- Offer Profile

-

Our Company. Your Partner.

We are an Austrian company that manufactures biomass energy systems for the international market. With our work we bear an economic, environmental and social responsibility for present and future generations.

Biomass plants with IQ: Listen, observe, understand

The many years of practical experience of plant operators in the daily interaction with energy from biomass is a constant element of KOHLBACH's continued development. We also carry out regular test runs for our customers and then immediately incorporate the results into the system concept. A KOHLBACH plant is always "state of the art", which is why we put our name on it.

Combustion systems

-

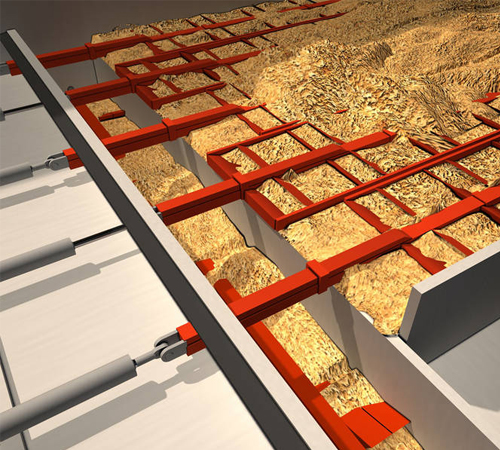

The combustion systems are individually adapted to the fuel and provide an optimal combustion of the biomass material.

We have the suitable furnace solution for the biomass fuel of the customer: sawdust, bark, wood chips, landscaping residues, nawaro wood, very wet or dry fuels with very high ash content, rough and inhomogeneous fuels or fine fuels, admixture of selected agrarian fuels — your solution is our combustion systems.

Your benefits by KOHLBACH:- Exemplary high efficiency and lowest emissions

- Reliable nominal power with all usable fuels and degrees of water content

- Reliable long operating life of combustion chamber

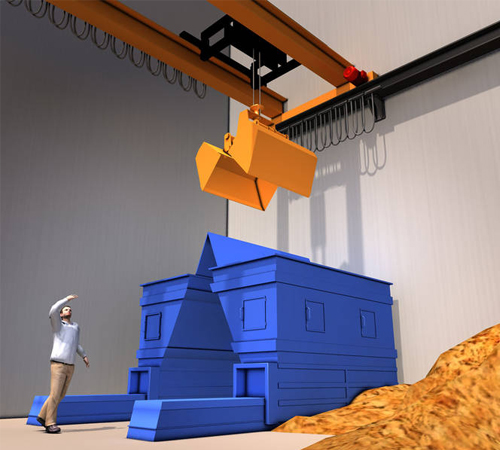

- Rapid and simple installation thanks to pre-assembled modules

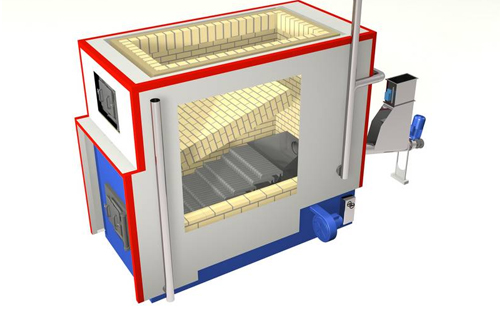

System K8

-

Furnace thermal output: 550 - 10.260 kW

Compact and yet adiabatic counter-flow furnace for optimised efficiency and lowest emissions even with very heterogeneous fuel material. Equipped with hydraulic moving grate, also suitable for very wet and dirty fuels with high ash content, as well as for 100% wet bark. Hydraulic fuel feed with shearing devices for fault-free feeding even with wet and rough fuel materials. Reliable nominal power with all usable fuels and degrees of water content.

Fuel

- Water content (% weight): 20 to 60 depending on configuration

- Size (nominal length mm): 30 to 100

- Maximum ash content (% weight): 10

Variants

Mechanical de-ashing OR automatic ash discharge to reduce operational maintenance workload and thus guarantee extended run times between maintenance shut-downs. Applicable for KOHLBACH boiler systems (water, saturated steam, superheated steam).

Supplementary equipment

Flue gas recirculation and/or air pre-heating for additional expansion of the range of usable fuels, available SNCR injection for use in particularly sensitive and emission-protected regions, special version available for the admixing of specified agrarian biomass (miscanthus, corncobs, etc.) upon specific customer request.

System K12

-

Furnace thermal output: 5.850 - 19.800 kW

Adiabatic centre-flow furnace for optimised efficiency and lowest emissions even with very heterogeneous fuel material. Equipped with hydraulic moving grate, also suitable for very wet and dirty fuels with very high ash content (up to A15), as well as for 100% wet bark, landscaping residues, Nawaro wood, etc. No arches thus preventing ash deposits and significantly reducing maintenance workload.

Fuel

- Water content (% weight): 20 to 60 depending on configuration

- Size (nominal length mm): 30 to 100

- Maximum ash content (% weight): 15

Variants

Mechanical de-ashing OR automatic ash discharge to reduce operational maintenance workload and thus guarantee extended run times between maintenance shut-downs. Applicable for KOHLBACH boiler systems (water, saturated steam, superheated steam).

Supplementary equipment

Flue gas recirculation and/or air pre-heating for additional expansion of the range of usable fuels, available SNCR injection for use in particularly sensitive and emission-protected regions, special version available for the admixing of specified agrarian biomass (miscanthus, corncobs, etc.) upon specific customer request.

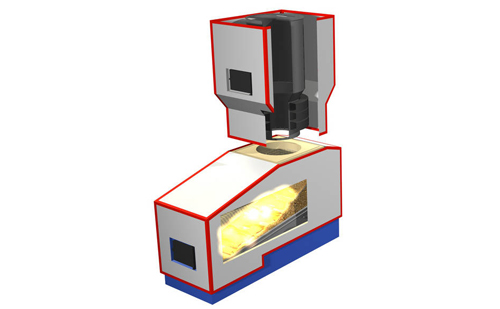

System K13

-

Furnace thermal output: 900 - 6.800 kW

Pellet combustion in industry-standard configuration for use with ENplus pellets and industrial pellets and wood chips for greater independence from the fuel market. Electrical moving grate, primarily for varying pellet qualities or pellet qualities that deviate from the standards. No arches thus preventing ash deposits and significantly reducing maintenance workload.

Fuel

- Ideal for ENplus pellets according to E14961-2 (quality): A1, A2, B (industrial pellets)

- Water content (% weight): less than 10

- Size (length and diameter mm): lenght from 3.15 to 40, diameter from 6 to 8

- Maximum ash content (% weight): 3

Variants

Mechanical de-ashing OR automatic ash discharge to reduce operational maintenance workload and thus guarantee extended run times between maintenance shut-downs. Applicable for KOHLBACH boiler systems (water, saturated steam, superheated steam).

Supplementary equipment

Flue gas recirculation and/or air pre-heating for additional expansion of the range of usable fuels, available SNCR injection for use in particularly sensitive and emission-protected regions, special version available for the admixing of specified agrarian biomass (miscanthus, corncobs, etc.) upon specific customer request.

System K15

-

Furnace thermal output: 1.250 - 5.800 kW

Equipped with hydraulic moving grate with grate bars in special quality for waste wood, also suitable for very dirty fuels with high ash content. Hydraulic fuel feed with shearing devices for fault-free feeding even with rough fuel materials. Reliable long operating life of the furnace thanks to full refractory lining, grate frame cooled with water and primary combustion chamber cooling.

Fuel

- Water content (% weight): 5 to 30

- Size (nominal length mm): 30 to 100

- Maximum ash content (% weight): 10

Variants

Mechanical de-ashing OR automatic ash discharge to reduce operational maintenance workload and thus guarantee extended run times between maintenance shut-downs. Applicable for KOHLBACH boiler systems (water, saturated steam, superheated steam).

Supplementary equipment

Flue gas recirculation and/or air pre-heating for additional expansion of the range of usable fuels, available SNCR injection for use in particularly sensitive and emission-protected regions, special version available for the admixing of specified agrarian biomass (miscanthus, corncobs, etc.) upon specific customer request.

System K16

-

Furnace thermal output: 5.850 - 19.800 kW

Centre-flow furnace for optimised efficiency and lowest emissions even with very heterogeneous fuel material. Equipped with hydraulic moving grate with grate bars in special quality for waste wood, also suitable for very dirty fuels with high ash content No arches thus preventing ash deposits and significantly reducing maintenance workload.

Fuel

- Water content (% weight): 5 to 30

- Size (nominal length mm): 30 to 100

- Maximum ash content (% weight): 15

Variants

Mechanical de-ashing OR automatic ash discharge to reduce operational maintenance workload and thus guarantee extended run times between maintenance shut-downs. Applicable for KOHLBACH boiler systems (water, saturated steam, superheated steam).

Supplementary equipment

Flue gas recirculation and/or air pre-heating for additional expansion of the range of usable fuels, available SNCR injection for use in particularly sensitive and emission-protected regions, special version available for the admixing of specified agrarian biomass (miscanthus, corncobs, etc.) upon specific customer request.

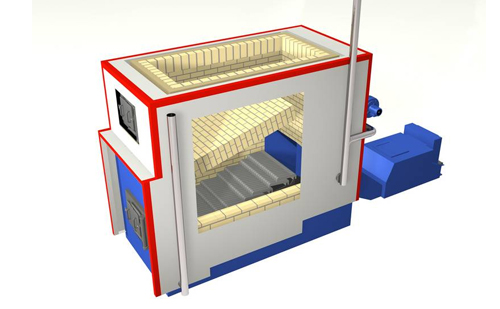

BOILER SYSTEMS

-

The boiler systems form the heart of every biomass system. Here Kohlbach offers a complete range of flexible industrial process heat applications.

Here Kohlbach offers a complete range of flexible industrial process heat applications: Warm/hot water, steam and thermal oil boiler plants assure a reliable and efficient supply of heat from 400 to 15,000 kW per module or with heat and electrical power, from approx. 3,000 kW thermal per module.

Your benefits by KOHLBACH:- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Warm water boiler - Boiler thermal output: 0,4 - 17 MW

-

The boiler systems form the heart of every biomass system.

Designed, constructed and tested in accordance with: Designed, constructed and tested in accordance with: EC directive 97/23/EC (Pressure Equipment Directive) whilst employing the following technical specifications: TRD regulations [German technical regulations for steam boilers], AD bulletins [pressure vessels workgroup], EN 287, EN 288, etc, monitoring of the quality assurance system through TÜV-Management Service GmbH, South German TÜV corporate group.

Parameters:

- Safety temperature (°C): 110

- Operating parameters (°C): 100/80

Hot water boiler - Boiler thermal output: 0,4 - 17 MW

-

The boiler systems form the heart of every biomass system.

Designed, constructed and tested in accordance with: Designed, constructed and tested in accordance with: EC directive 97/23/EC (Pressure Equipment Directive) whilst employing the following technical specifications: TRD regulations [German technical regulations for steam boilers], AD bulletins [pressure vessels workgroup], EN 287, EN 288, etc, monitoring of the quality assurance system through TÜV-Management Service GmbH, South German TÜV corporate group.

Parameters:

- Safety temperature (°C): 160

- Operating parameters (°C): 130/100

Advantages:

- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Saturated steam boiler - Boiler thermal output: 0,8 - 12 MW

-

Parameters:

- Maximum pressure (bar): 30

- Operating pressure (bar): 25

- Feed water temperature (°C): 103

Advantages:

- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Superheated steam boiler (fire tube) - Boiler thermal output: 3 - 12 MW

-

Parameters:

- Safety pressure (bar): 24,5

- Safety temperature (°C): 350

- Operating pressure (bar): 21,5

- Operating temperature (°C): 300

- Feed water temperature (°C): 103

Advantages:

- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Superheated steam boiler (water tube) - Boiler thermal output: 5 - 17 MW

-

Parameters:

- Operating pressure (bar): 49

- Operating temperature (°C): 450

- Feed water temperature (°C): 103

Advantages:

- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Thermal oil boiler - Boiler thermal output: 5,14 - 12,2 MW

-

Parameters:

- Supply temperatures (°C): 150 to 315

Advantages:

- Long operating life

- Exemplary high efficiency

- Low maintenance

- Extended full-load runtimes between maintenance shut-downs due to large heating surfaces reserves

Services

-

Our highly motivated and experienced service personnel attend to our customers' needs daily.

-

We are your contact partner for a smooth and rapid spare parts supply, the daily support for your system through to preventative annual servicing of all makes.

-

Our experience of over 60 years in biomass combustion, our service fleet and our own company production facilities make us your reliable and flexible partner.

- A service fleet is at your disposal round the clock across Europe

- Smooth and fast spare part supply, even decades later

- High Up-time of your plant

- Optimal emission values and consistently high degrees of efficiency

- Maximum service life of your plant

- Plant optimisation for all makes and manufacturers

-

Annual Service

-

The experienced, internal operating personnel of the KOHLBACH group assure the precise and reliable checking of all makes of boiler plants in accordance with the tried and tested KOHLBACH service checklist.

In doing so preventative measures can be implemented, so that you can operate your plant without worries and such that the availability of your boiler plant is maximised.

Spare and wear parts

-

Having our own manufacturing facilities guarantees you a smooth and fast spare part supply, even decades later.

Moreover, only select and established market leaders are relied upon as suppliers.

Plant optimisation

-

"Stay with the times and or time will pass you by" — this also applies for your plant.

Our service technicians are happy to advise you on plant optimisation and modernisation, so you can be satisfied with your plant for decades to come. We are happy to inspect plants of all makes and manufacturers for efficiency and the latest technical options for improvements. Contact us about the optimisation or modernisation of your existing plant — we can find an efficient and reliable solution for it.

Repairs

-

With great care we select only the highest quality materials and steels as well as the best control system technology for you so that your plant can meet the highest demands in daily use — under the most challenging conditions.

In the worst-case scenario, KOHLBACH has an entire highly qualified service fleet available for you round the clock. The KOHLBACH remote access can be utilised simply and quickly for remote diagnostics. Additional functions can even be programmed remotely according to your wishes, so quickly and cost-effectively it seems as though our technicians are really on site with you.

Wherever and whenever you want — one call is all it takes!

References

-

KOHLBACH's portfolio of references further reflects the multitude of heat users both geographically and across trades and industries

There you can find corporate headquarters and monasteries, military academies and children's villages, the remote heating of mountain villages and as part of the power supply for a city of over one million inhabitants. A school in Scotland and sawmills in Siberia.

The traditional flexibility and willingness to innovate have allowed KOHLBACH to address the multifaceted requirements of customers in the most diverse of locations. Short decision paths and international experience grown through many years offer our customers the security that their requirements will be understood.

FinkbeinerTriberg in the Black Forest, Germany

-

- Energy: 1.4 MW Electricity and 5.4 MW Hot water

- Fuels: Wood Industry Residues

- Country: Germany

- Year of construction: 2014

Salaspils, Latvia

-

- Energy: 3 MW Hot water, 100 °C

- Fuels: Forestry Residues, Wood Industry Residues

- Country: Latvia

- Year of construction: 2019

Vostok-resurs Uva, Russia

-

- Energy: 12 MW Superheated water, 120 °C

- Fuels: Wood Industry Residues

- Country: Russia

- Year of construction: 2021

Balzers, Liechtenstein

-

- Energy: 4 MW Saturated steam, 15.5 bar

- Fuels: Forestry Residues

- Country: Liechtenstein

- Year of construction: 2014

Ogre, Latvia

-

- Energy: 14 MW Superheated water, 115 °C

- Fuels: Forestry Residues, Wood Industry Residues

- Country: Latvia

- Year of construction: 2017