KRAL

Videos

Loading the player ...

- Offer Profile

Product Portfolio

KRAL Screw Pumps

- Cost-saving Conveying of High Quantities of Different Viscosities.

KRAL screw pumps are powerful, efficient and reliable. Low maintenance and low pulsation service even for high viscous fluids.

With KRAL screw pumps, you buy high quality and reduce costs for many years: through high flow rate, low-maintenance operation, flexible application possibilities, space-saving installation and long service life even with abrasive and corrosive media. KRAL products offer maximum flexibility for variable operating conditions – 70 years of experience in the industry speak for themselves.

Good controllability of the positive displacement screw pumps.

KRAL screw pumps offer the advantage of a linear flow rate principle. This enables simple and cost-effective volume control via the motor speed, as well as a consistently high and continuous flow rate, even if the viscosities change. This combination of cost-saving control with consistently high flow rates for high and low viscosity media is not possible with functional principles such as centrifugal pumps.

Low-pulsation pumping of liquids for various applications.

KRAL screw pumps are self-priming and pump fluids of different viscosities particularly gently and quietly. The pumped medium is not squeezed, there are no pressure pulses, which damage the pump, piping or other components or cause vibrations. Pumps, such as piston pumps, can damage the pump, the system and the pumped medium due to much stronger pressure pulsations. KRAL pump solutions are suitable for many different applications (e.g. oil, bitumen, polyurethanes) where operation without pulsation is necessary.

Screw pumps from KRAL offer high performance in a small space.

Space for setting up or installing of positive displacement screw pumps is expensive and often short. Compared to pump solutions with centrifugal pumps, for example, KRAL screw pumps offer a high flow rate, a small space requirement and high efficiency.

KRAL K Series Screw Pumps

- Universally applicable

screw pump.

For pumped media up to 16 bar

One of our best-selling products: compact and universally applicable, reliable and efficient. These are the KRAL screw pumps of the K series. Their housing is made from nodular cast iron and they have a sealed, lifetime-lubricated, service-free external bearing. The KRAL K series screw pumps are approved for use on board ships.

Operation, materials, components- Delivery rate: 5 to 2,900 l/min.

- Delivery rate KFT: 5 to 510 l/min.

- Max. differential pressure: 16 bar.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

- Viscosity: 10,000 mm²/s.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA. ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

Advantages of the KRAL K series screw pumps

Suitable for many applications, very compact, robust, flexible, excellent price-performance ratio. Perfectly adequate for pressures up to 16 bar. All products of the K series have an internal safety valve and can be ordered with DIN flanges in inline arrangement (except KFT and KFN). Like all KRAL screw pumps, the pumps of the K series are self-priming, deliver with low-pulsation and, in contrast to other functional principles, can be easily regulated.

KRAL L Series Screw Pumps

- Compact, low-wear pump up to 63 bar.

Robust, versatile and easy to maintain

Versatile, compact and efficient like the K series, but for higher operating pressures up to 63 bar: the KRAL L series screw pump is the preferred choice for medium-pressure applications in the marine sector as well as numerous applications in the oil and gas, power generation, mechanical engineering and chemical industries. It has a spheroidal cast iron housing and is approved for use on board ships.

Operation, materials, components- Delivery rate: 5 to 160 l/min.

- Max. pressure: 63 bar.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

- Viscosity: 7,000 mm²/s.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

Gear pumps have the disadvantage that they can only be operated at low speed due to the high risk of damage. KRAL screw pumps, on the other hand, are gentle on the medium, even at high speeds. This guarantees high operating efficiency and an excellent price/performance ratio.

All screw pumps of the KRAL L series also offer reliable startup, minimal wear, and ease of maintenance, which simplify operation. Available with magnetic coupling or external ball bearing (maintenance-free).

KRAL C Series Screw Pumps

- For pressures of up to 100 bar.

Efficient, self-priming high-pressure pump up to 100 bar

Pump solution for high pressures at an excellent price-performance ratio. With KRAL screw pumps of the C series you buy high-pressure pumps with all the advantages of our KRAL pumps K and L: robust, low-wear, flexible, space-saving, durable and much more. Compared to other pump solutions, KRAL screw pumps convince with highest reliability, even under different operating conditions the screw pumps are highly efficient.

Due to the wide range of possible applications, we offer the KRAL C series as standard in the CK, CL and CG series. The main components of these pumps are all the same, the differences lie in the individual details, matched to the requirements in different applications (see detailed description below).

Application examples: Injection pumps, feed pumps, burner pumps, jacking pumps, transformer oil cleaning pumps, hydraulic pumps and generally all applications in which efficient, reliable high-pressure pumps for lubricating media are required.

Operation, materials, components- Delivery rate CK: 1,750 l/min.

- Delivery rate CL: 1,750 l/min.

- Delivery rate CG: 3,550 l/min.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

- Pressure range: 70 bar; 100 bar.

- Housing: Nodular cast iron, steel and aluminium.

- Spindles: Steel, nitrided.

- Certifications: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, fluid media and steam.

- Manufactured to conform with API

KRAL W Series Screw Pumps

- The KRAL pump for difficult fluids

The W series from KRAL is primarily used when dirty, abrasive or low-viscosity media are used. Robust polymer coating and continuous flow rates at differential pressures up to 120 bar – these features are combined in the KRAL W series screw pump.

Operation, materials, components- Delivery rate: 15 to 290 l/min.

- Max. differential pressure: 120 bar. Viscosity: > 1 mm²/s.

- Max. temperature: To 180 °C, magnetic coupling to 300 °C.

- Installation: Wet or dry.

- Spindle housing: Nodular cast iron EN-GJS-400, polymer-coated or other material options.

- Screws: Steel, nitrided.

Optimum pump for special requirements

Pumped fluids such as cooling lubricants are difficult liquids. They contain abrasive dirt, mostly metal residues, and must be pumped at high pressure. In addition, they have a very low viscosity of only about 1 mm²/s. In the KRAL screw pump of the W series, the screw material and the casing coating have been designed for improved sliding properties in such a way that low viscosity fluids can be pumped with high efficiency. The running casing is coated with a resistant polymer that can absorb particles. The balancing cylinder of the screw pump has orifice insertions to reduce the leakage rate, therefore efficiency remains high.

KRAL Z Series Screw Pumps

- The screw pump for demanding liquids

Proven KRAL pump quality suitable even for aggressive and contaminated media

In the new Z series, KRAL applies its expertise in pump design and technology to two screw pumps. As a result, the KRAL Z series is capable of delivering aggressive, low- or non-lubricating, and contaminated media with the reliabiltity and quality that KRAL products are valued for by customers worldwide.

Operation, materials, components- Delivery rate: 330 to 17,660 l/min or 20 to 1,060 m³/h.

- Max. differential pressure: 25 bar.

- Temperature range in the pumped media: -40 °C to +300 °C.

- Housing: Ductile iron or welded steel.

- Screws: Solid or engineered.

- Approvals: ABS, BV, DNV-GL, LRS, RINA, others on request.

- ATEX: Device Group II, Device Category 2.

- Heating: Electrical, media or steam.

- API: Manufacturing according to API 676 possible.

How it works

The KRAL Z series pumps are positive displacement pumps that draw the liquid through the suction connection and continually feed it in two partial streams to the two screws. As a result, the pump is pressure-equalized axially. The pressure builds up linearly along the length of the screw. The housing design ensures that the gap between the screws and the housing remains sealed. This ensures that the pump can be primed very effectively, even when the suction line is empty.

Customized solution

The KRAL Z series can be implemented as a customized solution for any required application. For example, depending on the application, the screws can be designed solid or engineered. This results in substantial benefits for important aspects such as fatigue strength, media resistance, maintenance costs, and costs over the life-cycle of the pump.

KRAL Screw Pumps with Magnetic Coupling

- No more mechanical seal problems

KRAL magnetic coupling screw pumps pay for themselves quickly: they are maintenance-free, hermetically sealed (no product leakage, no crystallization of the pumped media) and temperature-resistant up to 300 °C. Frequent replacement of mechanical seals is no longer necessary, a single installation of a magnetic drive screw pump is sufficient. This saves costs.

Operation, materials, components- Delivery rate: 5 to 3,500 l/min.

- Max. differential pressure: 100 bar.

- Temperature range: -20 °C to 300 °C.

- Housing: Nodular cast iron EN-GJS-400, steel and aluminium.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

Leakage-free and clean

Critical fluids containing substances endangering the health or the environment should not leak to the atmosphere. In contrast to conventional shaft seals, KRAL screw pumps with magnetic coupling are hermetically sealed by the integrated containment can. People and the environment are not endangered.

Can be used up to 300 °C

Thermal distortion and the temperature limits of elastomeric sealing elements restrict the use of screw pumps in high temperature applications. If temperatures up to 300 °C are handled, KRAL screw pumps with magnetic coupling are the right choice.

Reduced lifecycle costs

Spare parts and maintenance costs for mechanical seals increase the life cycle costs. Mechanical seals in KRAL screw pumps have a high technological standard. Even during proper operation, however, they are still a wearing part. KRAL screw pumps with magnetic coupling are maintenance-free and pay for themselves after just three years.

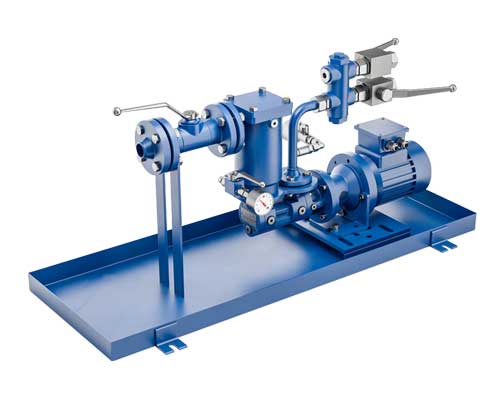

KRAL Oil Burner Pump Stations EK / EL

- Oil burner pump as complete station with additional functions

These positive displacement pump stations combine all the advantages of the KRAL screw pumps K and L with additional functions for smooth and user-friendly operation. KRAL screw pumps convey highly efficient lubricating fluids, are low-wear, very compact and space-saving.

Operation, materials, components- Delivery rate: 5 to 280 l/min.

- Max. differential pressure: 40 bar.

- Temperature range: -20 °C to 180 °C.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

- For viscous fluids up to 7,000 mm²/s.

The functions of the oil burner supply station of KRAL with K or L series screw pumps can be expanded individually, for example with:- Pressure regulation

- Degassing

- Flow metering

- Filter

- Gas / air separator.

The mounted display instruments can swivel. Left- or right-handed installation can be set up individually at the site.

KRAL offers the optimal solution for every customer requirement. Just ask us, we have probably solved a similar problem already!

Your advantages- Function individually expandable.

- Display instruments can swivel.

- Left- or right-handed installation.

- Equipped with KRAL screw pumps up to 40 bar.

- Low-wear and compact.

- Optimal solution for every customer requirement.

- For burner applications.

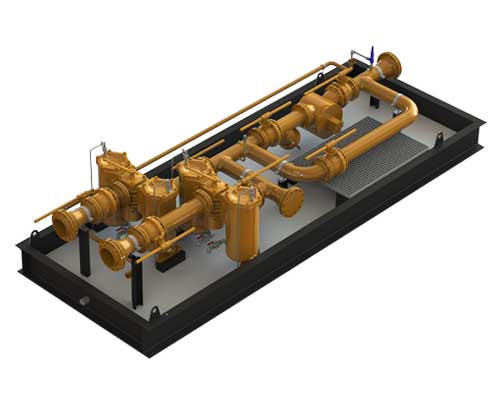

KRAL Pump Stations DKC / DLC / DS/L

- Two pumps provide more than double the advantages

Cost-effective solution for double the flow rate and for maximum operational reliability

There are critical applications in which a second screw pump is prescribed for security. With KRAL pump stations you have a cost-effective and space-saving solution with which you can prevent motor standstill, production interruptions and heating failures. Maintenance work can also be carried out during operation without pump standstill.

A further advantage of KRAL double stations is the possibility of parallel operation of the two 3-screw pumps. This means that the flow rate can be doubled, but the space requirement and effort are considerably less than with the installation of two single positive displacement pumps.

Typical applications are booster modules of oceangoing ships, and burner stations in marine and industrial applications. Maximum reliability is required. The most common operating mode is therefore that one screw pump is running and the other is switched off (standby).

Operation, materials, components- Delivery rate: 5 to 280 l/min.

- Max. differential pressure: 40 bar.

- Temperature range: -20 °C to 180 °C.

- Housing: Nodular cast iron EN-GJS-400.

- Triple screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

- Seal type: Mechanical seal standard or hard material.

- Available with magnetic coupling.

In the case of a ship, the failure of the fuel screw pump in the booster module means that the engine comes to a standstill. If the flame goes out in a burner, a production process will be interrupted or a heating system will fail. Such applications require security. For maintenance, the primary screw pump can be switched to the standby screw pump, without interruption.

Cost reduction through many functions in compact space

If a second screw pump is necessary, it soon becomes clear that the cost of design, pipework and control is considerable. The space requirement for a structure involving individual components is also very large. A significantly more economical solution is represented by the completely newly developed DKC and DLC dual stations by KRAL. Two screw pumps of the K series up to 16 bar or L series up to 63 bar are fitted to one block. The block integrates all functions within minimum space, and is available with many further options. And the flow rate can be doubled.

Alternate operation between two liquids

For alternate operation between light and heavy oil operation, for example, the operator does not have to carry out any complex pipework when using KRAL pump stations. As an option, a liquid changeover switch can be fitted. In this way, KRAL dual stations are connected to two pipeline systems with different liquids. Switching between the liquids is manual, electrical or pneumatic. For remote monitoring of the lever position, limit switches are available.

KRAL Flowmeters

- Highly accurate and robust

Applications

Our KRAL precision flowmeters combine the characteristics of robustness and high accuracy. For over 30 years, our products and systems have met a huge number of customer requirements to measure liquid mediums in different industries and applications.

The wide range of applications ranges from low viscose liquids, like petrol, acids and bases, to high viscose liquids with print colours or coal tar. Especially for fuels, like diesel, heavy fuel oil and marine diesel, as well lube or cylinder oil, our products and solutions for flow measurement and consumption measurement are used very often by our customers.

The KRAL flowmeters run with low friction and minimal pressure loss.

Measurement precision

The KRAL flowmeters are accurate to ± 0.1 % over a wide flow and viscosity range, as the repeatability is better than ± 0.01 %. The long working life and stability over time of KRAL flowmeters show that robustness and precision are not mutually exclusive. KRAL flow meters are the most exact positive displacement meters in the world.

The measuring principle

The measurement chamber consists of the casing and two screw spindles.The spindles are driven by the medium in a defined rotation direction and transport the medium continuously through the measuring chamber. The precise measured value is calculated from the known measuring- chamber volume and the spindle rotation speed.

KRAL Flowmeters OMP Series

- Robust solution for flow measurement of diesel and heavy fuel oil

The OMP series flowmeters are designed specifically for fuel consumption measurement for marine applications as well as others, and can be used in booster modules and burners.

A perfect combination of precision and robustness: Due to the precise measurement chamber volume, a broad range of measurements with a precision rate of 0.1 % can be achieved. Pipe bends and T-sections have no influence on the measurement accuracy or performance of the KRAL flow meter.

The extreme robustness is achieved by the spheroidal graphite iron housing, which provides optimal protection for the precisely manufactured screws. The screws of KRAL flowmeters quickly follow the changes of the fuel flow rate, the fuel pulses and may even change its flow direction briefly.

Through the use of a high quality state-of-the-art hybrid bearing, the measurement devices also run with low friction, gentle and minimal pressure loss. Long lifespan, resistance to pulsations in the media, and efficiency across the entire product life cycle are just a few of the benefits that KRAL flow meter OMP offers.

KRAL Flowmeters OME Compact Series

- Compact 3-in-1-device, ideal for diesel and light oil applications

KRAL measurement-devices from the OME flow meters in all design sizes always measure in both flow directions. This is made possible by the 3-in-1-sensors, which detect a change in the flow direction automatically and very fast. Another advantage is the integrated Pt100 temperature sensor, which also measures the temperature of the medium.

By using aluminum for the housing, OME series measurement devices are offered in a light design specifically for measuring light oil consumption, for industries such as inland waterway transport or power generation. As in all KRAL flowmeters, measurements across a range of 1:100 are also attainable for the OME series, due to the precise measurement chamber.

OME thus stands for combined precise measurement of flow, flow direction and temperature and all of this in the form of a compact, light, and robust meter.

KRAL Flowmeters OMG Series

- Universal device for manifold application needs

Due to their continuous ongoing development, the highly modular OMG series covers a broad range of applications. This series is therefore particularly suitable for manifold applications, such as mechanical engineering, chemical engineering and marine.

The flow meters OMG series also combines robustness with highest precision, characteristics for which KRAL flow meters are well-known worldwide. Due to the screw pump principle, all OMG series devices are very smooth-running and fast, and can follow quick, pulsation-related changes in flow rates. Due to their extremely robust construction, the OMG series provides optimal protection against external influences, such as system vibrations and mechanical stresses in harsh environments.

KRAL Flowmeters OMH Series

- Universal device for

manifold application needs

Due to their continuous ongoing development, the highly modular OMG series covers a broad range of applications. This series is therefore particularly suitable for manifold applications, such as mechanical engineering, chemical engineering and marine.

The flow meters OMG series also combines robustness with highest precision, characteristics for which KRAL flow meters are well-known worldwide. Due to the screw pump principle, all OMG series devices are very smooth-running and fast, and can follow quick, pulsation-related changes in flow rates. Due to their extremely robust construction, the OMG series provides optimal protection against external influences, such as system vibrations and mechanical stresses in harsh environments.

KRAL Flowmeters OMS Series

- Stainless steel design for demanding media

When selecting a flowmeter for demanding fluids, the issue of material resistance always arises. The KRAL flowmeter OMS series is a stainless steel design for low and high viscous media, equipped with ball bearings or plain bearings depending on the application.

Your Benefits - High accuracy positive displacement meter.

- Low service costs and long lifespan with KRAL products. Extremely robust liquid flow meter. Stabilization zones unnecessary.

- Low friction and minimal loss of pressure.

- Very compact design of the measuring unit.

- For harsh industrial conditions.

- Dosing of resin, paints, adhesives.

- Coating of propellers in wind power turbines.

- Insulating materials.

- Greases and waxes.

- Water volumetric flow measurements.

Materials - Housing: Stainless steel.

- Screws: Stainless steel (coated for high viscosity media).

- Bearings: Ball or sliding bearings.

- Gasket with ball bearings: Viton®.

- Gasket with sliding bearings: Teflon®.

Application examples

KRAL Flowmeters OMX Series

- Custom design flowmeters

The KRAL flowmeters OMX series are special fabrications to perform fluid measuring tasks that are outside the standard requirements. KRAL has designed the flowmeter OMX series for use on oilrigs for a static system pressure of up to 630 bar and the bronze model, which is especially suitable for deep-sea applications.

Your advantages Special solutions according to customer requirements.

- Proven high accuracy.

- Robust and compact design of the liquid measuring devices.

- No flow conditioning required.

- Easy installation and multiple port connection available.

- The most exact liquid displacement meters in the world.

KRAL Special Projects

- Innovative system solutions by KRAL

KRAL has been known as a manufacturer of high-quality pumps and flowmeters since 1950. Applications have become ever more demanding over the years. Refinery processes have been optimized and statutory regulations tightened up, in order to exploit oil as a resource better and with greater environmental protection. KRAL has amassed a great deal of knowledge in difficult fields such as the pumping and metering of heavy oils and low-sulfur fuels. This knowledge is invested in the development of our own products and their use in our customers` systems.

Success through experience

You will benefit from our expertise if you come to us for the construction and assembly of auxiliary units for power generation, for example fuel systems and lubricating oil systems for diesel engines, turbines and burners. We know that the production process from reviewing the specifications all the way to delivery and commissioning is very demanding. That is why we employ specialists for our special projects with just the right background and many years of experience.

KRAL quality

KRAL GmbH has been manufacturing pumps, pump stations, and flowmeters for fuels and lubricants for many decades. KRAL products are known for their excellent quality. We have installed and commissioned them for a large number of customers. In contrast with suppliers who only manufacture piping, KRAL offers proven systems expertise and problem-solving competence.

This experience as an established manufacturer with extensive practical knowledge is our outstanding strength in plant engineering. Our competence gives you the assurance that your complex overall project will be executed reliably.

Our experience for your safety

A fuel system and lubricating oil system consists of e.g. pumps, valves, instrumentation and pipes. Your organization supplies complex systems for power stations. You know that the components should not be regarded in isolation. An overall view and understanding are essential for safe and reliable operation. If a plant manufacturer lacks this competence, there is a significant risk that the system will not function.

KRAL Lube Oil Modules

- Reliable lube oil supply

Applications

KRAL lube oil modules fulfill an important function by reducing wear of rotating components on diesel motors. For example, crankshafts or connecting rod bearings are protected with a lubricating film. Because of the constant oil circulation, particles are carried away from the friction points, the oil is filtered and subsequently recooled.

Advantages

The reliability of the lube oil supply is a significant factor for the process and operational safety of the systems. Unexpected system standstills cause high costs. KRAL lubricating oil systems are quality products which provide the highest level of reliability.

KRAL lube oil modules to 16 bar- Liquids: Lubricating oil ISO VG2 to ISO VG1500

- Differential pressure: 1 to 16 bar.

- Flow rate: 5 to 300 m³/h.

- Temperature range: -10 °C to 150 °C.

KRAL lube oil modules from 16 bar- Liquids: Lubricating oil ISO VG2 to ISO VG1500

- Differential pressure: 16.1 to 300 bar.

- Flow rate: 0.2 to 20 m³/h.

- Temperature range: -10 °C to 150 °C.

KRAL Transfer Modules

- Unloading, loading and

transfering

Applications

KRAL transfer modules cover many applications. Examples include:- Unloading and loading systems for fuels and lubricating oils.

- Transfer of fuels among the tanks.

- Circulation systems which generate constant preliminary pressure.

- Feeder systems for multi-stage fuel preparation systems.

Advantages

KRAL fulfills the highest safety standards and offers high pump power performance for unloading, loading and transfering fluids fast.- Liquids: Lubricating oil ISO VG2 to VG1500, light fuel oil, heavy fuel oil.

- Differential pressure: Up to 160 bar.

- Flow rate: Up to 600 m³/h.

- Temperature range: -10 °C to 180 °C.

KRAL Slop Oil Modules

- Safely injection and load

Applications

Draining processes from steam generators, pumps or other components are often combined and collected in a slop oil tank. This mixture is either fed back into the combustion circuit or disposed of.

Advantages

KRAL slop oil modules have a high-pressure line to inject the slop oil into the combustion chamber and a low-pressure line to load tankers safely. Low-pressure and high-pressure lines are designed separately.- Liquids: Slop oil.

- Differential pressure: Up to 160 bar.

- Flow rate: Up to 600 m³/h.

- Temperature range: -10 °C to 180 °C.

KRAL High Pressure Modules

- For

ideal fuel atomization

Applications

High-pressure modules pump the fuel oil and generate the necessary pressure for ideal fuel atomization.

Advantages

Because of finely graduated sizes, KRAL high-pressure modules offer the highest possible efficiency.- Liquids: Light fuel oil, heavy fuel oil.

- Differential pressure: Up to 160 bar.

- Flow rate: Up to 600 m³/h.

- Temperature range: -10 °C to 180 °C.

KRAL Measuring Modules

- For the measurement of fuel delivery

Applications

Power plant operators record all parameters which help lowering operating costs. This is particularly interesting for the expensive fuel oil.

Advantages

The measurement of bunker delivery allows a comparison between the actual flow rate and tank invoice.- Liquids: Lubricating oil ISO VG2 to ISO VG1500, light fuel oil, heavy fuel oil.

- Pressure: Up to 250 bar.

- Flow rate: Up to 450 m³/h.

- Temperature range: -10 °C to 180 °C.

Pump Services

- Short reaction times. Fast and competent.

KRAL GmbH develops and manufactures all of its screw pumps at its headquarters in Lustenau, Austria. This enables rapid and customer-oriented solutions. Reliability and durability demonstrate the high level of quality.

Professional customer service is attested with positive customer feedback and the certified QM system in compliance with EN ISO 9001:2015.

You have chosen a great partner with KRAL. After the purchase, a reliable and fast service team is there for you and supports you. Flow Measurement Services

- Quality and efficiency down to the last detail

KRAL GmbH develops and manufactures all of its flowmeters at its headquarters in Lustenau, Austria. This enables rapid and customer-oriented solutions. Reliability and durability demonstrate the high level of quality.

Professional customer service is attested with positive customer feedback and the certified QM system in compliance with EN ISO 9001:2008.

You have chosen a great partner with KRAL. After the purchase, a reliable and fast service team is there for you and supports you.