogenerators. Some of these systems and Cryogenerators have been in operation for 60 years and are still maintained by Stirling.

The cryogenerators are manufactured in the Stirling workshop in Eindhoven. They are then shipped to HYSYTECH in Turin, Italy. In Turin the gas purification system is built and the cryogenerators are integrated in the plant.

HYSYTECH is an engineering company specialising in the planning, development and industrial implementation of new turnkey process technologies and plants in the field of renewable energies. HYSYTECH is mainly active in the production, treatment and recovery of industrial gases, organic liquids and energy. The company utilises the best processes of its own technologies.

Technical Advantages:

- Fully integrated process "Gas upgrading + Bio-LNG liquefaction + CO2 processing"

- Cryogenerator designed for -196°C

- Operating pressure between 11-14 bar, production of Bio-LNG at low pressures (Bio-LNG @ 2-4 bar or lower)

- "Plug and Play" and modular design (from 1 up to 20 t/d Bio-LNG)

- Compatible with any biogas plant and biogas upgrading system

- Energy-efficient plant technology

- High technical availability (> 8,400 h/y)

- Redundant design (no single machine dependency)

- Fully automatic operation

- CE, ATEX, PED certificates

Integrated plant engineering

Standard setup Fine cleaning & liquefaction 2 t/d Bio-LNG

Standard layout Upgrading & Liquefaction 5 t/d Bio-LNG

OPEX costs

BioLNG Production Energy Analysis

This report outlines the specific energy consumption (SEC) required for the liquefaction and processing of biofuels. It defines the electrical input needed per unit of mass or volume for three distinct stages: BioLNG, Biogas, and Biomethane.

The analysis includes an efficiency benchmark for Biogas processing. With an intrinsic energy content of 5.5 kWh per Nm³, the processing input of 0.903 kWh per Nm³ represents a parasitic energy load of 16.4%.

Specific Energy Consumption Metrics

- BioLNG: 2.312 kWh / kg

- Biogas: 0.903 kWh / Nm³

- Biomethane: 1.642 kWh / Nm³

Annual Energy Calculation

The total annual energy consumption is calculated based on a daily production rate of 2.3 tonnes over a standard 350-day operational year.

- Daily Production: 2.3 tonnes (2,300 kg)

- Annual Mass: 805 tonnes (805,000 kg)

- Calculation: 805,000 kg × 2.312 kWh/kg

To achieve an annual production of 805 tonnes of BioLNG, the facility requires a total electrical energy input of 1,861,160 kWh per year. This is derived from a specific consumption rate of 2.312 kWh per kilogram of BioLNG produced.

References

Reference Biomethane Liquefaction 2 t/d – Sweden – in operation since 11/2021

Reference Biomethane Liquefaction 1 t/d – Italy – in operation since 09/2018

Reference Biomethane Liquefaction 6 t/d – South Germany – in operation since 12/2024