Navigation : EXPO21XX > AGRICULTURE 21XX >

H22: Wood Processing, Handling & Transportation

> Bezner-Oswald

Bezner-Oswald

Videos

Loading the player ...

- Offer Profile

- OVER 100 YEARS OF WOOD INDUSTRY KNOWLEDGE AND EXPERIENCE

It all started in 1978 when N.M. Heilig B.V. was founded by Nicolaas Maria Heilig. The company started out with one welding machine, followed by the maintenance and production of various machinery. These services were the cause of an unrivaled success and, during the years, lead to specialization and acquisition of related businesses in machinery and installations for the bulk handling and recycling industry.In 2007, Bezner Anlagen- und Maschinenbau became part of Heilig Group. After that, in 2010, Heilig Group took over the Austrian Oswald Maschinenbau. The development in screening installations lead to a further diversification in recycling machines and conveying systems. To serve their particular market in the wood industry and the recycling industry, respectively Bezner-Oswald and Bezner Anlagen- und Maschinenbau GmbH went their separate ways.

Product Portfolio

TECHNOLOGY FOR FOREST WOOD, TIMBER INDUSTRIES, AND SAWMILLS

- Wood is a material that has been used in, for, and by many industries and households all over the world for centuries. A natural resource provided by mother nature. Free of charge. However, harvesting, processing, transportation, and woodworking are economic factors that make wood an expensive resource. Aside from this financial perspective, we also need to treat it with the utmost respect, making sure not to harm the environment.

If you are a company that processes forest wood, you can relate to the need for machines to be robust, efficient, and low in maintenance. That is precisely what we at Bezner-Oswald have been supplying our customers for more than a century. Not just single unit machines, but complete wood and timber or lumber processing installations. We think of ourselves as a company offering solutions rather than machines. That is why we are partners of the largest sawmill industries on the globe. WHAT WE CAN DO FOR YOU

WOOD PROCESSING AND WOODWORKING

- Whatever branch your company covers within the industry of wood processing and woodworking, wood as a natural resource needs to be grown and harvested first. Second, logs go through the initial woodworking process, for instance peeling or debarking. Next, wood is cut in sawmills and being processed into valuable products, from semi-final products to consumer products. Every step in the process adds value to the woodworking chain.

Wood processing includes various branches such as timber processing, sawmills, timber merchants, carpenters, roundwood producers, lumber yards, construction companies, and companies in the paper and cardboard industry.

Bezner-Oswald designs and manufactures machinery especially for organizations who process logs into semi-final products. We distinguish:

Timber | every activity to transform logs into wood ready for further processing. Think of machines for peeling, rounding, profiling, chamfering and pointing, and sawing.

Timber residues | every activity to maximize the application of lumber residues. Sawmill residue material is further processed in, among others, wood fiber products, OSB (oriented strand board), biomass, firewood. Think of machines for conveying and screens for sorting and batching wood chips, shavings, and sawdust.

REPAIR AND MAINTENANCE OF WOODWORKING MACHINERY

- Woodworking machines for the processing of logs require periodic inspection and maintenance to guarantee an optimal, reliable, and continuous production process and reduce downtimes. The experts of Bezner Oswald are qualified and experienced to execute both technical and electrical inspections and repairs on any installation, regardless of the brand. Based on your requirements, we offer the following agreements:

MAINTENANCE & REPAIRS

Timely maintenance and/or well-executed repairs with original parts keep your installations up-and-running in perfect condition. Besides equipment examinations, also lubrication, oil changes, and overhauls of parts or units can be included.

MODIFICATIONS

For upgrading, overhauling, and relocation of full installations or single units, Bezner Oswald offers their consulting, engineering, and manufacturing services to improve your recycling or bulk handling process.

INSPECTIONS & RISK INVENTORY

Regular inspections decrease unexpected repairs and expenses and reduce downtime. Our field service engineers check your installations on a standard number of points, e.g. operational safety, wear and tear, mechanical and electrical controls.

MACHINES FOR TIMBER, LUMBER, LOGS, AND ROUNDWOOD

- We have been supplying our clients, for instance sawmills, in the roundwood, timber, lum-ber, and log processing industry for over a century.

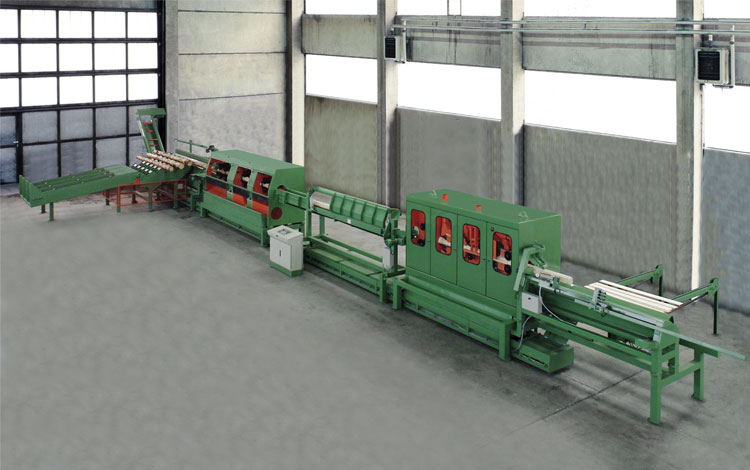

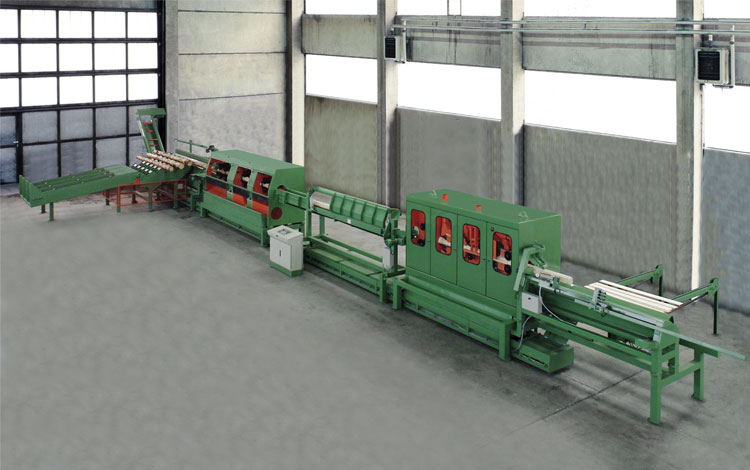

Please take into account that nearly every machine can be produced according to your needs, whether you require peeling, rounding, profiling, sawmills or screening. Conveying systems can bring single units to a complete wood processing line.

WOOD PEELERS FOR DEBARKING POSTS AND POLES

- For peeling and debarking roundwood, Bezner-Oswald designs and manufactures log and pole peelers for various dimensions. This type of forestry machinery can be customized to your requirements and provided with manual or automatic controls.

POST PEELER WP 35

The post peeler WP 35 is designed to handle roundwood with a diameter between 4 and 20 cm and a length between 0.7 and 6 meters. At your request, we manufacture the WP 35 as a manually operated machine or completely automatic integrated into a full peeling line.

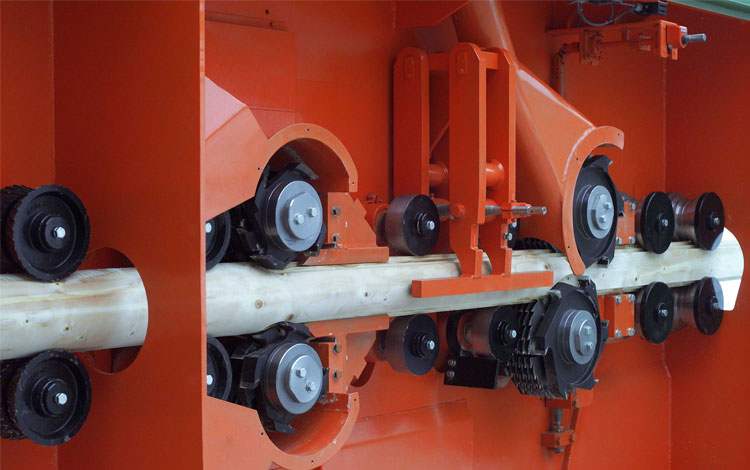

POLE PEELER FML

Still a single pass of rods and poles, but the Pole peeling machine FML handles roundwood with a diameter between 8 and 40 cm. The minimum length is 4 meters. The 8 spiral milling cutters gimbal-mounted in 2 peeling heads cut over the rotating wood in the fibers’ direction. The strong log debarking machine cuts through knots, butt swellings, and other difficult log parts. This results, even with dry wood, in splinter-proof and smooth poles.

FAST PEELER RSA I & II

Fast peeling machines are equipped with simple peeling discs for clean debarking of posts and stakes by hand. Bezner Oswald offers 2 types of fast peelers.

FAST PEELER RSA I

This type is designed with either a cutter disc to adjust the cutters in the machine or with carrier plates to adjust the cutters outside the machine. The last version offers a quick and accurate method of changing the cutters. The RSA I is commonly used for the occasional peeling of posts and palisades and for recleaning and pointing logs up to 12 cm in diameter.

FAST PEELER RSA II

This type is designed with a larger peeling disc and a stronger driving power. With the RSA II, you can manually peel, point or chamfer roundwood up to 25 cm in diameter.

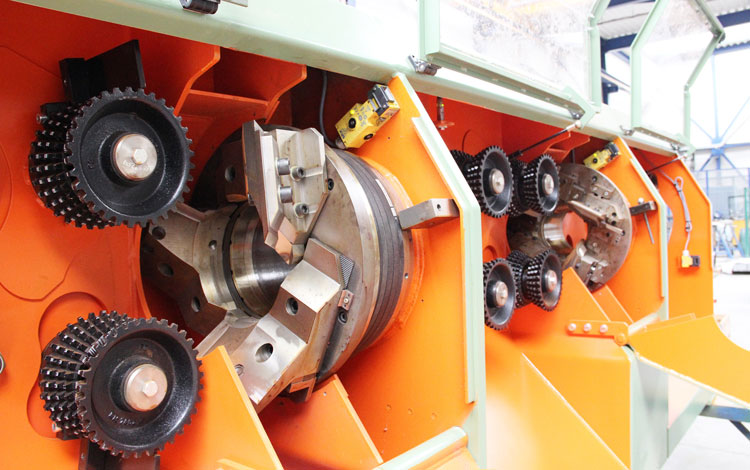

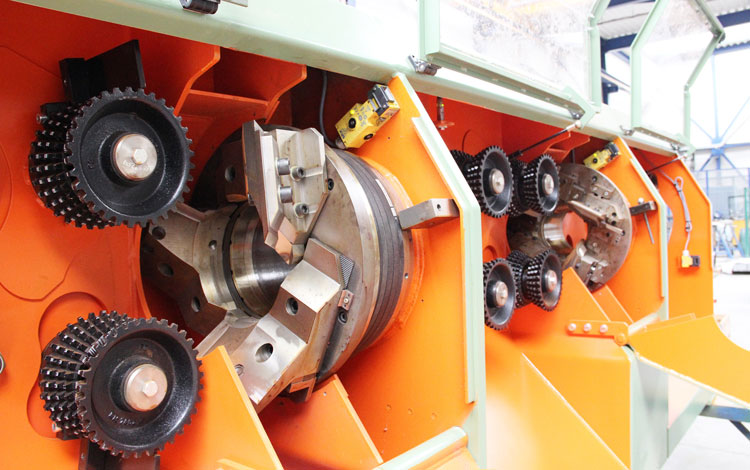

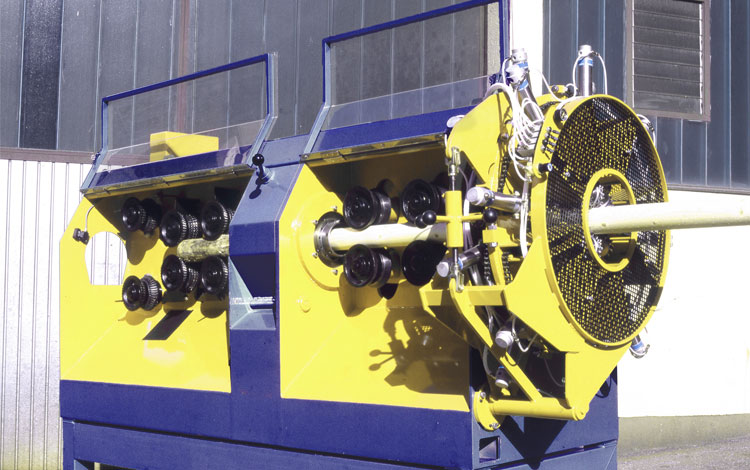

MODULAR-DESIGNS OF WOOD ROUNDING MACHINES

- The wood rounding machines Bezner-Oswald offers, are available in various models for different kinds of roundwood. Depending on your requirements for cylindrical logs or wooden dowels, we design machines provided with single or double heads.

Rounding heads are equipped with 3 or 4 knife holders. An alternative option is to apply 6 knife holders when smoothing and roughing knives are not mounted together within one knife holder. On average designs, the in-feed speed could reach 35 meters per minute.

We offer many modular types covering log sizes with a diameter from 30 up to 400 mm.

PROFILING MACHINE

- A profiling machine that does more than just profiling. At Bezner-Oswald, we design and manufacture machines from standard milling solutions up to fully integrated profiling installations. Planing and profiling in one machine which is made to measure.

The advantage of a customized profiler and planer machine is that you can choose for single or multiple milling stations, with milling heads fixed to order. This way the machine fits your installation perfectly and can be operated continuously. Also, it will produce any log size you desire, e.g., log house boards or simple square logs.

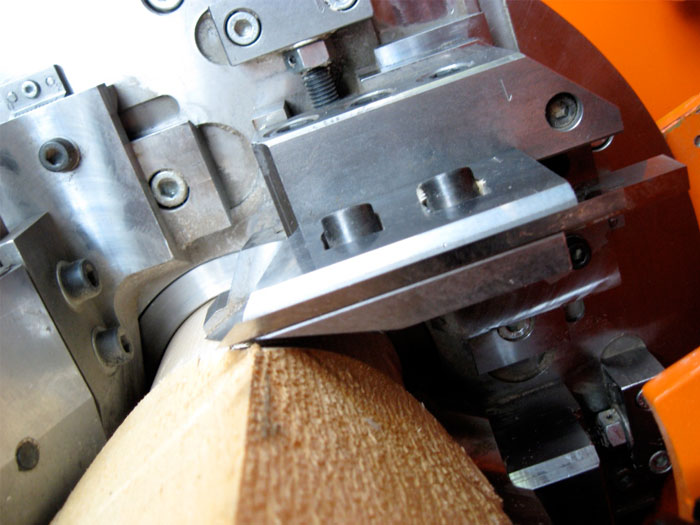

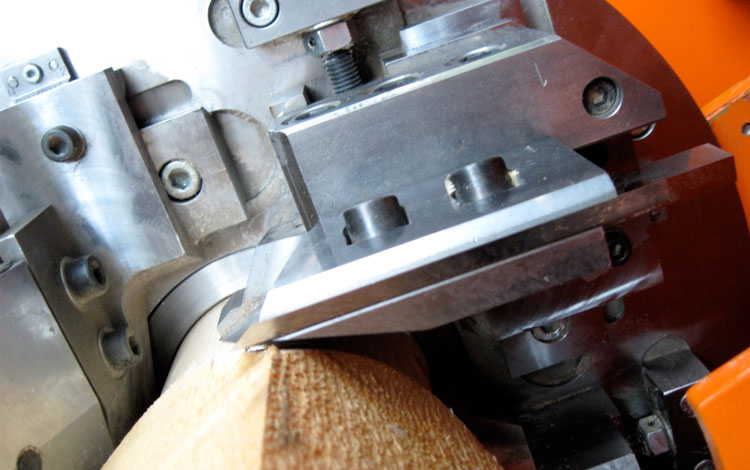

CHAMFERING AND POINTING MACHINE

- To chamfer and point your roundwood, Bezner-Oswald supplies a wide variety of machines. You can choose from manually operated, semi-automatic to full-automatic with CNC controlled machines. Apart from the manually operated versions, your machine can be tailored to produce either square or round points and chamfered edges.

The frame consists of a sturdy welded construction, while the entire chamfering unit is mounted on pneumatic cylinders. The pointing and chamfering section includes of a fixed chain track with peeling rocker. First, the wood is pointed after which is proceeds via a wheeled track with a chamfering unit.

A slip-on geared motor flanged to the housing of the motor rocker drives the peeling disk of the sharpening station. On the peeling disc, 6 knife holders with knives are mounted at a 60 ° angle polar. The planar surface of the peeling disc is milled according to the knife arrangement at a 40 ° angle to the axis of rotation. After each sharpening section, the roundwood is rotated at 90 ° through motor-driven friction wheel.

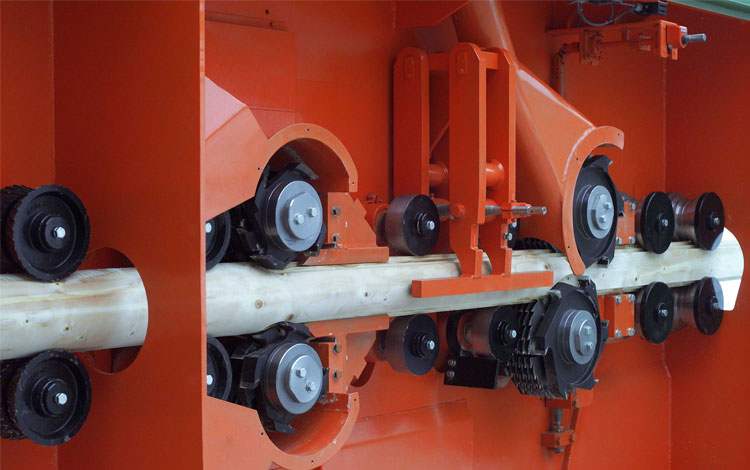

CONVEYING SYSTEMS FOR AUTOMATED TIMBER PROCESSING

- To convey roundwood in lumber processing operations, Bezner-Oswald offers a range of conveying systems. Every unit transports poles, logs, or roundwood in many varieties of lengths and diameters. Our scope includes:

- chain conveyors for logs

- belt conveyors for log in-feed and out-feed

- waste or residue conveyors

- buffer storage and stock conveyors

- longitudinal chain conveyors

- post peeler chain conveyors

- sorting conveyors step feeder (log feeder)

Of course, an automated wood processing line is composed of durable and high-quality units for rounding, profiling and chamfering in conjunction with material handling systems. Therefore, Bezner-Oswald is specialized in designing turnkey solutions for the timber industry. Besides tuning the handling capacity of the conveyors to the required dimensions of your roundwood, also the dimensions conveying machines themselves can be customized. According to your requirements, we can combine separate units into an efficient production line.

SCREENING MACHINE FOR FRACTIONING SAWMILL RESIDUES IN A SINGLE PASS

- The horizontal screening machine is a unit to invest in for fractioning sawmill residues such as shavings, sawdust, and wood chips. Economic and environmental factors increase the demand for these residues turning them into semi-finished materials for the wood-pulp industry. To illustrate, think of production facilities of panelboards, MDF, and paper.

Screens separate materials based on the difference in particle size. The ultimate residue recycling occurs when you can offer clean material. This entails materials of the same particle size in one batch without any contaminations like pins, bolts, nails, etc.

The screen machine Bezner-Oswald supplies, can separate sliced particles, sawdust or wood chips into several fractions (maximum 6) during a single pass. Dust is the first fraction (fines), while the most coarse materials are separated at the end of the screening process. Bezner was the first sawmill machinery manufacturer to include a swinging element in their screens. This element provides a steady and nearly noiseless separation.

Advantages of the Bezner-Oswald screening machines include:- over one century of experience in designing and manufacturing screens for the timber industry

- swinging element for steady and quiet screening

- durable and robust construction

- easy to operate and low maintenance

- optional sprinkler system for fire protection

- optional beat-ball cleaning system

PERFORATION MACHINE

- If your finished products require a perforation, you may want to include a perforation machine in your timber processing line. The perforation device can be mounted at the end of the rounding machine. At this point in the process, the poles will pass the device, and the perforation is automatically made.

The perforation machine Bezner-Oswald designs is equipped with 16 wheels for smooth and precise conveyance. Of course, the depth of the perforation depends on the type of wood and machine settings.

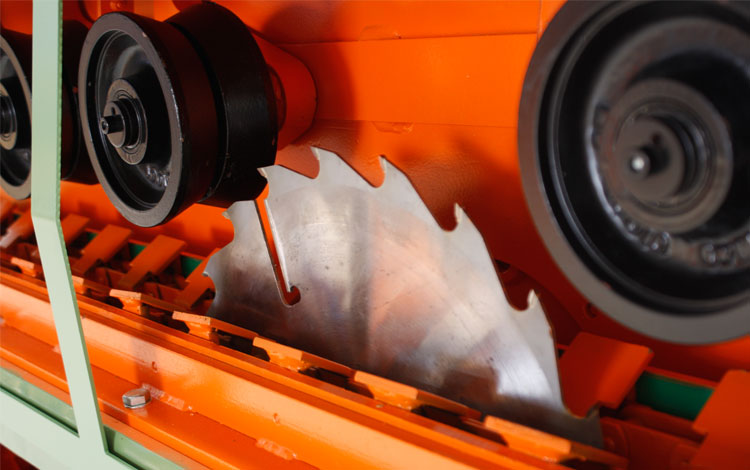

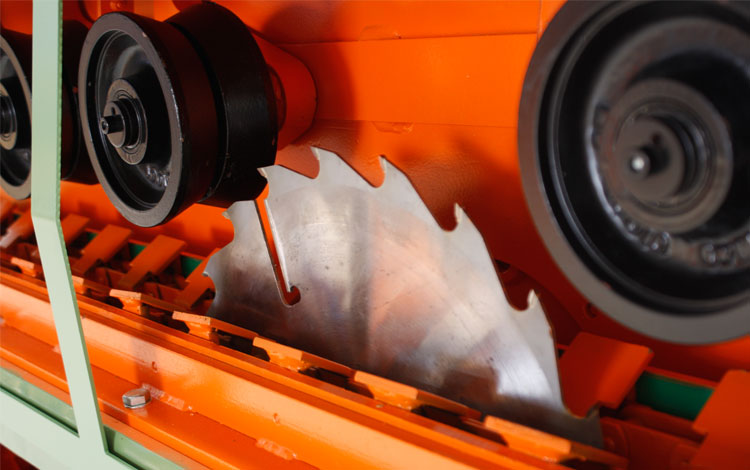

SAWS FOR THE SAWMILL, WOOD, AND TIMBER INDUSTRY

- Today, the growing awareness about the scarcity of nature’s natural resources rises our valuation of these materials. We have to put these resources to use moderately. Subsequently, enabling the sawmill industry to be competitive and efficient, timber and lumber production companies require durable and cost-effective machinery. They rely on machines that offer them a high throughput and high-quality finishing.

Bezner-Oswald offers a line of saws that can be supplied a stand-alone machine or integrated into a lumber production line. Many installations we have built in the past still run today.

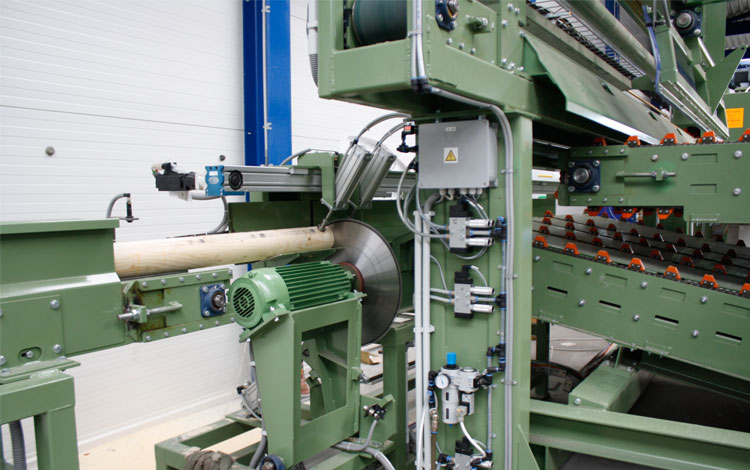

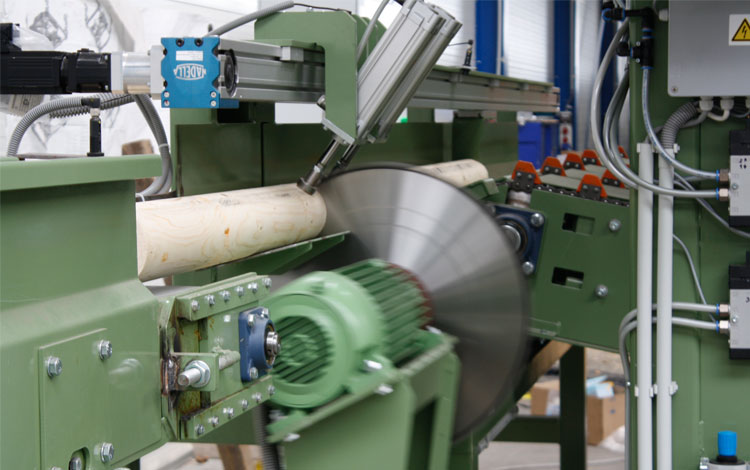

SPLITTING SAW FOR ROUNDWOOD, SINGLE MACHINE OR INTEGRATED

- For some purposes, instead of cross-cutting, splitting rondwood is required as a first step. The Bezner-Oswald splitting Saw CT is suitable for the center splitting of roundwood logs. For instance to produce fence laths, fence bars, semi-palisades, paddock stakes, etc. This log splitter machine handles logs that are rounded, peeled or fully debarked.

We manufacture the splitting saw with a saw blade fit for diameters between 40 and 120 mm. Another option is a wood splitter fitted with two saw blades working in the opposite direction. This type is available for diameters between 40 and 200 mm. For both machines applies that the speed is infinitely variable.

In combination with other machinery, we can design a splitting saw to complete your timber processing line. For instance, the splitting saw can be placed directly in conjunction with a prism-shaped groove behind the rod rounding machine. In this case, the rounding and splitting of the wood can be done in one working cycle.

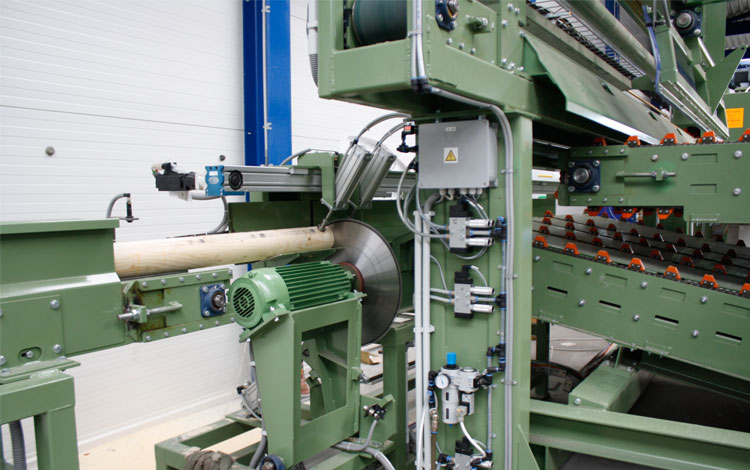

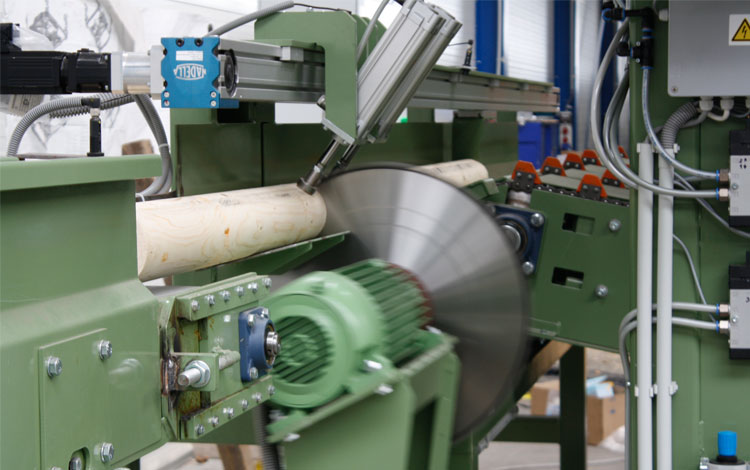

CROSS CUTTING SAW

- FOR BOTH HARD AND SOFT WOOD

A cross cutting saw serves as a machine to cross cut wood; both hard and soft wood. The machines Bezner-Oswald designs and manufactures handle both round and square logs with diameters or side-lengths from 60 up to 200 mm. Depending on your requirements and model, the output can run up to 300 units each hour.

The powerful machines we offer can be manufactured according to your needs. We can include electronics with microprocessor controls for manually or automatically controlled cross-cut stops and sorting devices for length and diameter sorting. Also, the machine can be supplied as stand-alone or as an installation together with stock conveyor, selection systems, belt conveyors, debarking devices, and sorting boxes. When the crosscut saw is part of an installation, this machine is also called an automatic saw.

As a crosscut saw manufacturer, Bezner-Oswald has more than a century of experience in timber industry machinery.

SERVICES

REPAIR AND MAINTENANCE OF WOODWORKING MACHINERY

- Woodworking machines for the processing of logs require periodic inspection and maintenance to guarantee an optimal, reliable, and continuous production process and reduce downtimes. The experts of Bezner Oswald are qualified and experienced to execute both technical and electrical inspections and repairs on any installation, regardless of the brand. Based on your requirements, we offer the following agreements:

MAINTENANCE & REPAIRS

Timely maintenance and/or well-executed repairs with original parts keep your installations up-and-running in perfect condition. Besides equipment examinations, also lubrication, oil changes, and overhauls of parts or units can be included.

MODIFICATIONS

For upgrading, overhauling, and relocation of full installations or single units, Bezner Oswald offers their consulting, engineering, and manufacturing services to improve your recycling or bulk handling process.

INSPECTIONS & RISK INVENTORY

Regular inspections decrease unexpected repairs and expenses and reduce downtime. Our field service engineers check your installations on a standard number of points, e.g. operational safety, wear and tear, mechanical and electrical controls.

SERVICE LEVEL

According to a mutually agreed and predetermined checklist, our experts check your installations on the operational use and safety of every machine, the system updates and the wear and tear. This guarantees and improves the potential of your overall installation. Bezner-Oswald distinguishes:- Service Level Agreement Inspections: agreement for periodical inspection to maximize and optimize the performance of your equipment and recording of spare parts to reduce downtime.

- Service Level Agreement Preventive Maintenance: agreement for periodical inspection and maintenance to prevent unplanned downtime and maintain and maximize your equipment’s reliability

The advantages of a Bezner-Oswald agreement for your installation include:- We keep stock of original parts to ensure quick repairs, offer maximum installation performance, and reduce your downtime.

- In some cases with older machinery, spare parts are inaccessible. We reconstruct spare parts or unit parts ourselves regardless of the brand or make of your installation.

- Up-to-date inspection, repair and maintenance reports

- No surprise expenses for emergency inspections

- Customized offers for repairs and spare parts

- Installation in perfect condition

- Reduced scheduled and unscheduled downtime

WOOD PROCESSING AND WOODWORKING

- Whatever branch your company covers within the industry of wood processing and woodworking, wood as a natural resource needs to be grown and harvested first. Second, logs go through the initial woodworking process, for instance peeling or debarking. Next, wood is cut in sawmills and being processed into valuable products, from semi-final products to consumer products. Every step in the process adds value to the woodworking chain.

Wood processing includes various branches such as timber processing, sawmills, timber merchants, carpenters, roundwood producers, lumber yards, construction companies, and companies in the paper and cardboard industry.

Bezner-Oswald designs and manufactures machinery especially for organizations who process logs into semi-final products. We distinguish:

Timber | every activity to transform logs into wood ready for further processing. Think of machines for peeling, rounding, profiling, chamfering and pointing, and sawing.

Timber residues | every activity to maximize the application of lumber residues. Sawmill residue material is further processed in, among others, wood fiber products, OSB (oriented strand board), biomass, firewood. Think of machines for conveying and screens for sorting and batching wood chips, shavings, and sawdust.