microsonic

- Offer Profile

- microsonic is a globally recognised specialist in ultrasonic sensors for applications in industrial automation technology. Examples are ultrasonic dual sheet control systems that work with no calibration at all, label sensors that use special teach-in methods to be able to detect even critical labels and splices at high transport speeds, and ultrasonic proximity switches with switching frequencies of up to 250 Hz.

Product Portfolio

Distance sensors

Cylindrical

mic+ ultrasonic sensors

-

mic+ sensors are available in four device designs with five different detection ranges

Highlights- Digital display with direct measured value output in mm/cm or %

- Numeric configuration of the sensor using digital display permits complete advance configuration of the sensor

- Automatic synchronisation and multiplex operation for simultaneous operation of up to ten Sensors in close quarters

Basics- 1 or 2 switching outputs in pnp or npn variants

- Analogue output 4–20 mA and 0–10 V with automatic switching between current and voltage outputs

- Analogue output plus 1 pnp switching output

- 5 detection ranges with a measurement range of 30 mm to 8 m

- microsonic Teach-in by using button T1 and T2

- 0.025 mm to 2.4 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

mic ultrasonic sensors

-

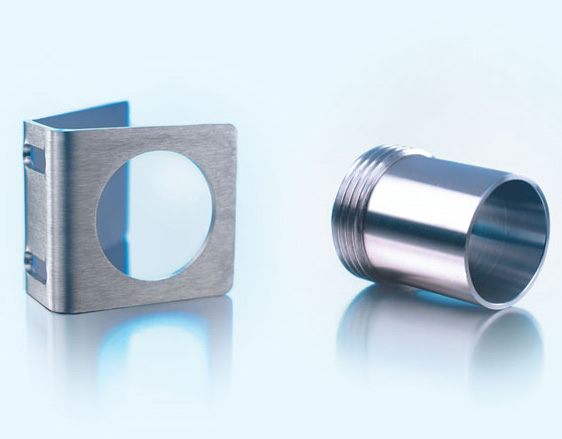

These completely metal mic sensors are available in two device designs with five different detection ranges.

Highlights- M30 housing and M12 circular connector in metal design for harsh usage conditions

- Automatic synchronisation for simultaneous operation of up to ten sensors in close quarters

Basics- 1 switching output in pnp variant

- Analogue output 4–20 mA and 0–10 V with automatic switching between current and voltage outputs

- 5 detection ranges with a measurement range of 30 mm to 8 m

- microsonic Teach-in on pin 5

- 0.18 mm to 2.4 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

wms ultrasonic sensors

-

The wms sensors are designed for use in microprocessor controllers with signal evaluation performed by the customer.

Highlights- Trigger input for control of the ultrasonic transmitter

- Echo output for customer-provided evaluation in the controller

Basics- 1 echo output with a load up to 10 mA

- 5 detection ranges with a measurement range of 30 mm to 8 m

- 0.36 mm resolution

- 9–30 V operating voltage

pico+ ultrasonic sensors

-

pico+ the "little guy" that can do it all: 4 ranges, 3 output signals, 2 housing variants and 1 IO-Link interface.

Highlights- Variant with 90° angled head

- IO-Link interface for support of the new industry standard

- Automatic synchronisation and multiplex operation for simultaneous operation of up to ten sensors in close quarters

Basics- 1 Push-Pull switching output, pnp or npn basis

- Analogue output 4–20 mA or 0–10 V

- 4 detection ranges with a measurement range of 20 mm to 1.3 m

- microsonic Teach-in on pin 5

- 0.069 mm to 0.1 mm resolution

- Temperature compensation

- 10–30 V operating voltage

- LinkControl for configuration of sensors from a PC

nano ultrasonic sensors

-

nano – what‘s in a name? At just 55 mm long, including plug, the nano is the shortest M12 ultrasonic sensor on the market.

Highlights- Ultrasonic sensor in the M12 threaded sleeve

- The total length including plug is only 55 mm

- Improved temperature compensation adjustment to working conditions within 45 seconds

Basics- 1 switching output in pnp or npn variant

- Analogue output 4–20 mA or 0–10 V

- 2 detection ranges with a measurement range of 20 mm to 350 mm

- microsonic Teach-in on pin 2

- 0.069 mm resolution

- Operating voltage 10–30 V for use with various voltage networks

Cuboidal

lcs+ ultrasonic sensors

-

The new lcs+ ultrasonic sensors come in a very compact square-shaped housing - with analogue or switching output + IO-Link.

Highlights- Very compact housing dimensions only 62.2 mm x 62.2 mm x 36.7 mm

- IO-Link interface for support of the new industry standard

- Synchronisation and multiplex mode for simultaneous operation of up to ten sensors in close quarters

- 8 m maximum detection range

- UL Listed to Canadian and US safety standards

Basics- 1 Push-Pull switching output, or 2 pnp switching outputs

- Analogue output 4–20 mA and 0–10 V with automatic switching between current and voltage outputs

- microsonic Teach-in by using button T1 and T2

- 0.18 mm to 2.4 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

lcs ultrasonic sensors

-

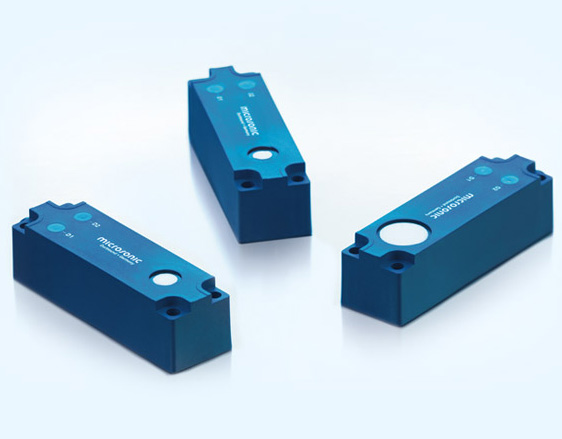

Ultrasonic sensors in the lcs series in cuboidal housing with lateral sound exit are available in three device variants with three different detection ranges.

Highlights- Up to 3 pnp switching outputs

- Automatic synchronisation for simultaneous operation of up to ten sensors in close quarters

Basics- 2 or 3 switching outputs in pnp variant

- Analogue output 4–20 mA and 0–10 V with automatic switching between current and voltage outputs

- 3 detection ranges with a measurement range of 30 mm to 2 m

- microsonic Teach-in on pin 5

- 0.18 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

sks ultrasonic sensors

-

Our "smallest sensor": The sks sensor in cuboidal housing.

Highlights- Very small housing dimensions with two M3 threaded sleeves

- Installation-compatible with many optical sensors a true alternative for critical applications

- Improved temperature compensation adjustment to working conditions within 45 seconds

Basics- 1 switching output in pnp or npn variant

- Analogue output 4-20 mA or 0-10 V

- microsonic Teach-in using a button

- 0.1 mm resolution

- 20–30 V operating voltage

ucs ultrasonic sensors

-

The ucs sensors in a sturdy metal housing are mechanically compatible with the industrial standard of opto sensors.

Highlights- Robust metal housing for harsh usage conditions

- Dovetail design for fast installation

- Mechanically compatible with the industry standard a true alternative to the optical sensor

- Automatic synchronisation for simultaneous operation of up to ten sensors in close quarters

Basics- 2 anti-valent switching outputs in pnp or npn variant

- microsonic Teach-in using a button

- 0.1 mm resolution

- Temperature compensation

- 10–30 V operating voltage

- LinkControl for configuration of sensors from a PC

zws ultrasonic sensors

-

The zws sensors are among the smallest ultrasonic sensors available on the market in cuboidal housings with Teach-in buttons.

Highlights- Ultrasonic sensor in miniature housing

- Installation-compatible with many optical sensors a true alternative for critical applications

- Up to 250 Hz switching frequency for fast sampling

- Optionally with SoundPipe waveguide attachment

- Synchronisation input

- Improved temperature compensation adjustment to working conditions within 45 seconds

Basics- 1 switching output in pnp or npn variant

- Analogue output 4–20 mA or 0–10 V

- 5 detection ranges with a measurement range of 20 mm to 1 m

- microsonic Teach-in by using a button

- 0.08 mm resolution

- 20–30 V operating voltage

Chemical-resistant

pico+TF ultrasonic filling-level sensor

-

The pico+TF sensors are ideal for the non-contact fill level measurement of chemically aggressive liquids or granules.

Highlights- Teflon membrane for protection against aggressive media

- M22 sleeve in PVDF

- IO-Link interface for support of new industry standard

- Automatic synchronisation and multiplex operation for simultaneous operation of up to ten sensors in close quarters

Basics- 1 Push-Pull switching output pnp or npn basis

- Analogue output 4–20 mA or 0–10 V

- 4 detection ranges with a measurement range of 25 mm to 1,300 mm

- microsonic Teach-in on pin 5

- 0.069 resolution

- Temperature compensation

- 10–30 V operating voltage

- LinkControl for configuration of sensors from a PC

crm+ ultrasonic sensors

-

Wear-resistant PEEK film protects the sensor membrane from chemicals, contamination and caking.

Highlights- Ultrasonic transducer protected by PEEK film for simple cleaning and high resistance to wear

- Stainless-steel housing

- Digital display with direct measured value output in mm/cm or %

- Numeric configuration of the sensor using digital display permits the complete advance configuration of the sensor

- Automatic synchronisation and multiplex operation for simultaneous operation of up to ten sensors in close quarters

Basics- 1 or 2 switching outputs in pnp variant

- Analogue output 4–20 mA and 0–10 V with automatic switching between current and voltage outputs

- 5 detection ranges with a measurement range of 30 mm to 8 m

- microsonic Teach-in using T1 or T2 buttons

- 0.025 mm to 2.4 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

hps+ ultrasonic sensors

-

hps+ in safety gear - When you need chemically resistant, pressure-resistant sensors.

Highlights- Optionally used in normal pressure or overpressure

- Teflon membrane for protection against aggressive media

- Stainless-steel or optional PVDF housing for hps+340 for use in the food industry

- Sealed against the housing with an O-ring made from FFKM for the highest possible chemical resistance

- Digital display with direct measured value output in mm/cm or %

- Numeric configuration of the sensor using digital display

Basics- 2 switching outputs in pnp variant

- Analogue output plus 1 pnp switching output

- 4 detection ranges with a measurement range of 30 mm to 8 m

- microsonic Teach-in using T1 or T2 buttons

- 0.025 mm to 2.4 mm resolution

- Temperature compensation

- 9–30 V operating voltage

- LinkControl for configuration of sensors from a PC

Hygienic Design

pms ultrasonic sensors

-

The design of the wash-down stainless steel housing with no crevices and dirt edges makes pms sensor perfectly suited to intensive cleaning and disinfection.

Highlights

- Innovative housing in Washdown Design, easy to clean, EHEDG certified

- Stainless-steel housings for use in the food and pharmaceutical industry

- PTFE membrane for protection against aggressive media

- Sealed against the housing with an O-ring made from FKM for the highest possible chemical resistance

- ECOLAB certified and FDA-compliant materials

- IO-Link interface for support of the new industry standard

Basics

- Push-Pull switching output pnp or npn basis

- Analogue output 4–20 mA or 0–10 V

- 4 detection ranges with a measurement range of 25 mm to 1,300 mm

- microsonic Teach-in on pin 5

- Temperature compensation

- 10–30 V operating voltage

- LinkControl for configuration of sensors from a PC

Special sensors

Web edge sensors

bks+ ultrasonic web edge sensors

-

The bks+ edge sensor facilitates the contact-free web edge scanning of foils, paper and other soundimpermeable materials.

Highlights- 2 housing designs with 30 and 60 mm fork width

- Available in 12 mm or 40 mm measurement range

- IO-Link interface for support of the new industry standard

- 0.01 mm to 0.02 mm resolution

- Very compact housing dimensions

Basics- Contact-free detection of the path edge for regulation of the web path

- Analogue output 4–20 mA and 0–10 V switchable between current and voltage output

- 3 LEDs and 1 button on the top of the housing

- Parameterisable with LinkControl

- Robust metal housing

bks ultrasonic edge sensors

-

The bks edge sensor facilitates the contact-free web edge scanning of foils, paper and other soundimpermeable materials.

Highlights- Compact design with only 30 mm fork width

- 0.025 mm resolution

- 0.1 mm relative accuracy

- 4 ms response time

- 8 mm working range

Basics- Contact-free detection of the path edge

- Analogue output 4–20 mA and 0–10 V

- 3 LEDs and 1 button on the top of the housing

- Parameterisable with LinkControl

- Robust metal housing for harsh usage conditions

Double sheet control

dbk+4 ultrasonic double-sheet control

-

The new ultrasonic double-sheet control dbk+4 combines multiple variants of its predecessor into a single unit, opening up entirely new possibilities for use.

Highlights- 3 control inputs for trigger, Teach-in and external sensitivity settings for the material

- Teach-in option e.g. for probing wafers stuck together by a water film

- Variant with 90° angled head for individual installation situations

- Variant with external M18 receiving transducer

- Variants with very compact transmitters and receivers in the M12 threaded sleeve

Basics- Reliable detection of single and double sheets

- No Teach-in needed (plug and play)

- Double sheet and missing sheet output

- Working distance between the transmitter and the receiver selectable from 20 to 60 mm

- Trigger option for applications in warehouse flow

- LinkControl for configuration of sensors from a PC

dbk+5 ultrasonic double sheet control

-

The dbk+5 extends the area of application of double sheet controls to heavy carton, corrugated cardboard, and plastic sheets.

Highlights- High-performance ultrasonic double-sheet control especially for the probing of corrugated cardboard as well as plastic plates several mm thick

- 3 control inputs for Teach-in, trigger, and external sensitivity settings for the material

- Teach-in option e.g. for probing plates stuck together with an oil film

- Compact design in M18 x 1 threaded tube

Basics- Reliable detection of single and double sheets

- No Teach-in needed (plug and play)

- Double-sheet and missing-sheet output

- Working distance between the transmitter and the receiver selectable from 30 to 70 mm

- Trigger option for applications in warehouse flow

- LinkControl for configuration of sensors from a PC

Label and splice sensors

esf-1 ultrasonic label and splice sensors

-

The esf-1 fork sensor can detect labels reliably even at high label speeds.

Highlights- 3 Teach-in methods for the detection of labels even outside the standard

- Response time < 300 µs: for use at high web speeds

- Housing in fork format with very compact dimensions

- Quick Teach

Basics- Label and splice sensor as a fork sensor

- 2 switching outputs for label/ splice detection and web break monitoring

- 3 LEDs and 1 button on the top of the housing

- Teach-in optionally via button or pin 5

- LinkControl as optional assistance for installation and commissioning

esp-4 label/splice sensor

-

esp-4: Label and splice sensor compact in a single unit, optionally with M12 sensor heads.

Highlights- 3 Teach-in methods to be able to configure the sensor individually for any task

- Response time < 300 µs for use at high web and label speeds

- Splice detection even for thick band materials

- Variants with very compact transmitters and receivers in the M12 threaded sleeve

Basics- Label and splice sensor in a single unit

- 2 switching outputs for label/splice detection and web break monitoring

- LinkControl as optional assistance for installation and commissioning

Accessories

Programming utilities

LCA-2

-

The LCA-2 facilitates the comfortable setting of numerous microsonic sensor series (nice to have).

Highlights- Three-digit digital display for the display of measured distance values in mm or cm

- TeachBox with four-button operation for programming of the sensor without a PC

- LinkCopy function for copying the sensor settings from one sensor to another without a PC

- Uniform microsonic teach-in for all microsonic sensors to keep easy things easy

Basics- Handy adapter for the programming of ultrasonic sensors

- USB interface for connection to a PC

- T plug to insert the adapter between the connector cable and the sensor

- LinkControl software free download of the current version on the Internet

- Backwards-compatible so sensors that have been in the field for a long time can still be programmed

- Future-proof since the LinkControl adapter will also support future generations of sensors

SyncBox

-

- SyncBox1 for the external synchronisation of mic+

- SyncBox2 for the external synchronisation of zws sensors