- Offer Profile

- INTERNATIONAL MARKET LEADER

IN THE FIELD OF MACHINE SAFETYThe Schmersal Group is one of the international market leaders in the field of machine safety. We are present in more than 60 countries with seven production sites on three continents as well as our own companies and sales partners.

Schmersal has special industry expertise in many fields of application: These include food production, packaging technology, machine tool construction, lift technology, logistics, heavy industry and the automotive sector.

OUR INNOVATIONS

-

Ergonomic operation, more compact design, higher safety level, combination of productivity with safety and integration of functions. These are only a few of the many characteristics on which our designers lay value when they write the specifications for new products and product families in co-operation with the product managers.

Schmersal has around 18,000 different safety switches, solenoid interlocks and solenoid interlock systems in its range - and new ones are being added all the time. Here you see the results: New features from the Schmersal Group. Always up-to-date

New version of SD Gatway

-

ENHANCED PRODUCTIVITY WITH HIGH-PERFORMANCE ERROR DIAGNOSIS

A NEW VERSION OF SCHMERSAL’S SD GATEWAYSchmersal has developed a new version of the SD Gateway for its SD bus. Users will be able to take advantage of the improved fault diagnostics offered by the new SDG Fieldbus Gateway. This in turn will help to increase machine and plant productivity by minimising downtime and simplifying commissioning and maintenance. The device is also user friendly and easy to install.

AZ Safety Switches

-

COMPACT AND FLEXIBLE

NEW SAFETY SWITCH WITH ROTATING ACTUATOR HEADThe new electromechanical safety switches with separate actuator from Schmersal: the AZ215/AZ216 and AZ315/AZ316 switches are used for monitoring the guard position of hinged or sliding guards. Their outstanding feature is the rotating actuator head made of die-cast zinc, which can be easily rotated in 90° steps prior to installation. This allows the head to be approached from the side in four different directions, as well as from above. With this versatile approach position and the ability to combine with different actuators, the AZ Series offers maximum installation flexibility and a range of universal applications for the user. The designer can use the AZ switch for both right and left hand designs on both hinged and sliding guard doors.

Safety Fieldbox SFB

-

NEW VERSIONS OF THE SAFETY FIELDBOX FROM SCHMERSAL FOR ADDITIONAL FIELDBUS SYSTEMS

Schmersal has developed two new versions of its Safety Fieldbox. This means that the box can not only be integrated into systems with PROFINET/PROFIsafe as before, but is now also be available for the EtherNet/IP with CIP Safety and EtherCAT with FSoE bus systems.

The benefit: the designer can now plan the safety functions of a machine in a project regardless of the fieldbus system that is used, as the three versions together cover the most commonly used control systems worldwide.

Safety light curtains/grids in Ex design

-

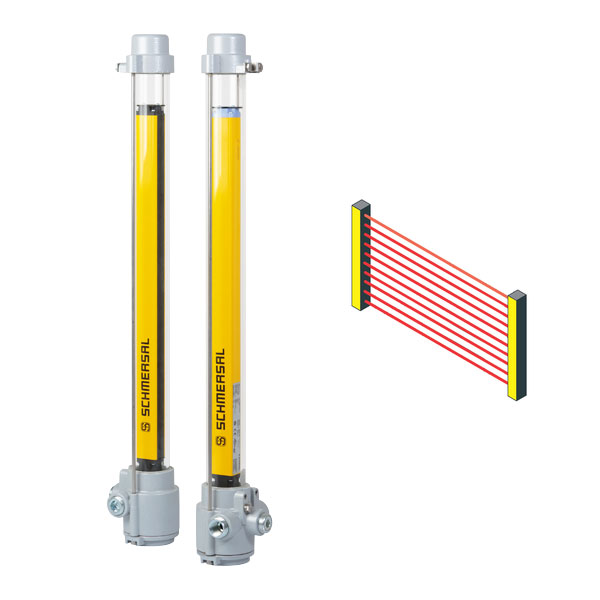

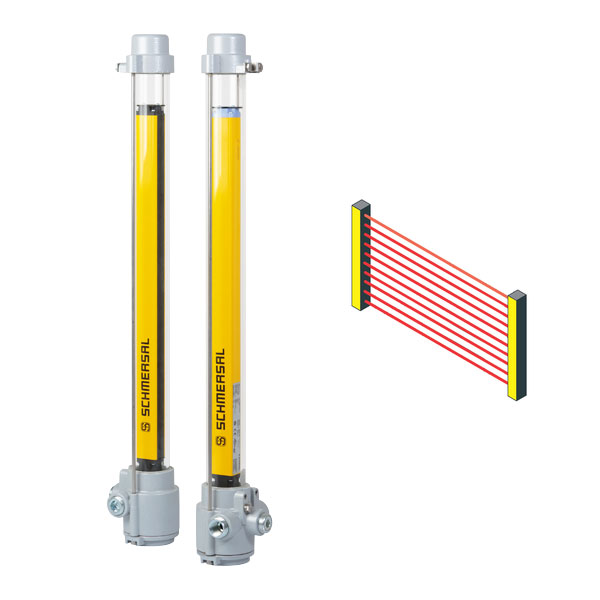

EX-SLC/SLG440

NEW SAFETY LIGHT CURTAINS/GRIDS IN EX DESIGNSCHMERSAL PRESENTS NEW SAFETY LIGHT CURTAINS/GRIDS IN EX DESIGN

The Schmersal Group has expanded its range of optoelectronic protective devices with a series of safety light curtains/grids in Ex design. The new EX-SLC/SLG440 series is designed in the ignition protection types EX d (gas atmospheres), EX t (dust atmospheres) and EX op is (optical radiation) and is thus especially suitable for access protection of potentially explosive areas in industrial production - namely for zones 1 and 21.

New ToF camera for automation technology

-

AM-T100

NEW TOF CAMERA FOR AUTOMATION TECHNOLOGY

MILLIMETRE-PRECISE 3D DEPTH IMAGES FOR PROCESS OPTIMISATION IN LOGISTICS AND PRODUCTIONThe Schmersal Group presents for the first time a 3D camera for the automated acquisition of digital process data in real time:The AM-T100 is a Time-of-Flight camera (ToF), which uses a Sony DepthSense™ sensor to create 3D depth images with millimetre accuracy. The camera uses ToF technology, i.e., runtime measurement of emitted light pulses in the infrared range (850 Nm), which are reflected off the objects being captured. This enables high-speed creation of a 3D image of the scene with millimetre accuracy that is available as a point cloud.

Command device H series

-

NEW COMMAND DEVICE SERIES

IN THE FOCUS OF DEVELOPMENT: HYGIENE, ERGONOMICS AND SAFETY

FOR FOOD-PROCESSINGThe H series from Schmersal will be showcased – Smart Production Solutions – as a full range of new command and signalling devices for hygiene-sensitive applications, particularly food processing.

Characteristic features of the range of command and signalling devices are gap-free transitions between sealing elements and surfaces and an absence of protruding parts. The command elements are easy to clean and so well sealed that they can withstand regular cleaning with high-pressure cleaners and aggressive cleaning agents.

Sensor Box SSB-R

-

SSB-R NEW MAGNET TRACK SENSOR BOX

PRECISE – LOW-COST – MAINTENANCE-FREEThe Schmersal Group is showcasing a new magnet track sensor box, designed to detect the position of electric monorail conveyors in the automotive industry and intralogistics.

Wear-free solenoid switches from Schmersal have long been used in the automotive industry. They are used to monitor the speed and position of moving machine parts, such as those on electric monorail conveyors used to transport bodies, engines, doors and other supplied parts to different assembly workstations in automobile plants. The new SSB-R magnet track sensor box now carries out these functions with significantly improved precision.

Pull-wire switches TQ215/TQ315 and ZQ215/ZQ315

-

TQ215/TQ315 PULL-WIRE SWITCHES AND THE ZQ215/ZQ315 PULL-WIRE EMERGENCY STOP SWITCHES

SMALL SWITCHES FOR HEAVY-DUTY APPLICATIONS

The new space-saving range of pull-wire switches from Schmersal is suitable for applications in cramped installation spaces. The dimensions of these compact switches are based on the standards for position switches – EN 50047 and EN 50041. The small pull-wire switches also have a robust metal enclosure, wide temperature range and the high protection class IP67, which makes them suitable for outdoor use and use in challenging environmental conditions, such as in the mining industry, heavy industry and raw materials processing.

The TQ215/TQ315 pull-wire switches can be used as signal transmitters, for applications such as starting machinery and plants. The switching command can be triggered at any point along the wire, with wire lengths of up to 25 m available.

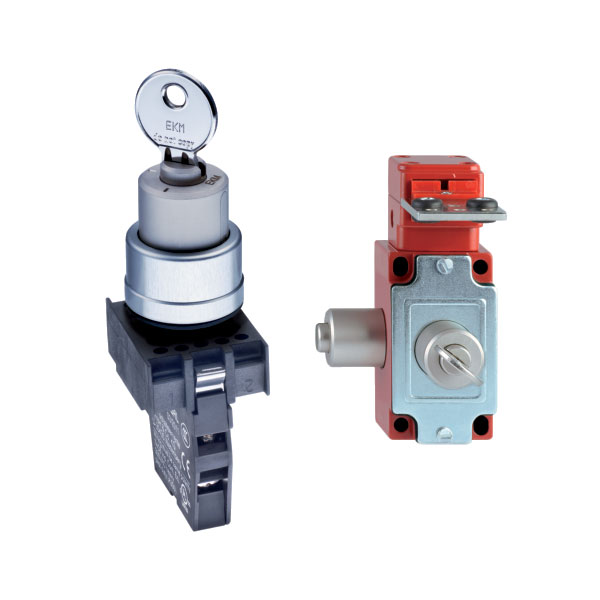

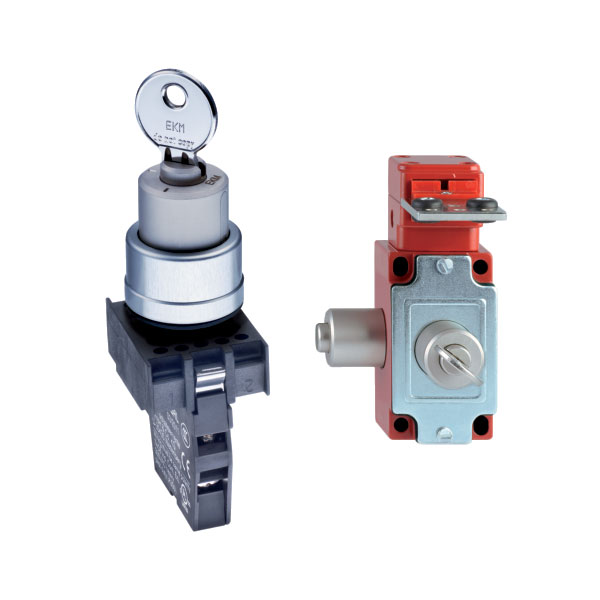

SAFETY SWITCH WITH SEPERATE ACTUATOR

- In the "Safe Switching and Monitoring" section, you will find an extraordinary large programme of safety-related switchgears for the position monitoring of guard doors and the non-contact protection of hazardous zones and danger points, as well as safety switching appliances for special applications.

Safety switch with actuator

Solenoid interlocks

Position switch

Safety switch for hinged guards

Safety sensors

Pull-wire emergency stop switches

Emergency-Stop button

Control panels

Safety light barriers

Safety light curtains, Safety light grids

Two-hand control panels

Enabling device

Safety-related tactile sensor

Foot switch

Key transfer system

AUTOMATION TECHNOLOGY

- In the Automation technology section, you will find switching appliances for mechanical position detection in various fields of application as well as (safety) sensors with different operating principles; this section also includes a comprehensive programme of command and signalling devices.

Cameras

Command and signalling devices

Foot switch

Inductive proximity switch

Position switch

Rotating spindle limit switch

Slack-wire switch

Belt alignment switch

Gear-switches

Micro switches

Photo-electric proximity switches

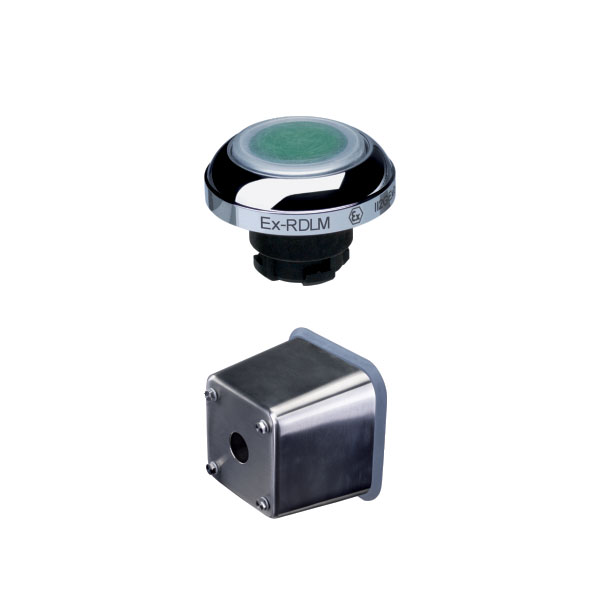

DEVICES FOR EX ZONES

- In the Ex switchgear section, you will find switchgear which can be used - in accordance with the harmonised standards - in areas with potentially explosive atmospheres due to the presence of gas and dust, e.g. position switches, safety switches and safety sensors with non-contact operating principle..

Many of the devices for Ex zones are suitable for use in safety-related applications in accordance with ISO 13489-1.

Safety switch with separate actuator

Solenoid interlock

Magnetic reed switch

Safety sensors

Safety light curtains, Safety light grids

Key transfer system

Position switches with safety function

Pull-wire emergency stop switches

Safety-monitoring module

Safety switch for hinged guards

Command and signalling devices

Belt alignment switch

Slack-wire switch

Position switch

SAFE SIGNAL PROCESSING

- In the Safe signal processing section, you can find safety relay modules and safety controllers for various safety technology applications (e.g. for emergency stop and guard door monitoring) as well as centralised programmable safety controllers and decentralised field bus systems, e.g. a modular concept for safety function control on small machines.

Safety-monitoring modules

Input expanders

Output extensions

Standstill monitors and time relays

Safety controllers

SYSTEM SOLUTIONS

- System solutions from Schmersal for functional safety can be individually adapted, offer easy and fail-safe installation and minimise the effort needed for wiring.

The Safety Fieldbox in 3 variants PROFINET with PROFIsafe, EtherNet/IP with CIP Safety and EtherCAT with FSoE, enables a high degree of flexibility as a simple plug&play solution: all common types of safety switchgear can be connected.

Schmersal offers a wide range of safety switches with integrated AS-Interface Safety at Work interface, which can be easily networked with each other via this safety bus system. The AS-i system is very flexible, because the configuration can be easily changed even on existing machines.

The SD bus (SD = serial diagnostics) offers cost-efficient safety solutions. The SD interface allows mixed systems of sensors and interlocks. The diagnostics data from series-connected safety switchgear are transmitted to a higher-level field bus system. The SD interface system helps to implement predictive maintenance concepts.

Safety-Fieldboxes

- The Safety Fieldbox is suitable for simple plug and play installation of up to eight safety switchgear devices. All common types of safety switchgear can be connected via the 8-pole M12 device connector: switches, sensors, interlocks, light grids and also control panels. This solution is also suitable for larger machines and plants, because up to 10 safety field boxes with up to 80 safety switchgear can be easily connected in series.

AS interface safety at work

- Application:

Easy, safe and reliable

AS-Interface Safety at Work (SaW) is the first safety bus system based upon the open standard of AS-International. Safety components such as emergency stops, safety switches, solenoid interlocks or safety light curtains are simply interconnected through the AS-Interface profile cable. For the evaluation of the safety-related signals, only a safety monitor is required.

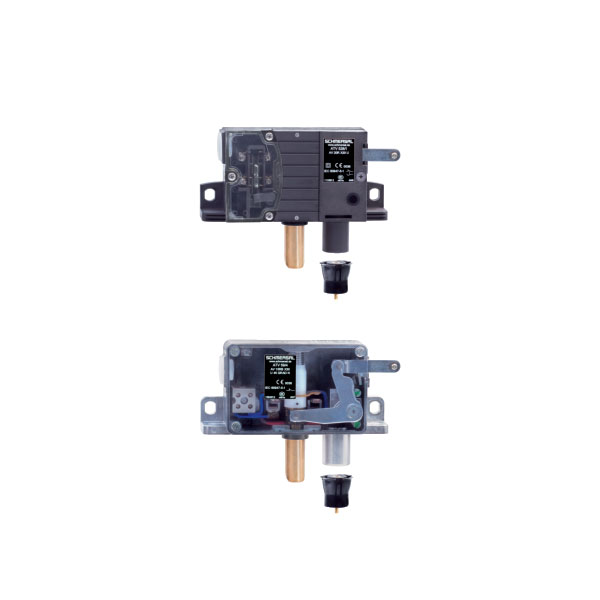

Serial diagnostics

- The serial diagnostics field includes safety switchgear, system components and installation accessories for safety interlocks, safety sensors and operating panels with SD interface.The SD interface allows comprehensive diagnostic data (switch states such as 'door open/closed' or error messages such as 'actuator in limit area' or 'excess temperature') from series connected safety switchgear to be transmitted to superior machine control systems. The data is transmitted via an SD gateway with industrial fieldbus protocols (PROFIBUS, CANopen, PROFINET IO, EtherNet IP, Modbus/TCP, EtherCAT). The SD interface also allows safety interlocks to be locked and unlocked individually, as well as configured. As such, the latching force of the MZM100-SD electromagnetic solenoid interlock can be set by SD interface.

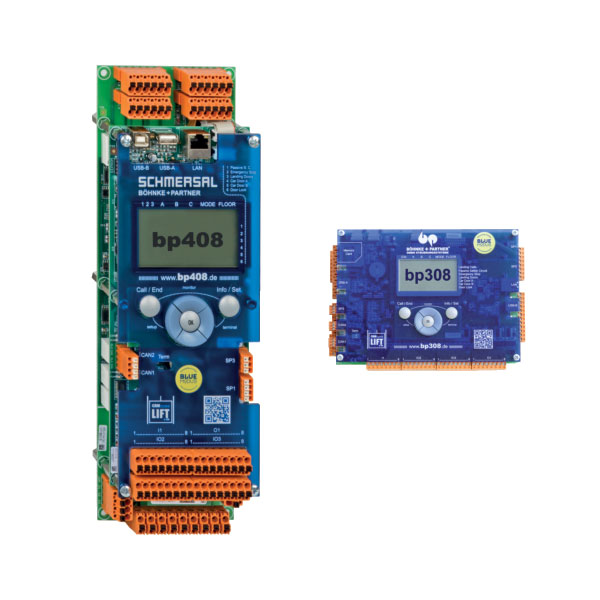

LIFT SWITCHGEAR

- In the Lift switchgear section, you will find lift switchgear for various applications in the shaft pit, the lift car and the machine room: floor and fine-adjustment switches, positive-break door contacts, position switches, magnetic reed switches, remote alarm systems as well as the USP ultrasonic elevator positioning system.

Control systems

Door locking devices

Positive-operation door contacts

Magnetic reed switch

Position switches with safety function

Pull-wire switches

Emergency call system for lifts

Top of car inspection (TOCI)

Inductive proximity switch

INDUSTRIES AND MARKETS

-

Our expertise is based on decades of experience in the field of machine safety. We know that each industry has different environmental and functional safety requirements.

Schmersal’s combined know-how is available to our customers at any time through our industry, product and sales management as well as our global network of qualified safety consultants.

No matter in which industry or on which continent you are working: We can contribute to optimising process efficiency and safety in your company.

AIRPORTS

-

In air transportation, safety is paramount, not only high above the ground but also on the ground. For example, a large number of baggage handling systems are in operation in airport terminals – important elements of sophisticated logistics to transport millions of suitcases quickly and reliably to and from the right aircraft.

Schmersal offers a broad portfolio for airports, consisting of automation components and safety solutions for airport logistics. These include, for example, our robust command and signalling devices, position monitoring and non-contact protective devices that ensure the safety of passengers and operating personnel at the conveyor belts.

ELEVATORS

- Around 6 million elevator systems are in operation in Europe alone. And the market continues to grow: Increasing urbanisation and an aging population are trends that continue to drive growth. Not only is the technology becoming more and more sophisticated, but the demands on the safety of elevator systems are also increasing.

AUTOMOTIVE

- Processes in automotive production are highly automated, and on the way to Industry 4.0, the automotive industry is taking a pioneering role compared to other industries. Long production lines with increasingly complex robotic systems, networked, highly efficient manufacturing, and flexible processes that enable individual customer requirements to be met are characteristic of everyday production in the automotive industry. Where so many people work closely with robots and automated tools, the demands on the functional safety of machines and plants are particularly high.

FOOD AND BEVERAGES

-

For the food industry, Schmersal offers a broad product portfolio of safety switchgear and control systems that meet the requirements of “hygienic design” and are certified according to industry specifications (e.g. Ecolab, EHEDG, FDA). Products designed specifically for this area meet humidity, moisture, detergent and temperature resistance requirements.

Many safety switches in the range specially developed for the food industry are made of stainless steel – a material that is particularly well suited to the industry due to its hygienic properties and robustness.

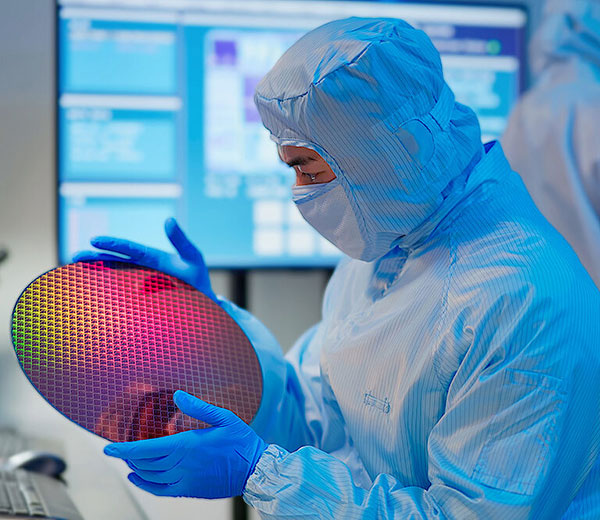

SEMICONDUCTOR INDUSTRY

- The semiconductor industry is a booming growth market with rapidly increasing demand. Whether laptops, tablets or smartphones – almost nothing works without microchips. But the classic industrial sectors of mechanical engineering and automotive also rely on semiconductors. Due to the rapid demand, high equipment availability is essential in the semiconductor industry. However, the industry also places the highest demands on safety, quality and cleanliness.

HEAVY INDUSTRY

-

Schmersal offers safety systems and solutions worldwide for all stages of the process chain of raw materials – from raw material extraction to raw material handling and processing.

Conveyor systems are at the heart of the continuous and safe transport of raw materials throughout the entire process.

WOOD INDUSTRY

-

Occupational safety has a high priority in the wood industry because machines with a high risk of injury are used in this sector, such as sawing machines.

Characteristic of the industry is that many machining processes are used outdoors and often harsh environmental conditions – e.g., flying wood chips, splinters, and sawdust – pose a challenge. Schmersal has therefore developed an outdoor-suitableportfolio of robust and explosion-proof safety components and systems especially for the wood industry.

INTRALOGISTICS

- Extensive automated plants, numerous and different safety switchgear: these are typical characteristics of intralogistics plants. Schmersal offers a broad portfolio of industry-specific safety components and systems for warehousing and material flow, as well as a diverse range of products for industrial trucks.

MECHANICAL ENGINEERING

-

Functional safety in mechanical engineering means, on the one hand, ensuring the protection of one’s own employees, and on the other hand, minimising the hazards that could emanate from the machines produced.

For mechanical engineering, Schmersal not only offers the world’s largest portfolio of safety components, but also more than 75 years of experience in the complex field of machine safety.

PACKAGES

- High speed, short cycle frequencies, 24/7 operation, integration into interlinked plants: machines and plants for the packaging industry operate under these conditions. Schmersal has developed a broad, industry-specific portfolio of safety components and safety systems especially for this area of application.

PHARMACY

- High demands on product safety and the reproducibility of production processes are the main challenges of the pharmaceutical industry. Typical applications include mixing, granulating, freeze-drying, coating, sterilising, filling, closing, sealing, cleaning and packaging. Personal and process protection as well as hygiene have top priority in this industry.

PLASTICS AND RUBBER

-

The plastics processing industry is an industry with a high level of innovation and is considered a pioneer in many areas of automation technology. Digitalisation and Industry 4.0 are the focus in the ongoing optimization of processes.

Machines used in the plastics industry operate at high production speeds and must be absolutely flexible. That is why plastics machines are increasingly modular in design.

REGENERATIVE ENERGIES

-

Renewable energies are becoming increasingly important in the context of the desired energy turnaround. Wind turbines and photovoltaics in particular are seen as a climate-friendly alternative to fossil fuels.

Low downtimes and efficiency despite permanently harsh weather conditions are top priorities for photovoltaic and wind power plants. At the same time, safety must be guaranteed at all times, both during operation and during maintenance and repair work.

TIRE INDUSTRY

- High degrees of automation and flexibility characterise the manufacturing processes of the tire industry. Production must be highly flexible because trends such as e-mobility and ever new vehicle types require an increasing number of tire variants. In addition, tire production is characterised by harsh environmental conditions, such as high temperatures and a high level of contamination.

ROBOTICS AND SYSTEM INTEGRATION

-

The Schmersal Group offers a comprehensive range of products and services for safeguarding industrial robots – from simple safety components to programmable safety controllers. We develop demand-oriented system solutions for robot manufacturers as well as application-specific special solutions.

For access and area guarding, we have various system solutions in our programme that are suitable for different robot systems, such as: non-contact and tactile protective devices, safety sensors, fieldbus systems and safety logics.

TEXTILE MACHINERY

- In the textile industry, the efficiency of production plants is a top priority. Progressive automation of production and logistics processes is coming more and more into focus. In a highly competitive environment, the goal is to further increase efficiency and productivity in the textile industry. Schmersal offers the textile industry a broad portfolio of safety components and safety systems specifically tailored to these applications. At the same time, the industry demands predictive maintenance solutions for higher plant availability. The corresponding requirements are met by Schmersal’s intelligent safety sensors based on condition monitoring.

MACHINE TOOLS

-

Schmersal offers the machine tool industry a broad product portfolio developed precisely for industry-specific requirements.

Productivity is an important factor in assessing the competitiveness of a machine tool. Schmersal products support in the machine tool sector the productivity of machines and reduce downtimes and stoppages.