- Offer Profile

- Innovative Sensor Technology IST AG is a world-leading manufacturer of physical, chemical and biological sensors. Our product portfolio consists of thin- and thick-film platinum and nickel RTD temperature sensors, thermal mass flow sensors, capacitive humidity sensors, humidity modules, conductivity sensors and biosensors. Our sensors are characterized by their accuracy and consistency in various measurement conditions.

Additionally, as a development & technology partner, IST AG provides consulting, development and production of customized sensors.

Physical, chemical and biological sensors

-

Innovative Sensor Technology IST AG is a world-leading manufacturer of physical, chemical and biological sensors. Our product portfolio consists of thin- and thick-film platinum and nickel RTD temperature sensors, thermal mass flow sensors, capacitive humidity sensors, humidity modules, conductivity sensors and biosensors. Our sensors are characterized by their accuracy and consistency in various measurement conditions.

Additionally, as a development & technology partner, IST AG provides consulting, development and production of customized sensors. New sensors

OOL Bubble Detector

-

Out of liquid Flow Meter for Bubble detection in various liquids

Suitable for water, oil and aggressive liquids, the robust steel sensor detects bubbles from approximately 1 mm diameter upwards. Based on continuous thermal principle the switch is reliable, robust and easy to implement.

Find out more about our OOL product range, from drip to bubble detechtion.

Force, torque and surface strain sensors

-

by Senstech

Physical thin film sensors for measuring large forces, shear stress, surface strain. Senstech is specialized in the development of standard and OEM sensor solutions for various measuring parameters, the application and structuring of thin layers as well as all other steps for the production of the sensor elements

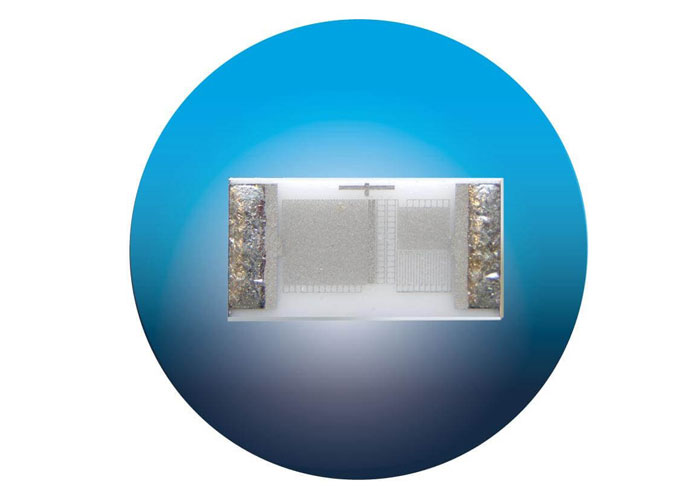

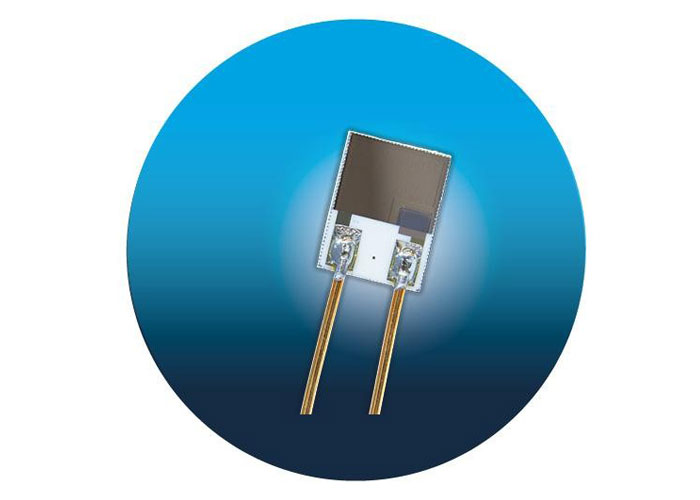

Conductivity sensor LFS1505.2L.20-4

-

Low cost four-electrode measurement for various conductivity measurement applications

This new conductivity sensor has a wide conductivity range, excellent long-term stability and fast response time. The four-electrode measurement guarantees optimal accuracy and comes with PTFE-insulated Cu/Ag wires. Customer-specific adaptions, ava

Sensor highlights

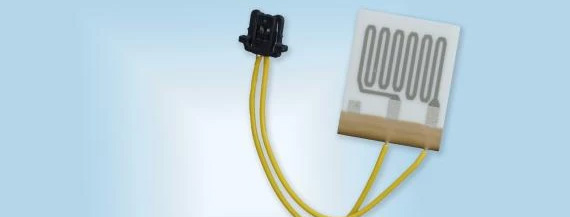

Micro-Heaters

- For precise, reliable and cost-efficient heating of solids, liquids and gases: our micro heaters are custom-built to fit your application's requirements.

Thermal infrared emitters

- Thermal infrared emitters for gas analysis, material detection & spectroscopy are used in numerous applications across a wide range of industries.

Nucleic Acid Extraction

- Spin Filter, Magnetic Beads, Smart Modified Surface or Polymer Mediated Enrichment: Automated or manual, find the right extraction technology and platform.

TEMPERATURE SENSORS

Temparature Sensors

IST AG offers a wide range of sensors based on different technologies suitable for any application. Our RTD platinum temperature sensors are extremely robust, highly accurate and low drift. Our nickel sensor components offer excellent long-term stability and are easily replaceable. Our TSic solid-state temperature sensors are calibrated with an integrated signal converter for analog or digital output - accurate, reliable and easy to integrate.

Platinum & Nickel RTDs & Semiconductors

PLATINUM TEMPERATURE SENSORS

-

IST AG platinum RTD temperature sensors are developed with the highest quality materials and cover a wide operating temperature range of -200 °C to +1000 °C. Their extremely robust construction makes the sensors function well in the harshest conditions while experiencing minimal drift. IST AG platinum RTDs have a a term stability and come in a variety of small dimensions and in various housings. IST AG platinum temperature sensors are available with a standard TCR of 3850 ppm/K and with accuracies according to the IEC 60751 norm.

With a temperature sensor portfolio thousands of products, we offer one of the widest ranges of Pt temperature sensors available - within very short delivery times! While many of our standard sensors are available from stock – the delivery time for special inquiries is approx. 6 weeks.

NICKEL TEMPERATURE SENSORS

-

Our nickel RTD temperature sensors come with an operating temperature range of -60 °C to +300 °C. They are characterized by a simple linearization and a steep characteristic curve. Suitable for e.g., HVAC applications, nickel RTD sensors offer an excellent long-term stability and easy interchangeability. IST AG’s nickel temperature sensors are available with various TCRs such as 6180 ppm/K (Nickel ND), 5000 ppm/K (Nickel NL), 6370 ppm/K (Nickel NJ), 6720 ppm/K (Nickel NA) and Balco.

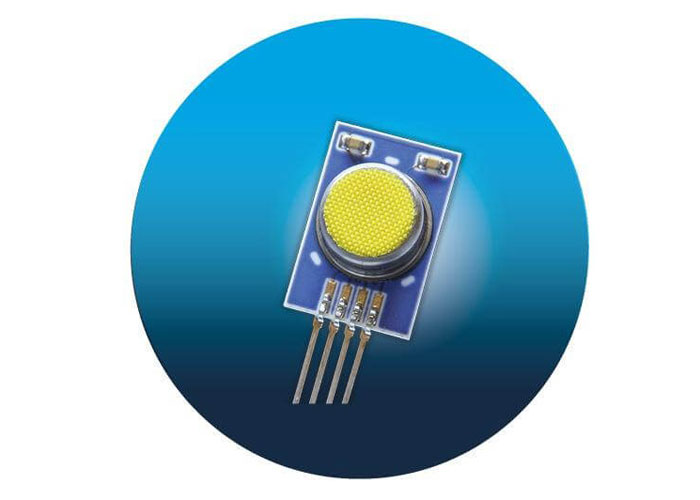

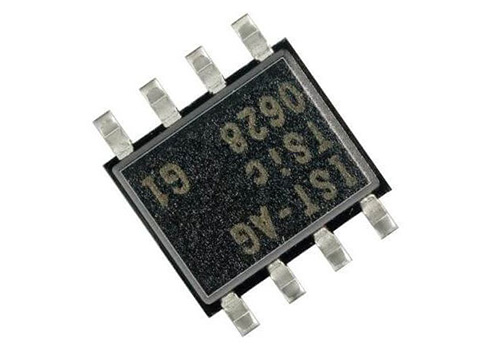

Semiconductor temperature sensors TSic

TSic sensors are semiconductor temperature sensors that feature highly accurate measurements within a limited temperature range. Thanks to their low power consumption, they are ideal for mobile applications.

TSic

The TSic is offered as a calibrated temperature sensor with an integrated signal converter for analog or digital output. Easily integrable, it offers excellent accuracy with long-term stability.

FLOW SENSORS

Flow sensors and modules

-

IST mass flow sensors can be found in various flow switches, controllers or meters as well as the heart of leakage or bubble detection systems. Our mass flow sensor elements utilize thermal measurement principles known for their long-term stability and ease of integration into any application with a known fluid. From the physical sensor level to a ready-to-use digital module, build your custom flow sensor with IST AG. Evaluation kits are available with the most common flow sensors.

Flow sensors and flow modules for gases, liquids and leakage detection

Gas flow sensor elements

-

Using accurate thin-film heating and temperature sensing structures ensures high sensitivity with a very compact and robust sensor. The dynamic range of anemometric gas flow sensors ranges up to 100m/s covering operational temperatures up to +400°C.

The FS7 (link to product in shop) is our most widely used gas flow sensor for applications with a known flow direction. The option of a simple housing keeps assembly into various flow channels easy to handle, and its excellent long-term stability makes the flow sensor ideal for control and safety applications.

With FS2 and MFS02 sensors, flow direction can be monitored along with the measured mass flow. Their extra wide dynamic range make them excellent candidates for applications ranging from medical microfluidics to large scale HVAC systems. Different assembly options with cable, carrier PCB or custom housing ensure optimal sensor positioning.

SFS01 is a silicon based calorimetric flow sensor with an ultra-fast response time suitable for medical and industrial flow applications with low flowrates and a mild temperature range.

Silicon Flow Sensor SFS01

- Very fast response time

- Very low energy consumption

- Easy system integration including temperature compensation

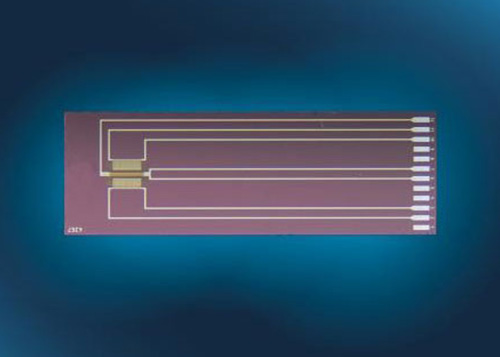

The SFS is IST AG's first flow sensor based on silicon technology. It is operated according to the calorimetric principle and can therefore detect not only the flow velocity but also the flow direction.

The symmetrical design of the SFS flow sensor allows an easy interpretation and evaluation of the measurement signal. The sensor can be used in different gases. It is characterized by a high sensitivity, a very fast response time and an extremely low energy consumption.

Well-adapted channel geometries allow the performance of the sensor to be optimally aligned to the desired application. The SFS01 flow sensor is ideally suited for space-limited applications, but can also be easily upgraded to complete ready-to-use systems.

Suitable application areas for the SFS01 flow sensor are flow measurements in battery-operated / portable devices, air conditioning technology (HVAC), automation technology as well as process and control engineering.- Flow direction Two directions (kalorimetric)

- Chip size/dimensions 6.0 x 2.0 x 0.525 mm

- Connection type Bonding Pads

- Flow range full bridge mode 0 to 3.5 m/s

- Response time t63 5 ms

- Response sensitivity 0.01 m/s

- Substrate Silicon

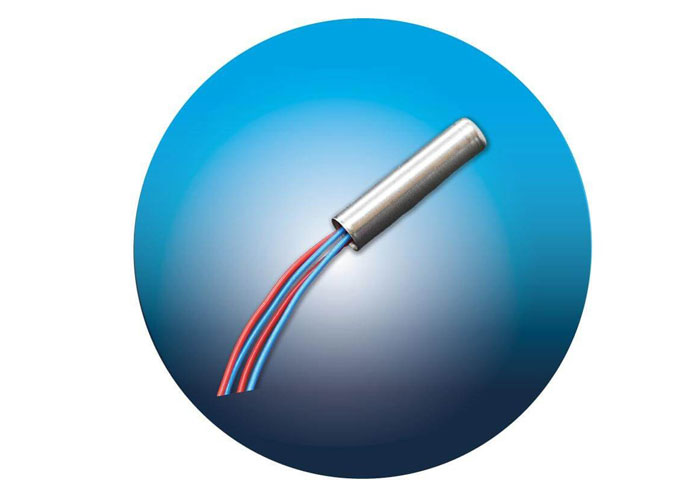

Liquid flow sensor elements

-

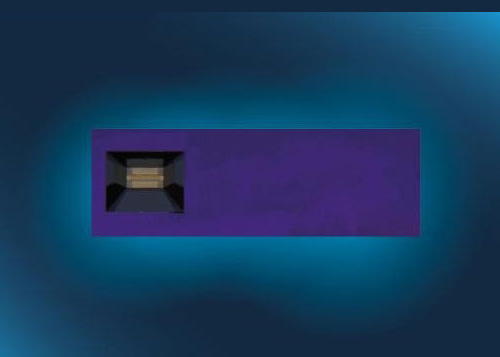

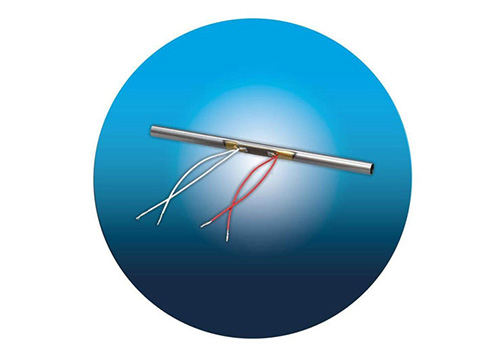

OOL stands for out of liquid and is a flow-through sensor with stainless steel as single wetted material. This robust anemometric sensor is suitable for various aggressive liquids including coolant mixtures, oils containing particles or cleaning chemicals used in CIP systems.

The highly accurate and reliable OOL liquid flow sensor is suitable for measuring liquid flow in aggressive liquids. A heater and a temperature sensor chip, both with backside metallization, are soldered on the stainless-steel flow channel, providing an excellent thermal contact with the liquid without being in direct contact with it. For fast measurement results, there is an out of liquid demo board available.

Flow modules

The OOL Mass flow meter is a digital module continuously monitoring mass flow and temperature. It comes in a sturdy housing with a factory calibration as a plug-and-play sensor solution.

IST's leakage detection Flow OOL-module is equipped with a highly sensitive flow sensor component, which can detect the smallest liquid flow quantities with an accuracy of

Suitable for a wide variety of applications from cooling circuits, dosing pumps, white goods, CIP systems for food industry, agricultural machines, industrial wet vacuum cleaners, to gear oil used in metalworking and mining, IST AG's new thermal OOL mass flow meter can be easily integrated into new or existing industrial systems.

Our OOL Bubble detector detects bubbles of various liquids, incl. water, oil or coolants Its reliable switch indicates bubbles from ca. 1mm diameter; suitable for various liquids, including aggressive liquids. It is independant of flowrate changes and suffers minimal pressure loss

HUMIDITY SENSORS & MODULES

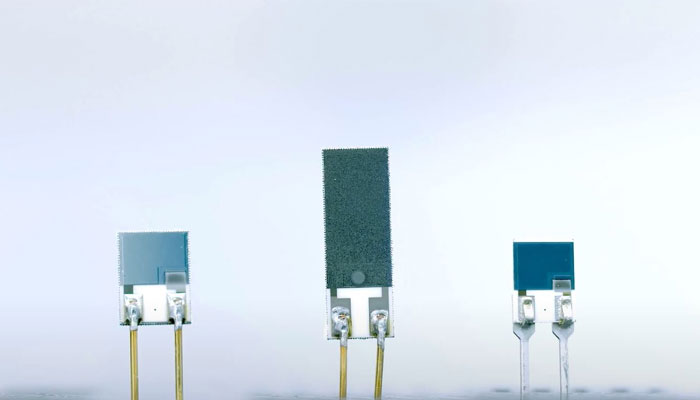

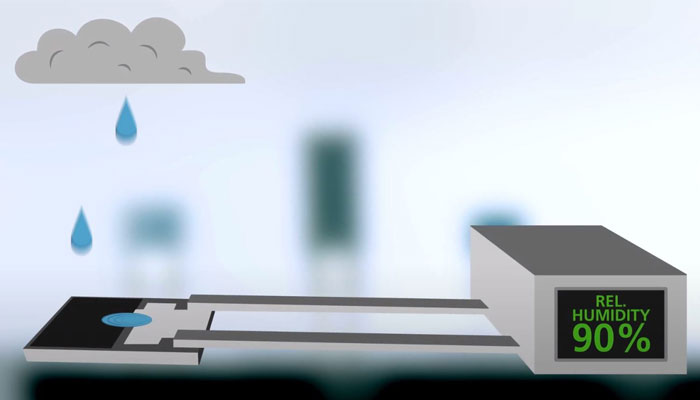

HUMIDITY SENSORS

-

Innovative Sensor Technology IST AG humidity sensors are capable of measuring 0 % RH to 100 % RH and operate at temperature ranges between -80 °C and +190 °C. The humidity product line features sensors with excellent linearity, low hysteresis, fast response times, and high chemical resistance.

IST’s humidity modules are assembled with the required sensor element and calibrated to the specified accuracy down to dew point measuring.

Humidity Sensors, Modules & Capacitive Sensors

Humidity Sensors & Modules

Humidity Sensors

High chemical resistance, very low drift a wide temperature range and condensation-resistance are just a few of the many characteristics of our humidity sensors. IST humidity sensors feature many different benefits, from a high humidity stability, over suitablility for extreme environments and to dew point measurement.

Humidity Modules

Techanically robust and with a chemical and condensed waterproof sensing area, IST AG's digital HYT humidity modules offer a wide application window and an optimal price-performance ratio. Precisely calibrated, the HYT modules deliver an outstanding accuracy and excellent long-term stability even at high humidity - ideal for sophisticated mass applications, industrial handheld devices and precise humidity transmitters.- Humidity Sensors for coolant leakage detection

- Industrial handheld devices

- Wind power

- Bioenergy

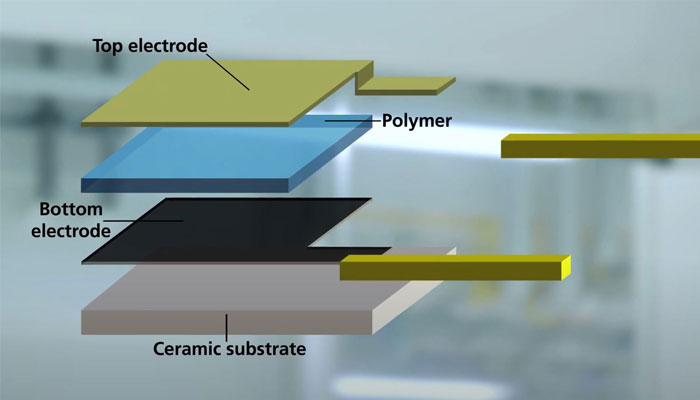

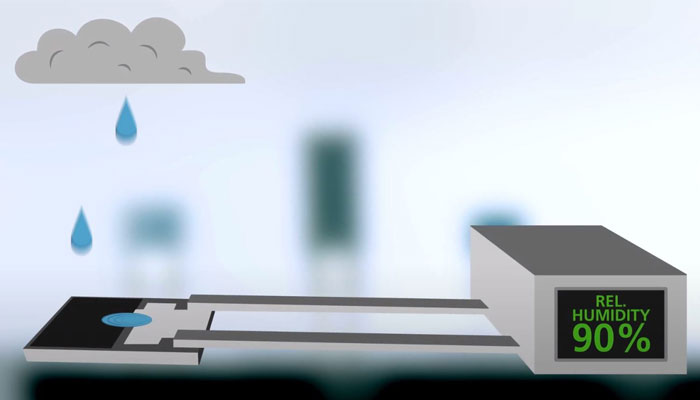

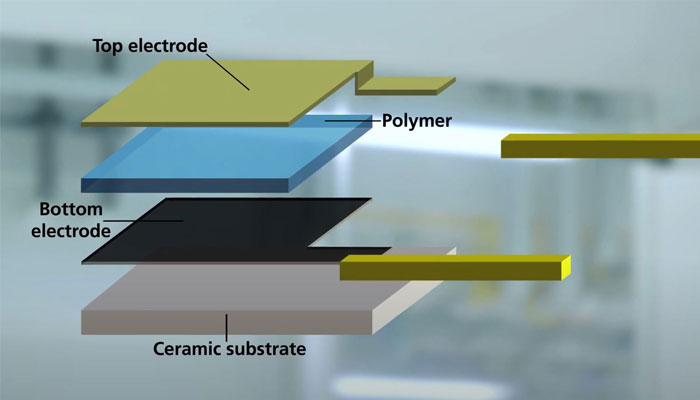

Capacitive RH sensors

Capacitive RH sensors consist of a ceramic substrate on which a thin film of polymer is deposited between two conductive electrodes. The sensing surface is coated with a microporous metal electrode, allowing the polymer to absorb moisture while protecting it from contamination and exposure to condensation. As the polymer absorbs water, the dielectric constant changes incrementally and is nearly directly proportional to the relative humidity of the surrounding environment. Thus, by monitoring the change in capacitance, relative humidity can be derived.

Innovative Sensor Technology IST AG humidity sensors are capable of measuring 0 % RH to 100 % RH and operating at temperature ranges of -80 °C to +190 °C. The humidity product line features sensors with excellent linearity, low hysteresis, fast response times, and high chemical resistance.

Humidity sensors are often used in:- Weather balloons

- E-mobility Industrial drying

- Wind power

- Bioenergy

- HVAC

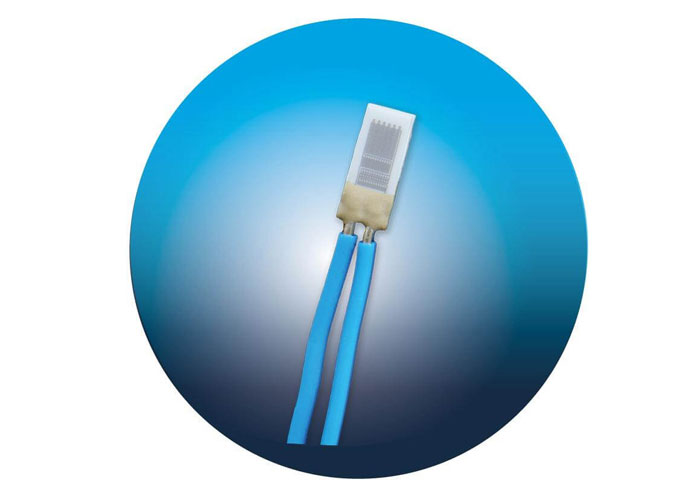

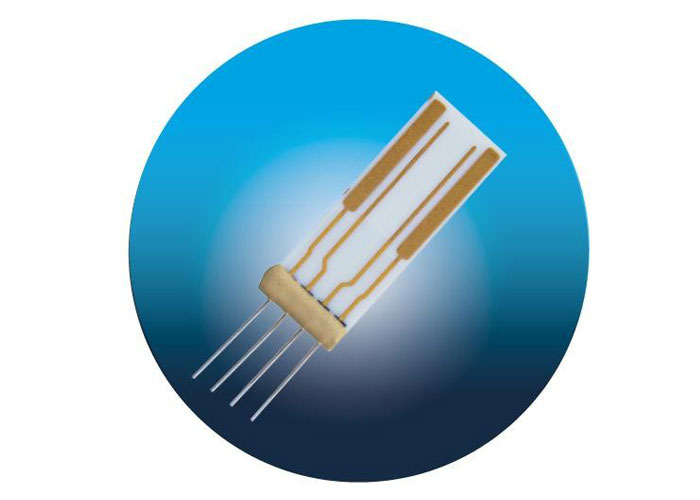

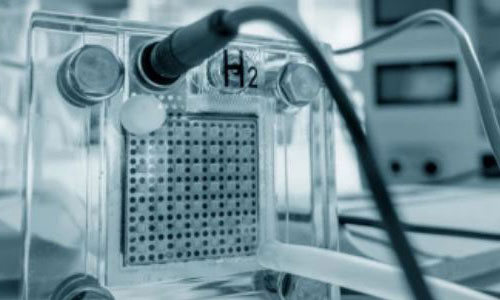

CONDUCTIVITY SENSORS

- IST AG’s conductivity sensors can be operated in a wide conductivity range from 10 µS/cm-200 mS/cm. They are available with different chip sizes and cell constants for tailor-made sensors to fulfill our customers’ demands. Since one of our main competences is the development of customized sensors, we encourage our customers to reach out to us to discuss their application and requirements, so we can recommend a sensor with an appropriate geometry and cell constant.

Conductivity Sensors

- Conductivity measurements are widely used in industrial and environmental applications as a simple and inexpensive way to monitor and to control the ionic concentration in a solution.

Therefore, conductivity sensors can be used in many different fields of applications, ranging from water purification and quality control, over e-mobility and fuel cells to chemical, bio and pharmaceutical processing, IoT and agriculture as well as in food & beverage industries.

Due to the wide range of applications for conductivity sensors, the entire conductivity range, from low to very high ionic concentration in solution is covered. Monitoring of coolant quality in e-mobility and fuel cells for example takes place in very low conductivity ranges whereas desalination plants or medical applications display high conductivity values.

Measurements in different conductivity ranges call for various sensor designs. The precision of a sensor in different conductivity ranges is highly dependent on size of sensor chip and electrode layout. Furthermore, the mobility of dissolved ions is tremendously affected by temperature. This temperature effect requires either temperature control of measured medium or compensation of measured conductivity. IOur ceramic-based conductivity sensors can include a resistive temperature sensor (Pt1000 IEC 60751 F0.3), allowing for accurate compensation directly at point of measurement.

What conductivity sensors are used for

- Conductivity measurements offer a simple and economical way to provide information on the ionic concentration and thus, the quality of measured medium of interest.

Conductivity sensors are widely used in industrial and environmental applications because they present a cost-effective, highly reliable measuring instrument that is independent of the sample medium.

Their applications range from water treatment and quality monitoring to leak detection in cooling & heat exchangers and condensers, to chemical processing, pharmaceutical and medical applications, food & beverage industries, and analytical laboratories.

Aqueous conductivity measurement

- In ground- and wastewater treatment as well as in water quality monitoring, conductivity sensors are used to determine ionic concentration of solution to subsequently remove impurities to ensure that water quality is adequate for application.

This concept is used, for example, in water quality monitoring of drinking water treatment, irrigation in agriculture, aqua farming, and swimming pools.

Non-aqueous conductivity measurement

- Applications are not limited to aqueous media. Conductivity sensors are also applied in non-aqueous media e.g. for quick, reliable, and continuous monitoring of coolant quality in e-mobility and fuel cells. Furthermore, they are incorporated in clean-in-place (CIP) and sterilization-in-place (SIP) processes, downstream processes to enhance quality of product.

Conductivity sensors will play a vivid role in upcoming IoT applications for example in healthcare and clinical diagnostics, agriculture and food & beverage. In medical devices they allow personal healthcare and diagnostic analysis, provide active drug dosing with feedback and are an essential part in dialysis. All above mentioned applications for conductivity sensors cover different conductivity ranges.

SI unit of conductivity

- The SI unit of conductivity is Siemens per meters (S/m) and is mostly given in mS/cm or µS/cm. Ultra-pure water has a conductivity of 0.05-0.1 µS/cm, tap water 300-800 µS/cm whereas sea water shows high conductivity values up to 56000 µS/cm. Measurements in different conductivity ranges call for different sensor styles. The precision of a sensor in different conductivity ranges is highly dependent on the size of the sensor chip and the electrode layout.

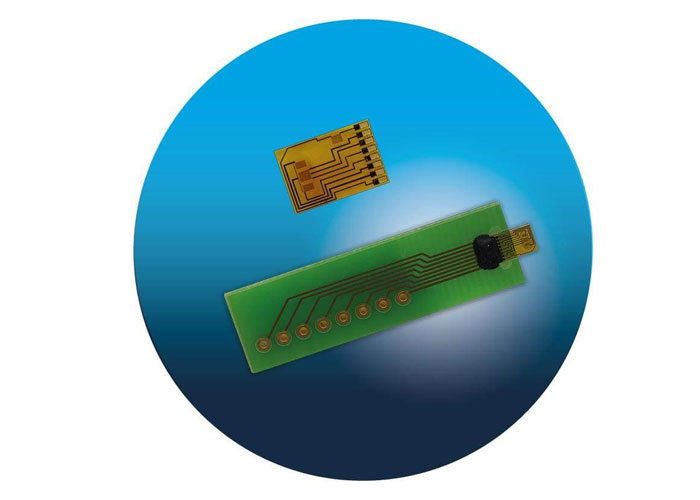

BIOSENSORS

BiosensorsS

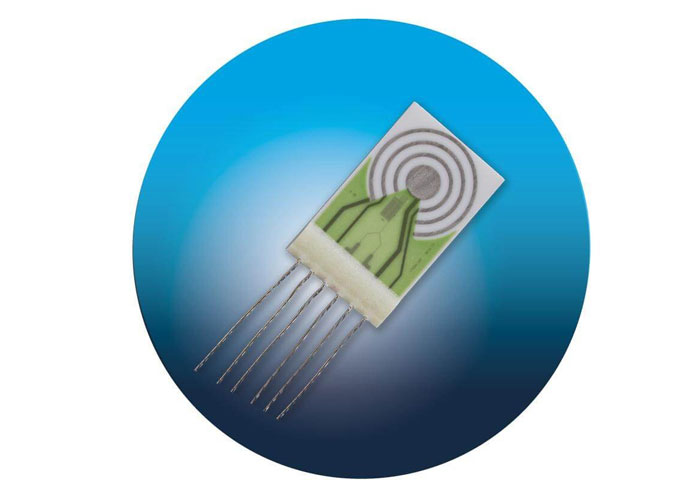

- Find the right biosensor for allowing measurements of your complex biological media. Designed for measuring the concentration of glucose, lactate, glutamine and glutamate in aqueous media, our biosensors are built on the enzymatic-amperometric measurement principle.

for measurement of Glucose and Lactate and microfluidic accessories

Multi-parametric measurements

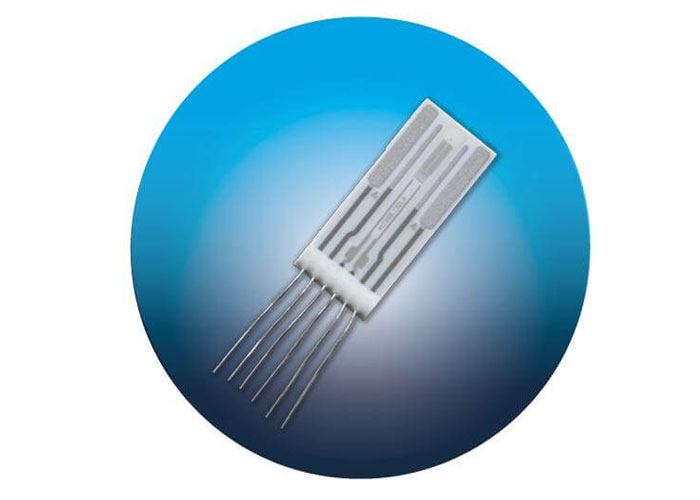

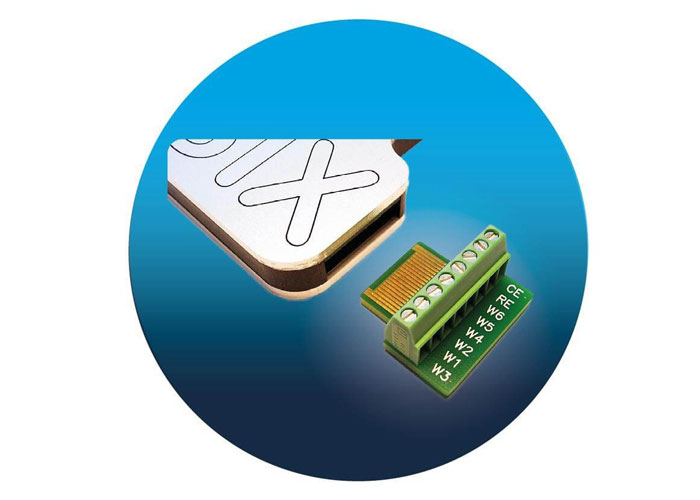

- The IST AG LV5 sensor is a flow-through biosensor and offers multi-parametric measurements. Up to 4 analytes can be measured simultaneously (glucose, lactate, glutamine, glutamate). The sensor features a very small flow cell (1 µL) and therefore requires minimal sample volumes when used as an analyzer.

Further advantages of the LV5 biosensor include:- Excellent long-term stability over a month in continuous measurement mode (lifetime varies depending on various factors, including the analyte concentration and buffer system (medium) amongst others)

- Long shelf life (under appropriate environmental conditions)

- Gamma and beta sterilization compatible

- Suitable for continuous and analyzer measurement modes

- Fast response time (depends on the buffer system (medium))

- Reference, counter and blank electrodes on-chip

- Integrated flow cell (various volumes)

The LV5 biosensor is suitable for sampling systems in laboratories or food and pharmaceutical industries.

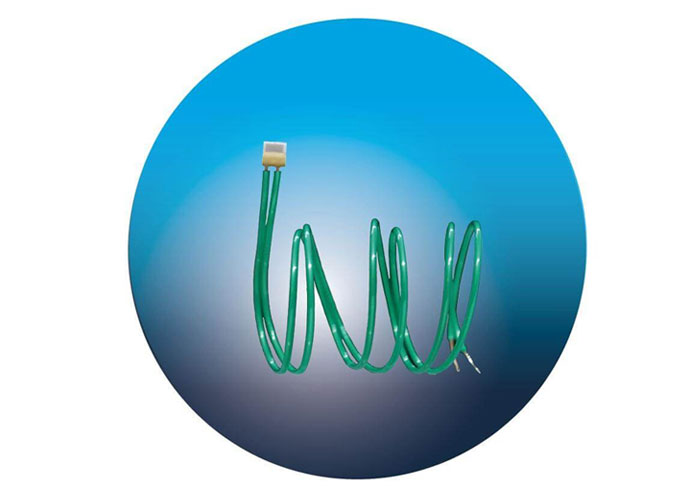

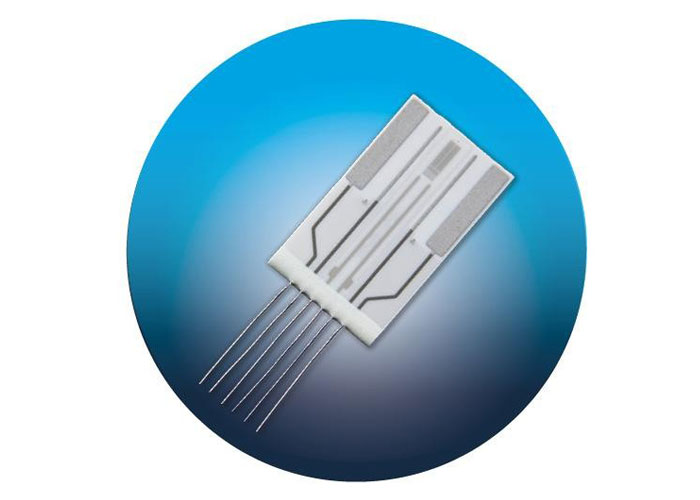

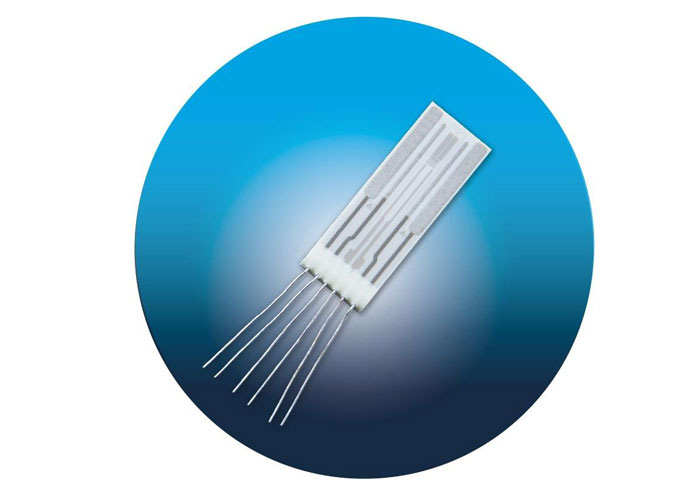

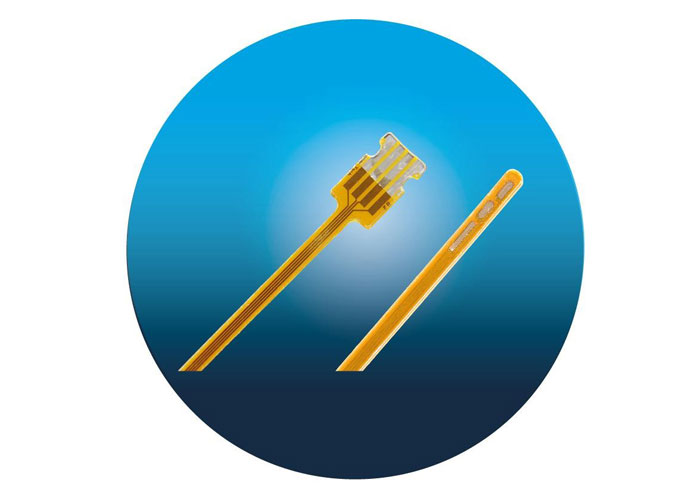

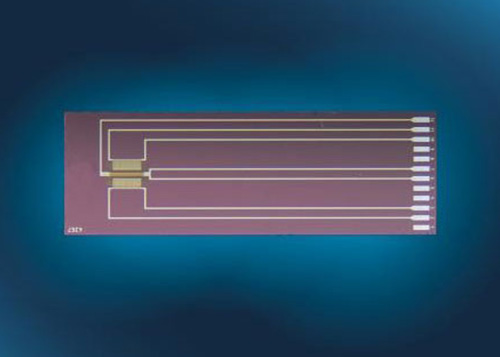

IV4 - Optimal for stable continuous single parameter dip-in applications

- The IST AG IV4 biosensor is a flexible stripe with large form factor ideal for direct dipping in the measurement media. It is designed for the detection of a single analyte, glucose as standard. This sensor is ideal for applications that require in-line continuous measurement with high reliability.

Further advantages of the IV4 biosensor include:- Excellent long-term stability

- Long shelf life

- Gamma and beta sterilization compatible

- Fast response time and outstanding reliability

- Reference, counter and blank electrodes on-chip

Given its compatibility with gamma radiation, the IV4 sensor can be used for example in bioreactors or aseptic media.

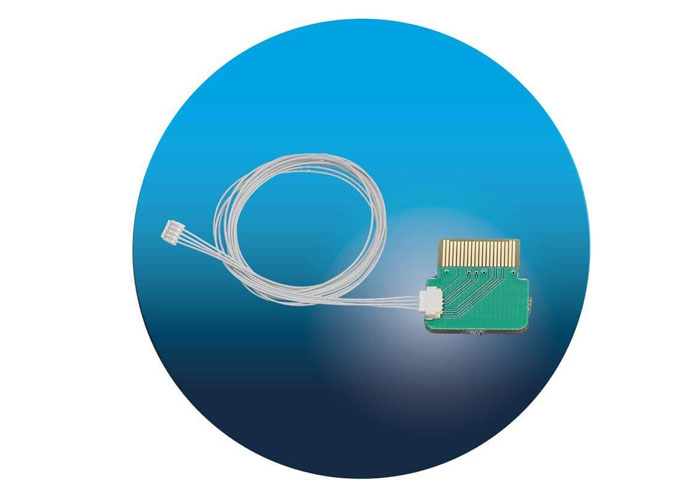

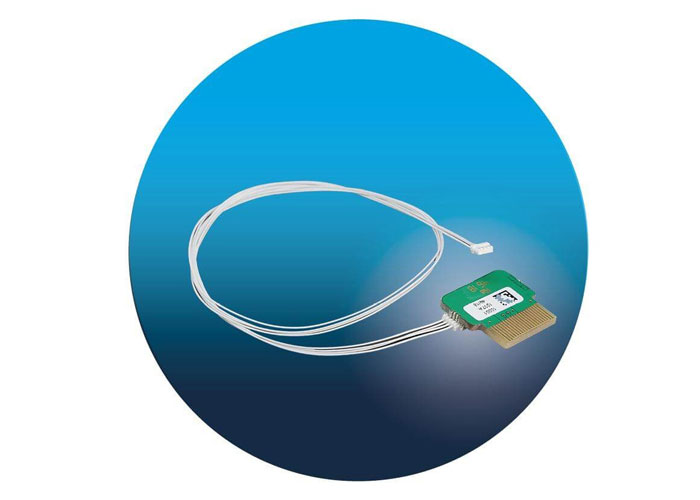

SIX Biosensor Transmitter - Evaluation Kit for Amperometric Biosensors

- The SIX Biosensor Transmitter enables a direct evaluation of LV5 and IV4 biosensors. It can be directly connected to a computer via USB or to any microprocessor via a standard TTL-serial interface. The evaluation software bioMON is also available for the acquisition of measurement data and its analysis in real time.

Further advantages of the SIXBiosensor Transmitter:- USB connectivity for easy evaluation

- OEM version with serial interface for easy integration in custom developments

- Very high current precision (approx. 20 pA)

- 6 current channels with common reference and counter terminals

- Current range can be factory-adjusted to meet specific requirements

- Very light weight

- Evaluation software bioMON available