- Offer Profile

-

From factory automation to logistics automation – sensor solutions from SICK are keeping industry moving. As a technology and market leader, SICK provides sensor intelligence and application solutions that create the perfect basis for controlling processes securely and efficiently, protecting individuals from accidents, and preventing damage to the environment.

SICK is one of the world’s leading solutions providers for sensor-based applications in the industrial sector. Founded in 1946 by Dr.-Ing. e. h. Erwin Sick, the company with headquarters in Waldkirch im Breisgau near Freiburg ranks among the technological market leaders.

New Products

deTem

-

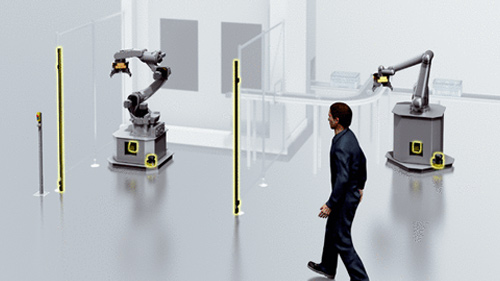

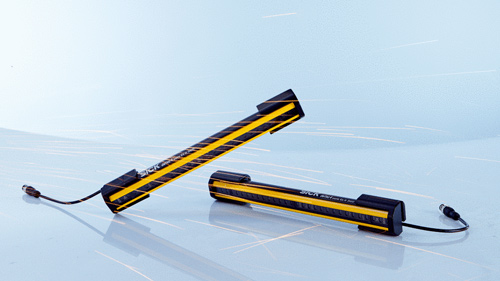

Efficient access protection

The deTem safety light-beam sensor offers high flexibility and efficiency in access protection and human-material differentiation in automated material flows. Useful functions of the safety light-beam sensor simplify and speed up the alignment process, thereby saving time during installation. The NFC and IO-Link interfaces form the digital basis for error and cause analysis. This can be carried out both on site and remotely. SICK also provides scalable function packages: from Core variants to flexibly configurable muting. Choose what best suits your requirements and move into the future with confidence.

Features:

- Large scanning range: up to 90 m in a compact housing

- Integrated alignment aids: Status LEDs and alignment laser with a visibility of 90 m

- Remote and on-site diagnosis via IO-Link and NFC

- Flexible 2- and 4-signal muting

- Core variants for cost-efficient protection

- Standardized connection, operating and accessories concept

SIG300

-

Universal IO-Link Master with IIoT competence and logic editor

The SIG300 Sensor Integration Gateway is a high-performance IO-Link Master with eight ports (class A/B) that consolidates the data from the connected devices and forwards them to the higher level system. The gateway provides up to 16 A, which is sufficient power for energy-intensive sensors and actuators. With variants for PROFINET, EtherNet/IP and EtherCAT as well as a REST API version, the SIG300 can be integrated into almost any system environment. Thanks to the programmable logic editor, simpler tasks can be executed autonomously and remotely. This shortens the response times for automated processes. Furthermore, the integrated web server allows fast, intuitive parameterization.

Features:

- 8 IO-Link input ports (Class A/B)

- Ethernet interfaces: PROFINET, EtherNet/IP and EtherCAT

- IIoT interfaces: REST API and MQTT

- Galvanically isolated pins for the power supply from class B ports

- Max. 16 A in the IO-Link Master with max. 4 A per port

- Programmable logic editor

- Configuration via web server

- Enclosure rating IP6

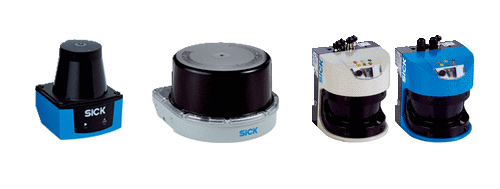

LiDAR picoScan100

-

2D LiDAR sensor – high-performance and cost-effective in compact housing

With a large scanning range, fine angular resolution and high sensitivity, the 2D picoScan100 LiDAR sensors are setting new standards as the successor to the TiM. They also reliably detect small and dark objects. The sensors deliver exact measurement data and feature integrated further processing of data that is transmitted through various communication interfaces. The compact picoScan100 sensors equipped with multi-echo technology have a rugged housing and ensure reliable measurement results even under harsh ambient conditions. They solve demanding industrial applications in indoor and outdoor areas. The picoScan120 and picoScan150 variants (Core, Prime, Pro) come with different features to suit individual requirements.

Features:

- Compact, rugged housing

- Scanning range: 75 m (90% remission); angular resolution: 0.5° to 0.05°

- Dynamic Sensing Profiles

- High measurement accuracy – measurement noise, scan field flatness and angular accuracy

- Scan rate: 15 Hz to 50 Hz

- Multi-echo technology

- Drivers: ROS, C++ and Python

- Integrated applications like contour localization on the picoScan150-LOC

Visionary AI-Assist

-

Intelligent collision avoidance and area surveillance with rugged 3D vision

The Visionary AI-Assist is a reliable assistance system, for example for the operators of mobile machines. The solution is characterized by the combination of a 3D camera for distance determination and AI-based person detection and can be used for collision avoidance: If people or objects are in the defined hazardous area, the sensor triggers warning messages. The data processing for this takes place on the device. The Visionary AI-Assist can also be retrofitted, and is easy to install and quickly integrated. The individually adjustable warning fields ensure smooth operation and efficient workflows. Visionary AI-Assist is also suitable for stationary area monitoring and navigation support on automated machines.

Features:

- AI-based detection of people

- 3D object detection using 3D data

- Switchable field of view size: 130° x 105° or 90° x 60°

- Protocols: SAE J1939, Rest-API, RTSP

- Interfaces: Digital I/Os, CAN and Ethernet

- Color image with RTSP stream

- All-in-one solution

- Rugged, shock and vibration resistant

OD200

-

More productivity through simple and reliable distance measurement

The compact OD200 displacement sensor delivers precise micrometer-range distance measurements—even on challenging surfaces like structured composites or shiny metals—without the need for a separate amplifier. Its compact housing, wide measuring range, and intelligent signal processing make it ideal for tight spaces and tough environments. Designed for flexibility across various applications, the OD200 is easy to integrate and configure thanks to its plug-and-play setup and smart factory settings, making it a powerful, stand-alone solution for boosting productivity.

Features:

- Repeatability: 2 µm ... 20 µm

- Linearity: ± 10 µm ... 100 µm

- Measuring frequency: up to 3 kHz

- Intuitive configuration via OLED display, IO-Link and SOPAS ET

- Measuring ranges from 25 mm to 160 mm

- Laser class 1

- Analogue and digital output with IO-Link interface

- Robust miniature housing

Lector83x

-

1D and 2D code identification using a camera for large fields of view and medium reading distances

The Lector83x camera-based code reader offers high reading performance at medium reading distances and is easy to integrate into industrial networks. The compact camera has a resolution of 3 or 5 megapixels, a large depth of field, and a wide field of view. In addition to very high computing power and the dual-port fieldbus as well as other connections, the compact design ensures fewer devices and installation effort at reading stations.

Using AI-based segmentation, the camera also identifies damaged codes at conveyor speeds of up to 2.5 m/s and correctly assigns them to objects. The Lector83x can be intuitively configured using a web server and is ready for use within a few minutes – even without specialist knowledge.

Features:

- AI-based segmentation, superresolution, multi-core CPU

- Large depth of field, wide field of view

- Resolution of 3 or 5 megapixels, various lenses and illumination colors

- Intuitive, application-based configuration via web server

- Three-dimensional assignment of codes to objects

- Dual-port fieldbus and DIOs

Detection Sensors

W10

-

Photoelectric sensors - Easy to install. Easy to operate. The one photoelectric proximity sensor for all applications.

The W10 photoelectric proximity sensor’s ease of use, sturdy design and performance make it ideal for precise object detection in demanding environments. The touchscreen display is intuitive to use, allowing parameters to be set quickly. Situation-dependent teach-ins allow convenient sensor adaptation to individual applications. The fact that various MultiMode functions and configurations, such as foreground and background suppression, are combined in a single sensor allows success in a wide range of applications.

UFW

Fork sensors - Easy and reliable web edge detection

The UFW fork sensor from SICK makes non-contact web edge guiding possible. Thanks to ultrasonic technology, the UFW detects a multitude of materials with great precision and is therefore ideally suited for applications with transparent films or light-sensitive materials. The compact housing designs (30 mm and 60 mm fork width) allow space-saving installation. Calibration is simple to perform using a teach-in button. Three LEDs indicate at a glance the position of the web material within the fork. Furthermore, the IO-Link communication interface opens up numerous possibilities for fine adjustment, analyses and monitoring.

IMX

-

Inductive proximity sensors - Inductive sensors with a quadruple sensing range for large distances in industrial environments

Significantly greater distances: IMX offers four times the sensing range of conventional sensors, setting a new standard for inductive proximity sensors. Sensing ranges of up to 50 mm ensure a higher process performance - making IMX ideal for applications that were previously inconceivable with inductive sensors. In space-critical applications, IMX sensors save installation space by using smaller designs. At the same time, the greater distance reduces mechanical damage. The rugged, durable design ensures less downtimes, stable processes and high plant availability.

MZCS

-

Cylinder Sensors - Very short cylinder sensors for economical use in C-slot cylinders

The MZCS magnetic cylinder sensor is an economical solution for precise end position detection on pneumatic cylinders. Two variants are available: the PNP/NPN and the DC 2-conductor version. Setup is particularly easy thanks to plug and play, so the sensor is ready to use in no time. The compact housing is ideal for C-slots, e.g., in SMC actuators. With a length of just 15 mm, the MZCS is one of the shortest sensors on the market and can therefore be used for position detection in compact actuators. Its sturdy design enables reliable operation even in demanding environments. It is a good choice for applications in the automotive industry, machine builders, the materials industry, and the consumer goods and electronics sectors.

GLL70

-

Fiber-Optic Sensors - Powerful and versatile fiber optic amplifier

The fiber optic amplifiers from SICK are suitable for the flexible integration of fiber-optic cables in confined spaces. The intuitive OLED display supports four languages and provides a flexible and user-friendly means of parameterization. The high transmitting power and the continuous threshold adaptation ensure a long-term reliable detection with minimal maintenance requirements. With its response time of 50 µs, the GLL70 offers a high detection range (depending on fiber-optic cable) and a diverse portfolio of high precision and adaptable fiber-optic cables. With a choice of NPN or PNP digital output within a single device, the range of variants and the storage costs can be reduced.

AS30

-

Array Sensors - More flexibility and efficient communication

The AS30 array sensor operates on the proximity scanning principle. It detects even the slightest differences in grayscale values within the field-of-view. Positioning of, for example, a paper web based on the web edge or a contrast line is only one of many possible applications. Widths, diameters, and gaps can also be detected. In reflector mode, the AS30 can even detect transparent materials.

Multi Physics Box

-

Condition Monitoring Sensors - Condition Monitoring sensors for vibration, shock, and temperature monitoring

The Multi Physics Box Condition Monitoring sensor allows for continuous condition-based monitoring of, for example, motors, pumps, conveyor systems or fans. It measures vibrations, shocks, and temperature, thereby providing indications of potential faults and machine failures. If the measured values exceed the individually configurable thresholds, an alert is output. For vibration values, the vibration monitoring thresholds for machines according to ISO 10816-3 can be implemented via a multi-stage alert. The sensor can be integrated into the machine or system via IO-Link or a simple alarm-based switching signal. Whether on-site or in conjunction with a Cloud Service: The Multi Physics Box creates a data foundation that can be used to avoid unplanned downtime and effectively lower costs.

MLG-2

-

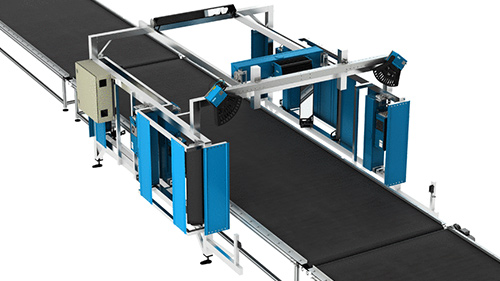

Fork sensors - Powerful light grid for demanding object measurement tasks

MLG-2 measuring automation light grids from SICK solve numerous applications in the logistics, packaging and automotive industries. The devices precisely determine the length, width and height of objects. Thanks to the modular sensor design and the broad product portfolio, the light grids are suitable for many different applications. For example, MLG-2 devices detect small cracks in battery foils and transparent materials or they measure material layers with the material teach function. Using industrial interfaces such as IO-Link, PROFINET, EtherCAT® or EtherNet/IP™, the beam data from the automation light grids can be transmitted to programmable logic controllers, which evaluate the data individually. The MLG-2 product also fulfills cybersecurity requirements.

CQ

-

Capacitive ProximitySensors - Reliable capacitive proximity sensors enclosed in a rectangular housing

Capacitive proximity sensors can detect all types of material: powder-based, granulated, liquid, and solid – even through plastic walls. SICK’s capacitive proximity sensors also feature high electromagnetic compatibility (EMC), which prevents incorrect switching.

CQ sensors feature rectangular housings that are suitable for all manner of installation conditions.

Distance Sensors

Dx100

-

Laser Distance Sensors - Reliable, fast, precise positioning

The Dx100 family combines leading edge technology with innovative design. The product’s phase-shift measurement technology ensures the highest performance, which, in co-operation with drives manufacturers, has been optimized for perfect integration into closed control loops. Our innovative 3-axis bracket, the smallest housing in its sensor class, as well as the intelligent quick lock system with fast connectors, offers optimized handling and reduced costs of ownership.

Dx50

-

Laser Distance Sensors - Measuring distances – reliable, precise and versatile

The Dx50 is a common distance sensor platform, offering multiple performance levels. With measurement ranges of up to 10 m or 20 m on objects or even up to 50 m when measuring on reflector, the Dx50 is suitable for many different applications. Based on a switching, analog or serial interface being available the Dx50 can easily be integrated in any application environment. Also the intuitive operating concept and a visible red laser allow a fast installation of the sensors. Thanks to the innovative HDDM technology the Dx50 provides excellent reliability, immunity to ambient light and precision when being in use. Offering an extremely good price/performance ratio the Dx50 is the right solution in many cases.

OL1

-

Laser Distance Sensors - Exact line guidance throughout the whole spectrum

The OL1 optical micrometer stands out due to its miniature design and is small enough to fit in the tiniest machine spaces. Thanks to the LED alignment aid and a function for aligning the light band integrated into the AOD1 evaluation unit, installing and aligning the sender and receiver unit is child’s play. In particular, the OL1 sensor shows its strengths with the high-precision edge guiding function, for instance with the repeatable guidance of electrode material in battery production or the double layer detection of thin wafers. Due to the high performance reserve, the OL1 determines the edge position of semi-transparent materials exactly or reliably moves thin textile threads or wires back on the right track.

UC30

-

Ultrasonic Distance Sensors - Rugged. Reliable. Rectangular.

The sensors of the UC30 product family impress with excellent performance in a compact cubic housing. Due to color-independent detection, high contamination tolerance and outstanding background suppression, UC30 sensors deliver stable measurement results even under challenging conditions. Various output signals with sensing ranges of up to 8,000 mm as well as high measurement accuracy due to the integrated temperature compensation leave no applications unsolved. Teach-in buttons and IO-Link also extend the diagnostic and configuration options of these ultrasonic sensors.

UM18

-

Ultrasonic Distance Sensors - Simple set up, perfect detection

The UM18 sensor product family provides simplicity and high functionality. The UM18 ultrasonic sensors are available in straight and angled versions for easy machine integration. A metal or plastic housing allows use in demanding ambient conditions. Due to four sensing ranges up to a total of 1,300 mm and LED status feedback, the sensors are suitable for a broad range of applications. Whether analog or PNP/NPN switching output, one or two push-pull switching outputs with IO-Link or the combination of analog and push-pull switching output with IO-Link, sensors of the UM18 product family leave nothing to be desired.

OD Precision

-

Laser Distance Sensors - Measuring each dimension with high precision

The OD Precision is a high accuracy, optical measuring system for measuring difficult object surfaces. In addition to glossy and dark black surfaces, it can also measure transparent and semi-transparent materials. The OD Precision is the only displacement measurement sensor that can connect three sensors to one controller, which reduces the amount of hardware required and makes it easier to measure the x-, y- and z-axes., e.g. for measuring the evenness of surfaces. In order to reduce investment costs, the sensor can also be operated via RS-422, thus eliminating the need for a controller unit.

Safety

deTem

-

Safety light-beam sensors - Efficient access protection

The deTem safety light-beam sensor offers high flexibility and efficiency in access protection and human-material differentiation in automated material flows. Useful functions of the safety light-beam sensor simplify and speed up the alignment process, thereby saving time during installation. The NFC and IO-Link interfaces form the digital basis for error and cause analysis. This can be carried out both on site and remotely. SICK also provides scalable function packages: from Core variants to flexibly configurable muting. Choose what best suits your requirements and move into the future with confidence.

multiScan100-S

-

Safety Laser Scanners - 3D LiDAR sensor with PL b for safe environmental perception in mobile outdoor applications

multiScan100-S is a 3D LiDAR sensor with performance level b according to ISO 13849 that has been specially designed for outdoor use. With its large three-dimensional field of view, the sensor solves complex automation tasks in a wide range of dynamic applications. The precise, safe measurement data forms the basis for numerous individual safety functions. The integrated 3D protective field evaluation makes it possible to avoid collisions between mobile machines and people or objects. The function can be easily integrated into safety controllers with the help of digital outputs. Thanks to its rugged housing, intelligent filter algorithms and safe multi-echo technology, the multiScan100-S offers high reliability even in challenging ambient conditions.

flexLock

-

Safety Switches - RFID-monitored safety locking device with 180° actuation radius

The flexLock safety locking device with RFID monitoring is characterized by an infinitely variable actuation radius of 180°. It thus offers a high level of flexibility for the safety locking function of doors and flaps – even with small door radii. The clearly visible LEDs show the device status continuously at all viewing angles. The open locking head and the rounded housing of the flexLock allow for easy cleaning. In addition, the high offset tolerance ensures easy mounting and high system availability, even when the door is lowered. Variants for personal or process protection are well suited for use in a wide range of applications up to PL e. The optional escape release allows the locking device to be unlocked from the hazardous area.

safeRS/safeRS3

-

Safety Radar Sensors - Safe radar systems for hazardous area protection in harsh environments

The safeRS and safeRS3 safe radar systems are electro-sensitive 3D protective devices for safe personal detection with very high machine productivity. They protect applications in accordance with PL d or SIL 2 in line with ISO 13849-1 and IEC 62061. A radar system consists of an evaluation unit and up to 6 sensors which enable switchover to a protected mode as soon as a person enters the protected area. The high resistance to dirt, dust clouds, wood chips, plastic particles and sparks as well as the insensitivity to ambient light such as solar radiation or infrared waves enables reliable operation, even under the toughest ambient conditions. The radar systems stand out due to their rugged sensor housing and quick and easy commissioning.am sensor simplify and speed up the alignment process, thereby saving time during installation. The NFC and IO-Link interfaces form the digital basis for error and cause analysis. This can be carried out both on site and remotely. SICK also provides scalable function packages: from Core variants to flexibly configurable muting. Choose what best suits your requirements and move into the future with confidence.

nanoScan3

-

Safety Laser Scanners - The smallest safety laser scanner from SICK – extremely rugged and highly precise

The nanoScan3 is the smallest safety laser scanner from SICK. It is well suited for the protection and localization of mobile platforms. Thanks to the reliable safeHDDM® scanning technology, it delivers high-precision measurement data and is extremely resistant to light, dust or dirt. The easy operation of the Safety Designer configuration software and the clever integration options of the nanoScan3 ensure flexibility in applications and also save time. The nanoScan3 therefore offers a high level of performance and availability in a compact housing, thereby securing system productivity.

L26

-

Safety Light-beam Sensors - Flexible machine safeguarding for type 2 applications

The L25 and L26 product families from SICK represent a new generation of single-beam photoelectric safety switch for type 2 applications, which, in combination with an external test device, facilitate operations and make processes safer and more efficient. Thanks to the innovative BluePilot operating concept with feedback LED, the alignment of sender and receiver is easier than ever. Smart Sensor diagnostic functions provide insight into the status of each individual sensor at all times, thus creating the basis for efficient communication. Thanks to the ultra rugged VISTAL® housing and predictive maintenance, the L25 and L26 are extremely reliable and prevent unscheduled machine downtime.

LiDAR and Radar Sensors

TiM

-

LiDAR Sensor - Compact 2D LiDAR sensor – cost-effective and high performing

The RMS2000 radar sensor detects objects very reliably, even under especially harsh ambient and weather conditions, e.g., in strong rain or snowfall, thick fog, or high dust loads. Detection fields can be flexibly configured in the working range of the sensor. This enables the RMS2000 to simultaneously and very accurately detect distances, angles and speeds of objects. Depending on the parameterization of the device, detections classified as relevant can be signaled via the digital outputs, or measurement data transmitted via the Ethernet interface for further use.

multiScan100

-

LiDAR Sensor - Compact 3D LiDAR sensor with high detection reliability under harsh ambient conditions

The multiScan100 3D LiDAR sensor generates a large 3D point cloud in which people and objects can be detected. The point cloud makes the multiScan100 suitable for wide-area environment perception and therefore also for large machines. The sensor can be used for mobile and stationary applications and reliably detects drop-off edges and obstacles ahead. The multiScan100 can be individually configured and easily integrated into applications. High-resolution scan layers or large scanning ranges, among other things, can be selected during configuration. In addition to the device, there is a continuously growing modular software kit with apps and software add-ons. A system plug for common interfaces ensures quick and flexible sensor implementation.

RMS2000

-

Radar sensors - 2D radar sensor for reliable object detection in especially harsh weather conditions

The RMS2000 radar sensor detects objects very reliably, even under especially harsh ambient and weather conditions, e.g., in strong rain or snowfall, thick fog, or high dust loads. Detection fields can be flexibly configured in the working range of the sensor. This enables the RMS2000 to simultaneously and very accurately detect distances, angles and speeds of objects. Depending on the parameterization of the device, detections classified as relevant can be signaled via the digital outputs, or measurement data transmitted via the Ethernet interface for further use.

LMS5xx

-

LiDAR Sensor - High-performance 2D LiDAR sensor for accurate detection of far away objects

The LMS5xx 2D LiDAR sensor is the successor of the successful LMS2xx family. With numerous innovative functions, the LMS5xx increases the productivity of existing applications and opens up entirely new application possibilities. The new, ultra-fast multi-echo technology makes laser measurement applications less sensitive to weather conditions and increases the reliability of captured data. Reduced power consumption as well as intelligent self-monitoring functions ensures extraordinarily low total cost of ownership. With the two Lite and PRO variants, the right version is available for every application. The LMS5xx boasts the best price-performance ratio on the market in this sensor class.

MRS6000

-

LiDAR Sensor - 3D LiDAR sensor with multilayer technology and large vertical aperture angle

The MRS6000 3D LiDAR sensor uses a high scanning point density and an aperture angle of 120° to reliably detect its environment across 24 layers. Special mirror technology ensures high scanning field stability. With the aid of multi-echo technology, the sensor scans through rain, dust, and fog, while simultaneously multiplying the point density. These properties are particularly useful for creating a 3D point cloud without any gaps, which can be used to tackle a whole host of demanding applications.

LMS4000

-

LiDAR Sensor - Very fast 2D LiDAR sensor for precise and demanding measuring tasks

The LMS4000 2D LiDAR sensor is particularly well-suited for use in intralogistics, material handling and in all areas in which goods must be quickly and systematically analyzed and moved. SICK offers the ideal solution for measuring, evaluating and processing objects in terms of position, shape, volume or surface quality. Regardless of the object position in containers, cartons or on pallets, or whether they are free-standing or touching one another, the LMS4000 measures precisely with high sampling density and a wide dynamic range. When used in conjunction with SICK Nova, the measurement data is immediately evaluated and aggregated into a turnkey application solution. A high throughput with comprehensive process reliability and low maintenance needs is the result.

Machine Vision and Identification

InspectorP62x

-

Machine Vision - All-in-one vision sensor with electric focus and rugged housing

The InspectorP62x is an industrial all-in-one vision sensor that is easy to use, compact and versatile. The integrated system of teach auto focus optics and flexible illumination provides high-quality images right out of the box. The included and pre-installed Quality Inspection toolset of SICK Nova welcomes both expert and non-expert users to configure the sensor in no time using an accessible and intuitive web user interface. As it is based on SICK AppSpace, the InspectorP62x allows for further extension or replacement of functionality through a growing collection of SICK Nova Tools or SensorApps from SICK AppPool, or through custom development if needed.

CLV50x

-

Fixed Mount Barcode Scanners - 1D code identification using a compact scanner for standard applications

SICK’s miniature line of barcode scanners are barely larger than a USB plug and can easily be installed where space is extremely limited. The CLV50x series is also easy to configure via its online tool and configuration barcodes. These mini barcode scanners boast excellent decoding performance, with a large depth of field that allows for flexibility in your application. This ultra-compact series is ideal for applications in the OEM and machine builder marketplace, such as packaging systems, circuit board processing, clinical analyzers, robotic inspection, etc. The CLV503 is ideal for slow moving applications – with a scanning frequency of 100 Hz. The CLV505 offers a high scanning frequency of 1,000 Hz and is suitable for conveyor speeds of up to 5 m/s, depending on the application.

Ranger 3

-

Machine Vision - Superior 3D performance in a small package powered by ROCC technology

Fast got faster. Highly accurate and with an unmatched measurement speed, the Ranger3 streaming cameras can be configured for a wide range of needs. Powered by our unique 3D sensor tailored for demanding vision applications, Ranger3 serves as a key component in inspection systems worldwide. The camera extracts the true 3D shape of an object, regardless of its contrast or color and as a result, improves quality for a multitude of products. The next generation Ranger3 enables even higher speed and RGB high-resolution line scan functionality. Cost-effective integration is guaranteed through GigE Vision and GenICam compliance. Ranger3 offers big 3D performance in a small housing.

RFU63x

-

RFID - UHF transponder identification using an RFID read/write device for long sensing ranges

The RFU63x is an ultra-high frequency (UHF) RFID solution for industrial environments. Via integrated application management software, the RFU63x is able to solve common industrial applications without any external "middleware" and can, therefore, be used as a stand-alone solution. This is possible due to an integrated filter and data management system. With 4Dpro compatibility, the RFU63x is easy and cost-efficient to integrate in common industrial environments. Different options for parameter cloning between systems (e.g., integrated microSD memory card feature) reduce maintenance time. The integrated feedback LED can be used to read diagnostic or process feedback.The InspectorP62x is an industrial all-in-one vision sensor that is easy to use, compact and versatile. The integrated system of teach auto focus optics and flexible illumination provides high-quality images right out of the box. The included and pre-installed Quality Inspection toolset of SICK Nova welcomes both expert and non-expert users to configure the sensor in no time using an accessible and intuitive web user interface. As it is based on SICK AppSpace, the InspectorP62x allows for further extension or replacement of functionality through a growing collection of SICK Nova Tools or SensorApps from SICK AppPool, or through custom development if needed.

Ruler3000

-

Machine Vision- The fast way to high-performance 3D

Highly accurate with an unmatched measurement speed, the new generation Ruler3000 3D cameras will be the number one choice for machine vision system integrators and industrial applications. Being powered by the unique 3D CMOS sensor from SICK tailored for superior image processing, their measurement results are very reliable. The factory-calibrated sensor extracts the true 3D shape of an object, regardless of its contrast or color. The numerous versions of Ruler3000 offer a solution for a wide range of challenges and can deliver accurate measurement values down to 0.8 µm in height with a resolution of 3200 data points per profile. Thanks to the guaranteed field-of-view concept, commissioning is easy. GigE Vision and GenICam compliance ensures cost-effective integration.

HW19

-

Mobile Handheld Scanners - Mobile 1D and 2D code identification for read ranges up to 16 m

The HW19 mobile handheld scanners detect a large number of codes, including 1D, 2D and Digimarc codes. Variants with a read range up to 16 m allow a convenient scanning of codes from far away, even from a manned forklift truck. No more time-consuming getting on and off required for the driver. The rugged housing with an enclosure rating of IP65 or IP67 enables the mobile handheld scanners to withstand adverse ambient conditions. The cable and wireless variants deliver flexibility and mobility. Connection modules for integration into industrial fieldbuses such as PROFIBUS or Ethernet TCP/IP are available from SICK. The HW19 scanners with their powerful reading performance even under demanding working conditions ensure high throughputs and productivity.

Motion Control Sensors

MWS075

-

Measuring Wheel Encoders - Compact measuring wheel encoder with high flexibility and easy installation

The MWS075 measuring wheel encoder from SICK precisely measures dynamic linear surface movements using direct contact. It is customizable and supports all available encoder interfaces and measuring wheel interfaces, thereby allowing it to be seamlessly integrated into the application environment. The intelligent design combines compactness with flexibility and measurement accuracy. A manually adjustable contact pressure ensures precise and repeatable measurements of speed and position. The rugged spring arm has a spring travel of ± 5 mm and a maximum contact pressure of 15 N. The patented spring travel limiter protects the MWS075 from overload. The measuring wheel encoder enables accurate measurement results, system longevity, and reliability in a variety of industrial sectors.

ANS/ANM58

-

Absolute Encoders - High-resolution absolute encoder with PROFINET interface and IRT function

The ANS/ANM58 is a powerful 58 mm absolute encoder. The numerous shaft and flange types as well as axial and radial connections make it suitable for integration into many different applications. Thanks to the combination of a precise optical singleturn measuring system and mechanical multiturn, the ANS/ANM58 provides reliable data for movement monitoring and process control. Thanks to the PROFINET interface with Encoder Profile version 4.2, processes can be executed synchronously via the IRT (Isochronous Real Time) function, which increases productivity. The encoder also provides a lot of diagnostic data for condition-based system maintenance. With an installation depth of just 39 mm for the radial type, the ANS/ANM58 is ideal for tight installation situations.

OLM

-

Linear Encoders - Linear encoders with fieldbus interfaces for precise positioning

OLM linear encoders from SICK ensure precise positioning on travel paths of up to 10 km. The encoders combine high traversing speeds with fieldbus interfaces, setting a benchmark in positioning via bar code strip. The position data with a measurement accuracy of 0.15 mm and the exact speed values enable reliable plant operation. The OLM linear encoders also have an integrated LED illumination unit. And thanks to the non-moving parts, the devices offer a long service life, even under demanding ambient conditions.

TMS/TMM61

-

Inertial Sensor - Precise inclination measurement in a compact design

The TMS61 one-dimensional inclination sensor and the TMM61 two-dimensional inclination sensor are setting new standards with respect to size, flexibility, and performance. In their small, rugged plastic housings, the sensors offer excellent resolution and accuracy – what's more, this is achieved over the entire measuring range and in an extremely wide range of ambient conditions. The CANopen interface enables a whole host of device parameters to be adapted, allowing the sensor to be perfectly tailored to the application. The new PGT-12-Pro handheld programming tool from SICK makes configuration much easier. As a result, the user is ready to go in just a few clicks and can cut out the time-consuming task of configuring the sensor via the control system.

SCon

-

Motor Feedback System - Interface converter for converting HIPERFACE® into HIPERFACE DSL® signals

The sCon®, which is compatible with the SES/SEM70, SES/SEM90 and STS motor feedback systems from SICK, converts HIPERFACE® signals into HIPERFACE DSL® signals. The compact design of the interface converter makes it easier to integrate into the motor installation space. It also has an external temperature input for measuring the winding temperature.

STS

-

Motor Feedback System - Motor feedback system with HIPERFACE® and different internal diameters

The STS motor feedback systems with magnetic principle of operation offer high performance for precision hollow shaft motors and direct drives. The absolute, non-contact and bearingless measuring system is suitable for different hollow shaft diameters thanks to its scalability. The communication via HIPERFACE® is compatible with the leading frequency inverters and supports the operator with automated commissioning of the application.

Process Sensors

LXRH

-

Level Sensor - Radar sensor for hygienic applications – precise, reliable and user-friendly

The LXRH free-space level sensor enables continuous level measurement of liquids and bulk materials in hygiene applications. The sensor performs non-contact measurement. Thanks to the hygienic design, the adapters, and a special sealing concept, the sensor meets the stringent requirements of the FDA and EHEDG. High precision and a scanning range of 15 m with no dead zone make the sensor ideal for storage tanks, process vessels as well as mixing, filling and dosing systems in the food and pharmaceutical industries. The non-contact measurement principle also simplifies installation. No calibration is required. Parameterization is possible via IO-Link and via WPAN and app even using mobile devices. The 360-degree status LED and color coding make it possible to read the operational status of the sensor even at a large distance.

TBS

-

Temperature Sensor -Temperature monitoring made easy

The TBS temperature switch is easy to use and has a rugged design. It is designed for temperature measurement and monitoring of operating liquids, such as hydraulic oils, coolant lubricants and cleaning liquids in machine building and manufacturing. With up to two binary outputs and one analog output, it can be used in many applications. A large, well legible display and three pushbuttons facilitate setup. The intuitive menu navigation and display use familiar and standardized features and programming. The switching state of the binary outputs is displayed by highly visible LEDs. During installation, the TBS is uniquely flexible due to its two rotation locations. It is possible to rotate the display and the process connection independently of the sensor body, ensuring both clean cable layout and that the display is facing the user. Temperature measurement is done using a Pt1000 element that is located in the tip of the stainless steel probe.

PBS plus

-

Pressure Sensor - Multifunctional pressure switch with display, IO-Link and switchable analog output

The PBS plus is an electronic pressure switch, pressure transmitter and display in one and is available with up to two switching outputs, analog output and IO-Link. It is set using three large pushbuttons and the display or via IO-Link. The housing can be twisted in two places - the display and the electrical connection can be optimally aligned in any mounting situation. With measuring ranges of 0.4 bar to 1,000 bar (gauge pressure), the PBS plus can be used in many different applications. It also has absolute pressure and vacuum measuring ranges. The PBS plus is highly resistant to corrosion due to the fully-welded stainless steel membrane. Process data is transmitted to the control via IO-Link as measured values in bar. The diagnostic options make it possible for temperature values to be read out in °C and minimum and maximum values for temperature and pressure to be monitored.

T-Easic FTS

-

Level Sensors - Clever dry-run protection in pumps

The T-Easic® FTS thermal flow sensor measures flow and temperature of liquids in accordance with the calorimetric principle. Available as an industrial variant with VISTAL® housing and display or as a hygienic stainless-steel variant, the T-Easic® FTS is suitable for a wide range of applications. Depending on the requirements, the sensor features two digital outputs for limit value monitoring, a pulse output for volume recording or an analog output for continuous recording of measured values. A special feature is integrated empty pipe detection for optimal dry-run protection in pumps. Parameterization can be done via IO-Link or the display. Media taught-in at the factory such as oil and water accelerate commissioning; other liquids can be calibrated quickly and easily.

LBV3xx

-

Level Sensors - Vibrating level switch for reliable level detection in bulk materials – maintenance-free, ATEX-approved and suitable for use with foodstuffs.

The vibrating level switches in the LBV3xx product series reliably perform tasks as full, empty or demand detectors in bulk materials. A piezoelectric drive causes the rugged sensors with vibrating fork or vibrating rod to vibrate. As soon as bulk material covers the vibrating rod or fork, the vibration amplitude changes. The sensors reliably detect this change and convert it into a switching signal. The products can also be used in the food industry. While the LBV31x compact device is suitable for lateral mounting, the LBV33x tube-extended sensor with sensing ranges of up to 6 m is used for vertical mounting. With a wide range of process connections and several electronic variants, LBV3xx offers a solution for numerous applications, even in explosive atmospheres.

Pressure sensors - PFT-2

-

Flow Sensors - Non-contact flow measurement

The non-contact FFU ultrasonic flowmeter detects the flow volume of conductive and non-conductive liquids. Swimming against the current requires more strength than with the current – this is the simple fact on which ultrasonic flow measurement according to the phase difference process is based. Its compact design enables the device to be used in a wide range of applications, including those with limited space. This sensor with an enclosure rating of IP67 features a seal-free sensor design with high-quality polysulfone (Ultrason S), which not only makes it possible to use the device in harsh ambient conditions, but also ensures high process reliability. The large cleartext display also helps provide simple, fast, and hassle-free commissioning.

Flow Measurement

FLOWSIC600

-

Flow Meters

This product and the corresponding services are now supplied by Endress+Hauser.

FLOWSIC100 Process

-

Flow Measurement Instrument

This product and the corresponding services are now supplied by Endress+Hauser.

FLOWSIC200

-

Flow Measurement Instrument

This product and the corresponding services are now supplied by Endress+Hauser.

FLOWSKID

-

Flow Metering System

This product and the corresponding services are now supplied by Endress+Hauser.

FLOWSIC100 Flare-XT

-

Flow Measurement Instrument

This product and the corresponding services are now supplied by Endress+Hauser.

FLOWSIC550

-

Flow Meters

This product and the corresponding services are now supplied by Endress+Hauser.

Network and Connection Technology

GM700

-

Gas Analyzers

This product and the corresponding services are now supplied by Endress+Hauser.

MARSIC300

-

Gas Analyzers

This product and the corresponding services are now supplied by Endress+Hauser.

Shelter Solutions

-

Gas Analyzers

This product and the corresponding services are now supplied by Endress+Hauser.

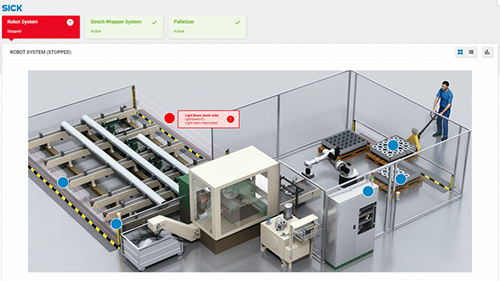

Systems

Triton Floor-LOC

-

Localization System- Reliable localization of mobile robots using the texture of the floor

Triton Floor-LOC is an industry-proven localization system for mobile robots in logistics and production. Its image-based technology uses the micro-structures of the floor to continuously determine the position of the vehicle. The localization is based on natural floor features and provides accuracy in the sub-millimeter range, even in highly dynamic environments. Moreover, it does not require any infrastructure. The system continuously self-learns, allowing it to operate with gradual changes to the floor surface. In addition to stand-alone use, Triton Floor-LOC can be used with a LiDAR-based localization solution such as LiDAR-LOC.

Sorter Inspection System

-

Quality Control System - Continuous monitoring for optimized maintenance and early defect detection

The Sorter Inspection System records measured values that can indicate irregularities and possible defects in sorting systems such as tilt-tray or cross-belt sorters. This optimizes maintenance work and reduces both consequential damage and downtime – ensuring a high level of availability and reliability of the sorting systems.

The values recorded using 3D measurement technology (laser triangulation) allow direct or indirect conclusions to be drawn about the condition of the sorter elements. Typical criteria include the position of the individual trolleys in relation to the measuring system, the diameter of rollers, the flatness and position of mechanical parts (e.g. tilting mechanism) and even the presence of individual trolley components.

Coriva System

-

Localization System - omlox-certified localization, tracking, and management of assets

The Coriva System is a real-time localization system (RTLS) for industrial applications based on ultra-wideband. It determines the exact position of assets such as vehicles, workpieces, materials, etc. in real time. The recorded position data is used for seamless tracking and tracing of assets, thereby enabling continuous monitoring of goods movements and material flows. The system consists of mobile UWB tags (CorivaTag) that are located, and a permanently installed infrastructure (CorivaSat) in the location area. The software (CorivaEngine) calculates the positions of the mobile devices. The recorded position data can be forwarded to an omlox hub via standardized interfaces. The Coriva System is omlox-compliant and thus supports the world's first open standard for industrial localization systems.

Digital Services and Software

Location Management

-

Insight Tools - Material Flow Digitalization: Localize seamlessly with standardized data

Location Management lays the foundation for transparent and efficient material flow by tracking and tracing assets in real time. CorivaHub is a core software solution for location management that transforms location data into standardized, globally consistent geographic coordinates. Based on the omlox hub standard, location data is sourced from various providers and locating technologies such as UWB, WLAN, GNSS, WPAN and RFID. By collecting these position updates and identifying data, the software can digitally visualize the assets. The seamless OT/IT integration allows for real-time data exchange, even to external systems, and provides comprehensive monitoring.

AI-SICK Stream Software

-

Engineering Tools - Take control of your 3D streaming data

To easily handle streaming high-quality 3D data, the SICK Stream software solutions enable parameterization, processing, and rapid integration into your own software ecosystem.

The Stream Setup configuration software comes included with the Ranger3 and Ruler3000 3D cameras and provides quick and easy configuration, collection, optimization and evaluation with the user-friendly evaluation tools for e.g., noise reduction and false data removal. With the Stream SDK (software Development Kit), rapid camera integration is enabled by supportive C#/C++ APIs into your PC application.

AI-Assist

-

Application Software - Software for intelligent collision avoidance and area monitoring

AI-Assist is a software solution that processes sensor data to create a reliable assistance system. The software solution processes 3D data and 2D images supplied by a sensor. Based on the 3D data, objects can be recognized and the distance to the objects calculated. The 2D data is also used for AI-based recognition of people. This enables people to be distinguished from objects, which is why the solution is particularly suitable for avoiding collisions. If there are people or objects in the previously defined hazardous area, the system emits a signal.

AI-Assist can be combined with the Visionary-B Two stereo camera. The camera processes the data directly on the device, so no additional computing unit is required.

Service

Installation and Commissioning

-

Engineering and Integration - Ready to go in just a few steps: smooth installation and commissioning by the OEM

Qualified technicians take care of the assembly, mounting and wiring of the sensors as well as the application-specific configuration and fine adjustment. SICK thereby enables high availability and efficiency from day one. Whether supported remotely or by qualified specialists on site, customers benefit from planning certainty, time and cost savings, and a documented final acceptance.

Repairs

-

Technical Support - Repairing instead of buying new: economical and sustainable

Repairing defective devices saves money, conserves resources and reduces waste. SICK supports you from local error analysis through to complete repair with final testing. The final test is carried out in the same way as for a new device and ensures that the repaired product is fully functional again. You also receive targeted assistance in avoiding further failures. Repairs are often possible even after the official end of service, provided the necessary spare parts and test equipment are available. This extends the life cycle of your SICK product, reduces the total cost of your investment, and conserves resources.

Software and Firmware Maintenance

-

Maintenance and Inspection - Safety and performance – up-to-date systems thanks to SICK

SICK purchases, tests and installs patches so your system is protected during operation. SICK's software and firmware maintenance thereby ensures that operating systems on industrial PCs and servers are always up to date. Extensive functional tests and assessment reports are an integral part of the maintenance offering in order to preventively close safety gaps, eliminate program errors, and prevent malware attacks.

Training

Product, System, and Software Trainings

-

Training and Education - Practical and up-to-date training

The user trainings from SICK impart target group-specific knowledge - for efficient and optimally adapted application of the products used. Sensors, sensor systems, software or services can be the focus of the trainings. The experts from SICK teach trainings based on practical experience and provide extensive information about a wide range of functions up to and including fault diagnosis. The makes it possible for customers to develop optimal application solutions. Trainers adapt courses flexibly based on individual needs of the participants.

Safety Competence Training

-

Training and Education - Protection for persons, machines and plants - correct and efficient

Safe plants and machines provide legal certainty for both manufacturer and user. The protection of persons, machines and plants in many countries and regions in the world is therefore regulated by laws and standards. SICK offers safety trainings for the safety of machines and plants in factory, logistics and process automation, from basic knowledge to expert qualification with final TÜV certificate. Ensuring safety with efficient technical solutions are always at center stage. The trainings are available all over the world and take into account special regional features of regulatory and standard specifications. All trainings are run by qualified experts with many years of practical experience.

Technology Training

-

Training and Education - Understanding complex topics

Choosing the right technology is often crucial to the success of a project. But only those who know the respective strengths and limitations can make well-founded decisions. Our technology training courses give you a comprehensive insight into the principles of operation, fundamentals, advantages and disadvantages of various technologies. Our experts impart application-oriented background knowledge and provide training with a technological focus. This knowledge will help you to find the right solution, avoid mistakes, reduce costs – and put your company in a good position.

Accessories

Brackets

-

Mounting Systems

Your sensors can be securely mounted using brackets from SICK. The brackets also enable precise alignment and perfect functioning of the sensors in various applications.

Mirror

-

Reflectors and Optics

Mirror columns, deflector mirrors and mirror adapters are used to deflect light in optical systems. The areas of application are diverse: mirrors enable multi-sided access protection of large hazardous areas, extend detection areas, and enable applications with limited space thanks to a more compact design.

Wire Draw Mechanism for Rope Pull Switches

-

Wire Draw Mechanism

Rope pull switches consist of a safety switch and a wire draw mechanism. The wire draw mechanism can be used to trigger an emergency stop of the system in hard-to-reach or long machine areas. The appropriate wire draw mechanism can be selected according to the application. Important accessories include pulleys, ropes and rope clamps.