- Offer Profile

- Feinwerkoptik Zünd AG supplies different industry sector European-wide and in USA with optical and opto-mechanical products as well as with services within the range of product and process development.

Optical components and systems

- Feinwerkoptik Zünd is one of Europes leading companies when it comes to manufacturing and developing as well as custom and mass production of optical components and systems. For many years we have stood for outstanding quality and maximum innovative strength.

Optical Components

Spherical optics

-

Spherical optics with sizes 0.2 to 10.0mm are produced in following production types: single part production, small batch series and mass production. Surface form deviation can be measured and documented.

Spherical optics with sizes >10.0 to 20.0mm are produced in following production types: single part production, small batch series and mass production. Surface form deviation can be measured and partly documented.

Spherical optics with sizes >20.0 to 30.0mm are produced in following production types: single part production, small batch series. Surface form deviation can be measured and partly documented.

Achievable Tolerances

- center thickness: 0,040mm

- diameter: 0,002 mm

- cylindricity: 0,001 mm (depending on ratio diameter / length)

- true running: 0,002

- surface form deviation: 3 / 0,2 (0,1) @ λ = 632 nm

- centering tolerance: 4 / 1‘ (depending on radii)

- surface imperfection tolerance: 5 / 2 x 0,01 (depending on size of effective area)

- Ra (polished): 1,5 nm

- Rq (polished): 2,0 nm

- Ra (grinded): 1,0 µm

- Rq (grinded): 1,5 µm

Plano optics

-

Plano optics with sizes 0.2 to 10.0mm are produced in following production types: single part production, small batch series and mass production. Surface form deviation can be measured and documented.

Plano optics with sizes >10.0 – 100.0mm are produced in following production types: single part production, small batch series. Surface form deviation can be measured and partly documented.

Plano optics with sizes >100.0mm are produced in following production types: single part production, small batch series. Surface form deviation can be measured partly and partly documented.

Achievable Tolerances

- thickness: 0,003 mm

- surface form deviation: 3 / 0.2 (0,1) @ λ = 632 nm

- surface imperfection tolerance: 5 / 2 x 0,01 (depending on size of effective area)

- edge length: 0,05

- square: 3 / 0,2 (0,1) 15“

- Ra (polished): 1,5 nm

- Rq (polished): 2,0 nm

- Ra (grinded): 1,0 µm

- Rq (grinded): 1,5 µm

Assemblies

-

Optomechanical assemblies are e.g. objective lenses built in a holder: There are no general tolerances available because each single assembly of these interdisciplinary products are worked out individually.

Available Tolerances

- true running : 0,002

- "centering tolerance": "4 / 1‘ (depending on radii) "

- "cement wedge": "4 / Δ 1‘ (depending on diameter, radii, cement)"

Systems

Miniaturized Camera

-

Development and production of a miniaturized camera with maximum resolution and flexibility. The dimensions of the components that enter the body are said to be as low as possible in order to shorten the healing process and to ensure the accessibility to the smallest vessels.

With the definition of the image sensor a big part of the requirements in the miniaturized camera already were transmitted:

- Lowest possible outer diameter of the housing

- Optics with an object angle of 85°, individually aligned to the camera sensor

- Electronic data transfer and data processing for displaying on the monitor

Technical data objective:

- Requirement:

- Object distance: 20,0 mm

- Field of view: 80 - 90°

- Specification:

- Focal length objective: 1,10 mm focusable

- Main beam-angle: 25°

- Shape of the last lens surface: Plan

New opportunities for Medicine & Technology

The individually adaptable optics along with the corresponding camera provide the essential part to a whole new ranges of applications.Maximised resolution with minimal size

With the development and production of this miniaturised camera was shown, that very small construction size (ø1.55 x 2.5) are sufficient to view and evaluate the picture of hard-to-access areas on a display screen – whether inside the human body or in a non-human cavity.

Miniaturized Camera

-

Demands of surgery:

Violations of the eye need to be kept very low during surgical interventions. Therefore, focus of development is on the size of instruments – the smaller the better.

Two important demands: - Working distance between endoscope and retina varys. No constant focal plane can be assumed because it is hard to guess the mentioned distance.

- The path of image transmission needs to be much longer than the diameter of the eyeball.

- Object (retina or optic nerve)

- Objective

- Part of image transmission

- Intermediate image

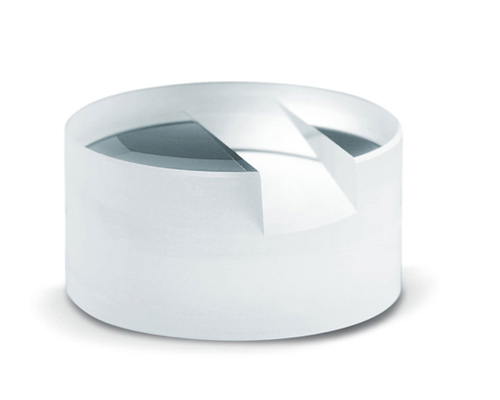

Image Slicer for Spiffi

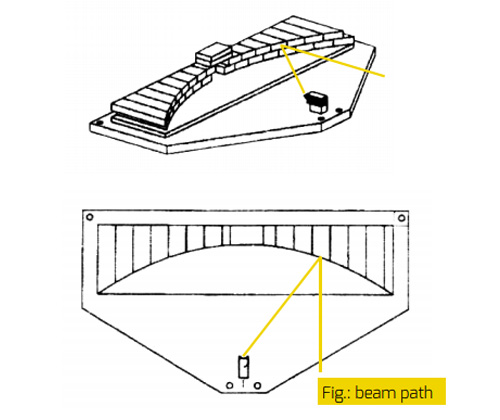

- The image slicer devides the image into 32 equal sized elements and arranges one element by another to a pseudo long image chain. The goal was to undermatch all the challenging specifications and tolerances of angles and position of each single element.

Project overview

- The focal plane of the telescope is on the small Image Slicer to devide the image into 32 parts and to refl ect the NIR radiation in direction big Image Slicer. Due to parabolic arrangement of the mirrors from big Image Slicer, the single image elements are stringed to a row of image. The following spectrometer analyses the radiation to defi ne material composition.

Technical specifications

-

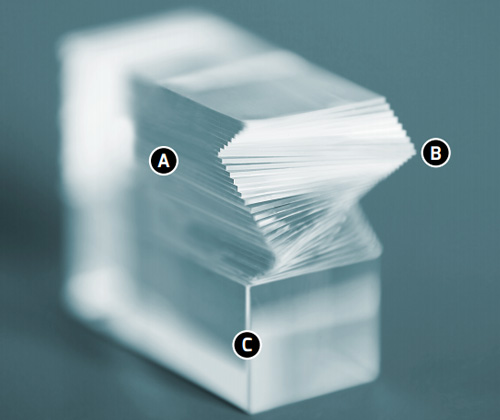

All parts (about 70) are optically contacted (contact blocked). Cements are inappropriate for assembly because the whole Image Slicer gets cooled down to 77K during application. The cooling-down is also the reason why material needs to have zero thermal expansion: Zerodur was choosen for all parts.

At the end, the surfaces are coated with gold.In total, 17 different small Slicer were manufactured. Each Slicer features a Wall- and Absolut- angle. The refl ecting surfaces stands skewed referring to entering beam path.

Effective realization

-

A: 32 small Slicers are stacked and contact blocked

B: Due to 17 different Wall- and Absolut- angles, the NIR- rays are reflected to defi ned direction

C: The stand brings Slicer to exact heightMore than expected

Standard to date of 16 stacked small Image Slicers has increased by 100% to 32 Image Slicers. The high defi ned goal has been fulfi lled. Expectations to project plan had been outreached: Lead time had been minimized in spite of high effort especially during manufacturing of high precise toolings.

Applications

Technical Solutions

-

The new dimension of high-resolution imaging systems

We are recognized all across Europe as a specialist in the manufacture and development of flat optics and round optics as well as in combining them into subassemblies with ultra-small dimensions. Tailor-made, customized solutions for all customer requirements are our strength.Always a step ahead for our customers

Technological progress is a result of far-sighted thinking. We are treading a completely new path of possibilities in optics with the development of our new miniaturized systems. Unimagined opportunities are opened up for technical industries by their enormous robustness (also withstanding heat, acid and oil) coupled with maximum performance. We are ISO 9001 certified and our great flexibility guarantees deliveries just in time, getting your products onto the market even more quickly. Capitalize on the uncompromising precision of our engineering skills and products, all resulting from Swiss quality work! Together with you, we will develop a model tailored to your requirements. Space & Defence Solutions

-

One small step for man - one giant leap for high-end technology

We are recognized all across Europe as a specialist in the manufacture and development of flat optics and round optics as well as in combining them into subassemblies with ultra-small dimensions. We reach for the stars with tailor-made, innovative solutions for all customer requirements.Custom manufacturing for specific requirements

Our Swiss-quality work results in optical components and opto-mechanical subassemblies of the highest quality and uncompromising perfection. In this way, required specifications are met and the ability to withstand challenging ambient conditions is ensured. We know this: unusual application conditions require unusual performance. Talk to us about your specific requirements! We love the challenges presented by high-end technology. Only through them do we rise to our best performance. Medical Solutions

-

Medicine of the future calls for innovative solutions

We are recognized all across Europe as a specialist in the manufacture and development of flat optics and round optics as well as in combining them into subassemblies with ultra-small dimensions. Tailor-made, customized solutions for all customer requirements are our strength.The result of experience and pure passion

Particularly in medicine, conscientious precision work and Swiss quality are in high demand. For more than 20 years we have developed and manufactured optical systems and components for medical technology, with each of our successes inspiring us all over again. Miniaturized systems that are both innovative and creative give medical technology access to new worlds! Together with us, you too can experience the gigantic future to be found in miniaturized dimensions.

Technical specifications:

By means of delivered informations, a feasibility study with different optical concepts was worked out to evaluate advantages and disadvantages referring production, assembly and service at a very early time.

The specifications were defined after choosing the best concept.

Effective realization

New standard at surgeries in the eye

With this optic of ophthalmic endoscope a new scale of rod lenses has been achieved. This optic defi nes proverbial the core of the smallest endoscope.