Videos

Loading the player ...

- Offer Profile

- BEDNAR FMT is a

progressive manufacturer of agricultural machinery with

specialization on production of machines for tillage, seeding,

fertilising and slashing.

Thanks to the close and strong relationship with farmers, BEDNAR FMT ranks

among the most innovative manufacturers developing and producing machines

with good values reducing costs to the farmers. BEDNAR FMT s.r.o. was

founded in 1997 by Msc. LadislavBednář.

The company is currently employing more than 250 people and exports its

products to 35 countries around the Europe, Asia, Australia, North and South

America and Africa.

Product Portfolio

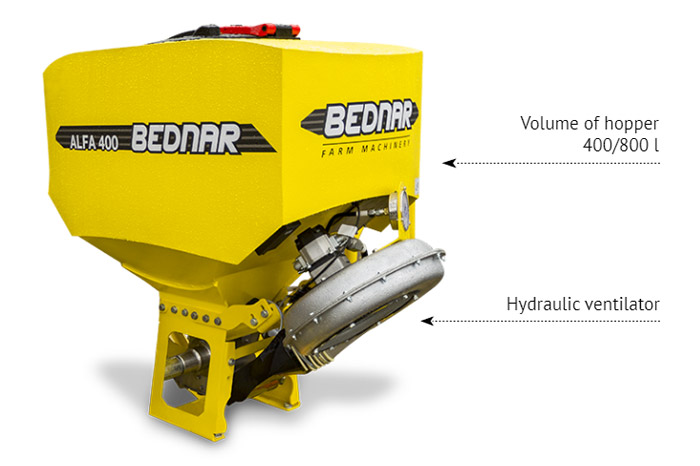

SEEDING AND FERTILIZING

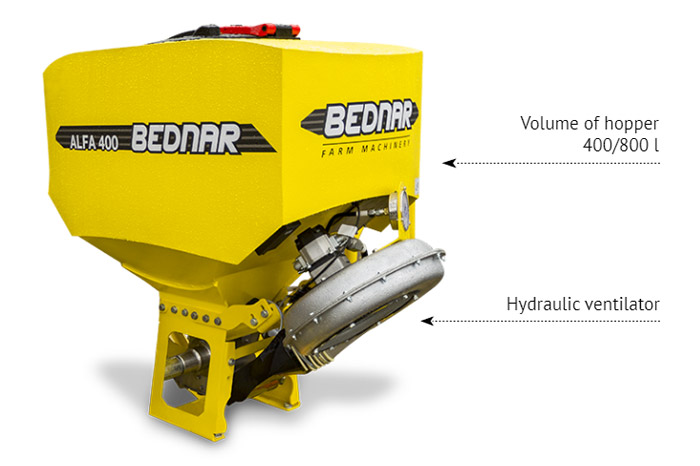

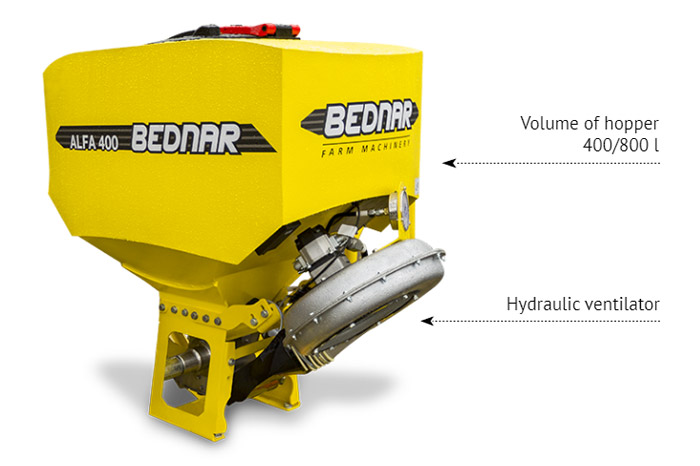

ALFA DRILL

Seeding Unit

- Sows cover crops and grasses,

combines the workflows.

- Limits soil erosion.

- Weed disposal.

- Increases the nitrogen in the soil due to the cover crops.

- Improves the soil structure by intercropping.

- Increases biological activity.

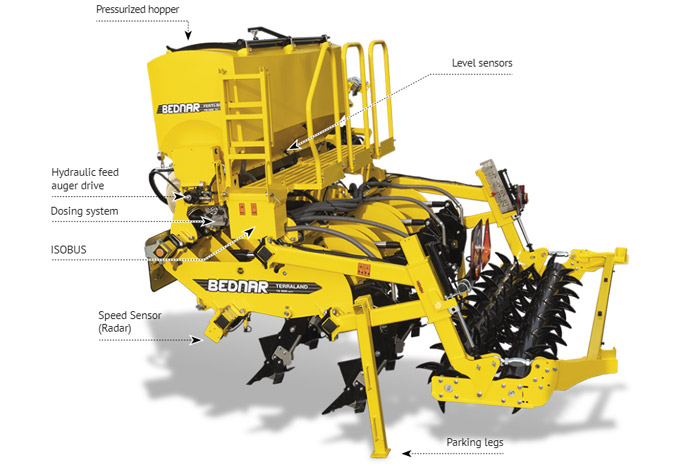

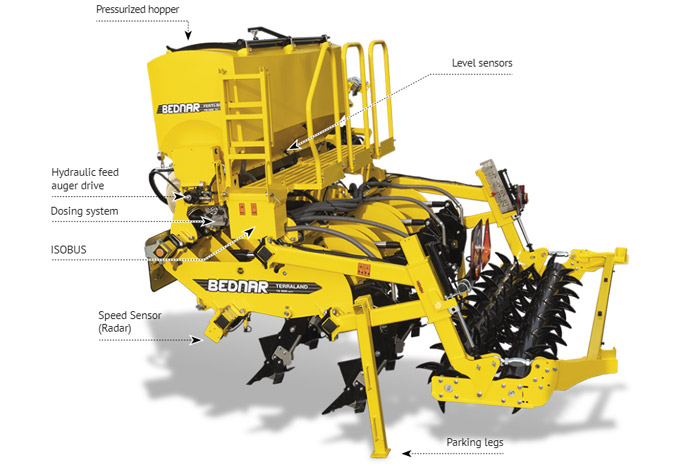

ALFA DRILL is a seed drill designed for establishing cover crop, additional grass, or for all-area fertiliser application. It can be installed on various types of BEDNAR machines. The dispensing area below the hopper includes the time-tested robust stainless metering system from the Omega seed drill machines. The strong hydraulic fan ensures a good function also in a larger width. The unit is controlled via ISOBUS directly from the tractor (depends on the actual configuration). End sensors simplifying operation can be applied.

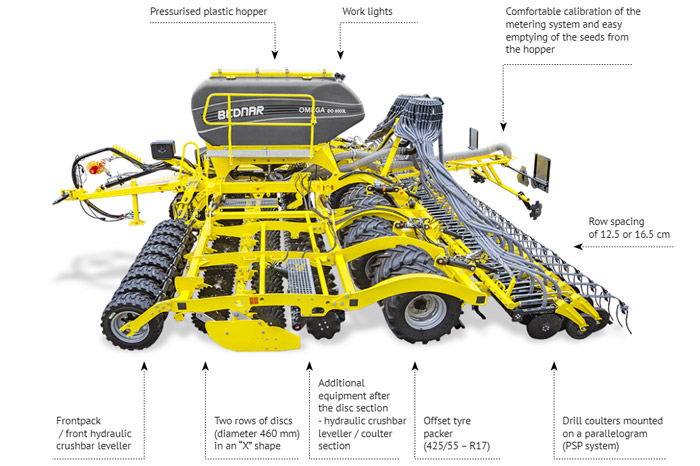

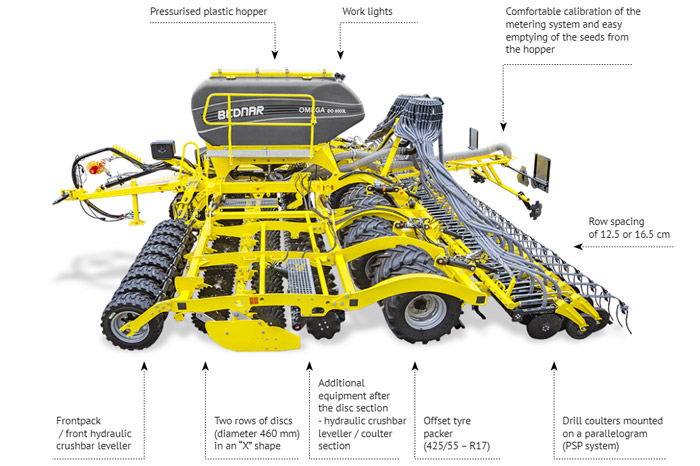

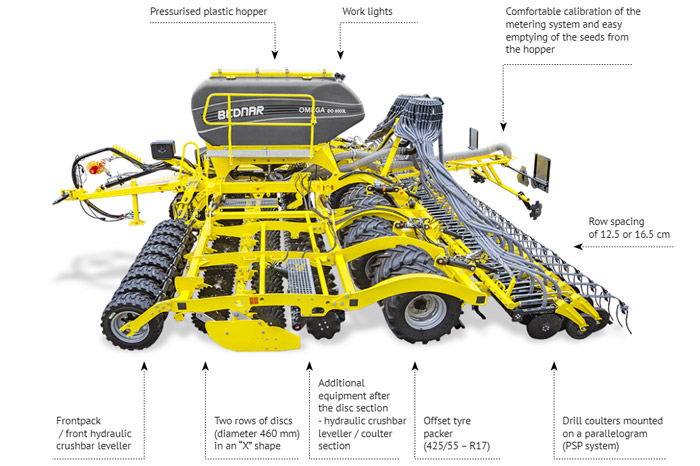

OMEGA OO_L

Seed Drill

-

- Precise seedbed preparation thanks to discs of diameter 460 mm and a

coulter section.

- Precise placing of seed at an identical depth across the entire machine

span thanks to the PSP system – downforce on the seeding coulters up to

130 kg.

- The “X” layout of the disc section secures precise holding behind the

tractors.

- Offset tyre packer with a self-cleaning effect secures the stability of

the seed drill.

- Light and robust machine structure.

- Comfortable and quick seeding quantity calibration.

- Intuitive control via the ISOBUS terminal.

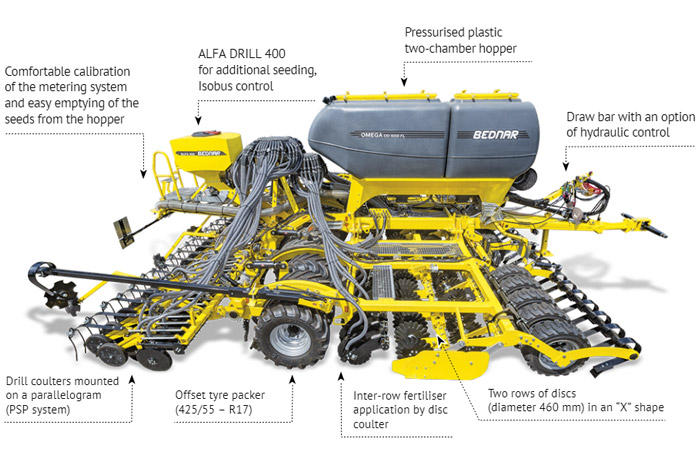

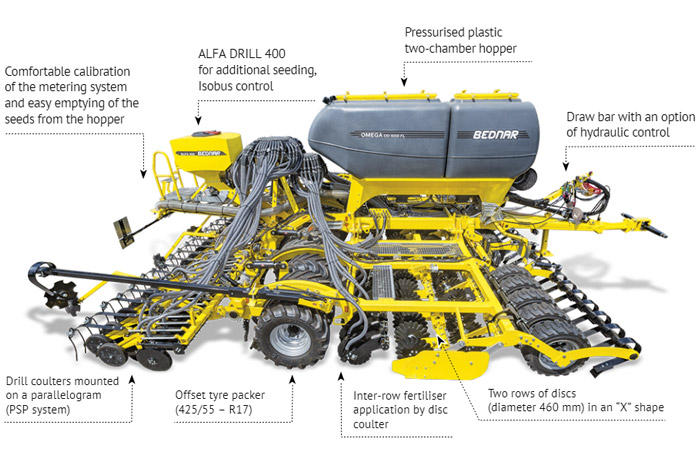

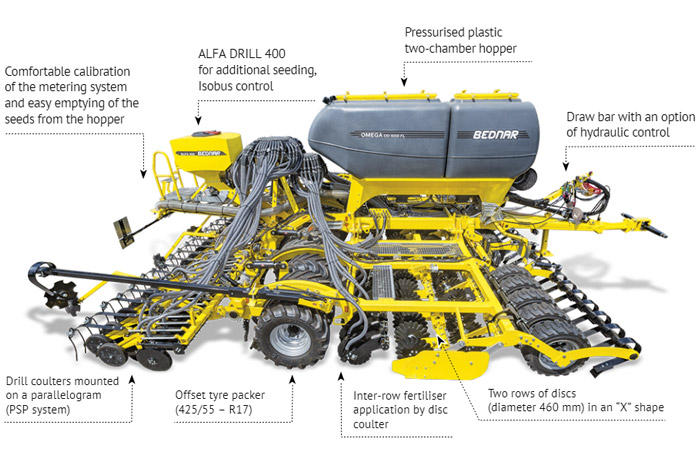

The OMEGA OO_FL is a versatile seed drill of a light concept with disc soil preparation allowing for seeding various types of crops with a high variation of the seeding amount both in the conventional technology system (ploughing) and in the minimising system with the possibility of additional fertilising. A major advantage of the Omega seed drill is the placement of the disc sections into an X.

Thanks to the pressurized hopper, it is possible to supply even larger doses of fertilisers.

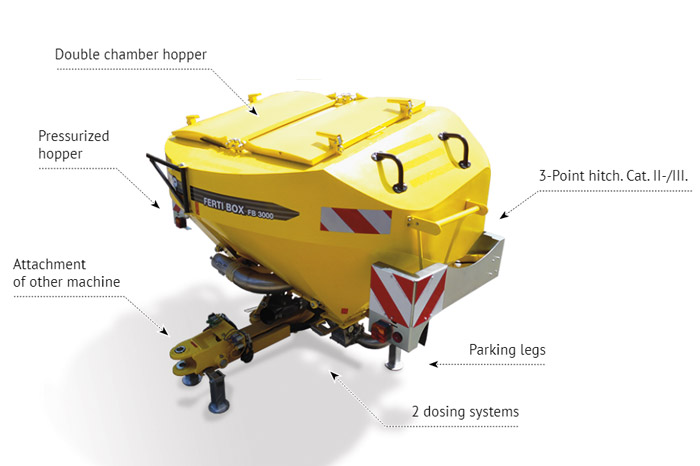

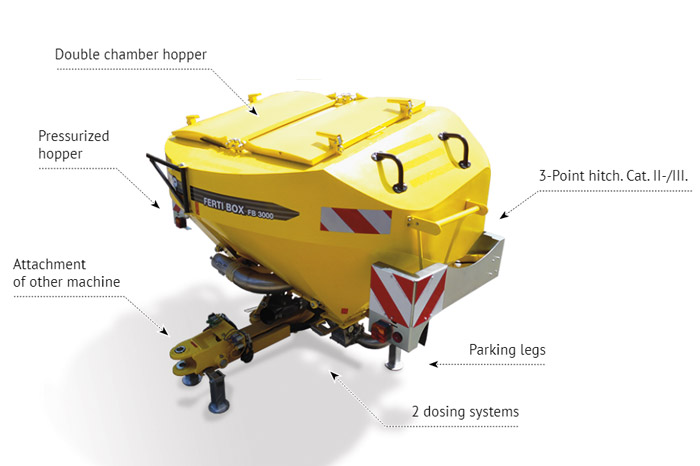

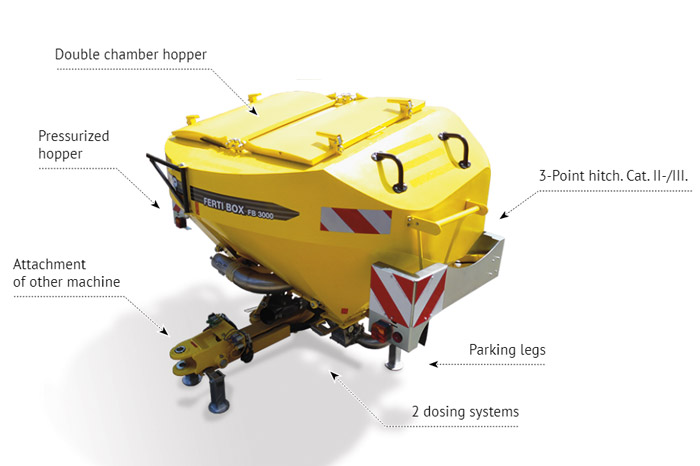

FERTI-BOX FB

Hopper for fertiliser and seeds

-

- Low number of fills due to the high-volume hopper with a 3 000 l

fertiliser (seed) volume.

- 2 electrically powered stainless steel dosers allow you to change the

dosage size depending on the agronomic requirements.

- Pneumatic material transport (fertiliser/seed) from the doser to the

soil by the distributors with air regulation.

- 2 types of fertiliser (seed) can be dosed, or 100 % of the volume can be

used for one type of fertiliser (seed).

- Batching controlled via the ISOBUS system.

OMEGA OO_L is a versatile seed drill of a light concept with disc soil preparation allowing for seeding various crop types with row spacing of 12.5 or 16.5 cm with large seeding quantity variation in both the conventional soil preparation system and in the minimising one. The arrangement of individual working parts secures the unique and competition-less soil preparation before sowing in combination with precise seed placement, low weight, and simple setup.

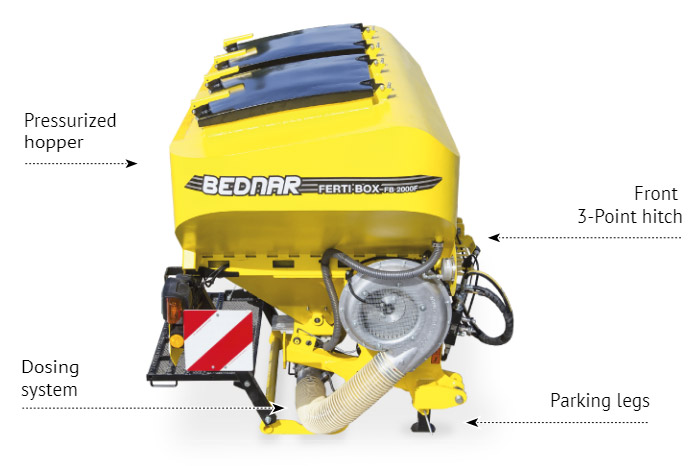

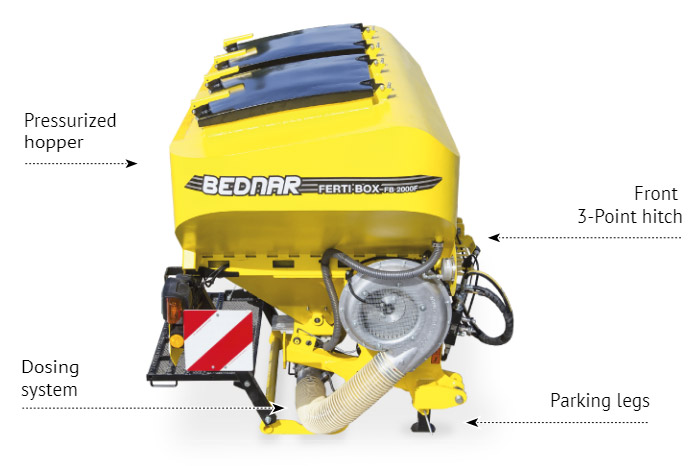

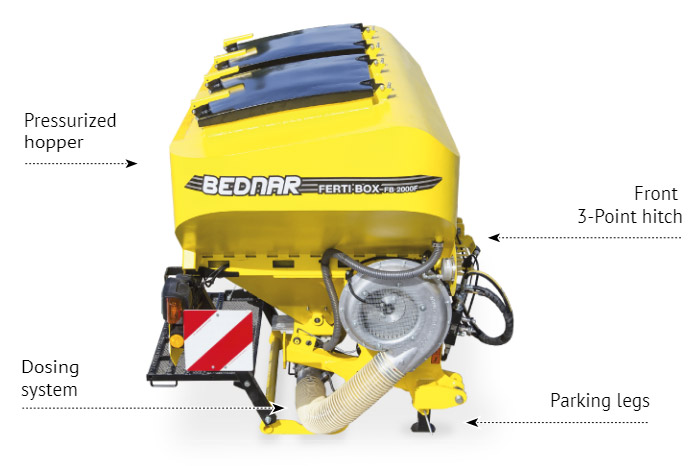

FERTI-BOX FB_F

Hopper for fertiliser and seeds

-

- Low number of fills due to the high-volume hopper with a 3 000 l fertiliser

(seed) volume.

- 2 electrically powered stainless steel dosers allow you to change the dosage

size depending on the agronomic requirements.

- Pneumatic material transport (fertiliser/seed) from the doser to the soil by

the distributors with air regulation.

FERTI-BOX FB is primarily designed to place the fertiliser directly into the soil profile.

The Ferti-Box is attached to the tractor using a 3-point cat. III and IV hitch.

The hopper is equipped with a separate frame to which one of the soil tillage machines is attached (Terraland TO, Terraland DO, Fenix FO).

The fertiliser (seed) is transported pneumatically from the hopper to the application end of the tillage machine.

The ends can be adjusted to a different application depth depending on the agronomic requirements to position the fertiliser.

FERTI-BOX FB_F

Hopper for fertiliser and seeds

-

- Pressurised hopper for precise dosing of fertilisers.

- Dosing controlled by the ISOBUS system.

- 1 (2) electrically powered stainless steel doser allows you to change the

dosage size as required.

- Pneumatic transport of material (fertilizer / seed) from the doser to the

soil.

FERTI-BOX FB_F is a mounted front hopper primarily designed to place the fertiliser directly into the soil profile. Ferti-Box FB_F is attached to the tractor´s front hydraulics of category II./III. Material (fertiliser/seed) is transported pneumatically behind the tractor to another machine (Terraland TN, TN_Profi, Fenix FN/FN_L, Row-Master RN/RN_S etc.).

The Ferti-Box FB_F hopper is pressurised! This design increases the dosage accuracy, especially with fertilisers which are more demanding in terms of their distribution. An advantage of the Ferti-Box FB_F hopper is the very good view of the crop and road from the tractor´s cab.

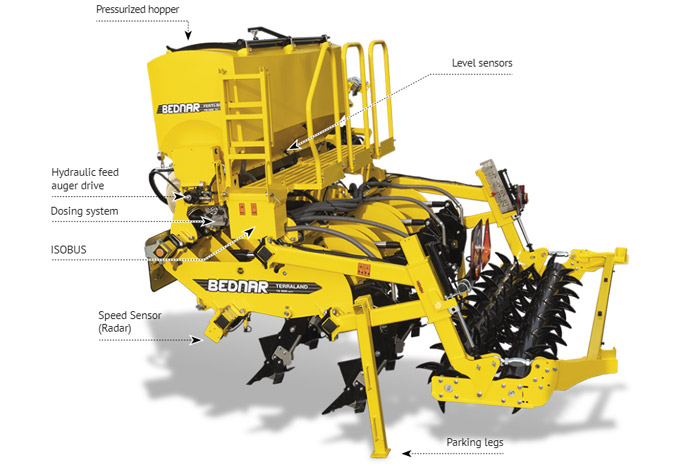

FERTI-BOX FB_TN

Hopper for fertiliser and seeds

-

- Pressurised hopper for precise fertiliser batching.

- Hopper for the Terraland TN chisel ploughs.

- Batching controlled via the ISOBUS system.

- One batching stainless mechanism with electric drives allows changing the

batch size according to your agronomical needs.

FERTI-BOX FB 1500 TN is designed for current or future users of the TERRALAND TN chisel ploughs. The hopper with a capacity of 1,500 litres is integrated directly onto the frame of the chisel plough. The fertiliser is delivered to the dispensing mechanism by a hydraulically controlled screw conveyor and then pneumatically to the application end pieces of the chisel plough.

FERTI-CART FC 3500

Cart for fertiliser and seeds

-

- A pressurised cart for precise fertiliser batching.

- Cart made of plastic.

- 1 stainless dosing system with electric drivers that allows changing of

the batch quantity according to the agronomic need.

- A strain-gauge weighing system with data transfer.

- Batching controlled via ISOBUS.

FERTI-CART is a pressurised cart designed primarily for direct application of fertilisers into soil horizons. FERTI-CART is designed to maximally accommodate work and manipulation with solid fertilisers.

FERTI-CART is made of plastic and the nozzle of the cart has a large angle of slope so that lower-quality fertilisers can be applied as well. The main use of the cart is in connection with other machines for soil cultivation, such as a Terraland, Terrastripor, Fenix.

Ferti-Cart FC is pressurised! This solution increases the accuracy of batching, mainly in fertilisers with more demanding distribution.

TILLAGE

Disc cultivator

SWIFTERDISC XN

-

- High quality, swift, inexpensive stubble cultivation up to 12 cm.

- Zero maintenance bearing discs lasting for a lifetime.

- High operating speeds of up to 15 km/h due to the customized design.

- The performance of the 520×5 mm discs is not affected by wear and tear due

to the truncated cone shape.

- The Alfa Drill option to drill covering crops.

- A-discs (aggressive) give you the option of a better cutting and mixing

effect.

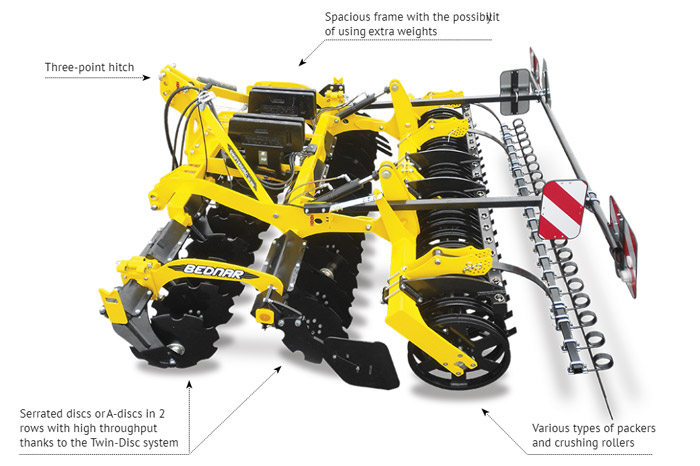

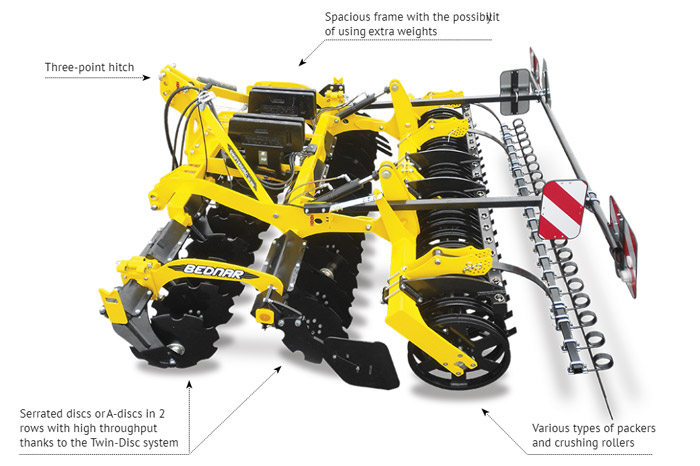

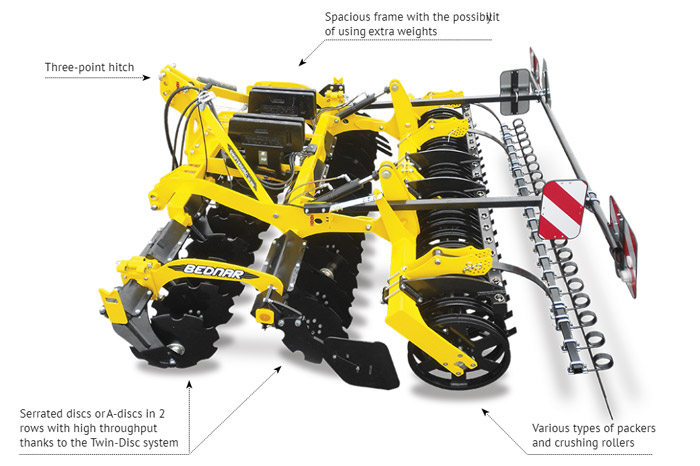

SWIFTERDISC XN is a mounted disc cultivator of short conception, with individual suspension of the discs with rubber segments that are ready for swift, low cost, quality stubble cultivation.

The SwifterDisc XN can also be used for seedbed preparation minimizing the need for conventional tillage systems.

Each arm is fitted with a pair of discs (Twin-Disc system). The machine aggregates with a tractor over a 3-point hitch cat. II./III.

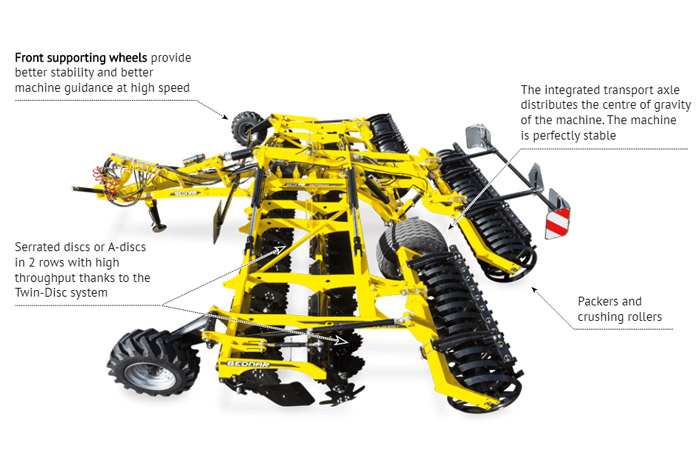

SWIFTERDISC XO_F

-

- Swift, low cost stubble cultivation up to 12 cm.

- A perfectly flat field left in its wake due to the rear packers which

consists of 3 parts which overlap each other.

- The Alfa Drill option to drill covering crops.

- High working speeds of up to 15 km/h due to the excellent stability of the

machine. Higher working speed = better quality work.

- A-discs (aggressive) give you the option of a better cutting and mixing

effect.

- A transport axle placed in front of the rear packer = excellent stability

also at high working speeds and a small turn radius.

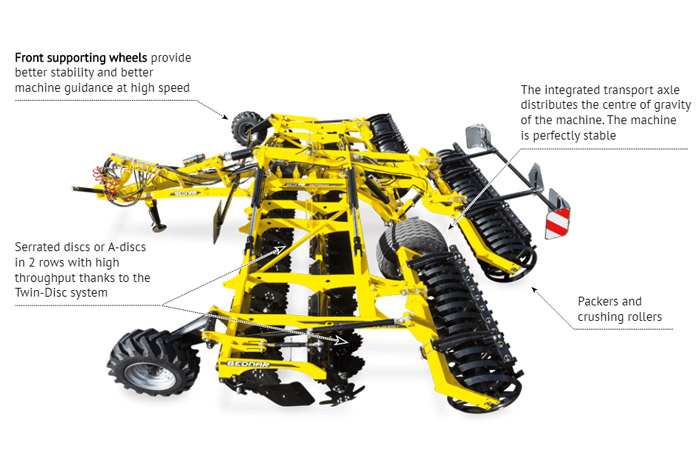

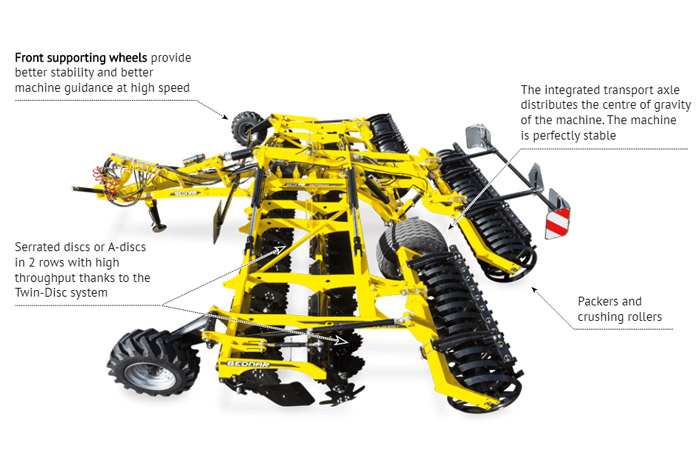

SWIFTERDISC XO_F is a short compact disc cultivator with high working speeds of up to 15 km/h.

Thanks to the precise distribution of the center of gravity (the axle is placed in front of the rear packer) the machine excels and is perfectly stable, irrespective of the high operating speeds.

Each arm is fitted with a pair of discs (Twin-Disc system). The offer also includes the unique A-discs which cut crop residue better and mixe it with the soil. This will allow you to cultivate large amounts of crop residue.

SWIFTERDISC XE

-

- Wide disc cultivator for enormous daily output.

- Fast operating speeds of up to 15 km/h due to the customized design.

- Folds up in a forward motion.

- High quality, swift, inexpensive stubble cultivation of up to 12 cm.

- Zero-maintenance bearing discs lasting for a lifetime.

- The performance of the 520×5 mm discs is not affected by wear and tear due

to the truncated cone shape.

SWIFTERDISC XE is trailed wide disc cultivator in a compact design with individual suspension of the discs with rubber segments, which make the machine ready for high quality, swift and inexpensive post-harvest stubble cultivation or seedbed preparation.

Thanks to the broad working width combined with high speeds, a massive daily output can be achieved.

The unique folding system allows the machine to be compacted in a forward motion resulting in smaller dimensions for transportation.

Each arm is fitted with a pair of discs (Twin-Disc system).

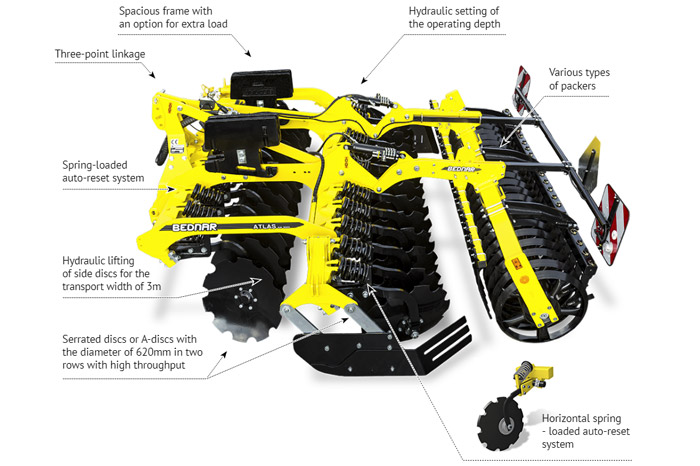

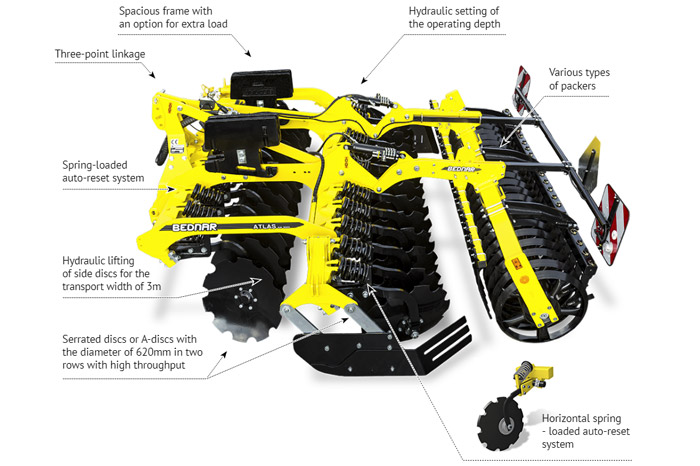

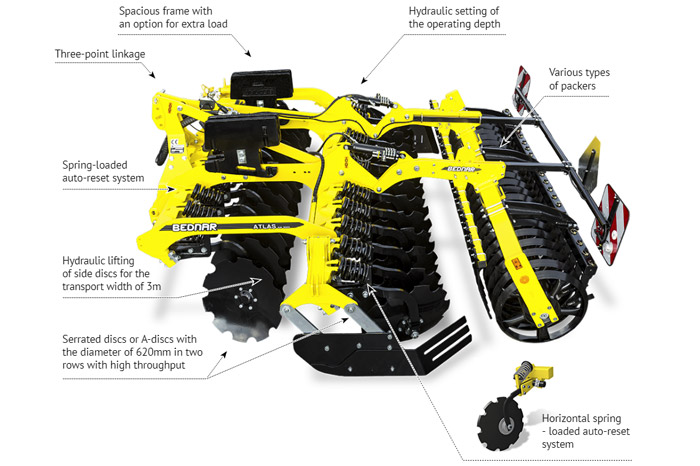

ATLAS AN_PROFI

-

- Excellent stubble cultivation even in cases of large amounts of crop

residues.

- Maintenance-free arms attachment using the Flexi-Box system.

- Large discs of 620 x 6 mm in diameter.

- The discs are placed on maintenance-free, axial ball bearings.

- Individual spring-loaded auto-reset system securing of discs against

overload.

- The same working angle of the discs without any impact on wear and tear.

ATLAS AN_PROFI is a mounted disc cultivator of short design which is able to incorporate a large amount of crop residues in one passage.

The discs measuring 620 x 6 mm allow you to perform deeper stubble-tillage at up to 16 cm, mixing crop residues and the soil intensely.

The AN model is equipped with spring-loaded auto-reset system securing of each disc which increases pressure on the soil and thus ensures better entry of the discs into the soil. Furthermore, the arms are attached to the frame through the maintenance-free Flexi-Box system (no lubrication).

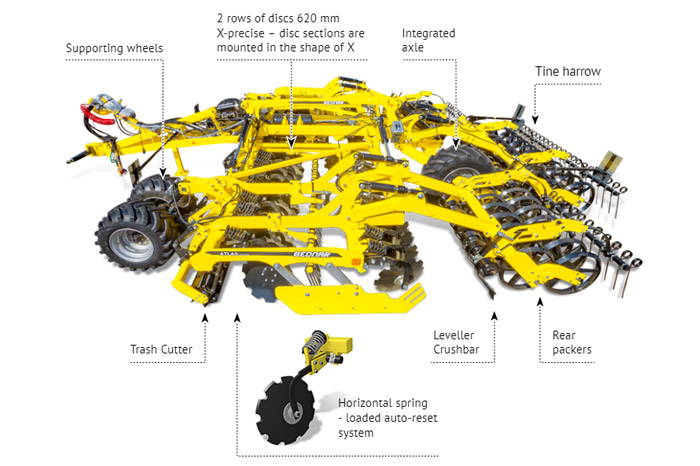

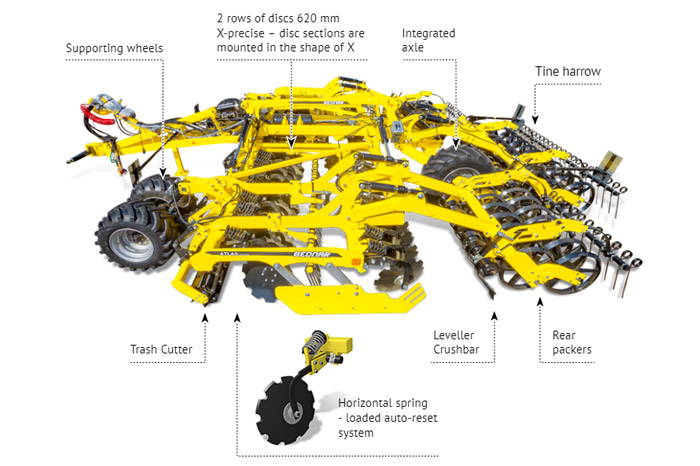

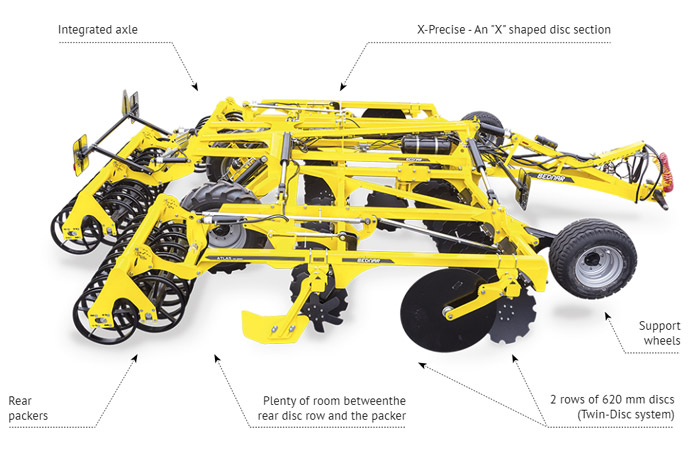

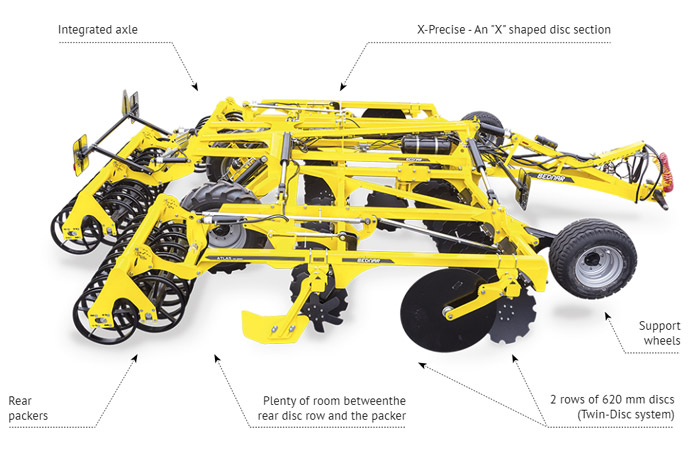

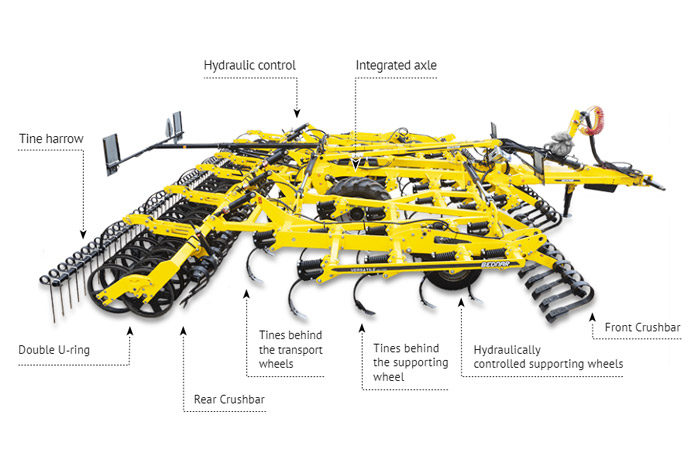

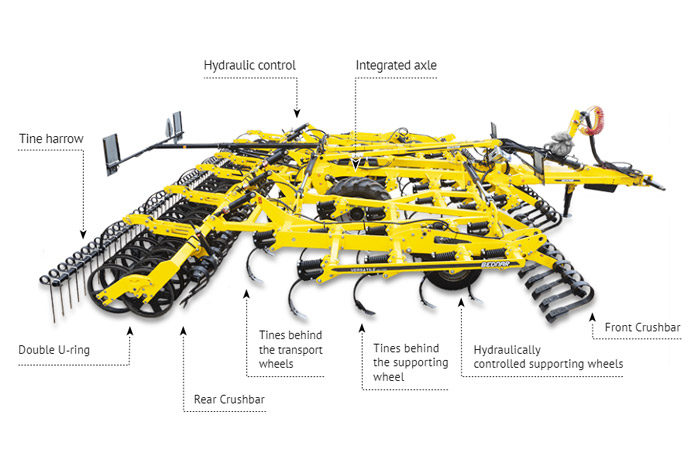

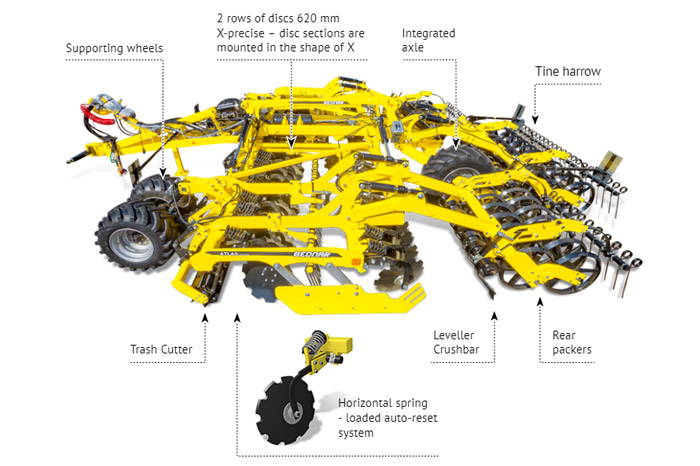

ATLAS AO_PROFI

-

- No-maintenance attachment of arms with the Flexi-Box system.

- Each disc well suspended thanks to spring-loaded auto-reset system.

- X-shaped disc arrangement.

- Integrated axle = smaller turning radius.

- Front cutting roller Trash Cutter.

- Fully hydraulically-controlled machine.

The ATLAS AO_PROFI is a compact short disc cultivator of a robust structure suitable for both minimising systems of soil processing (working in a large quantity of plant residues) and for the traditional manner of farming utilising cultivation.

The main advantages of the machine include the X-shaped arrangement of the discs, which prevents drifting of the machine, and the integrated axle, which eliminates swaying of the machine during work.

The disc size 620×6 mm allows for performing stubble cultivation up to 16 cm with intense mixing.

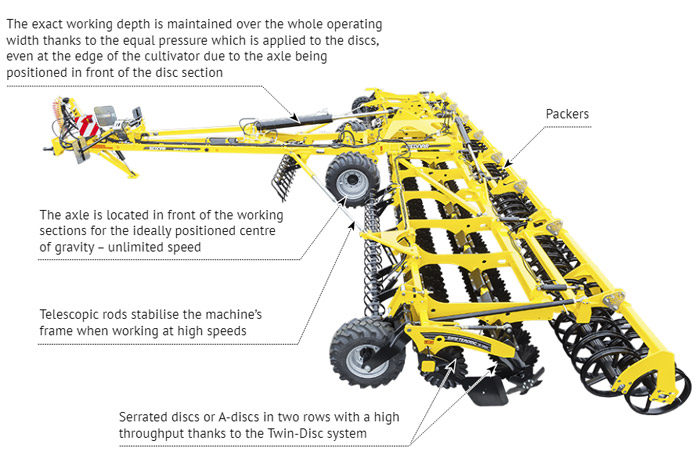

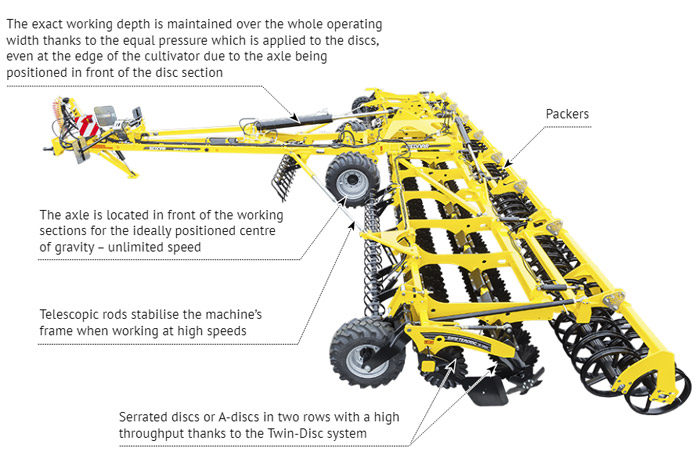

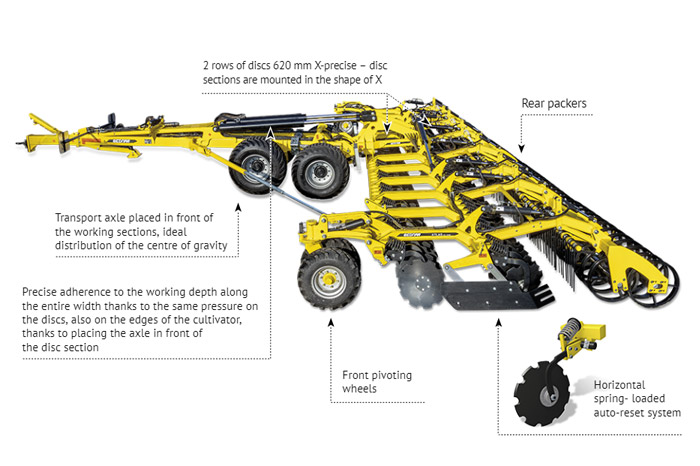

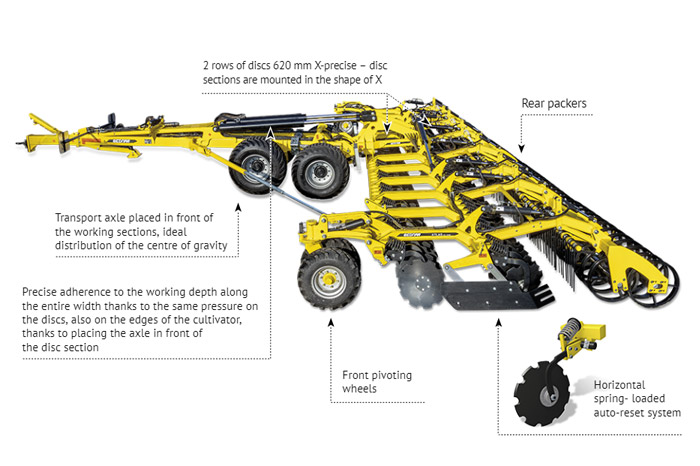

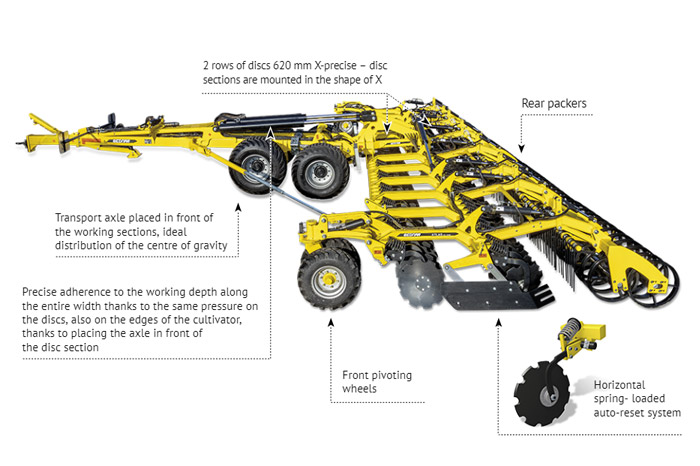

ATLAS AE_PROFI

-

- No-maintenance attachment of arms with the Flexi-Box system.

- Each disc well suspended thanks to spring-loaded auto-reset system.

- X-shaped disc arrangement.

- Transport axle placed in front of the working discs.

- Front pivoting wheels and rear packers.

- Electrohydraulic machine control (Load Sensing).

- Machine transport width: 3m, machine transport height: 4m.

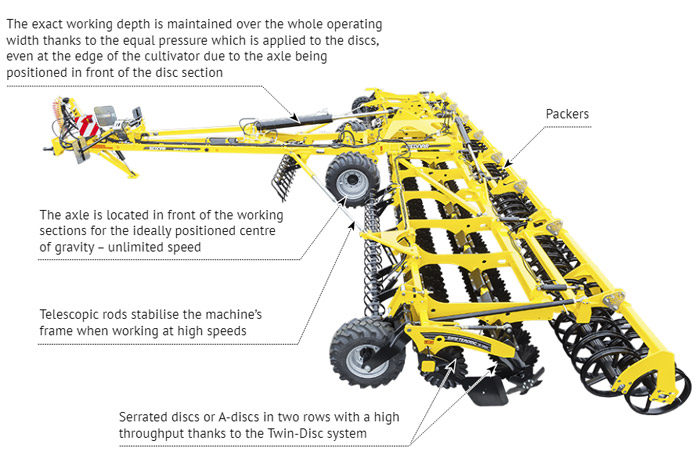

The ATLAS AE_Profi is a wide short concept disc cultivator designed for huge daily performance and costs savings, thanks to the wide span of the machine and high working speeds.

The main advantages of the machine include the X-shaped arrangement of the discs, which prevents drifting of the machine, and positioning of the transport axle in front of the working discs. With this design, the machine does not sway while working. The operator will appreciate the simple and comfortable electrohydraulic control of machine functions.

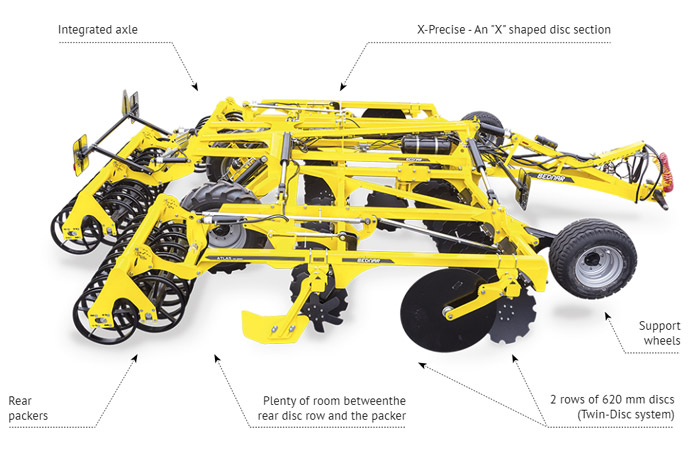

ATLAS AO_L

-

- Quality cultivation up to the depth of 16 cm even with a higher quantity

of crop residue.

- Twin-Disc system (pair disc attachment) provides high material throughput.

- X-precise – an X-shaped disc sections guarantee a precise pass behind the

tractor.

- Maintenance-free disc bearings with lifelong filler material.

- Integrated axle for perfect stability in high working speeds and low turning

radius.

ATLAS AO_L is a universal heavier type of a short disc cultivator designed for cultivation right after the combine and for cultivation of a high quantity of crop residue, such as grain corn.

The machine has the advantages of modern disc cultivators: positioning of disc sections in X shape and an integrated axle.

The size of discs (620 mm) and the own weight of the machine allow cultivation in the depth of up to 16 cm.

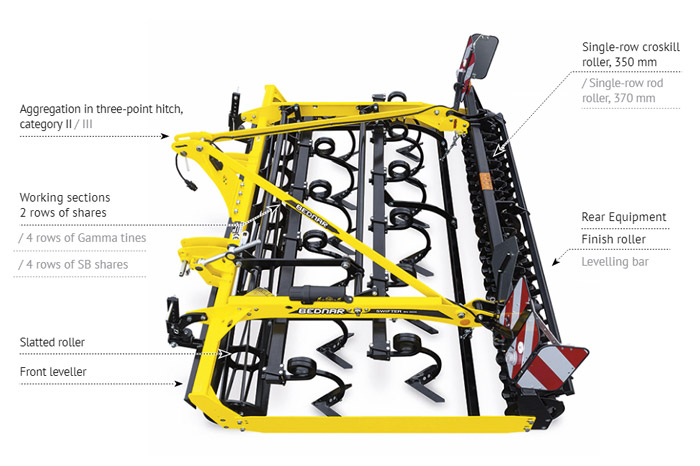

Seedbed Cultivator

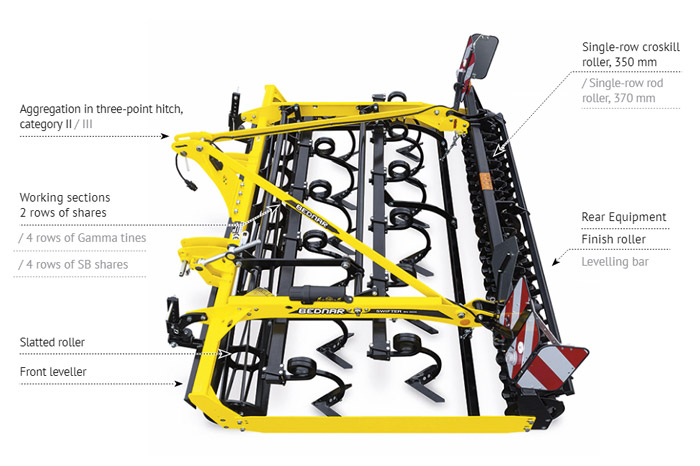

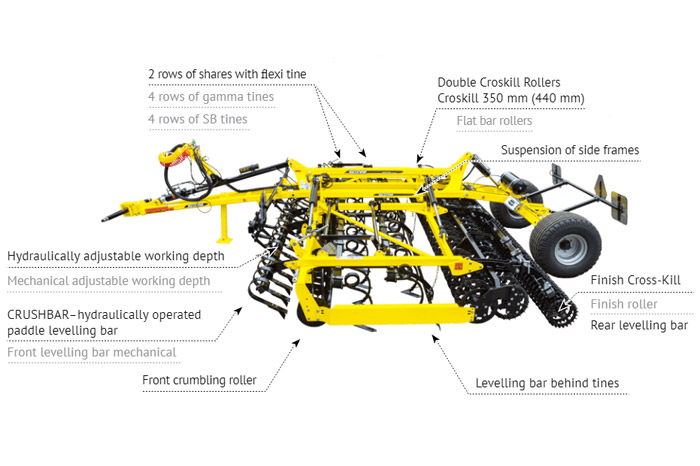

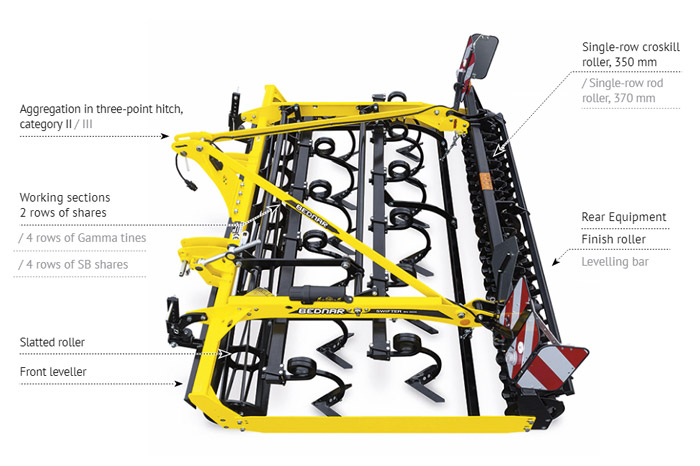

SWIFTER SN

-

- Perfect preparation for seeding in one pass.

- Combining 7 working operations in one pass.

- Sections can be alternated – shares, gamma tines or SB-sections.

- The ideal partner for a low power class of tractor.

- Crosskill roller.

SWIFTER SN is a mounted seedbed cultivator which manages to combine all working operations in a single pass, needed to prepare a perfect seedbed even in a rough furrow.

The machine can be used in traditional systems of farming as well as minimum tillage systems.

The design enables an easy exchange of the internal frame with shares for a frame with gamma tines or a frame with SB-sections.

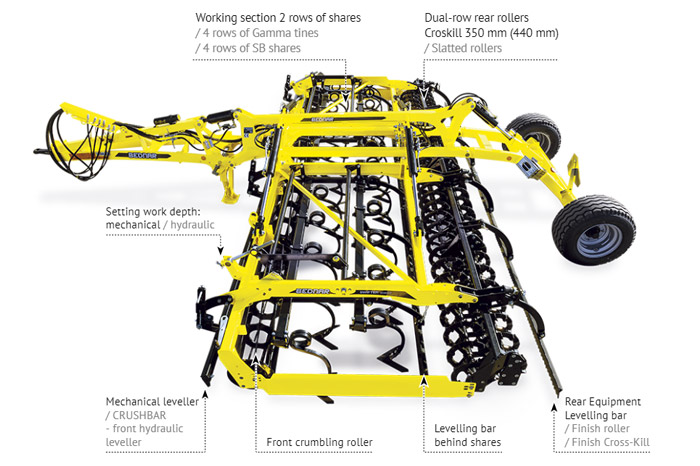

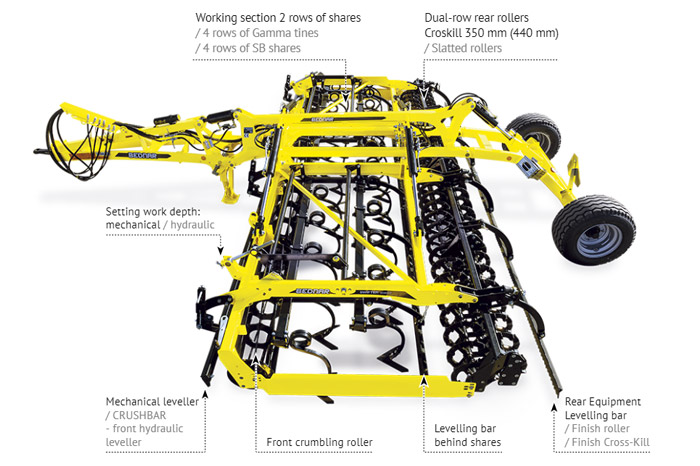

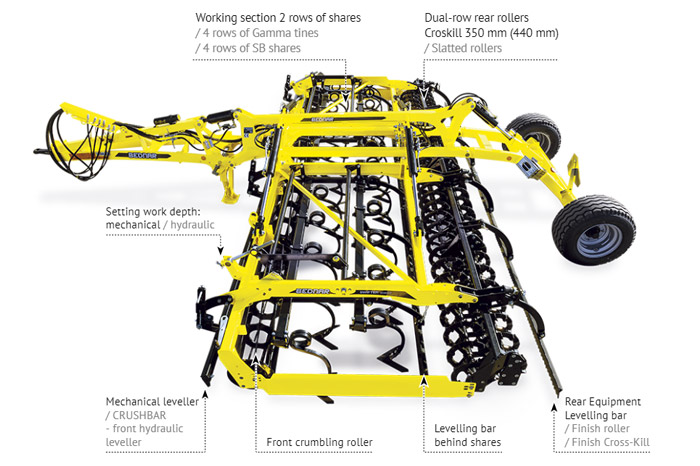

SWIFTER SO_F

-

- Hydraulic working depth adjustment controlled from the tractor cabin.

- Perfect preparation for seeding in one pass.

- Combining up to 7 working operations at once.

- Easily interchangeable internal frame with different types of working

sections.

- Crosskill roller for a better crumbling effect.

- Increased performance thanks to the high operating speed.

- Low acquisition costs.

SWIFTER SO_F is a seedbed cultivator that is based on the traditional SO version. Simple and lightweight it combines all working operations (up to 7) for seedbed preparation in a single pass.

The machine can be used for conventional farming as well as minimum tillage systems.

The machine facilitates easy exchange of an internal working sections.

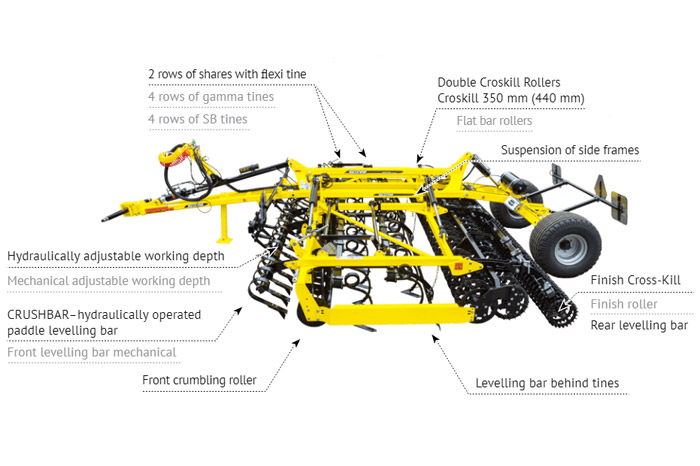

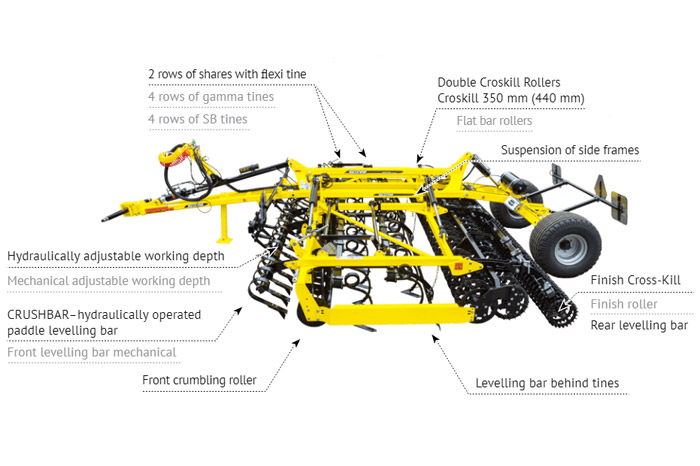

SWIFTER SO_PROFI

-

- Perfect preparation for seeding in a single pass.

- Hydraulic setting of the working depth from the tractor.

- Easy replacement of the internal frame with

various types of working

sections.

- Option to use 3 cross-kills for better reverse soil consolidation.

- Combining up to 7 operations into one.

- A patented suspended system for the working sections.

SWIFTER SO_PROFI is a modern type of seedbed cultivator that is able to prepare the field for seeding in a single pass. A great advantage is the overall suspended of the working frames using a system that allows working with the machine at high speeds of up to 15km/h. The Swifter machine now also comes with the optional finish cross-kill for better seedbed consolidation.

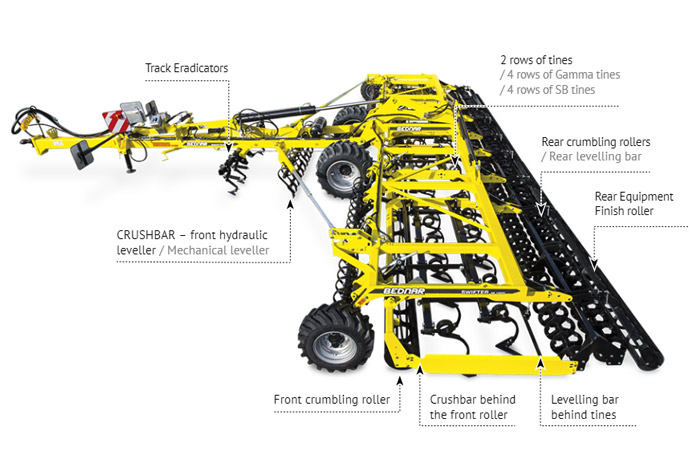

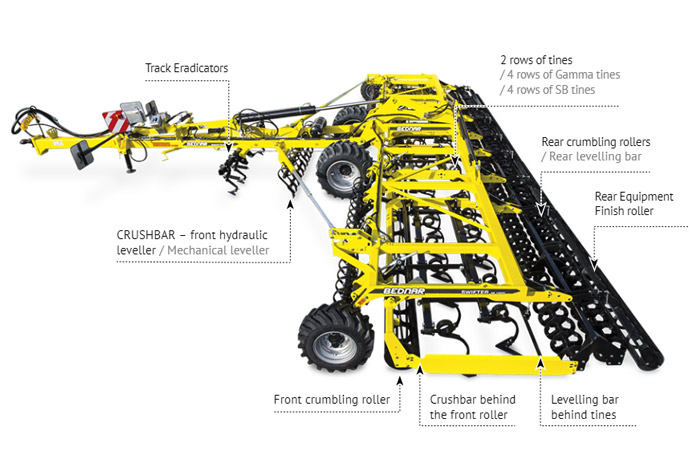

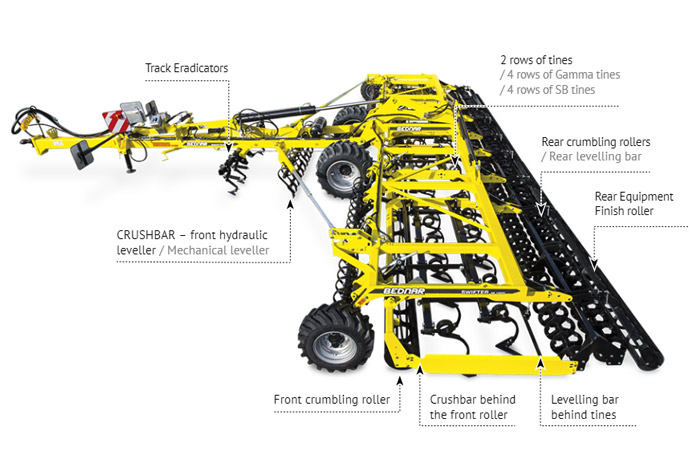

SWIFTER SE

-

- Perfect seedbed preparation in one pass.

- Combining up to 8 working operations at once.

- Enormous daily output due to working width and high working speed.

- Perfect surface contouring due to the independent placement of section

Wave-Flex.

- The swift exchange of internal components according to the needs and soil

conditions.

SWIFTER SE is a trailed seedbed cultivator with a broad operating width which can swiftly prepare a seedbed in one pass even in a rough furrow.

This new model of the range is characterized by its unique capability to fold itself up in a forward motion for more compact transport dimensions. This facilitates transportation over rough terrain also.

Easily interchangeable inner frame components (tines / gamma tines / SB-section).

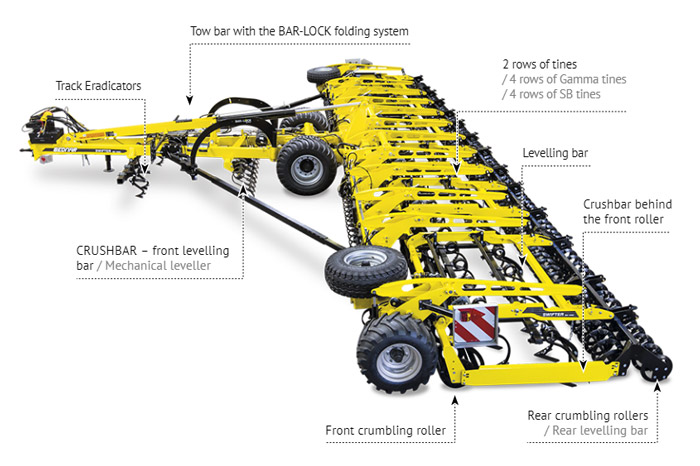

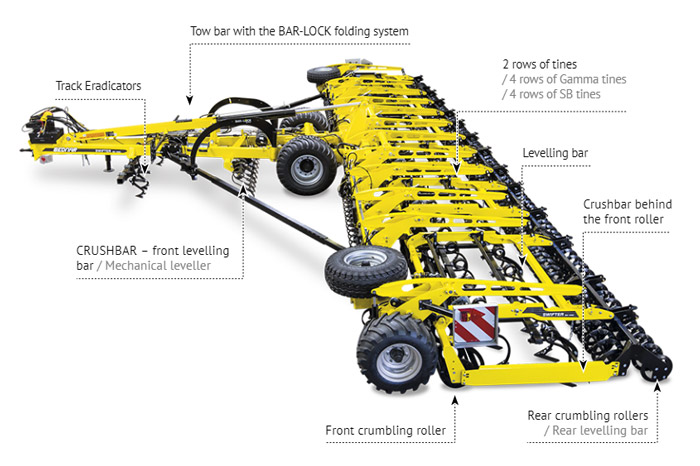

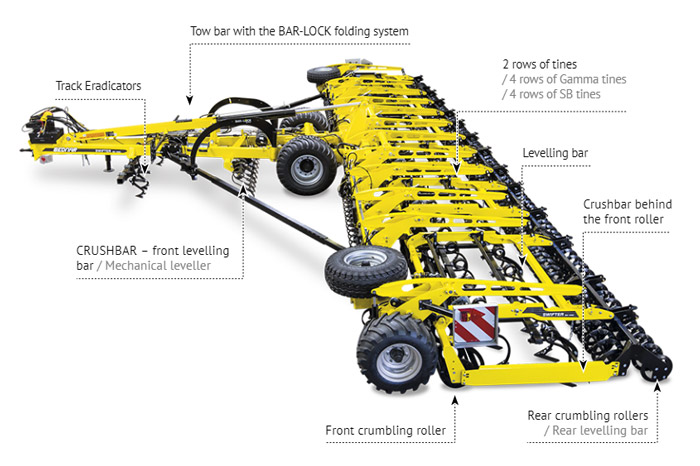

SWIFTER SM

-

- Up to 8 working operations are merged into one pass.

- Perfect seedbed preparation in one pass.

- A unique folding mechanism that is operated from the tractor cabin =

Bar-Lock system.

- Perfect surface contouring due to the independent placement of section

Wave-Flex.

- The swift exchange of internal components according to the needs and soil

conditions.

SWIFTER SM is a trailed seedbed cultivator with a broad operating width which can swiftly prepare the seedbed in one pass even in a rough furrow.

Broad working width ensures maximum productivity and significantly shorten the time required to comply with agro-technical terms.

Inside frame of sections can be easily replaced (tines / gamma tines / SB-section).

Swifter SM, despite the large working width, is easy to use.

The machine is folded and unfolded easily and safely with the help of the Bar-Lock system.

Versatile Cultivator

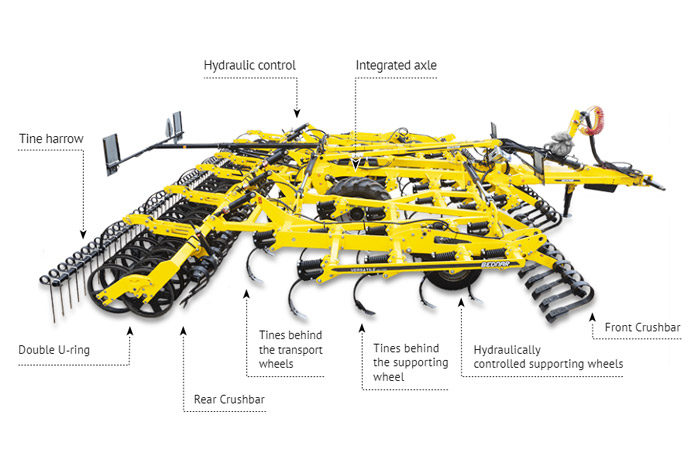

VERSATILL VO_PROFI

Universal Cultivator

-

- Seedbed preparation of fields with a higher amount of post-harvest

residue, even in moister conditions.

- Intensive precise stubble cultivation of up to 15cm. Perfectly flat soil

profile bottom.

- Perfect troughput of the machine thanks to the 5-row tines arrangement.

- Spring-loaded auto-reset system of each tine.

- Integrated axle = smaller turning radius.

- Possibility of working without rear rollers.

Fully hydraulically controlled machine. VERSATILL VO PROFI is a universal tine cultivator designed for seedbed preparation of fields with a higher amount of post-harvest residue, or for intensive stubble cultivation of up to 15 cm, thanks to the horizontal spring-loaded auto-reset system of each tine.

The tines are arranged in 5 rows; this solution provides perfect material throughput of the machine. Thanks to the perfect overlapping of the shares, the land is undercut evenly (mechanical weed control).

The transport axle is located in the middle of the machine, which reduces the radius of turning at headlands.

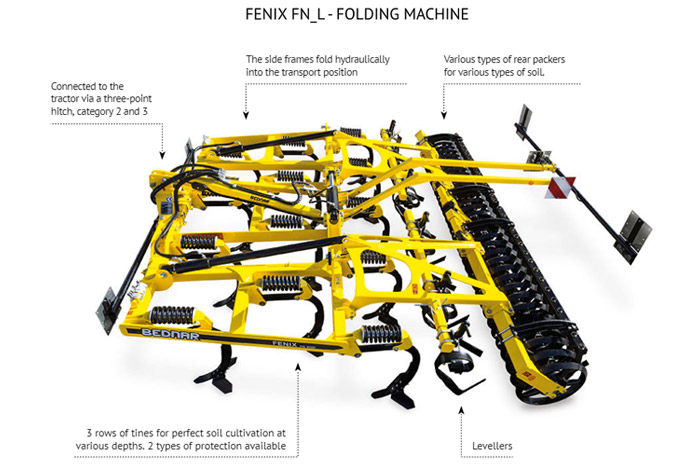

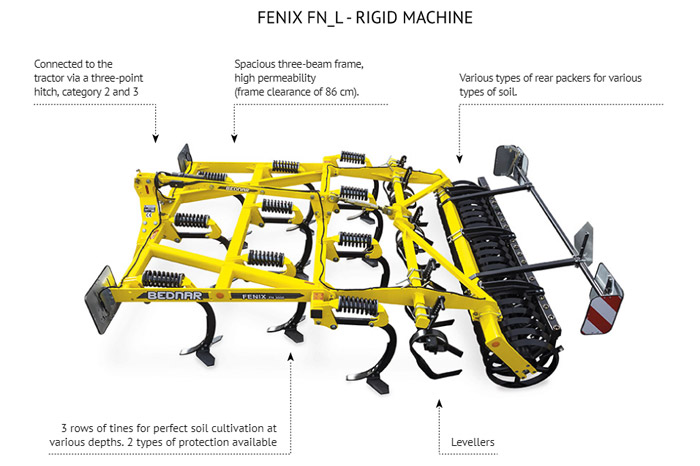

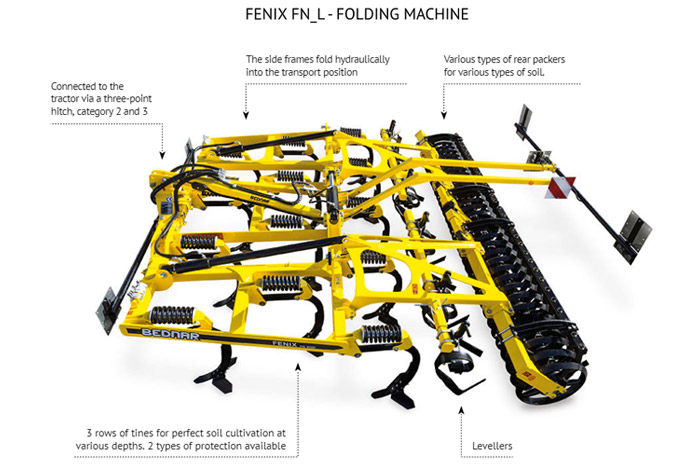

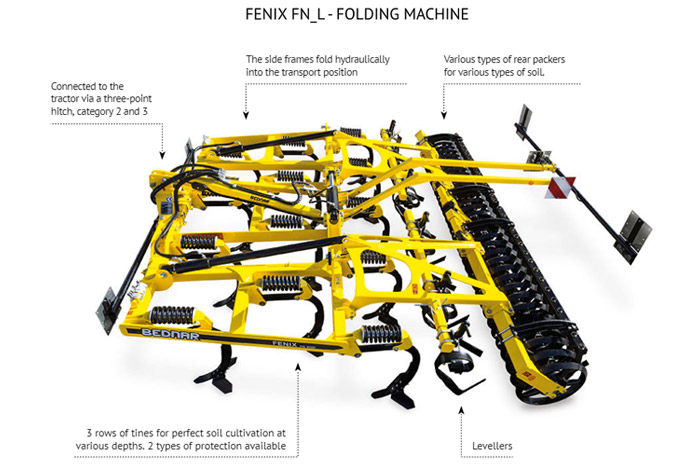

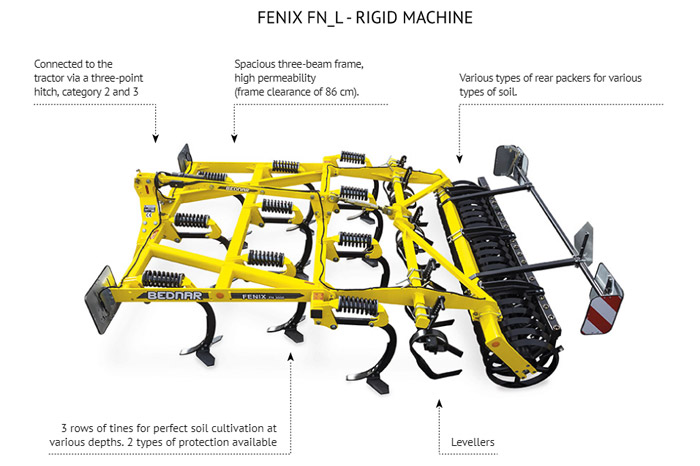

FENIX FN / FN_L

Versatile Cultivator

-

- Versatile use from shallow stubble cultivation to deep loosening up to

35 cm.

- Thanks to spring-loaded auto-reset system.

- High strength thanks to the triple-girder frame of a 100×100 mm profile.

- Wide selection of tines, chisels (standard or Long Life chisels) and rear

packers.

- Excellent machine throughput even with high crops thanks to 80 cm frame

clearance.

- The option of hydraulically setting the working depth directly from the

tractor‘s cabin.

FENIX FN/FN_L is a simple 3-row versatile cultivator suitable for smaller and medium sized farms which are looking for tools that provide options and versatility.

The Fenix FN/FN_L can be used for various working operations from shallow stubble cultivation to deep tilling.

Thanks to the variety of share and chisel types which can be affixed to the tines, you can work at various depths with various tillage intensities.

Chisel Plough

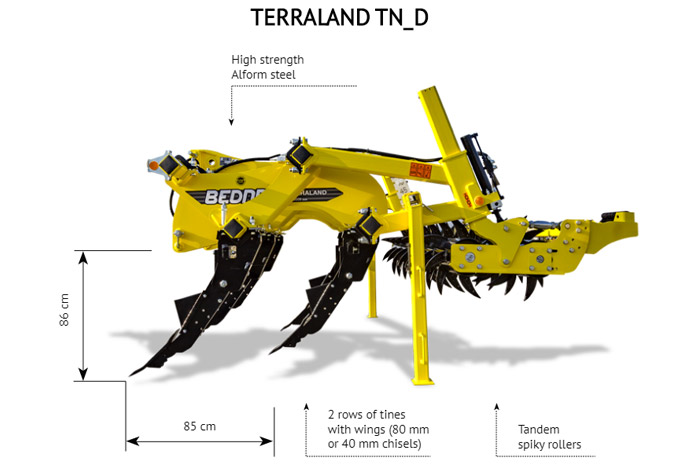

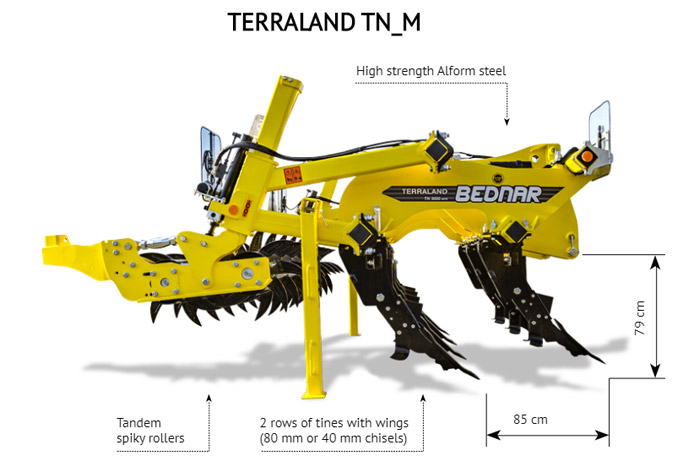

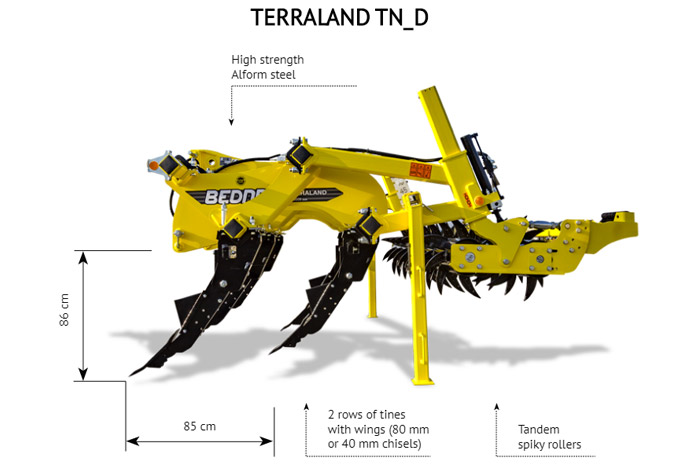

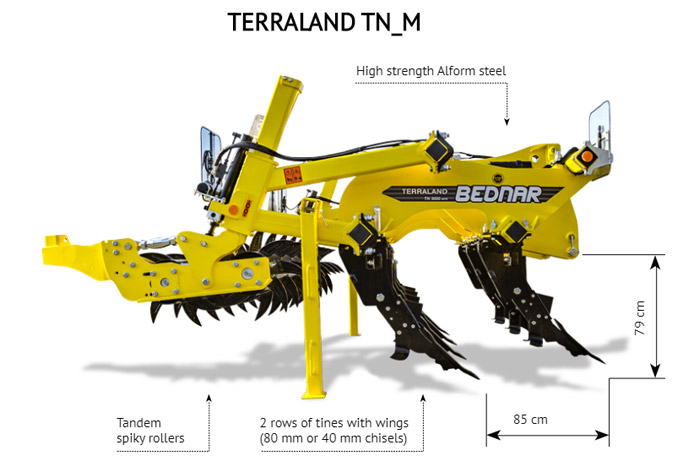

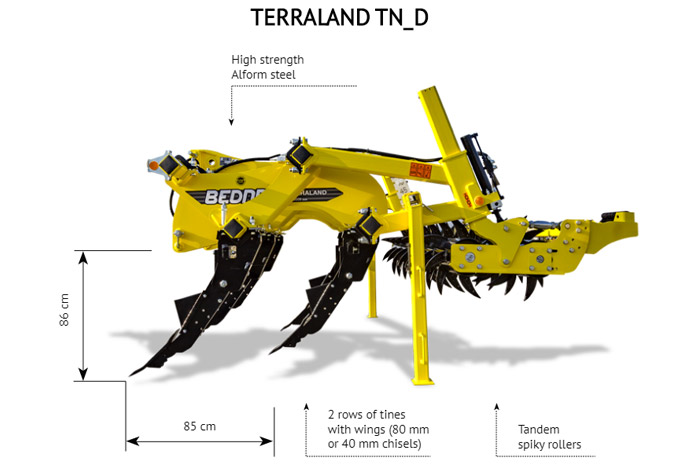

TERRALAND TN

-

- Intensive tillage up to depths of 65 cm.

- 3 times angled operating elements ensure easy soil penetration.

- Quick-Change system – easy exchange of double sided chisels.

- Rigid and solid frame.

- Extremely high throughput of the machine. The frame height is 79/89 cm.

- Made of high-strength Alform steel.

- Disrupting compressed layers paving the way for moisture to roots.

TERRALAND TN is a chisel plough that enables inexpensive, fast and deep soil tillage up to a depth of 65 cm.

The unique design of the tines allows all types of soil to be treated whilst requiring the use of less horsepower.

In practice is appropriate to use the machine in range of depths of 25–55 cm, thus disturbing compressed soil layers and providing an all round healthier soil profile.

The frame is made of high-strength Alform steel.

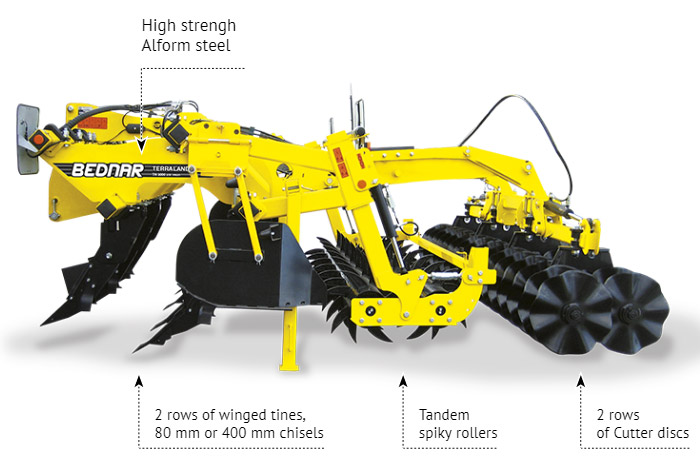

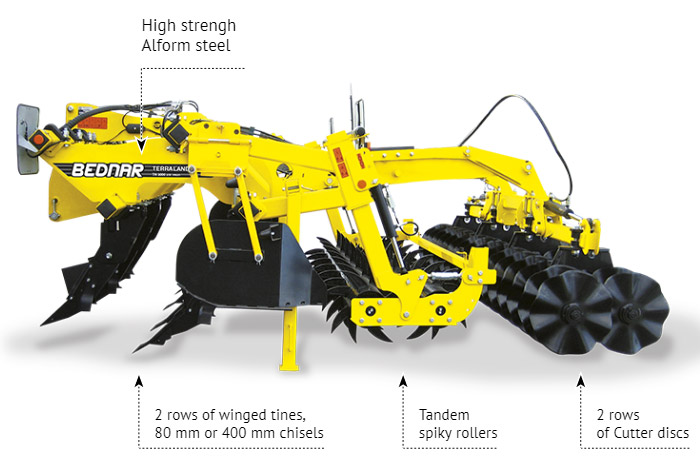

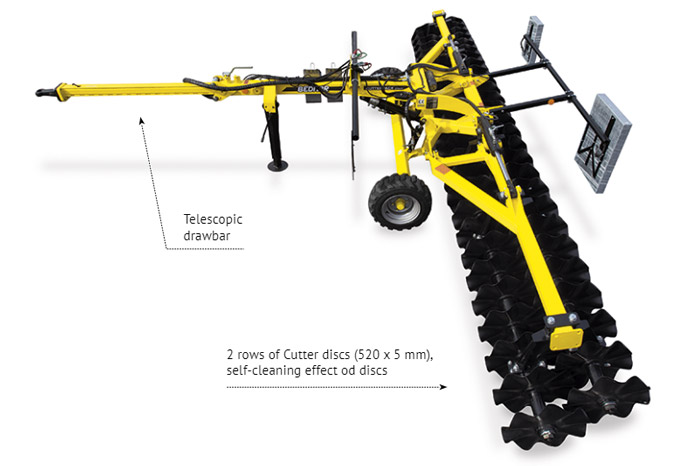

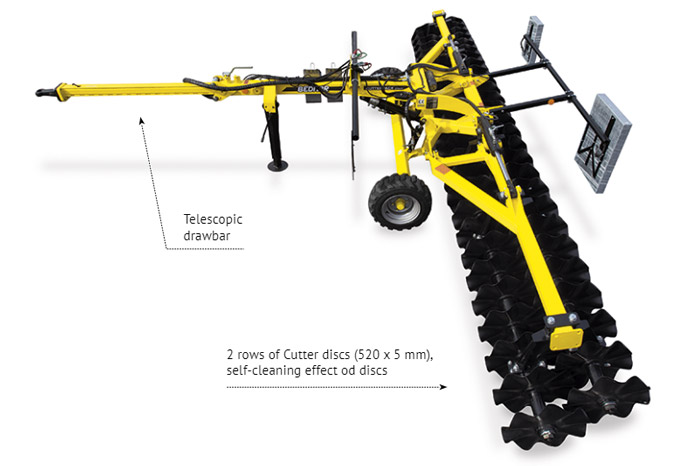

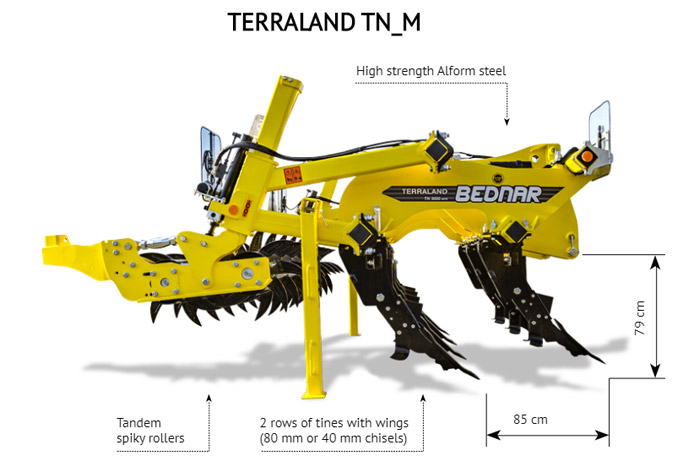

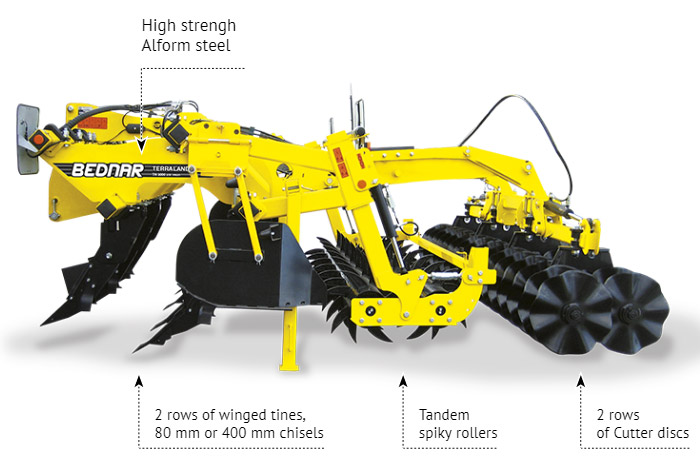

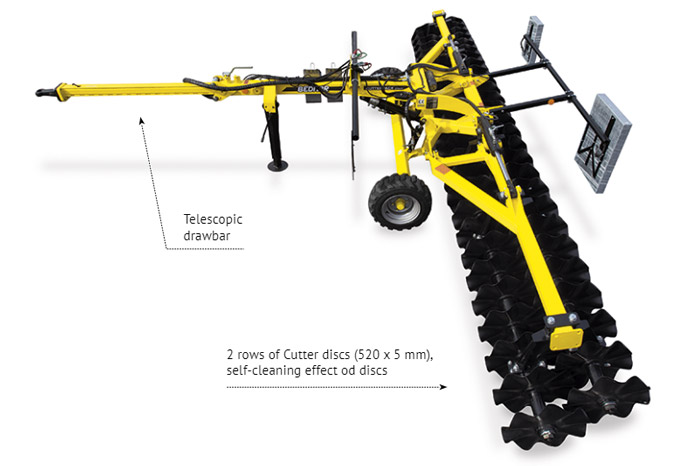

TERRALAND TN_PROFI

-

- Intensive tillage up to depths of 65 cm.

- Extremely high throughput of the machine. The frame height is 79/89 cm.

- Intensive tillage up to depths of 65 cm.

- Made of high-strength Alform steel.

- 2 rows of Cutter discs for perfect finalization.

- 3 times angled operating elements ensure easy soil penetration.

TERRALAND TN_PROFI is a classic chisel plough Terraland TN completed by 2 rows of Cutter discs with self-cleaning effect, which perfectly finalize the work of tines and rear tandem spiky rollers.

The ideal soil preparation for seeding is done by the Cutter discs in one pass.

The Cutter discs are folded up by hydraulics on the machine resulting in smaller dimensions for transportation.

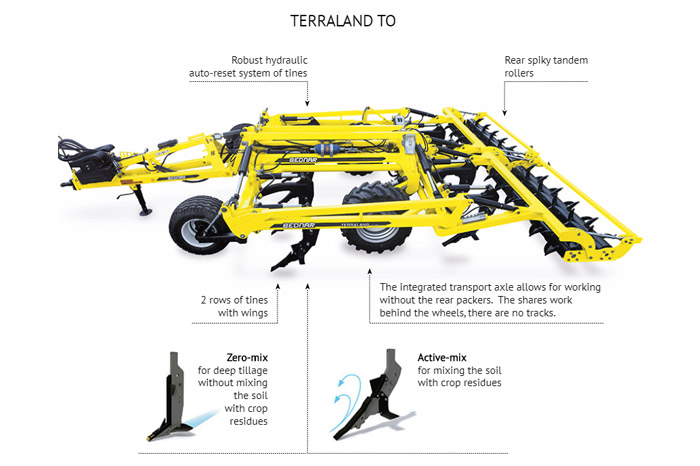

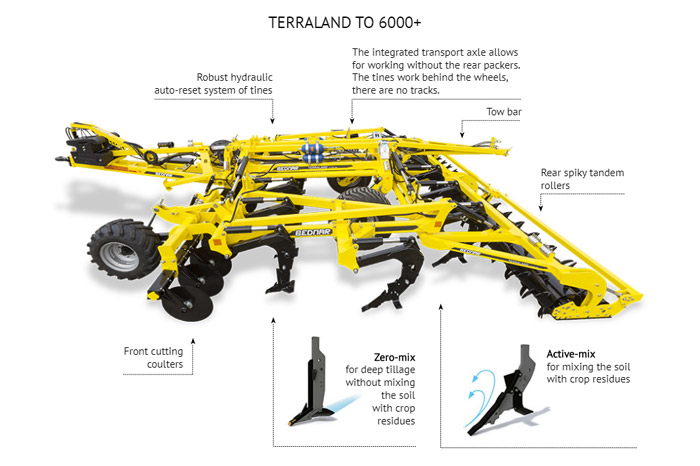

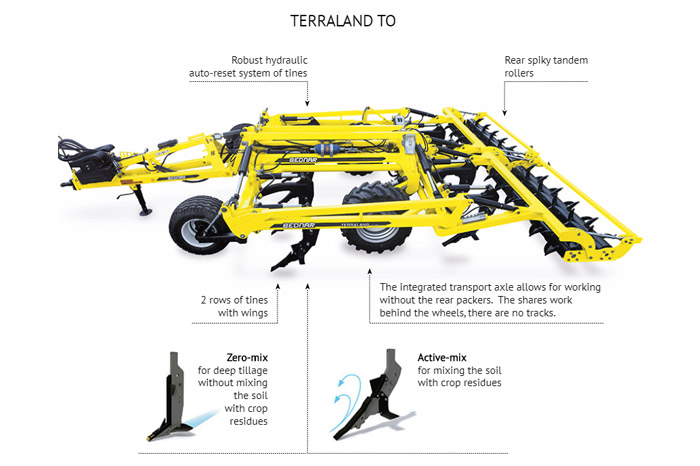

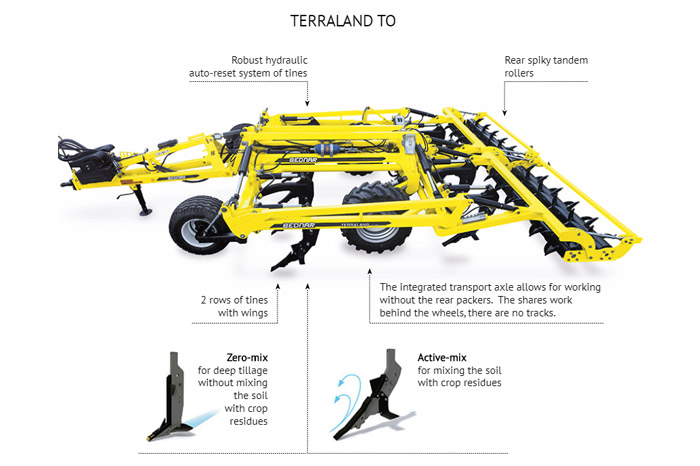

TERRALAND TO

-

- Transport axle placed between tines.

- Transport width of 3 m.

- Extremely high throughput of the machine. The frame height is 79 cm.

- Zero-maintenance side frames, axle and rollers attachment to central frame.

- Trailed packers can be connected to the machine.

- 4-girder central frame.

- Quick-Change system – easy exchange of double sided chisels.

- Intensive tillage up to depths of 55 cm.

TERRALAND TO is a trailed chisel plough for intensive tillage depths of up to 55 cm and working width of 6 m.

The perfect tillage even in hard soils is done by 2 rows of tines and rear tandem spiky roller.

The central frame is formed by 4-girders and the frames of working sections are made of 150×150 mm profile for higher resistance.

The transport axle is placed between tines which enables to work without the roller (e.g. in wet conditions).

Having a rear drawbar means the Cutterpack or Presspack trailed packers can be connected to the machine to finish off the job in hand.

TERRASTRIP ZN

-

- Deep cultivation down to 65cm.

- Alform high-strength steel design.

- Intensive deep tillage of strips for growing row crops.

- Rigid and solid frame.

- Long Life chisels 40mm and 70mm.

TERRASTRIP is a chisel plough which processes soil in strips where row crops such as maize, sunflower, sugar beet etc. grow. The ploughshare spacing is 70cm and 75cm for maize and sunflower, 45cm and 50cm for sugar beet.

We recommend adding profile fertilisation to loosening directly into the root zone of plants. The loosened and fertilized strips create an ideal environment for a rich root system.

Effective and target-oriented soil tillage, which reduces the costs while increasing the yield of the individual row crops.

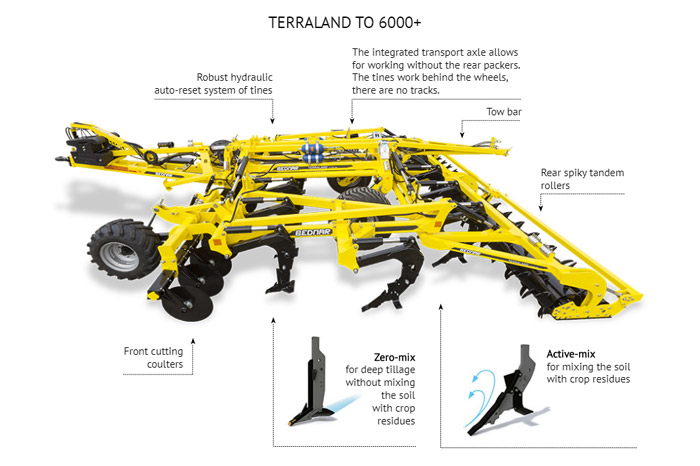

Combined Chisel Plough

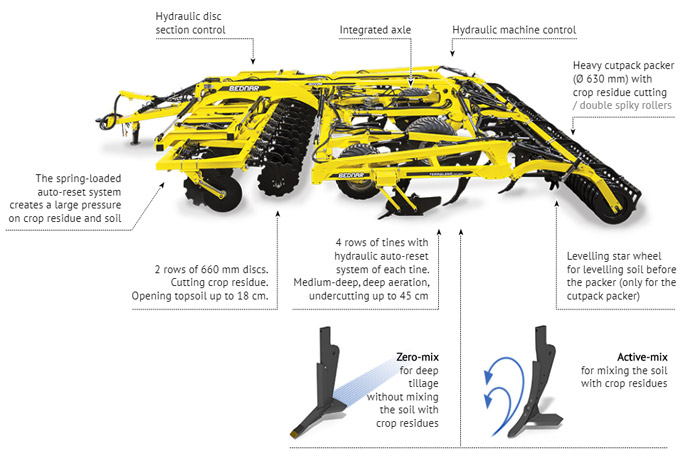

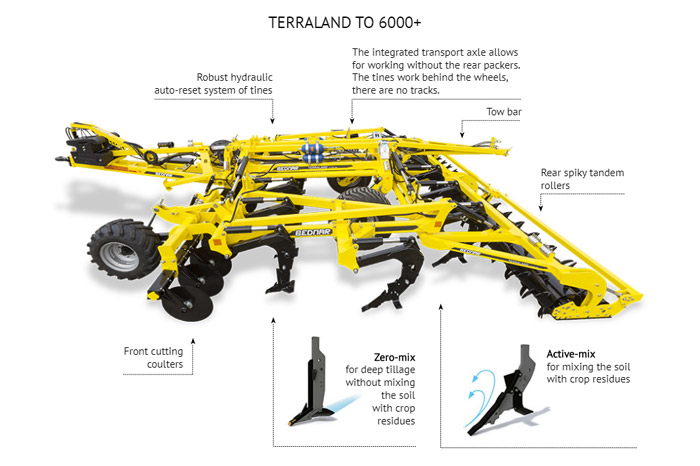

TERRALAND DO

-

- Integrated axle allows the machine to work without the rear packers.

- Excellent cutting of large amounts of post-harvest residue and disruption of

root balls by 2 rows of large 660×6 mm discs secured by the spring

auto-reset system.

- High material throughput thanks to the tines placed in 4 rows (37.5 cm

spacing). It is possible to put every second tine out of operation

hydraulically (75 cm spacing). The auto-reset system of tines is hydraulic.

- 2 types of interchangeable tines: Active- Mix for an intensive mixing of

soil and crop residues, or Zero-Mix for deep tillage of soil profiles

without mixing.

The TERRALAND DO is a robust, combined (discs and tines) machine which can be used for cutting and tilling large amounts of post-harvest residues in a single pass and mixing them thoroughly with loosened soil up to max. 45 cm (Active-Mix tines), or for deep tillage of land without mixing the soil (Zero-Mix tines) also up to a depth of 45 cm.

The machine can be equipped with 2 types of rear packers for various soil conditions.

The machine can also be used with a Ferti-Box (37.5×75 cm) for storage fertilisation, or along the width.

Trailed Packers

CUTTERPACK CT

-

- Prepares the seedbed in a single pass.

- Self-cleaning Cutter discs.

- Crushes clods effortlessly after the previous operations.

- A compact transport length thanks to the telescopic drawbar.

- The perfect levelling effect.

- Can be used separately, or in combination with BEDNAR machines.

CUTTERPACK CT is a detachable packer composed of 2 rows of self-cleaning Cutter discs.

The cutter discs cut crop residue, lumps, and cover crop residue and afterwards levels the surface so that the field is ready for sowing.

The Cutterpack is equipped with a telescopic drawbar, which significantly reduces the transport length.

PRESSPACK PT

-

- Prepares the seedbed in a single pass.

- Self-cleaning steel rings.

- Crushes clods powerfully after the previous operations, especially in heavy

soils.

- A compact transport length thanks to the telescopic drawbar.

- A perfect levelling effect and compaction of the fields.

- Can be used separately, or in combination with BEDNAR machines.

PRESSPACK PT is a detachable packer composed of 2 rows of steel rings, which are designed for the sowing preparation of heavy soil types.

The sharp edges around the rings effectively crush the clods in the toughest soils and level fields.

The Presspack weighs 600 kg/m on compact soil and prevents the loss of moisture that is needed for the next crop.

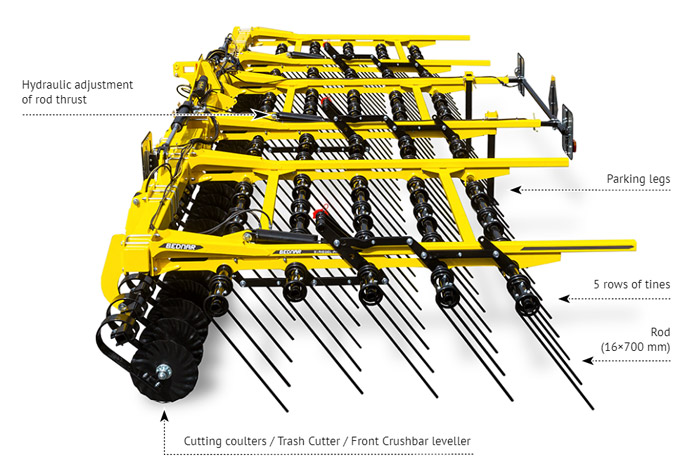

CROP RESIDUE MANAGEMENT

Straw Harrow

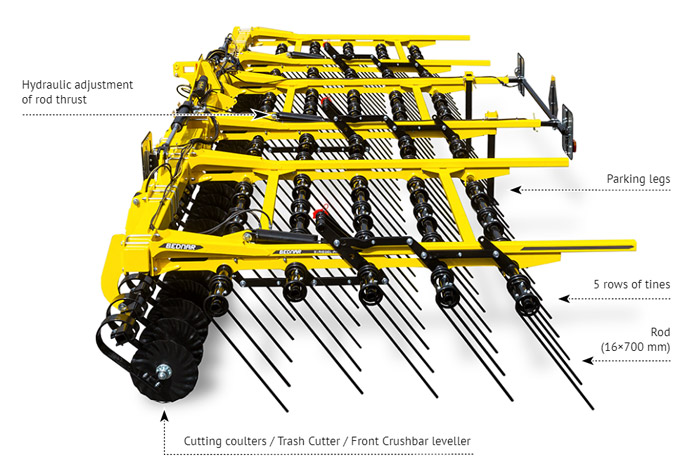

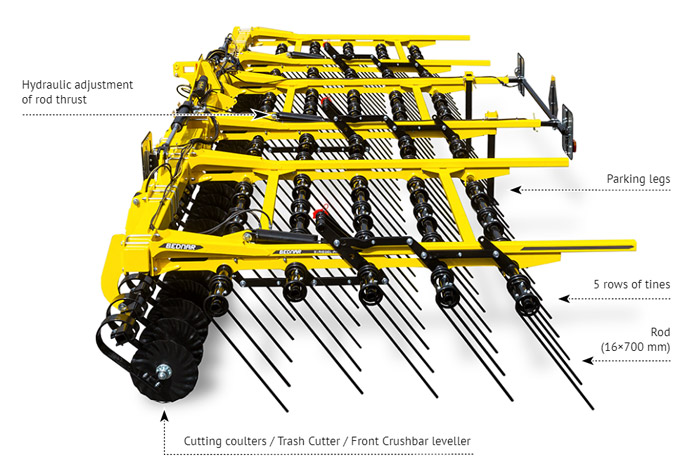

STRIEGEL-PRO PN

-

- Seeding unit ALFA DRILL for establishing of cover crops.

- Meadow and pasture treatment.

- Management of plant remnants after harvest, spring preparation on heavy

humid soils.

- Hydraulic adjustment of the tine working angle.

- Cutting coulters or cutting roller Trash Cutter for disruption of the stalks

and uncut stubble or hydraulic bar – Crushbar for spring preparation.

STRIEGEL PRO PN is a 5-row field harrow used for solving the management of post-harvest residues for their harrowing, activation of weed grain growth, for restoring the permanent grass growths, and seedbed preparation up to 4 cm in the spring season.

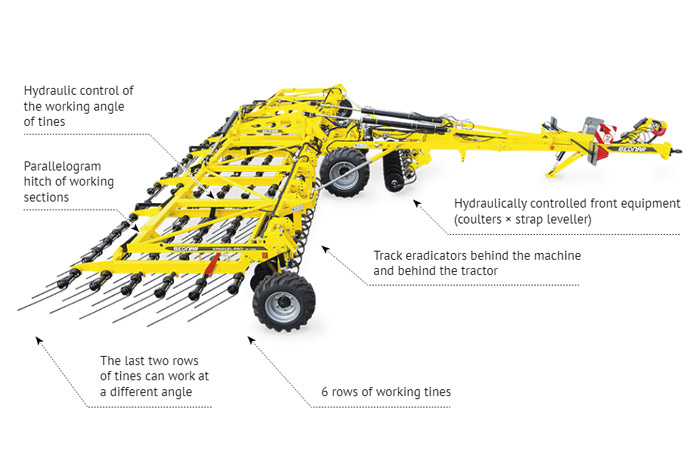

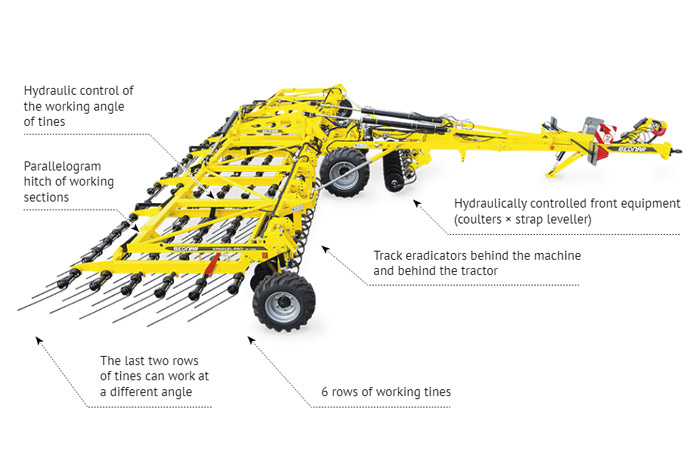

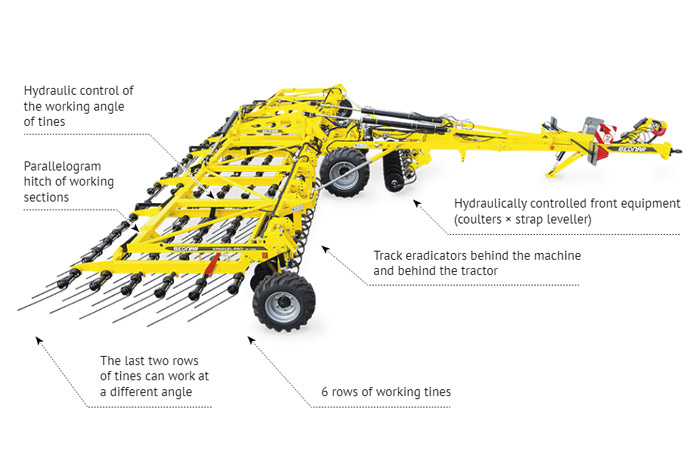

STRIEGEL-PRO PE

-

- Perfect surface contouring thanks to the independent seating of the

working sections on the parallelogram linkage.

- Cutting coulters for disrupting stems and stubble residue or hydraulic –

Crushbar leveller for spring preparation.

- Independent working angles of the first section (4 rows of tines) and the

second section (2 rows of tines).

- 6 rows of tines with large overlap guarantees a good integration of

material.

- Management of crop residue after harvest, spring preparation of heavy and

wet soils.

STRIEGEL-PRO PE series is 6-row straw harrow equipped with two independently hydraulically controlled working sections of tines.

The first section includes four rows of tines that disrupt the top soil layer at 2–4 cm. The second section includes two rows of tines for final surface treatment.

In addition, the machine may be equipped with cutting coulters for summer management of crop residue in the stubble-field.

For the spring preparation, the machine may be equipped with a front hydraulically controlled leveller – Crushbar for top soil levelling. The paddles of the levelling bar can be mounted on the coulter tines and vice versa.

Slashing

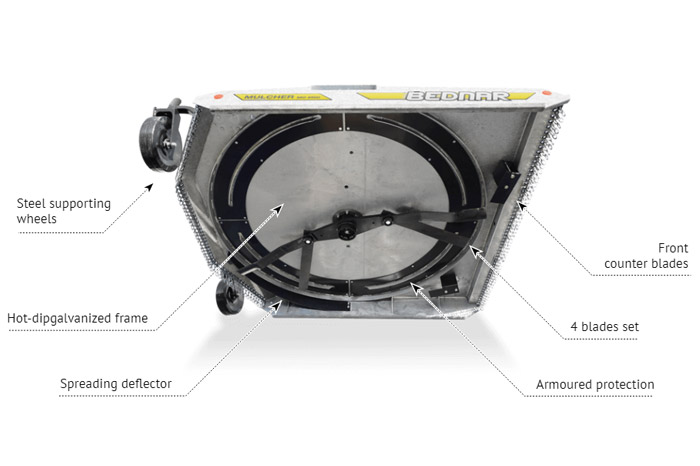

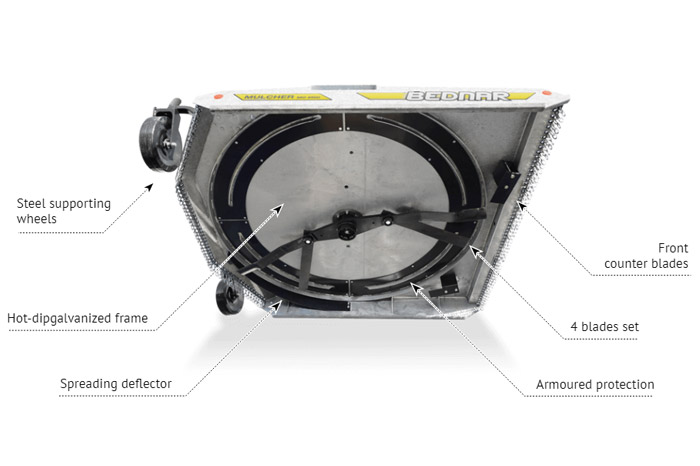

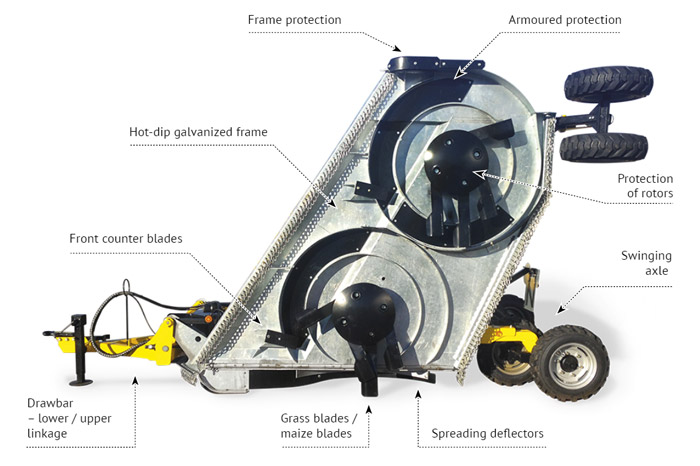

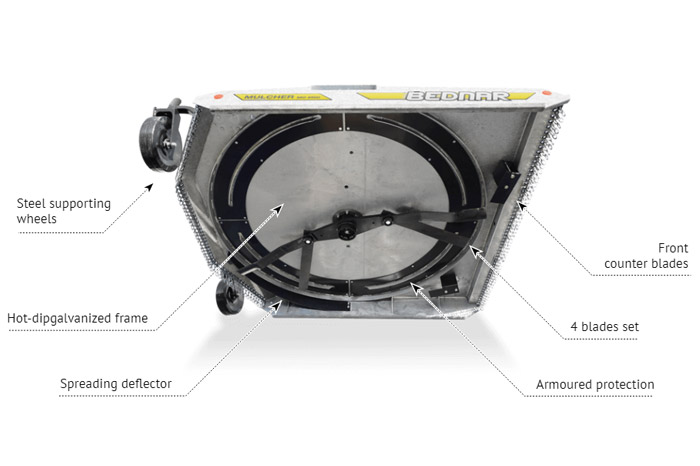

MULCHER MO

-

- Excellent maneuverability in complicated terrain.

- Galvanised zinc coated machine bodies

- The solution for smaller farms and forest management.

- Armoured protection from damage preventing.

- Universally applicable to both perennial grassland and arable soils.

- Shielding from damage with the help of the friction clutch.

MULCHER MO is a mounted single rotary cutter that mulches perennial grasslands and crop residue in arable soils, or self seeded trees.

The MO model is manufactured with a galvanised hot dip finish and is an excellent option for smaller farms, municipalities or mulching the vegetation in the woods.

The machine is aggregated to a tractor with 3-point category II. hitch.

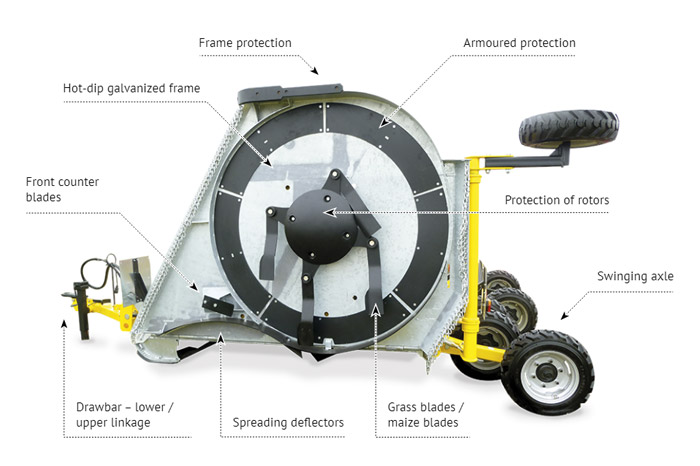

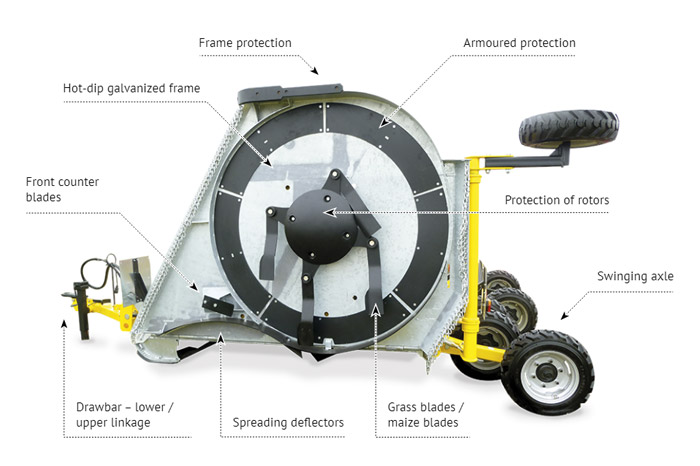

MULCHER MZ

-

- Rigid and solid frame ready for extreme seasonal output

- The main components of the machine have been galvanized increasing

resistance to the elements and plant acid juices.

- Armoured plating at the bottom of the machine prevents puncturing from

stones during the working process.

- A choice of blades for grassland or maize, designed to cut vegetation on

arable soil as grain maize, sunflower, etc.

MULCHER MZ rotary cutter is designed for mulching perennial grasslands, crop residue on arable soil (maize, sunflower, canola, etc.) and self-seeded trees.

Working widths of 4,5 and 6 m combined with the machine’s high work rate guarantees a top of the range performance at a low daily operating cost.

The robust construction of its zinc coated body makes it the ultimate machine for use in some of the harshest conditions known to farming.

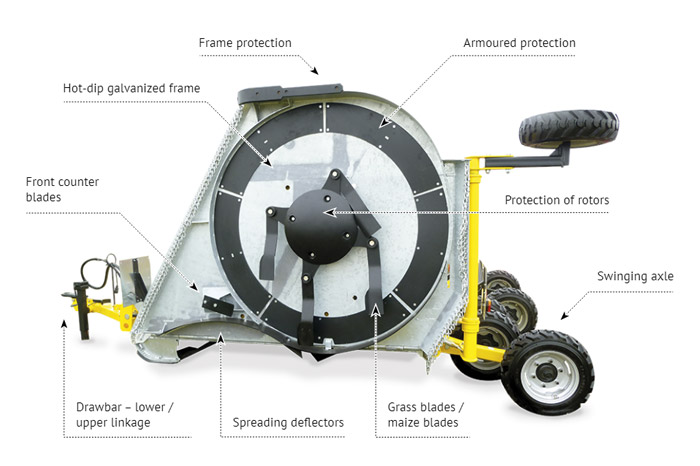

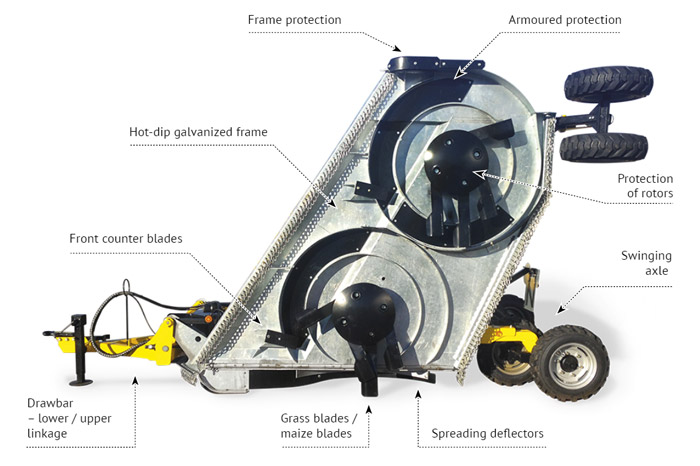

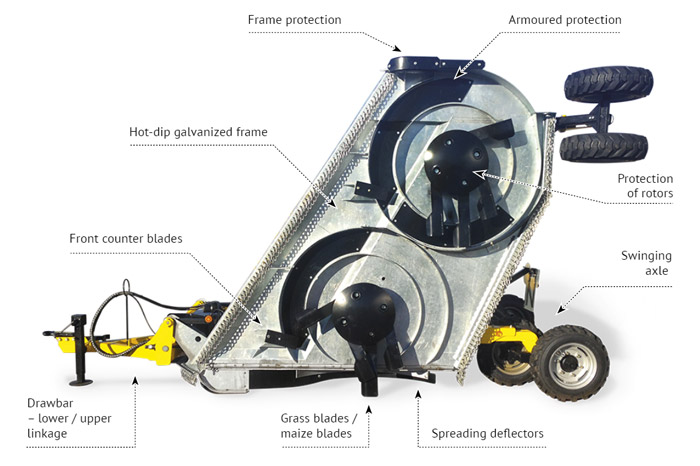

MULCHER MM

-

- Rigid and solid frame ready for extreme seasonal output

- A choice of blades for grassland or maize, designed to cut vegetation on

arable soil as grain maize, sunflower, etc.

- The main components of the machine have been galvanized increasing

resistance to the elements and plant acid juices.

- Armoured plating at the bottom of the machine prevents puncturing from

stones during the working process.

MULCHER MM is a wide rotary cutter, which mulches perennial grassland, crop residue on arable soil (maize, sunflower, canola, etc.) and self-seeded trees.

The robust construction of its zinc coated body makes it the ultimate machine for use in some of the harshest conditions known to farming.

The machine with the working width of 7 m which destines this machine for optimal daily performance.

INTER-ROW CULTIVATION

Inter-Row Cultivation

ROW-MASTER RN_S

-

- Precise inter-row cultivation with elimination of weeds and weed beet.

- The silent-block seating of the working units increases down pressure on the

soil

- Disruption of the soil crust provides more air for the sugar beet crop.

- The CultiCam precise optical self-guiding allows cultivation from the start

of the growth of the crop.

- Maintenance-free parallelogram linkage with a support depth wheel.

- 3 types of working parts – 3 shares for early cultivation, 1 share + 2

chisels for late cultivation, ridging bodies.

ROW-MASTER RN_S is an inter-row cultivator designed for the disruption of the soil crust and regulation of weeds in the sugar beet crop.

The cultivator has various working parts (shares, chisels, ridging bodies) with a varied setting variability so that it is possible to respond to the current soil conditions and the size of the crop.

Each working unit operates on a parallelogram linkage seated on silent blocks. This unique maintenance-free design creates permanent down pressure on the support wheel.

The machine may be equipped with the CultiCam device, which can navigate the machine starting at two true leaves of the sugar beet, thus allowing for very early inter-row cultivation.

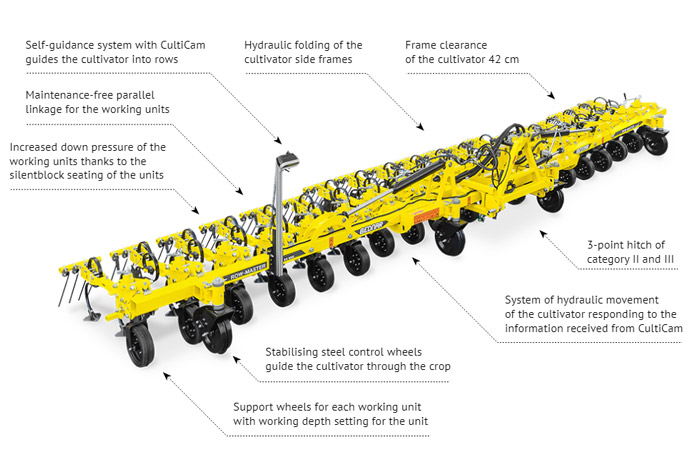

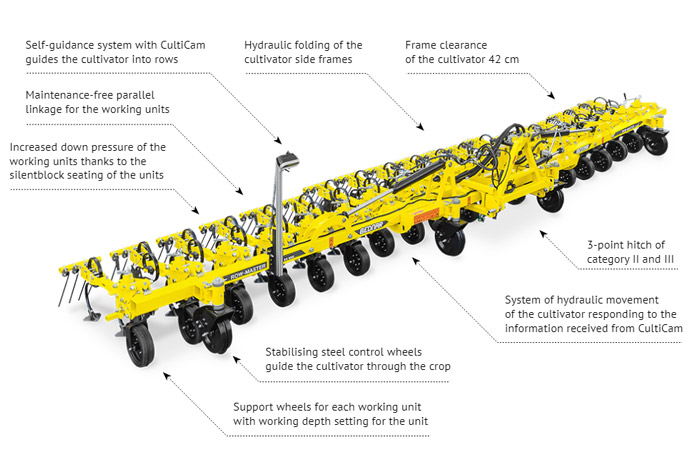

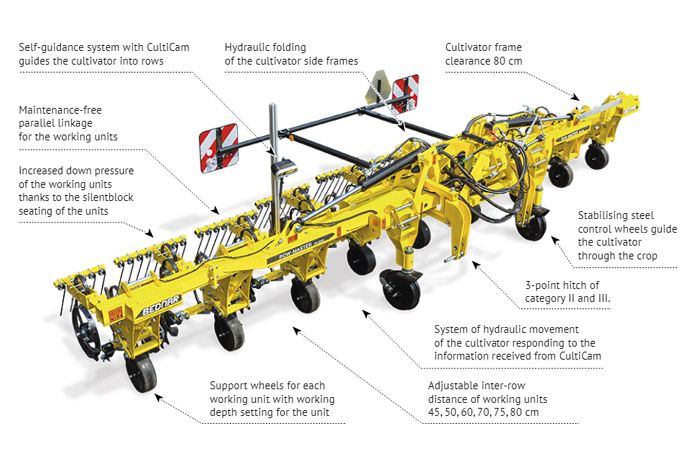

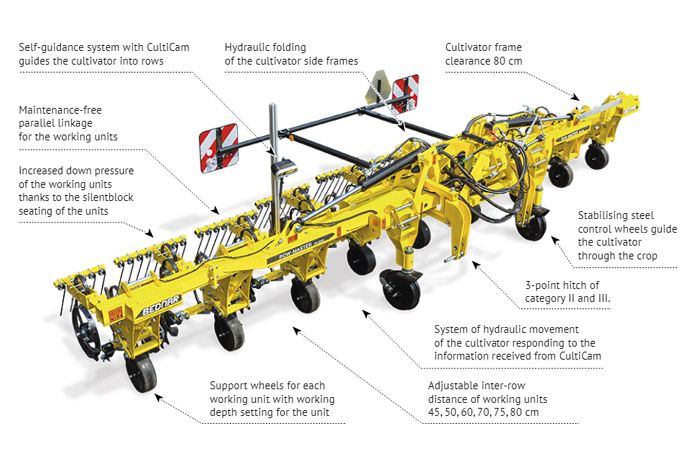

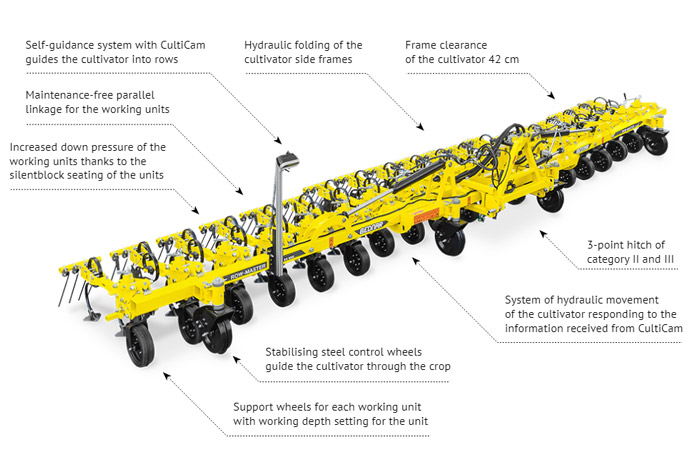

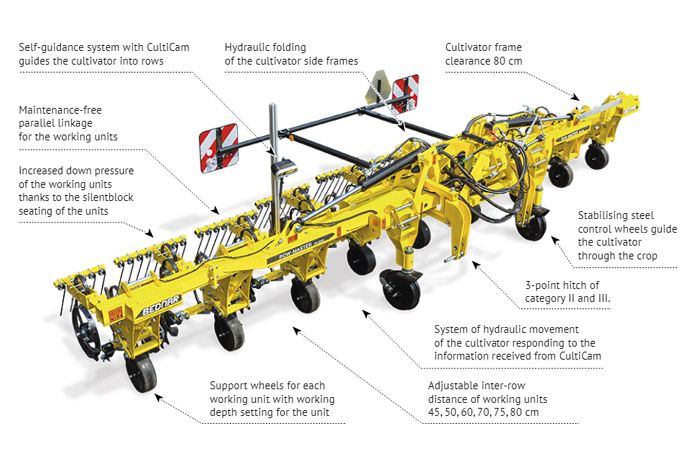

ROW-MASTER RN

-

- Universal robust frame for several types of working sections and a great

variability of inter-row spacing.

- Maintenance-free parallelogram linkage with a support depth wheel.

- Several types of working parts – shares for early cultivation, share and

chisels for late cultivation, chisel with mouldboard for tough conditions.

- Large frame clearance of 80 cm.

- The silent-block seating of the working units increases down-pressure on the

soil.

- Possibility of side-dressing the crops – granular or liquid fertilisers.

- The CultiCam precise optical self-guiding.

The ROW-MASTER RN is a universal inter-row cultivator designed for the disruption of the soil crust in maize, sunflower, sugar beet and other row crops.

Massive frame with high clearance allows cultivation even of high crops. Each working unit operates on a parallelogram linkage seated on silent blocks. This unique maintenance-free design creates permanent down-pressure on the support wheel and improves the entry of working parts to the soil.

The machine may be equipped with the CultiCam device which can navigate the machine as early as from the first emergence of the crop.

Line cultivation

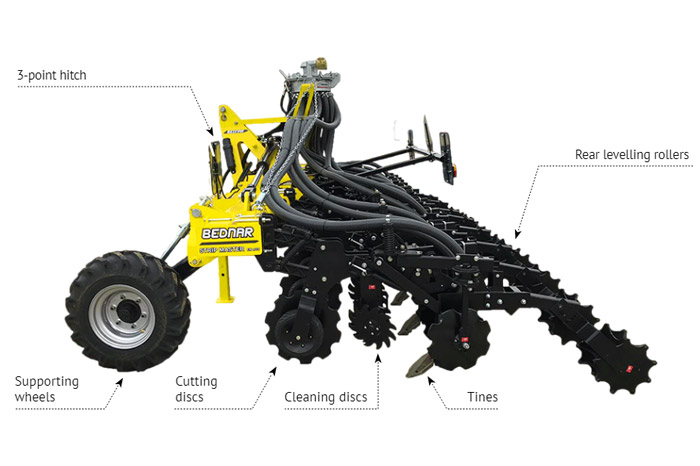

STRIP MASTER EN

Strip-till / Chisel plough

-

- Row cultivation.

- Loosening up to the depth of 35 cm.

- Cleaning the lines from plant residues.

- Breaching hardened layers

- Fertiliser depositing into two layers

- Individual working units on a parallelogram

The STRIP MASTER is a line cultivator that processes soil in strips of 75 cm (70 cm) up to the depth of 35 cm. The machine excels with perfect line processing and cleaning of those lines from plant residues, namely even a large quantity of post-harvest residues, e.g. after harvesting corn for grain.

The STRIP MASTER machine is suitable for the technology of soil processing for the protection of soil against water and wind erosion.

The machine allows for application of both mineral and liquid fertilisers including liquid manure or digestate from biogas