- Offer Profile

-

Since 1972, Trimos has managed to position itself as the leader in its fields of activity and guarantees a “Swiss Made” manufacturing quality level. Trimos is focused on 3 segments in the dimensional metrology field:

- Height gauges

- Horizontal measuring instruments

- Surface analysis instruments

We offer «turnkey» solutions based on the following modular items:

- Instruments

- Large range of accessories

- Hardware

- Software and driver programs

HEIGHT GAUGES V-LINE

HEIGHT GAUGE TVM

-

Very robust and mobile instrument for height measuring and tracing in production environment.

The TVM instruments are perfect for height measurements and scribing work and reliable in all kinds of workshop conditions. The result of an unique, compact design of the instrument is great mobility and extreme stability.

Because of its advanced measuring system, the self-contained working time of the TVM is one year. Therefore it can be used for multiple applications in the workshop area. The simplicity of manipulation allows constant change of the user without any time-consuming training.

The success of the TVM among competitive gauges is outstanding. More than 14’000 instruments are in use worldwide. A large range of accessories for all kinds of measuring applications is available.

- Robust and compact construction

- Perfect for use in production area

- Accurate and reliable measurements

- User friendly

- Opto-RS232 data output

- Rechargeable battery pack

- Two models: cast iron base or a granite base

HEIGHT GAUGE V3

-

Height gauge developed for the most difficult workshop environments.

The height gauge V3 have been developed for the most difficult workshop environments. Manufactured in their entirety in Switzerland, they will guarantee a robust, precise and reliable product on the long run. For more than 40 years Trimos philosophy has been to offer easy-to-use instruments that are very efficient in production environment.

The display unit provides functions that are directly accessible and depicted with symbols easy to understand.

This allows for easy and quick handling even by unqualified personnel. The large 2-line « Black Mask » display offers an exceptional contrast in all lighting conditions, a unique characteristic on the market.

The V3 measuring column represents the entry-level of Trimos universal measuring columns. It fully benefits from the developments realized on superior models. A robust and easy-to-use instrument including all functions essential for a use in the workshop.

- Measuring ranges 400 and 700 mm

- Extremely easy to use

- Electronically adjustable measuring force

- Autonomy: 40 h (lithium-ion batteries)

- Standard probes up to 400 mm

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

HEIGHT GAUGE V4

-

An easy-to-use, universal and reliable height gauge for the most difficult workshop environments.

The height gauge V4 have been developed for the most difficult workshop environments. Manufactured in their entirety in Switzerland, they will guarantee a robust, precise and reliable product on the long run.

For more than 40 years Trimos philosophy has been to offer easy-to-use instruments that are very efficient in production environment.

The display unit provides functions that are directly accessible and depicted with symbols easy to understand.

This allows for easy and quick handling even by unqualified personnel. The large 2-line « Black Mask » display offers an exceptional contrast in all lighting conditions, a unique characteristic on the market.

The V4 measuring column offers the same functions as the V3. In addition it is equipped with a second probe holder as well as with an air cushion for easy displacement on the measuring table. The programmable functions buttons of the handle allow a quick access to the functions most used.

- Measuring ranges 400 and 700 mm

- Extremely easy to use

- Electronically adjustable measuring force

- Autonomy: 40 h (lithium-ion batteries)

- Larger than 300 mm probes as standard

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

- Wireless data transfer (optional)

HEIGHT GAUGE V5

-

Height Gauge with excellent repeatability and with a revolutionary displacement handwheel offering its user the choice of the displacement mode of the measuring carriage, either manual or motor-driven.

The height gauge V5 is the descendant of the legendary V+ line, from which thousands of copies have already been sold in workshops all over the world and are universally recognized for their easy use and their high quality.

Trimos was the first to offer vertical measuring instruments on the market more than 40 years ago. The V5 represent a consolidation of know-how accumulated over the years. The very legible display and the user-friendly functions offer exceptional comfort use. But that’s not it: The V5 is equipped with a revolutionary displacement handwheel which offers its user the choice of the displacement mode of the measuring carriage, either manual or motor-driven. Each one of these modes, suffers from no compromise, which means that the user who prefers a manual instrument will not notice a difference with a classic manual instrument and the same applies to the motor-driven displacement. This innovation avoids having to make a difficult choice during the purchase and can accommodate multiple potential users with the same instrument.

The design of the V5 with its side probe holders revives an old Trimos tradition: They enable measuring with long, robust probes guaranteeing an excellent repeatability.

- Measuring ranges 400, 700 and 1100 mm

- Extremely easy to use

- Electronically adjustable measuring force

- Manual or motor-driven displacement

- Larger than 300 mm probes as standard

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

HEIGHT GAUGE V6

-

Measuring with excellent repeatability. Height gauge with all essential functions for the workshop

The height gauge V6 is the descendant of the legendary V+ line, from which thousands of copies have already been sold in workshops all over the world and are universally recognized for their easy use and their high quality.

Trimos was the first to offer vertical measuring instruments on the market more than 40 years ago. The V6 represent a consolidation of know-how accumulated over the years. The very legible display and the user-friendly functions offer exceptional comfort use. But that’s not it: The V6 is equipped with a revolutionary displacement handwheel which offers its user the choice of the displacement mode of the measuring carriage, either manual or motor-driven. Each one of these modes, suffers from no compromise, which means that the user who prefers a manual instrument will not notice a difference with a classic manual instrument and the same applies to the motor-driven displacement. This innovation avoids having to make a difficult choice during the purchase and can accommodate multiple potential users with the same instrument.

The design of the V6 with its side probe holders revives an old Trimos tradition: They enable.

- Measuring ranges 400, 700 and 1100 mm

- Extremely easy to use

- Electronically adjustable measuring force

- Manual or motor-driven displacement

- Larger than 300 mm probes as standard

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

HEIGHT GAUGE 2D V7

-

This Height Gauge 2D combine technological innovation and tradition. With their touch-display and lateral insert holders, the V7 rank as universal instruments for the workshop.

The height gauges V7 combine technological innovation and tradition.

With their touch-display and lateral insert holders, which have proven their worth for decades, the V7 rank as universal instruments for the workshop.

In spite of an entirely revisited interface, Trimos instruments philosophy has been maintained and the user will have no difficulty whatsoever to rapidly take it in hand.

The touch display allows a maximal simplified use as no superfluous information is displayed and therefore the number of functions buttons is limited to what is strictly necessary.

Functions, normally considered as complex, such as 2D, programming, statistics, become child’s play. It results in an unequalled ease of use and therefore a substantial increase in productivity.

The pair of lateral insert holders comes from generations of instruments that have forged the reputation of Trimos. Their great robustness and flexibility allow the use of very diverse probes up to 400 mm long with a breath-taking repeatability.

The V7 are equipped with the revolutionary displacement handwheel allowing the user to choose either the manual or motorized displacement mode.

- Measuring ranges 400 to 1800 mm

- Simple and easy-to-use graphic interface

- Electronically adjustable measuring force

- Manual or motor-driven displacement

- 2d, programming, statistics

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

HEIGHT GAUGE V8

-

Height gauge with extreme precision, repeatability, high resolution and with Swiss made finish. It is equipped with specific handle for fine adjustment.

After the very successful launch of the V-line height gauges, Trimos has developed a new instrument in its height gauge family, the V8.

The mechanical design and delivery scope of the V8 are identical to the V9. It shares the features that made the model V9 so successful: extreme precision and repeatability, high resolution, and Swiss made finish. What is to underline about this new model is its specific handle for fine adjustment. Trimos developed this fine adjustment to answer to specific applications requiring a fine adjustment of carriage position.

The V8 guarantees, like its predecessors, an extremely easy use with great robustness, flexibility and extreme precision.

The large 2-line « Black Mask » display of the V8 offers an exceptional contrast in all lighting conditions. The display provides functions that are directly accessible and depicted with symbols easy to understand.

- Measuring range 400 to 1100 mm

- Specific handle for fine adjustment

- Manual displacement

- Exceptional precision level

- Large range of accessories

- All possible adjustments without tools

- Interfaces RS232 and

- USBWireless data transfer (optional)

HEIGHT GAUGE 2D V9

-

This Height gauge 2D has been developed for the most demanding users. Laboratories and workshops for whom measuring reliability is determining will fully appreciate its exceptional precision level and its "Swiss Made" finish.

The height gauge V9 has been developed for the most demanding users. Laboratories and workshops for whom measuring reliability is determining will fully appreciate its exceptional precision level and its "Swiss Made" finish.

Metrological performances have been the core of the development of this height gauge. No compromise on precision and repeatability have been tolerated. This is why some construction details, particularly probe holders differ from other models.

The display, based on an entirely tactile interface, offers an ease of use never reached yet on a vertical measuring instrument. The menus and functions displayed obey to a very strict philosophy and design. This allows a great efficiency, even in complex tasks such as programming, 2D mode, angles measurements or statistical analysis of results.

The V9 are equipped with a revolutionary displacement handwheel allowing the user to choose either the manual or motorized displacement mode.

- Measuring range 400 to 1100 mm

- Exceptional precision level

- Electronically adjustable measuring force

- Manual or motor-driven displacement

- 2d, programming, statistics

- Vast range of accessories

- All adjustments possible without tools

- RS232 et USB interfaces

- Wireless data transfer (optional)

PORTABLE CMM CNC

C-LINE

-

Trimos new C-Line is the world’s first truly portable CNC Coordinate Measuring Machines designed for the workshop. This product line is part of the new TRIMOS 3D product group.

Portable: At only 13,5 kg, the CNC C-Line goes with you wherever you need it. No longer are you required to take the part to the CMM, the C-Line can be deployed directly in the manufacturing process.

Easy-to-Use: The C-Line is easy to operate using a portable PC. The concept of this product has been thought for optimal user experience and ease-of-use.

Software: The C-Line is delivered standard with the ControlC software, which allows you to perform many type of measurements: distance, circle, plane, line, point… To take full advantage of the performance of the C4, we advise the optional Aberlink software, 3D software offering the advantage of ease of use. Other measurement software are compatible: PolyWorks, CMM Manager, Verisurf etc.

MEASURING BENCHES

MEASURING BENCH TELS

-

Simple and robust instrument for small dimensions measuring. Ideal for bar turning workshops.

The Mini-Horizontal TELS is the ideal instrument for checking small dimensions. It is part of the horizontal instruments family.

The instrument is mainly used for checking internal and external dimensions, such as ring gauges, plug gauges, thread plug gauges and for measuring precision production parts.

The reliable concept is easily suitable for the use in workshop environment. An electronic probe and digital display unit or simply a dial indicator can be applied to perform all measurements. The selection of the measuring system depends on the required accuracy.

The range for internal measurements from 10 to 100 mm and external measurements from 0 to 100 mm covers a large number of applications. The absolute measuring range is 25 mm and a preset setting is necessary to obtain an entire length. A wide range of accessories are available.

- Ideal for checking small dimensions

- Easy manipulation

- Suitable for use in workshop area

- Wide range of accessories

MEASURING BENCH ALESTA

-

Presetting instrument for 2 points bore gauges. Its motorized positioning and specific result in a very efficient use.

The Alesta family is a product that simplifies the setting of 2-point bore gauges. It replaces the traditional way using a lot of different rings.

Thanks to innovative adapters, a positioning error will be eliminated and the speed of measurements increased. You just input the dimension into the key board and the required mobile carriage will position itself automatically onto this position. The mobile carriage system will always stay in the desired position even when applying a force on the anvils.

The stable granite base combined with a high precision measuring system guarantees excellent measuring results. Using a tolerance table the carriage can be positioned to the selected tolerance range. This table can be tailor-made to customer’s requirements. This product achieves a typical return on investment of 2 years. The acquisition of new rings and their calibration will be eliminated. The instrument range includes 3 models: 300, 500 and 1000 mm.

- Ideal for use in the workshop area

- Very simple manipulation

- Motorized carriage movement

- Stable granite base

- High precision measuring system

- Tolerance data base

- Wide selection of adapters and accessories

- Internal and external measurement possible

MEASURING BENCH HORIZON GRANITE

-

Presetting and calibration benches for comparative measurement instruments up to 12000 mm. Perfectly adapted to workshops environment, thanks to their robust construction.

The «Horizon» instruments respond to the current requirements for quality inspection in manufacturing areas. They allow a quick, precise checking and setting.

The instruments are perfect for setting all kinds of comparative measuring equipment and for checking length, internal and external diameters, thread gauges etc.

The new innovative concept with incorporated measuring system and display unit ensures excellent results by easy manipulation and is the answer to various demands in the field of production. Simplicity of use is an additional valuable advantage.

The Horizon Granite instrument exists from 3000 to 12000 mm. A wide selection of easy interchangeable accessories completes the application possibilities.

- Ideal for use in the workshop area

- Very simple manipulation

- Precise checking and setting made easy

- Wide selection of accessories

MEASURING BENCH HORIZON SETTING HS4 - HS5 - HS6

-

Horizon Setting HS4, HS5 and HS6 are the ideal instruments for the control and calibration of measuring means with fixed and variable dimensions.

Horizon Setting Hs4, HS5 and HS6 are the ideal instruments for the control and calibration of measuring means with fixed and variable dimensions. Its high precision and finishing level position it as a top of the range model for workshop or laboratory use. It is the perfect answer to current needs in the manufacturing field.

This new model is based on the already well known Trimos Horizon Premium, but a new electronics and innovative display are incorporated. A modern and ergonomic design, as well as a great ease of use guarantee optimal and high productivity measuring results.

Trimos proposes a complete range of instruments from 3000 mm to 12000 mm. All measuring ranges are direct, which means that the whole measuring range is available without adjustment or intermediary re-calibration. A large selection of easily interchangeable accessories completes the possible applications and guarantees a correct positioning of the instruments to be calibrated.

- Delivered with two parallel 25 mm TEL5 gauge blocks

- Robust design, ideal for use in workshop

- Very simple use

- Fast and precise checking

- Works on battery or power supply

MEASURING BENCH HORIZON PREMIUM (HPD)

-

Measuring bench for the checking of fixed and variable dimension measuring means. A top range for daily use in the workshop.

The HORIZON PREMIUM instruments fulfill today’s requirements of high accuracy quality control equipment in production areas and take into consideration EN ISO 9000 standards.

The instruments may be used in a workshop area or installed in a quality control room for checking of measuring gauges and setting of all types of comparative measuring equipment. The well-designed, reliable new concept, obtained by superior engineering, ensures high precision and optimum results by easy manipulation as well as a valuable level of productivity.

The instrument is equipped with computer, TFT screen and Trimos-WinDHI software.

Instruments with a measuring range from 500 to 3000 mm are available, all of them built in one single piece. All measuring ranges being direct, it means that the whole measuring range is available without adjustment or intermediate re-calibration.

- Ideal for use in laboratory and workshop

- New ergonomic concept

- Measuring carriage with fine adjustment

- Large range of accessories

- Adjustable measuring force

- Modular design

- Direct measurement over the whole range

MEASURING BENCH TWINNER

-

TWINNER is a universal instrument for the measurement of cylinder-shaped parts, which replaces a great number of conventional instruments in the workshop. This measuring centre, multifunctional, flexible and mobile, allows to measure and document practically all that is manufactured by turning.

This instrument has been specifically developed for the workshop and lends itself perfectly to a use in production, close to the machining centre.

TWINNER allows the quality control of sole parts as well as that of small batches. Other areas of use are the control and acceptation of machine tool. All revolution parts can be precisely measured, without adjustment necessary. The range of parts that can be measured spreads over typical turning parts, such as axles, gearbox shafts, camshafts, crankshafts, transmission shafts, joints and revolving parts, to parts with very elaborate geometry.

TWINNER is available in the following dimensions: lengths of 400, 800, 1200 and 2000 mm and diameters of 125 or 160 mm. The manual use and control of the TWINNER are performed by a PC with TWINNER soft.

- Built for workshop use

- Simple handling

- Use without preliminary knowledge

- No user's influence thanks to constant measuring force

- Excellent repeatability

- Very fast change of parts

- Easy calibration

- Complete selection of accessories

CALIBRATION BENCHES (LAB)

CALIBRATION BENCH THV

-

Calibration bench for certification of equipment such as ring gauges and thread plug gauges. Its small dimensions and highly precise measuring system make it the ideal instrument for a mobile calibration station..

The horizontal THV instrument has been designed for calibration and certification of gauging equipment of small dimension.

It allows easy and precise checking of plug gauges, ring gauges, thread plug gauges, test and dial indicators as well as measuring of high precision production parts.

The incorporated opto-electronic measuring system guarantees high accuracy. A separate display unit or a PC with Trimos WinDHI software can be used to display the measurement results.

The THV instruments can also be delivered without measuring system. An electronic probe or a dial indicator shall then be used as measuring system.

Due to its small size, The THV can be moved easily. It is therefore frequently used as mobile calibration station.

- Ideal for use in a clean room and in the workshop area

- The instrument meets the requirements of all ISO 9000

- Very simple manipulation

- Large range of accessories

- Checking of external and internal dimensions

- According to the application, can be sed in horizontal or inclined up to 90°

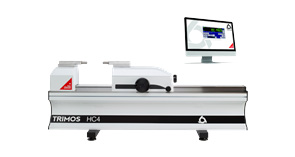

CALIBRATION BENCH HC3 / HC4 / HC5

-

Measuring bench for the checking of fixed and variable dimension measuring means. A top range for daily use in workshop or in laboratory.

The Horizon Calibration HC3, HC4 and HC5 instruments fulfill today’s requirements of high accuracy quality control equipment in production areas and take into consideration EN ISO 9000 standards.

The instruments may be used in a workshop area or installed in a quality control room for checking of measuring gauges and setting of all types of comparative measuring equipment. The well-designed, reliable new concept, obtained by superior engineering, ensures high precision and optimum results by easy manipulation as well as a valuable level of productivity.

The instrument is equipped with computer, TFT screen and Trimos-WinDHI software.

Instruments with a measuring range from 500 to 3000 mm are available, all of them built in one single piece. All measuring ranges being direct, it means that the whole measuring range is available without adjustment or intermediate re-calibration.

- Ideal for use in laboratory and workshop

- New ergonomic concept

- Measuring carriage with fine adjustment

- Large range of accessories

- Adjustable measuring force (except HC3)

- Modular design

- Direct measurement over the whole range

CALIBRATION BENCH LABCONCEPT / LABCONCEPT PREMIUM

-

Labconcept/Labconcept Premium Universal calibration benches for all type of equipment. These instruments are ideally adapted to measuring laboratories, thanks to their exclusive WinDHI software and extensive range of accessories.

The Labconcept and Labconcept Premium are high precision calibration systems that meet the most sophisticated requirements.

The up-to-date, well designed modular concept enables extremely secure functioning, facilitates the manipulation and therefore increases the productivity in the measuring laboratory. Simplicity and high accuracy have been associated.

This new concept, integrating a computer and a touch screen as well as the appropriate Trimos-WinDHI software with all necessary measuring functions guarantees the best results. A temperature compensation system as well as a gauge management system can be installed to enhance the system performance.

Instruments with a measuring range from 300 to 2000 mm are available, all made in one single piece. All measuring ranges being direct, it means that the whole measuring range is available without adjustment or intermediate re-calibration.

- Meets the requirements of all ISO 9000

- PC with exclusive software WinDHI

- High precision measuring system

- Dimensionally stable instrument base

- Adjustable measuring force (0-12 N)

- Large range of accessories

- Direct measurement over the whole measuring range

CALIBRATION BENCH LABCONCEPT NANO

-

A new reference in matter of dimensional metrology. The unique combination of an ultra accurate measuring system and the motorization of XYZ axes make it the most performing calibration system on the market.

The Labconcept Nano is a new reference in the field of dimensional metrology. It integrates 40 years of knowledge and continuous improvement. It is a remarkable instrument for all measuring tasks that require extremely high accuracy.

The uncompromising design of the Labconcept Nano offers an ideal and performing platform for checking and calibration of all kinds of gauges and measuring instruments. Checking of internal and external dimensions will be done as a fully automatic procedure by the three motorized axes XYZ and the legendary simplicity of use of Trimos WinDHI software.

The Labconcept Nano is completely designed and manufactured in Switzerland according to the highest quality standards. Robustness, reliability and longevity are our traditional values.

The Labconcept Nano combines tradition, experience and a strong technological lead. It integrates the latest measuring and motorisation technologies and can be considered as the first “full digital” calibration instrument. A regular PC controls all electronic components. This low-power solution avoids heating and keeps the energy, maintenance and repair costs at a reasonable level. The linear bearings used in all guideways have proven their superiority over all other technologies in terms of precision, wear, rigidity, temperature stability, reliability, dust protection and maintenance. They ensure exceptional repeatability and precision through time.

- Unequalled level of accuracy

- Exceptional repeatability

- Motorized CNC axes X, Y and Z

- Selection of displacement speed by software

- Measuring force (0-12 N) and locking of measuring anvil performed by software

- Integrated temperature compensation system

- Absolute measuring range on all models: 350 mm

- Application ranges: 350, 600 and 1100 mm

- Measuring of parts up to 60 kg

- 2 screens in standard package

- CNC controlled measurement even on diameters and threads

PORTABLE MEASURING ARMS

PORTABLE MEASURING ARMS - A-LINE

-

Extremely easy and accurate 3D measurement for quality control, inspection, or verification of small and large size parts.

Trimos A-line portable articulated measuring arms allow an extremely easy and accurate 3D measurement.

The A-line arms certified according to ISO10360-12 or ISO10360-02 standard allow quality control, inspection, verification of small and large size parts. Thanks to an extremely stable carbon structure, all models are light and easy to operate. You can choose between the A3, A4, A5, A6+, A7, A8+, A9 and AT models according to your application.

For pipe inspection with laser fork and a dedicated software Trimos AT is the perfect equipment. Based on the A5 and A6 arm design, this portable articulated arm is ideal for quick and accurate inspection of pipes and any other parts within its range.

Different Laser Scanners can be combined with our 7 axes arms for a complex-profile contour scanning . All Laser Scanners can be quickly applied to the rotating 7th axis of the arm.

FLEXIBILITY AND PROBABILITY

All arms may be provided with a wireless Bluetooth device, batteries or the two options for a complete wireless portability.

- Measuring ranges from 250 mm to 9000 mm

- Portable measuring instrument

- Extremely easy to use

- Certified according to ISO 10360-12 standard

- Exist in 5, 6 or 7 axis configuration

- Protection with electromagnetic brake

- Laser Scanners for the 7 axes arms

SURFACE MEASURING INSTRUMENTS

-

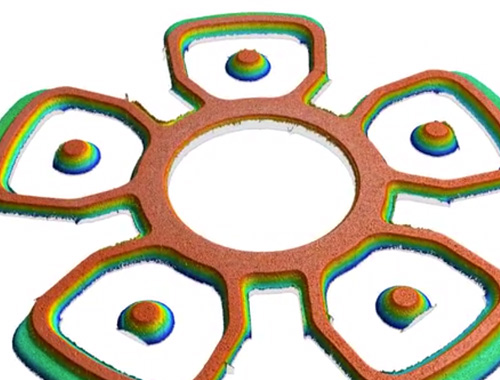

OPTICAL MEASUREMENT WITH TR SCAN PREMIUM

Analyze surfaces texture with nanometer precision is already a technological challenge, but TR Scan Premium is able to perform this task with a good speed!

The TR Scan Premium is used in workshops and laboratories worldwide. It is completely designed and manufactured in Switzerland by TRIMOS.

The TR Scan adapts a large range of materials such as steel, aluminium, brass, titanium, silicon, gold, ceramics, glass etc. The system can be tailored to fit the requirements of many industries: Automotive, Aircraft, Machine Tool, Watch, Railway, Medical, Materials, Optics, Electronic...

A REVOLUTIONARY CONCEPT

-

TR Scan 3D LINE use the CCML - Chromatic Confocal Microscopy Line technology.

The chromatic confocal line sensor TRIMOS CCML1 offers an incredibly fast 3D measurement of 384.000 points per second, that is to say more than 23 million points per minute with nanometric scale resolution.