SinceVision

Videos

Loading the player ...

- Offer Profile

-

Sincevision, a leading manufacturer of cutting-edge sensor technology, empowers manufacturers worldwide to achieve unparalleled quality control and precision in their production lines. Our innovative solutions are which is designed to address the specific needs of the modern manufacturing landscape.

SinceVision specializes in industrial sensors, offering a range of products including 3D Laser Profiler, Laser Displacement Sensor, Spectral Confocal Displacement Sensor, Through-Beam Edge Sensor, and Full-Spectrum Sensor.

Product Portfolio

Worl-Class Sensor Manufacturer Pioneering Precision in Sensor Technology

SH3 Series

- Small size, high performance, convenient for narrow space applications, modular and platformized design and production ensure product consistency and stability, without fear of high, low temperature, vibration and other working conditions.

SH6 Series

- Ultra-clear and high-quality color image, up to 5 million pixels, rich ISP processing, highly integrated internal system, fully considering EMC electromagnetic compatibility, meeting military level standards in external strong interference environments.

SH2 Series

- SH2-201 is another masterpiece of SinceVision high-speed camera family for high-endscientific research and national defense. Through the integrated hardware and softwarecircuit desian, the volume is further reduced, but the perormance is uncompromisina. it isequipped with a new CMOS sensor to provide excellent resolution and fine image details.Thanks to the self-developed flash parallel storage architecture, TB-level non-volatile storagecan be obtained without changing the volume, making it possible to record for a long time.

3D Laser Profiler

- SinceVision's industry-leading 3D Laser Profilers with 6400 X-axis profile points and Z-axis repeatability accuracy up to 0.1μm.

SR Series

- Specially tailored for the transit rail industry, it has super fast scanning speed, up to 67K/s

SRI Series

- INTEGRATED 3D LASER PROFILER

Laser Displacement Sensor

- Explore SinceVision's Laser Displacement Sensor, designed for high-accuracy distance measurement in automation and inspection applications. Ideal for precise, reliable results in industrial settings.

SG Series

- The fastest sampling frequency in the industry is 590kHz, the detection output is fast response, with ultra- high precision, ultra-high stability, effective measurement of precision material thickness and high-speed moving displacement

SGI Series

- Ultra-high integration, no need for external amplifier and controller, provide rich communication mode, to meet the diversity of detection needs

SD33 Series

- Integrated small body integrates a variety of communication methods, high precision and high performance, stable and accurate detection data, successful landing in various industries ranging applications

SD22 Series

- Equipped with four digit display and film key, multifunctional simple operation, small size, built-in rich detection mode

SD-C Series

- Built-in controller and digital display, ultra-small size and lightweight body suitable for various installation environments, with superior cost performance

Spectral Confocal Displacement Sensor

- SinceVision's Spectral Confocal Displacement Sensor for accurate, non-contact displacement and thickness measurement across various materials. Perfect for high-precision industrial inspection needs.

SC Series

- Not afraid of various special materials, the maximum mirror measuring Angle 60°, super Angle without measuring blind area, ultra small spot 5.8um, ultra high detection frequency 10kHz

SCI Series

- Sampling frequency up to 33kHz for stable detection of fast-moving objects and high-frequency vibration amplitude

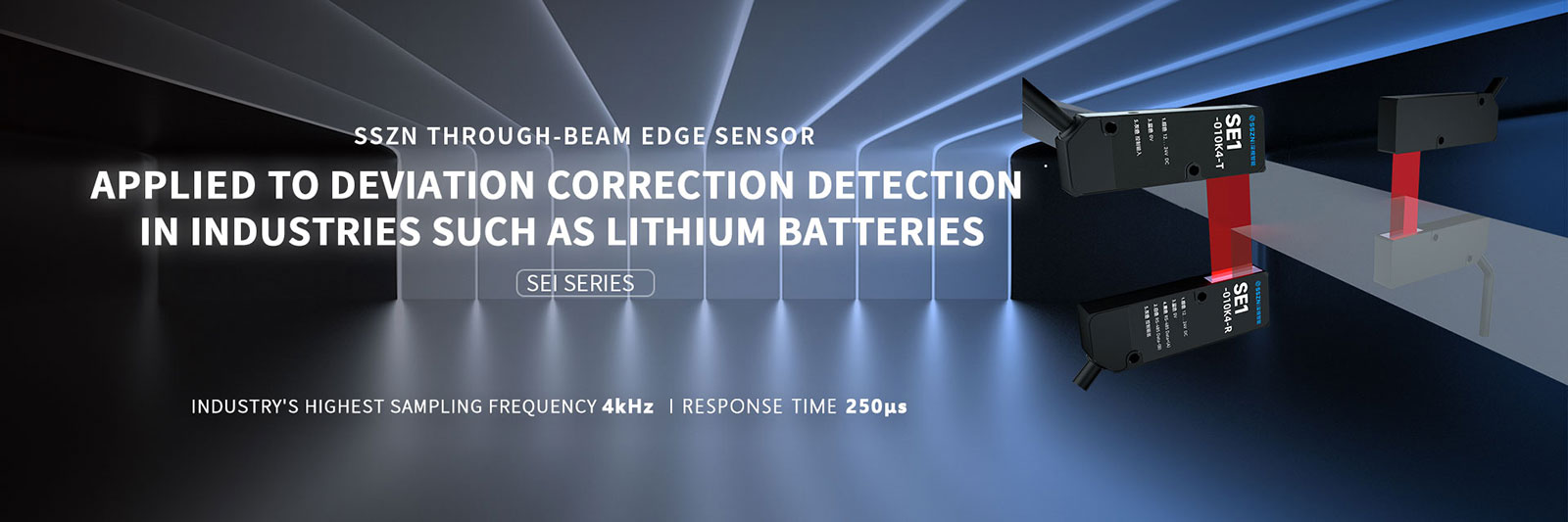

Through-Beam Edge Sensor

- SinceVision's Through-Beam Edge Sensor, offering non-contact, high-speed edge detection for precise positioning. Ideal for web edge control, sheet metal detection, and quality control across multiple industries.

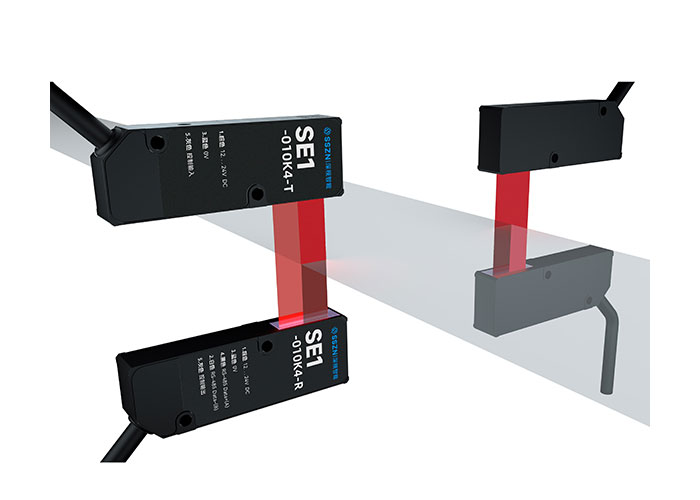

SE1 Series

- The edge measurement sensor is mainly used in the detection of coiling, pole plate defect and diaphragm correction in the lithium electric industry. The maximum sampling frequency is 4kHz and the response time is 250s

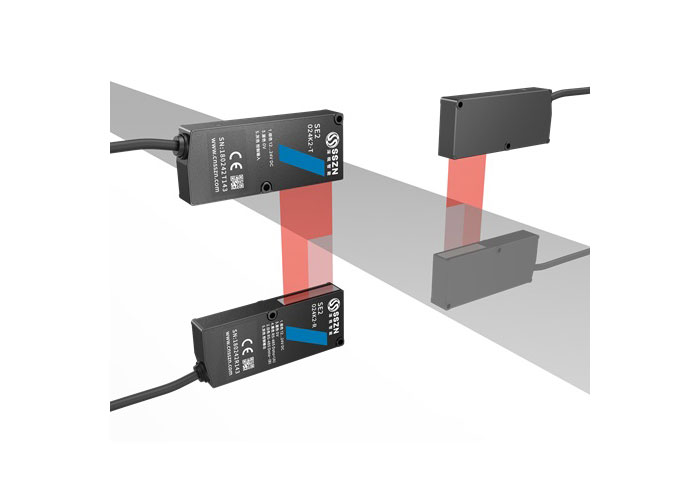

SE2 Series

- It is mainly used in the correction detection, semiconductor, industrial manufacturing, etc., with a repetition accuracy of 50μm and a sampling period of 0.5ms.

Full-Spectrum Sensor

- SinceVision's Full-Spectrum Sensor, is engineered for precise color detection across a full spectrum. Perfect for high-precision industrial automation and quality control applications.

SS1 Series

- Combining optical and electronic technology, it adopts RS485 communication mode, with response time as short as 200μs, which can accurately and quickly identify and distinguish various colors.

Applications

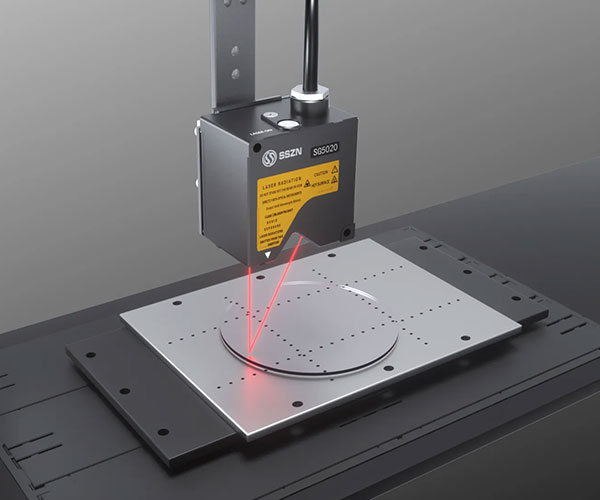

Semiconductor - Wafer flatness detection

- The lack of smoothness of wafers will lead to the change of thermal stress in the packaging process, which will affect the normal use of chips, so the requirements for the surface finish of wafers are very high. It adopts deep vision intelligent high-precision displacement sensor SG5000 series, supports specular reflection type installation, and can judge the flatness by multi-point values on the wafer.

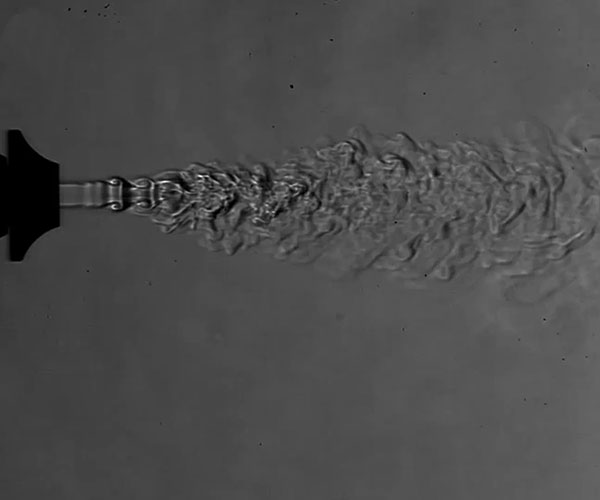

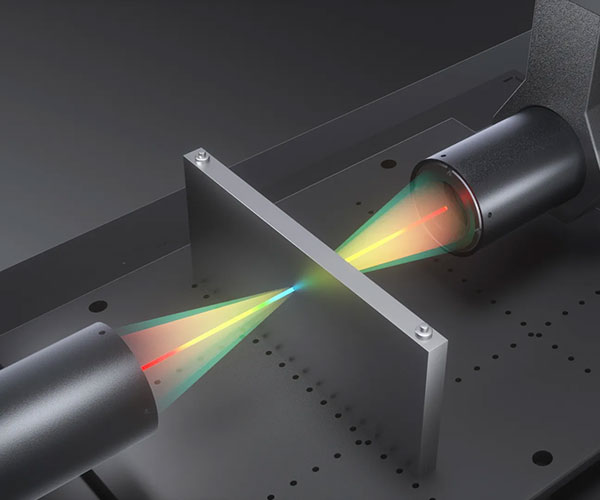

Hydrodynamics - Schlieren imaging

- Based on the principle that the refractive index gradient of light in the measured flow field is proportional to the flow density of the flow field, the change of the density gradient in the flow field is transformed into the change of the opposite light intensity on the recording plane, so that the region with drastic density changes such as shock wave and compression wave in the compressible flow field can be observed and distinguishable. The relationship between injection velocity and morphology of different gas nozzles with different specifications was analyzed by the scheme of high-speed camera and schlieren instrument.

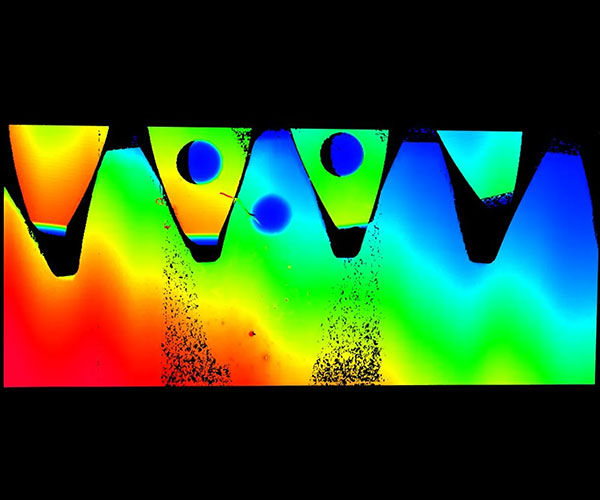

Mechanical manufacturing - Gear gap detection

- The clearance size of the gear is an important parameter, reasonable clearance will make the gear more smooth and durable, in the practical application of gear, if there is no clearance between the gears, it will lead to mutual extrusion of the gears, temperature rise and other problems, so it is necessary to detect the clearance of the gear.

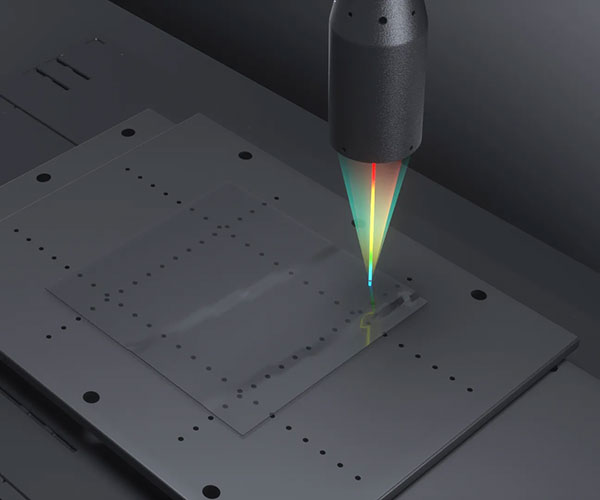

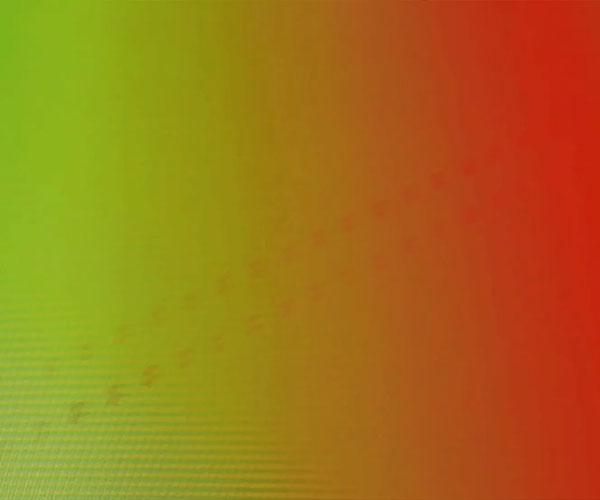

Consumer Electronics - Measurement of glass substrate thickness, flatness and warpage

- Glass substrate is a basic component of liquid crystal display device, its main thickness is 0.7mm and 0.5mm, the thickness size control is very strict, it is necessary to accurately measure the thickness of the glass, warping and parallelism. Using deep view intelligent spectral confocal sensor SC series, the height and thickness of the glass substrate can be collected in one measurement.

Photovoltaic - Silicon wafer separation testing

- As the carrier of solar cell, the quality of silicon wafer directly determines the conversion efficiency of the cell. At present, in the process of cutting silicon rods into silicon wafers by the front-end process of silicon wafers, the cutting process will cause surface dirt, thickness, size and hidden cracks and other defects of silicon wafers. Therefore, after cleaning silicon wafers, it is necessary to detect the separation quality of silicon wafers and separate them with different qualities. Using 3D vision to carry out online detection of thickness and other sizes, it can improve product qualification rate, improve production efficiency, reduce production cost, and avoid defective silicon wafers entering solar photovoltaic modules.

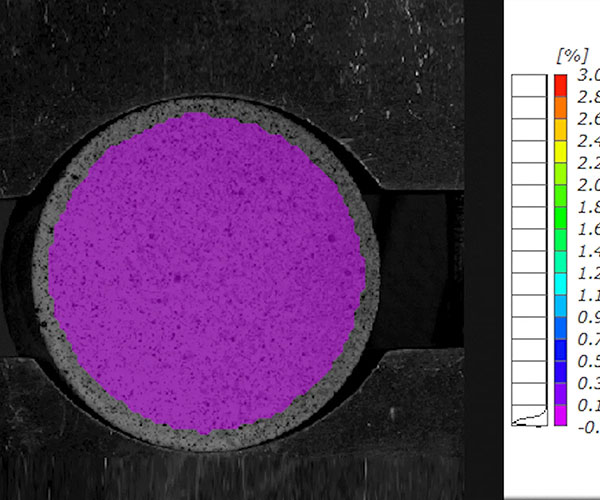

Mechanics of materials - Binocular DIC measurement of concrete cracks

- DIC (digital image correlation) can directly measure the mechanical behavior of rock mass surface, and detect the failure form, failure location, area and development trend of rock mass under external force by measuring the displacement and strain characteristics of rock and soil surface. It provides a reliable scientific research tool for material and structure safety assessment of engineering construction, and is widely used in rock and soil triaxial compression test. Geotechnical splitting test, slope vibration test, 3D printed concrete material and structure test, recycled concrete structure test, construction engineering material test and other fields. The DIC technology is used to analyze the full field deformation of rocks, local such as the deformation of rocks, and the evolution process of shear zones.

Lithium - Cell thickness measurement

- After the cell is produced and tested, it is necessary to measure the thickness of the tested cell and control the quality and quality products. Deep view intelligent spectral confocal sensor SC series is used to measure the thickness of the cell.

Automobile - Windshield impact test

- Glass fracture trace refers to the crack shape and crack distribution formed by glass fracture under the action of load. To study the characteristics of broken glass marks, the main purpose is to analyze the distribution of crack morphology, determine the load and failure mode. The splashing and cracking of glass is an extremely fast process, so it needs the assistance of high-speed cameras to shoot and study. In this case, the iron ball is lowered at the speed of free fall at a height of 40 meters to simulate the scene when the human body hits the car at a speed of 100 kilometers per hour, so as to observe the glass breaking process, the direction and speed of the splashing and crack extension of glass slag.

Bionics - Motion trajectory analysis of medical mechanical action

- Minimally invasive ocular medical devices use cutting-edge technologies to provide convenient, scientific and efficient solutions for visual function and visual skill assessment, visual diagnosis, visual intervention and corrective treatment, so that smart technology can truly benefit public eye health. Through the front end of the medical instrument, a medical ball with a diameter of 2-3mm is popped out at a speed of 0.3-0.9m/s, and the ball hits the eyeball with a certain force to achieve visual diagnosis, visual intervention and corrective treatment. Due to the fast movement of the ball, high-speed cameras are needed to observe the process, and then diagnose the ball when it pops out to the eyeball. The speed and displacement of the ball must be controlled to ensure and diagnose the safe trajectory of the ball.