- Offer Profile

- Datalogic is a global technology leader in the automatic data capture and factory automation markets, specialized in the designing and production of bar code readers, mobile computers, sensors for detection, measurement and safety, RFID, vision and laser marking systems. Closeness and timely response to every customer requirements, together with continuous innovation and high quality offering, are the distinctive elements at the base of Datalogic success for over 50 years. Its cutting-edge solutions help to increase the efficiency and quality of processes in the Retail, Manufacturing, Transportation & Logistics and Healthcare industries.

DATALOGIC - EMPOWER YOUR VISION

FIXED RETAIL SCANNERS

Single Plane Scanners

- Specifically designed for retailers that require high performance in a compact, horizontal or vertical form factor, the single plane products are tailored for medium to high volume POS applications at an affordable price. These products are particularly effective for grocery, department, drug, do-it-yourself centers and general retail environments.

Presentation Scanners

- Counter space can be at a premium in outlets such as pharmacies, convenience stores and other specialty stores. The crisp, clean enclosure color options of black or white fit in on any counterspace from postal offices to boutiques. Product displays and POS systems compete for space and keeping the limited counter space clear for the customer is critical. This is where Datalogic technology leadership and designs excel. Datalogic presentation scanners come in a variety of designs, offering versatility for your point-of-sale. The advanced image technology and omnidirectional reading capabilities join to offer customers a quick and seamless checkout experience. Their exceptional reading performance ensures efficient throughput and strong ROI. While Datalogic presentation scanners have a small footprint, they deliver a large impact on the shopping experience.

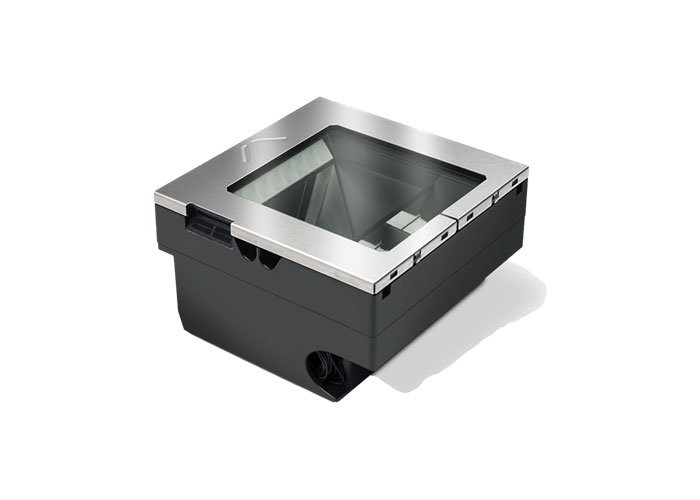

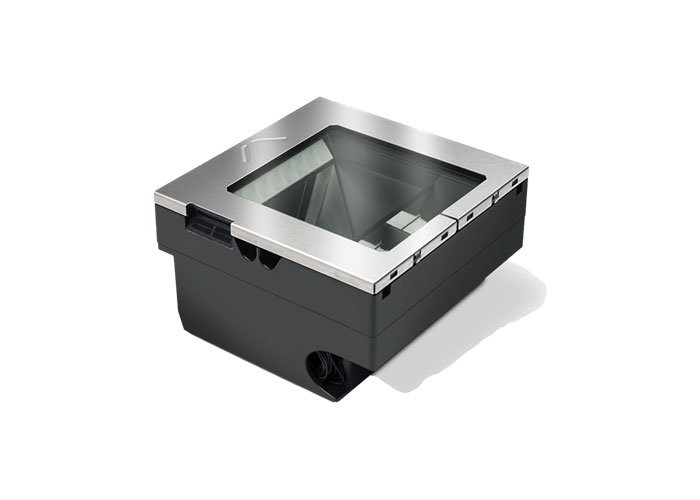

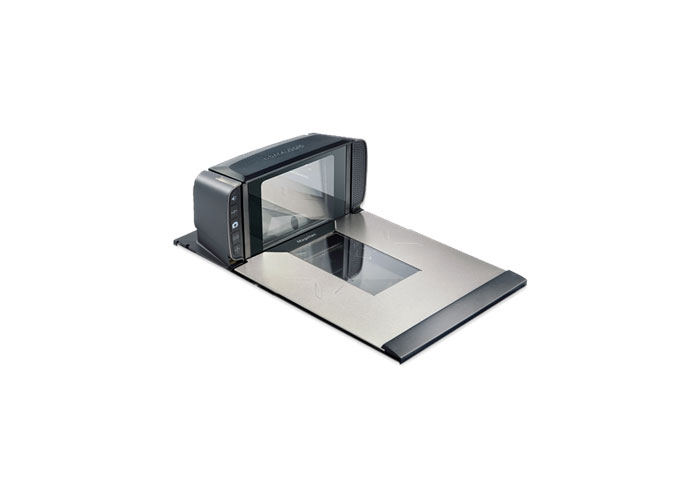

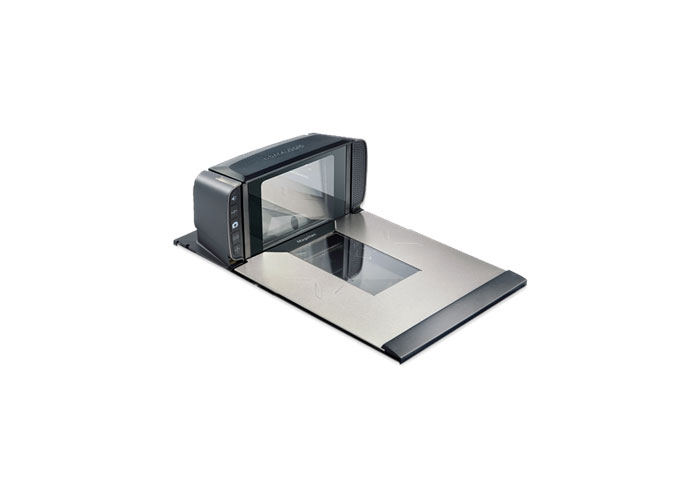

Multi-Plane Imaging Scanner/Scales

- Datalogic is the undisputed global leader in grocery on on-counter in-counter scanner/scales for checkout. Innovative technology and industry leading design is at the core of products used worldwide. The Magellan brand is the standard against which all products for grocery checkout are measured. Magellan sets the standard for reliability and performance. Datalogic pioneered the use of 100% digital imaging technology resulting in the Magellan 9800i, the industry’s first full imaging scanner scale. No other manufacturer delivers innovative grocery checkout solutions like Datalogic.

Loss Prevention

- A successful ROI is not ensured merely by stocking shelves with interesting and desired goods, teaming your stores with staff, and opening your doors to the public. Your investments must be protected from any causes of shortage both from the inside and outside. Loss Prevention can have a devastating impact on your overall bottom line month to month. The source of these shortages can vary. Intentional or non-intentional actions, negligent business practices and acts of vandalism may be the instigating force of realized shortages. On a personal level the origination of such practices may be from vendors, customers and other outside forces as well as employees. A common tactic of shoppers in contributing to shortages would be to have items obscured in the bottom-of-basket (BOB). Datalogic designs scanners to give the retailer peace of mind, knowing there are technologies in place to stand up to shrinkage.

HANDHELD SCANNERS

-

Handheld scanner solutions are specifically designed for automatic data capture applications and process automation throughout the customers’ entire value chain in the retail, manufacturing, transportation & logistics and healthcare industries. Handheld scanners offer outstanding performance and reliability through the different scanning options: linear or area-imaging technologies. The standard, rugged, or antimicrobial enclosure allow their use in any environment, and their ergonomic design make these scanners easy to use also for long period.

The wide range of Datalogic general purpose handheld readers offer an assortment of choices for most of data collection activities. Product sets propose corded and cordless options together with best-in-class reading technologies, ready to solve current and future needs and applications.

From digital or printed 1D and 2D barcodes, to Direct Part Marking (DPM) or Digimarc™, Datalogic offers handheld scanning solutions for every barcode reading application.

Whether your application requires a quick reading performance, ease of installation and use, accuracy and reliability, Datalogic has you covered.

General Duty

-

Whether your organization is looking for an entry level-cost solution with top guaranteed scanning performance and a reliable read every time, a device that sits comfortably in your hand and never gives you fatigue, no matter how long your shift of work may be, an easy to aim product that gives clear audible, tactile and visual feedback on each read, good or bad, general duty handheld scanners are the right solution for a wide range of applications.

The wide range of Datalogic general purpose handheld readers offer an assortment of choices for most data collection activities. Product sets offer corded and cordless options together with best-in-class reading technologies, ready to solve current and future needs and applications.

A very affordable and easy to use handheld scanning solution, the general duty models are extremely easy to setup. The simple and seamless configuration of these scanners with connectivity to all manner of hosts, makes them the only solution you will need for your business.

Industrial

- Datalogic's PowerScan industrial handheld readers are data collection's definitive example of ruggedness and durability. Often imitated, but never rivaled, the PowerScan products rise above the fray with their outstanding performance and unyielding reliability.

Accessories

- Datalogic is able to provide a range of accessories designed to complement and enhance scanner operation and ensure communication and mobility.

MOBILE COMPUTERS

- Mobile computers are full independent computers that integrates all the necessary peripherals and interfaces needed for collecting, manage, and store the data gathered via barcodes. Mobile computer integrates, in a small form factor, all the necessary components of a computer, such has a display, a Wi-Fi system, an operating system (Windows® or Android™), a keyboard (virtual or physical), a battery and a professional scan engine. In addition to these features, every Datalogic mobile computer sports a rugged enclosure, able to withstand drop from various heights and to work in harsh situations. The rugged enclosure allows the devices to operate in all kind of professional conditions and resist to shocks, direct waterjets or very dusty environments.

Vehicle Mount Computers

- Vehicle mount computers are extremely rugged and designed for forklifts, industrial vehicle, and other extreme usage in hazardous zones. Offered in a range of sizes from a compact 7" version for easy hand holding to a huge 21" display industrial computer. There is a form factor to fit every requirement. Mobile computers’ solutions help to fill orders faster, without any loss of accuracy and are designed to withstand extreme temperature, shock, and vibration. And yet they will continue to perform in warehouse management, cold storage, harsh outdoor, manufacturing shop floors, as well as in -truck. Equipped with multiple connectivity options such as Bluetooth, WLAN, wired ethernet, they will read any barcode thanks to inbuilt imaging technology and when used with a connected handheld scanner.

Handheld Computers

- Streamlining all processes throughout the complete supply chain is no longer a ‘nice to have’ solution, it is a ‘must have’ in order to achieve success. Datalogic offers a full line of handheld mobile computers in various form factors meant to fit the many unique needs of our customers. The environs of the store floor, warehouse and transports are varied requiring different solutions. Datalogic has designed its handheld mobile computer line, so the customers can have peace of mind. Barcodes can be scanned near or far, damaged or not, 1D or 2D, whether inside or out no matter the weather.

Software and Tools

- A wide range of software and tools for a simplified, integrated solution to support Datalogic’s mobile computers for developers and system integrators.

Wearable Scanner

- Any time two hands are required to function in the workplace, wearable scanners are the best solution to allow workers to use both hands to pick faster and expand productivity dramatically, while reducing errors and repetitive motions. Datalogic’s wearable bar code scanners provide outstanding performance, leading to higher flexibility and uninterrupted workflows.

Laser Marking Systems

-

Laser marking is the solution of choice for reliable traceability applications in modern industrial environments, where permanent, indelible, reliable marking results are mandatory.

Industrial laser markers can be easily integrated into new or existing traceability infrastructures. They can interact with your Manufacturing Execution System (MES) or ERP platforms allowing for more flexible, less expensive, and faster manufacturing. If your production needs versatility, Datalogic laser markers will take you to the next level, with format changeovers in unbeatable time, seamlessly from mass production to size one.

Thanks to a wide and comprehensive product portfolio of laser marking solutions, Datalogic can offer a solution for virtually any Direct Part Marking (DPM) application on a wide variety of materials, including metals, resin, thermoplastic, silicon, glass, and ceramic. Datalogic also offers solutions for marking organic materials such as wood, cardboard, leather, and produce. Depending on the materials to mark, there is a wide range of Laser Marking technologies to use: Fiber, DPSS, CO2, UV, Green, among many others. The source of the laser makes a big difference on the quality of the mark depending on the material that is being marked, and Datalogic can provide all needed advice and solutions in that regard.

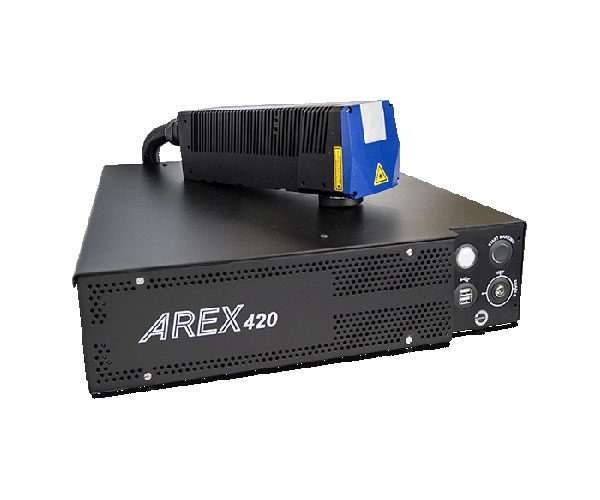

AREX400

-

The AREX400 laser markers offer unbeatable marking performances

AREX400 is the top performing family of laser markers based on Fiber Laser Technology, dedicated to industrial Direct Part Marking (DPM) applications. AREX400 offers IP64 environmental resistance on the marking head, native communication protocols, quiet operations and embedded Safe Laser Off (SLO).

Powered by the innovative Lighter Software Suite, Arex400 is available in several configurations and power sizes to ensure the best results on nearly every application.The new AREX401 has the same compact and rugged scan-head design and delivers an incredible average power of 100W, expanding the marking capabilities on automotive and aerospace components in terms of marking speed and engraving depth. This ensures reliable traceability on components that are exposed to high stress and wear or that are subject to aggressive post processing and finishing.

Lighter MARVIS

-

One software suite for laser marking and traceability needs

LIGHTER Suite combines into a unified software environment a powerful vectorial editor, an advanced laser controller and the innovative MARVIS (MArk Read Verify Integrated Solution) feature to in-line validation of marked traceability codes. Lighter's single GUI (Graphical User Interface) ensure user friendly operations and powerful and reliable runtime perfomance.

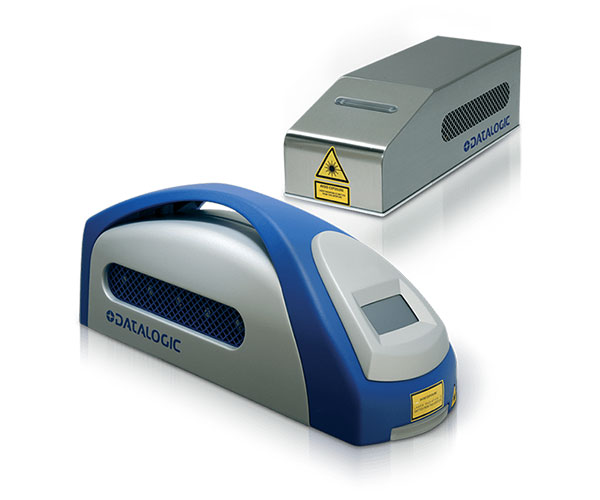

UNIQ

-

The first Ultra compact, all-in-one fiber laser markers

UniQ™ is the first ultra-compact “ALL-IN-ONE” laser marking system based on fiber laser technology. Thanks to compact dimensions, the rugged IP54 grade housing, the complete absence of an external controller and fiber optic delivery cable, UniQ™ laser markers are really unique.

With 15W of optical laser power, the UniQ™ laser marker offers flexibility in marking on a wide spectrum of materials. The ultra-compact design and the high efficiency, low noise, cooling system allows for easy integration even in tight spaces and complex environments. UniQ™ laser markers are powered by the latest version of Ligher, Datalogic’s laser marking software suite, and offer maximum customer ease of use and great flexibility in system integration.

EOX

-

CO2 laser markers for paper, cartons and organic materials

Extremely reliable, Datalogic EOX family offers high quality permanent marking on a widest range of material.

Its configuration offers extreme flexibility for the integration both in production line as well as in stand-alone systems.

EOX embedded controller and the advanced features of its marking platform, EOX offers permanent coding and marking opportunity in a variety of applications.

The eox is available at 10 W and 30 W.

ULYXE Family

-

The first ultra-compact solid state laser marker on the market

The Ulyxe product line provides ideal laser marking solutions for both stand-alone applications and industrial production lines. Integrated 6W DPSS laser marking system, due to its cost-effective, innovative design, Ulyxe becomes the first choice in marking solutions by providing the best price/ performance for plastic and metal marking applications.

VLASE

-

High peak power laser markers for thermoplastic materials

The NEW VLASE is a complete family of Solid State laser marking products available in three different wavelengths: 1064, 532, 355 nm, with power up to 20 W.

The New VLase family, based on the unified ONE.RACK control platform, is available with compact, air cooled high performance, high peak power Solid State laser sources, suitable for demanding industrial applications and hard-to-engrave materials.

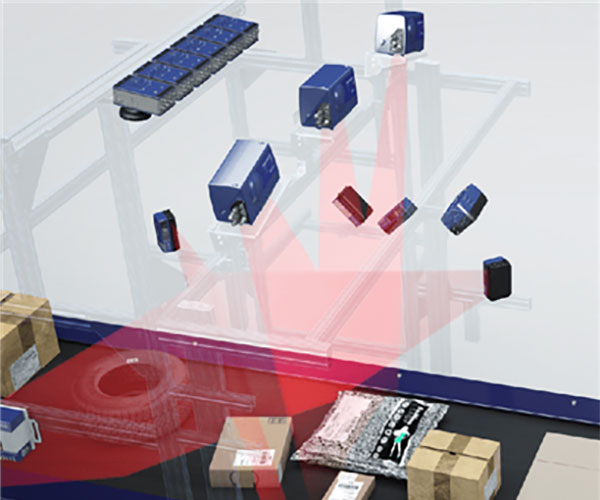

Stationary Industrial Scanners

-

Stationary industrial scanning solutions are specifically designed for applications that are not permanently monitored by operators and are used in a wide variety of industries. Stationary position scanners offer various options for how output data can be used and interface with your business PCs, servers, or ERP, in virtually any fieldbus protocol, providing real value on how your organization uses this business intelligence data. With Datalogic’s versatile portfolio of stationary industrial scanners, customers can get a solution for a full array of barcode reading needs. From printed 1D and 2D barcodes, to Direct Part Marking (DPM), to Digimarc™ packaging, Datalogic offers a solution for nearly every barcode reading application. Whether your application requires image-based, single-plane, omni-direction, or line scan barcode reading capabilities, Datalogic has you covered.

Stationary industrial scanning allows innovative companies to increase their throughput, improve their accuracy, and add a high level of traceability to their manufacturing, warehousing, logistic, and distribution processes. Integrating stationary industrial scanners in these types of applications provides a cost-effective way to increase and improve internal processes without the hassle of adding additional personnel and overhead. Since 1972, Datalogic helps you maximize your organizations capabilities with innovative stationary industrial scanning technologies.

1D reader scanners

- Stationary industrial 1D reader scanners bring increased speed in throughput

Increased accuracy, traceability and throughput result when stationary industrial 1D reader scanners are implemented in the manufacturing lines of the Electronic, Automotive, Pharma, Food & Beverage, and Logistics industries. Datalogic’s broad range of stationary industrial 1D reader scanners offers many options from which to choose, including laser barcode scanners. The implementation of customized stationary industrial 1D reader scanners throughout conveyor lines allows for barcodes to be viewed, scanned, recorded and information transmitted, even when a line operator is not available to do so. This translates into faster throughput and higher accuracy rates for the manufacturers. Each manufacturing line presents with its own unique application needs that should be properly addressed to receive optimal benefits and a strong ROI. Automating processes lowers the actual staffing needs resulting in a stronger bottom line and allows operators to turn their attention to other important areas where they are needed.

2D Imager Readers

-

Data capture for maximized throughput

Datalogic’s family of 2D Imager Readers will transform your traceability capabilities in all logistics, intralogistics and shop-floor stationary industrial scanners applications. They bring industry-leading performance, flexibility, and a low total cost of ownership to machine builders and end users, and effortlessly read the most challenging printed labels and directly marked parts. All the 2D Imager Readers have the features and capabilities that enable the highest throughput possible and the most reliable performance. These features include easy setup with continual feedback, an extensive range of modular lens and lighting options, and cross network industrial connectivity for any situation. By utilizing the latest in sensor technology, Datalogic’s image-based ID scanners provided the most cost-effective stationary industrial scanners solutions available on the market. Datalogic’s 2D imager readers are equipped with state-of-the-art CMOS sensors that provide an unbelievable performance. The various 2D imager readers in resolutions from WVGA to 9MP providing the ideal device to maximize your ROI When combined with the advanced image processing electronics and smart lighting solutions, you have a family high-speed imagers that can easily decipher the most challenging and hard to read barcodes such as those in intralogistics, or DPM barcodes such as those in the automotive and electronics industry.

Connectivity

- Complete range of connection boxes, controllers and accessories for reader network building and flexible connection to all industrial fieldbus

Software and Tools

-

The ability to monitor performance and diagnose system component problems is key to the success of an automation system in order to maintain high levels of continuous operation. Stationary industrial scanners are strategically placed throughout the manufacturing floor and logistics chain to collect and transmit specific information. Efficient plant maintenance requires tools that deliver real-time monitoring, diagnostics and analytics tools to maximize system uptime. With specific software and tools, the collected data can be analyzed locally or remotely to ensure the system works at its top capabilities.

Through the use of the correct software and tools you are able to easily configure specific scanners to work at their peak performance in collecting data from codes determined to be found on the fast moving automated systems such as 1D and 2D codes including Data Matrix, QR and DPM (Direct Parts Marking) codes. Datalogic’s innovative supervisory software solutions monitor operational activities of stationary industrial scanners by a web browser-based interface. Data is collected from different scan points through an Ethernet TCP/IP network then displays the received information flow as a visual onscreen readout. The ability for real-time analysis and corrections results in increased throughput and decreased downtime on the line.

Dimensioners

- Datalogic’s family of stationary industrial scanners are an essential addition to the success of the manufacturing, warehousing, logistics, and distribution industries. Datalogic furthers the ability of accuracy on belt and cross-belt conveyor systems with its ultra-high performance in-motion dimensioners providing items volume measurement. When the dimensioner is used in conjunction with the strategic placement of image-based and laser-based scanners in specific locations along the line, the result will be seen increases of the throughput, accuracy and traceability, while enhancing the ROI, mainly due to enabling Revenue Recovery thanks to Legal for Trade certification of the measurement.

Linear Cameras

- Linear cameras are a subset of stationary industrial scanners’ solutions and are used in applications where there is a critical need for the highest possible read rates on fast-moving goods. Like other stationary industrial scanners, they are designed for use in areas that are not permanently manned by human personnel. Courier, 3PL, postal sorting, retail, distribution, and e-commerce are key areas where self-contained, highly reliable cameras give companies the leading edge. Linear cameras give the perfect mix of long-range reading and 360° coverage for identifying any barcode (1D, 2D, Digimarc) and high-resolution image capture. Installation and maintenance are simple thanks to the web-based setup, field swappable compact flash cards and secure mounting brackets. Whether your application requires image-based, single or multiside, omni-direction, or linear imager, Datalogic has you covered.

Solutions

- Datalogic is widely associated with some of the best products available globally in the automatic data capture and process industries. You will find our handheld scanners, linear cameras, 2D imagers, mobile computers, connectivity gateways, and software across our key verticals of Retail, Manufacturing, T&L, and Healthcare. The world is becoming more connected, and industry and consumers want better customization and service. Our aim is to provide maximum flexibility when it comes to connecting asset, people, and data, leading to greater operational visibility, the ability to make real time decisions, speed up operations, and ultimately increase revenues. Most Datalogic products come with a range of options to suit every need, depending on customer requirements. It’s not always about the benefits that a single hardware item brings, however. Our products are often combined to create more complete solutions.

System Integration

- Datalogic stationary industrial scanner products are found across nearly every industry and are instrumental in keeping everything flowing. Critical systems such as those used in airport Baggage Handling Systems (BHS), Mass Flow Detection Systems (MFDS) for non-conveyable parcels, and Tire Sorting applications require complex data integration and transfer. Although much of this is taken for granted, there are powerful connectivity solutions from Datalogic for the facilitation of data transfer. The most powerful of these is the flagship SC5100 System Controller that provides integration throughout the stationary industrial scanner portfolio of DS/DX laser readers, AV imagers, DM dimensioners.

RFID Readers

2128P RFID Sled

- Designed to provide the best-in-class performance for quickly reading large numbers of UHF RFID tags, the 2128P reader boasts improved levels of accuracy and RFID read/write performance. All items within range are read simultaneously. In-reader Tag de-duplication software removes duplication of tag reads, thereby improving reading performance and facilitating data flow. Sophisticated user feedback and embedded processes and accelerometers provide the most configurable, in-depth and capable ‘search and find’ features currently available.

As the ePop-Loq® system provides a wired connection between the Memor 11 and 2128P RFID Reader, sensitive data can be given that extra level of security by avoiding the use of Bluetooth® data transfer.

Original Equipment Manufacturer (OEM)

-

Original Equipment Manufacturer (OEM) scan engines and scan modules solutions are specifically designed for embedded applications in a variety of industries. Scan engines and scan modules offer various options for how data is captured and output over various interfaces to your host system. Available in either RS232 or USB interfaces, the scan engine or scan module can capture data accurately and efficiently to ensure your system provides the highest level of traceability.

Scan engines and scan modules allow innovative companies to increase their throughput, improve their accuracy, and add a high level of traceability to any application within the healthcare, retail, transportation & logistics, and manufacturing verticals. Integrating scan engines and scan modules in these types of applications provides a cost-effective way to enhance traceability within the application with the ultimate in reliability and accuracy. Since 1972, Datalogic helps you maximize your organizations capabilities with innovative OEM barcode readers.

Gryphon 4500 Fixed Series

-

Easy, Fast, and Built to Last

Are you ready for an integrated scanning solution that combines ease of use, lightning-fast performance, and unmatched durability? Look no further than the Gryphon 4500 Fixed Series. With two versions available (with and without housing), and packed with value-added features and state-of-the-art architecture, this series of scan modules is designed to meet the demands of diverse industries and applications.

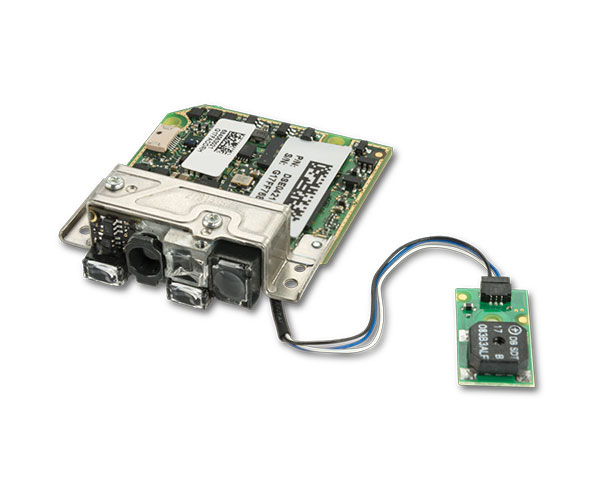

DSE04XX Series

-

The DSE Miniature 2D Decoded Scan

The DSE04XX Series is the decoded versions of the DE2011-DL ultracompact high performance 2D imager engine. It is comprised of the DE2011-DL and a decoder board. The scan engines feature an exceptional high-speed sensor which enables image capture at a full 60 frames per second, delivering outstanding motion tolerance.

The scan engines feature an outstanding depth-of-field, a large field-of-view, high motion tolerance, snappy reading, and excellent decoding performance on poorly printed codes or bar codes displayed on mobile devices and computer screens. It is capable of reading all common 1D and 2D barcodes.

Magellan 34xxVSi OEM

-

Now available in an OEM format.

Datalogic’s Magellan 3410VSi OEM scanner is a high-performance imaging single plane scanner for a variety of applications including self-checkout, customer service kiosks, reading mobile loyalty cards, coupons, tickets, or boarding passes. With the same electronics and optics as the Magellan 3410VSi, the OEM scanner provides strong performance and a large reading area in a small, easy to install package.

Magellan 1500i OEM

- The Magellan 1500i OEM is a high-performance presentation scanner

Datalogic’s Magellan 1500i OEM scanner is a high-performance presentation scanner for a variety of applications including Point of Sale and price checking as well as reading mobile loyalty cards, coupons, tickets or boarding passes. The Magellan 1500i OEM pairs the imaging scanning expertise developed for larger Datalogic scanners with an innovative, compact design to create the most powerful presentation scanner on the market. The addition of Digimarc® Barcode decoding makes the Magellan 1500i OEM scanner uniquely capable of handling both current and future scanning needs.

DE1011-SR

-

The DE1011-SR is a high performing miniature 1D linear imager.

The DE1011-SR scan engine is an ultracompact high performance 1D linear imager with many features which surpass the performance of a laser scan engine. The DE1011-SR scan engine comes with a brighter, longer and more visible scan line. It also has a long reading range enabling users to read bar codes from longer distances and is capable of reading high density bar codes.

Halogen DE210X Micro

-

Halogen DE210X Micro scan engine for outstanding motion tolerance

The Halogen™ DE2102 scan engine features a megapixel sensor optimized for scanning high density and difficult to read codes. The dual-color LED Illumination can be programmed for white or red illumination which is useful for Digimarc® compatibility and specialized needs. The ‘4-Dot & Cross’ laser aimer is identical to the one in the Halogen DE2X1X scan engine family.