Navigation : EXPO21XX > AGRICULTURE 21XX >

H21: Wood Processing, Handling & Transportation

> WESTTECH

WESTTECH

Videos

Loading the player ...

- Offer Profile

- Individual customer service

is our primary factor of success. Every Woodcracker product range is

developed by the experienced Westtech team of engineers, always in close

collaboration with you – our customers. It is our goal to continuously

optimise the product range according to customer requirements and the

application areas.

Product Portfolio

Woodcracker

Woodcracker C

-

- Various installation options to conventional carrier vehicles, e.g. excavators

- Additional use of the carrier vehicle to its fullest capacity

- Low-service and low-wear due to special cutting system

- Sturdy cutting mechanism, easily replaceable blade

- Easy-to-operate due to user-friendly controls

- Multigrip-controller and autospeed system for high efficiency and economic fuel consumption

- Collection function enables expanded harvest process

- Bundled, ordered storage of the harvested material

- Clean cutting surface of hardwoods and softwoods

- Vertical removal of the tree – no damage to the trees and objects nearby.

- Soil-protective harvest due to the use of an excavator

Woodcracker CB

-

- Various installation options

- Low-service and low-wear due to special cutting system

- Light-weight

- Simultaneous harvest of several trees in one step using the collecting function saves time

- Air drying of the harvest product before chipping enhances the biomass quality

- Clean cutting surface enables the plant to spr out again

- Eco-friendly harvest maintaining soil fertility

- Cost-effective harvesting method

- Also applicable in mini-forests for easy forest maintenance

Woodcracker CL

-

- Suitable in small wood areas as well as in large-scale forests for quick thinning and forest care.

- 2.5 ton – 7.5 ton excavators or farm loaders

- In hard wood up to 19 cm Ø

- In soft wood up to 25 cm Ø

- Net weight: 210 kg

- Durable and low-wear cutting system

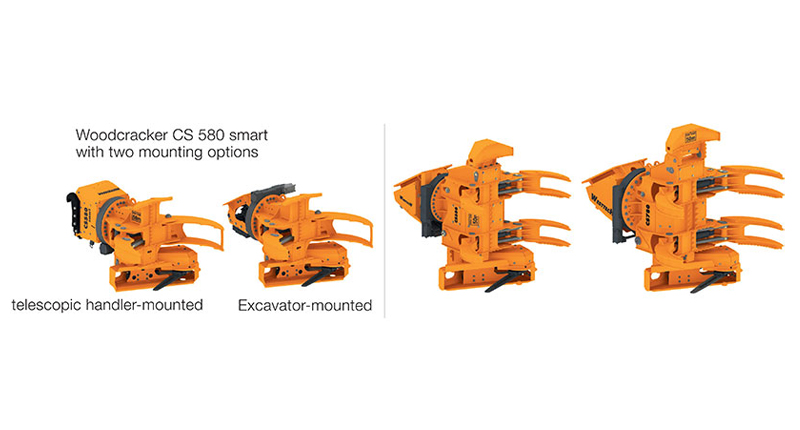

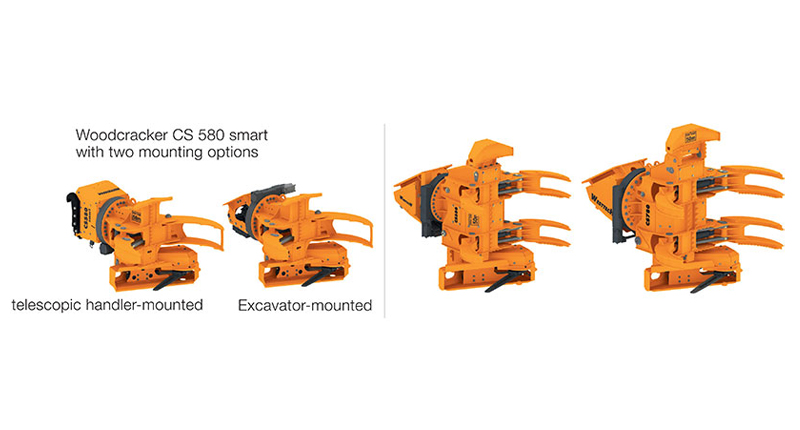

Woodcracker CS

-

- Saw unit as cutting device is oscillatingly suspended

- Tiltfunction of cutting device avoids clamping of the saw

- Two strong and independent gripper parts for a safe manipulation of the wood

- Cutting diametre up to 75cm

- Application area: felling due to safety reasons

Woodcracker L

-

- Versatile mounting possibilities to carrier vehicles mainly semi-stational on forwarders, wood cranes or chipping machines

- Optimal cost/benefit ratio

- Easy integration into existing harvest processes

- Sturdy and proven technology – low-service and low-wear

- Minimal effort, even with the thickest root trunks

- Flat design for any possible machine application

Woodcracker W

-

- Versatile mounting possibilities from the tractor to the excavator

- Sturdy, proven technology – low-service and low-wear

- Available in 5 machine sizes

- Endless turning rotator available as optional equipment

- Autospeed allows for a higher split capacity

- The rotator makes the splitting tongs flexible in application

- Patented roller system reduces the friction resistance and thereby minimises the force exerted

- The opening width does not determine the splittable diameter but only the largest end piece

- Easy supply of the pre-split material in chippers

- Pre-splitting wood allows a natural drying process and as a result an increase in biomass quality and energy yield

Woodcracker S

-

- Can be easily mounted to all conventional carrier vehicles

- Non-hazardous method compared with milling

- Root material is left flush to the ground maintaining natural growth cycles

- Securing the soil by preserving the root material

- Eco-friendly work method

- Low wear and service

- Additional biomass mobilisation through the harvest of residual trunk wood

Woodcracker R

-

- Mountable to all conventional carrier vehicles

- Removal and chipping of the root stock in one step

- Rough separation into root material and soil residue directly during the harvest

- Chipping possible directly after the harvest in the shredder

- Gentle removal of the root stock from the soil without any damage

- Sturdy cutting mechanism, low-service and low-wear

- Through additional biomass mobilisation, another source of revenue is generated for the forestry business

Woodcracker G

-

- Mountable to all conventional carrier vehicles

- Adaptation of the rake width to individual r equirements

- Large-scale clearance possible

- Gripping fingers can also be used as a gripper

- Stable, low-wear model

- Quick processing of large-sized, accumulated material due to large opening width of the gripper

Woodcracker TK

-

- Rapid change system

- Enables upright removal of trees

- Various mounting options to commercial machines

MOWBLOWER

-

- MOWBLOWER is suitable for all inaccessible grassland areas and vegetal overgrowth, e.g. between field and meadow.

- Especially in ditches or back slopes, Mowblower demonstrates its strength.

- Frequent application areas are brooksides, roadsides, paths and unploughed strips along fields.

- Environment: the blowing-out of cut grass supports the cycle of nature. The habitat of small animals is preserved.