- Offer Profile

- Klotz specializes in the design and manufacturing of assembly lines and test benches, in particular systems for the production and testing of vehicle steering systems and their components. The development of modern technical software for the automation of machinery and equipment is in addition to the traditional engineering the logical continuation of the corporate strategy: cutting-edge innovation. Klotz provides hands-on technology. Where else engineers and computer scientists can see immediately the success of their work? Whether technology in the machine or algorithm for control: The staff at Klotz reinvent mechanical engineering. Industry 4.0 and the Internet of Things can be experienced every day in exciting projects for international clients at Klotz.

Solutions

- Versatile expertise in mechanical engineering: solutions for diverse processes and individual requirements

In the course of our work, we have developed comprehensive expertise that covers a broad spectrum of mechanical engineering topics. Here we present some solutions from various projects - without any claim to completeness. If you have individual and special requirements in your company, please do not hesitate to contact us. We will be happy to look for a special solution for you together.

Our New Solutions

-

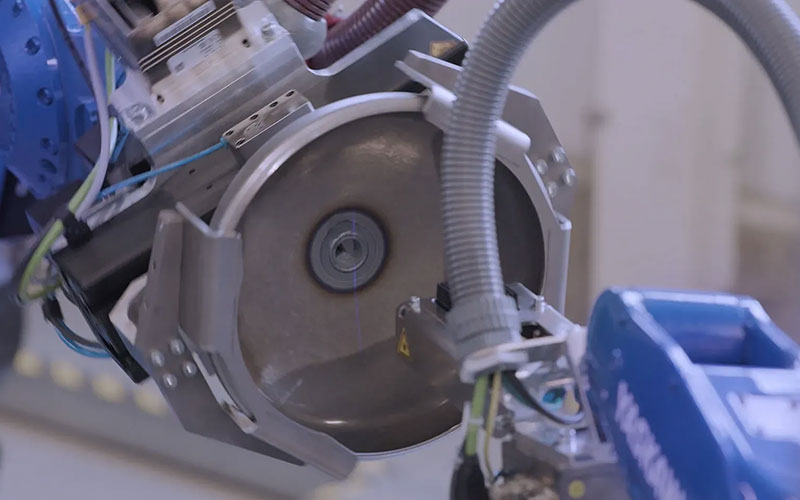

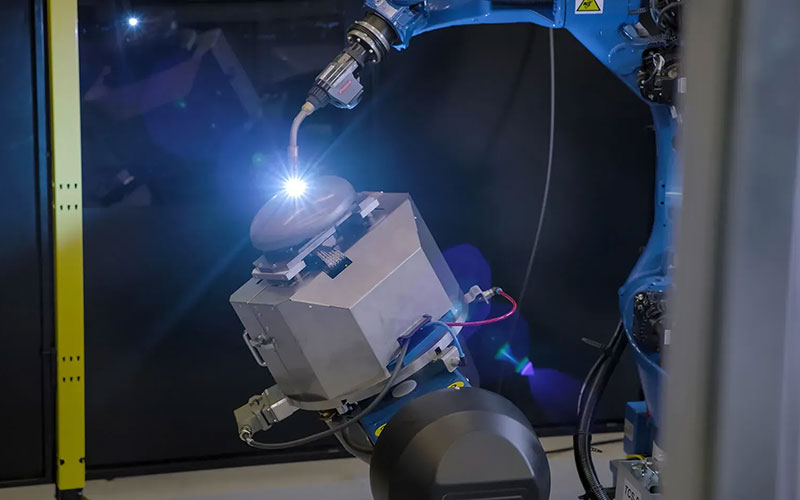

KLOTZ has developed a state-of-the-art welding cell for bottom nozzles on pressure vessels to counter the increasing shortage of skilled workers and the growing number of variants in production. This innovative system automates the entire process from component feed to seam inspection, supported by a precise welding robot.

The welding cell combines a flexible bin-picking system, precise turn/tilt positioning and optical quality control in accordance with EN ISO 5817.

It ensures increased productivity, reduces dependency on operating personnel and guarantees consistently high seam quality, even with changing component variants.

Bottom nozzle welding system with automatic parts handling

-

Task: Automation in the face of a shortage of skilled workers and a high number of variants

Industrial production is under increasing pressure: the availability of qualified skilled workers is decreasing, while at the same time the requirements for quality, process reliability and flexibility are increasing. Manual handling quickly becomes a bottleneck, especially when it comes to components with a wide range of variants, different geometries and larger tolerances - both in terms of time and reproducibility.In this specific case, the previously manual welding process for base nozzles of pressure vessels was to be replaced by an automated solution. The aim was to increase productivity, reduce dependency on operating personnel and at the same time ensure consistently high seam quality - even with frequently changing component variants.

Solution: Fully automated welding cell with integrated quality assurance

KLOTZ has developed a fully automated welding system that takes care of all key process steps - from parts handling to quality control. At the center is a welding robot with turn-tilt positioning, which executes the circumferential seams precisely and reproducibly. A specially designed clamping device ensures the exact alignment of the components - even with larger tolerances.

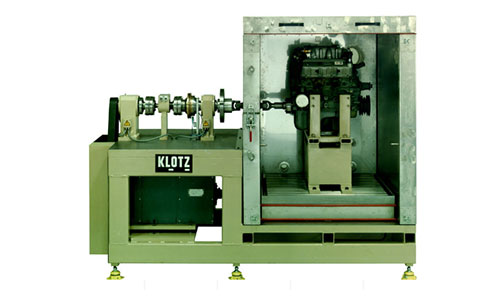

Test Benches

-

Looking at the history of Klotz GmbH, the entry into the Measurement technology and Testing technology in 1982 was one of the decisive moments in the company's history. Since then, we have built up extensive expertise in the design, development and construction of a wide range of different solutions. One focus is on functional testing: for example, solutions for engines, transmissions, steering systems, axial joints and clutches. We have also made a name for ourselves with numerous durability, performance and leak test benches and Test benches for special measuring and testing tasks, such as ultrasonic and diameter testing systems for pistons, radiation measuring devices for radioactive barrels and surface tension testing devices for enamel, which have been under constant development for 30 years and more.

Klotz now stands for a particularly high level of expertise in the field of test bench software. Today, a team of computer scientists is constantly developing the most sophisticated technical software solutions independently of projects, which are a basic prerequisite for today's testing requirements: individually tailored solutions from a single source.

End-of-line test bench for car steering systems

- These fully automated end-of-line (EOL) test benches for electromechanical car steering systems enable efficient, precise and flexible end-of-line testing and adjustment. This solution integrates testing and adjustment processes in one system and ensures high accuracy and efficiency. The test bench can set up and contact fully automatically, perform vibration analyses and enable customer-specific adjustments. The EOL test benches offer a cost-effective solution to the challenges of modern car steering production.

Final test bench for commercial vehicle steering systems

- The final test bench for commercial vehicle steering systems carries out a comprehensive 100 % test of commercial vehicle steering systems at the end of an assembly line, including checking friction torque, efficiency, reverse torque, valve characteristics and internal leakage, as well as adjusting and testing final limiting valves.

End-of-line testing for high-performance electric motors

- Special test benches for high-performance electric motors enable fully automatic set-up, contacting, leakage and performance tests and autonomous operation. They offer flashing, residual bus simulation, customer-specific software installation as well as vacuum and overpressure leakage tests. With robotic or manual loading, high flexibility and efficiency with cycle times under 20 seconds.

End-of-line testing for electric power steering systems (EPS/EPAS)

- The end-of-line test for EPS/EPAS steering gears ensures a 100% test, including functional and acoustic testing. Modern Klotz steering gear test benches enable precise computer-controlled function tests for mechanical and electromechanical steering gears. Integrated residual bus simulation (CAN/Flexray) and equipment with robust structures, load units, docking units for vehicle points, torque measurement and user-friendly operating console ensure the highest quality standards.

Vibration friction wear test rig

- The oscillating friction wear test bench, also known as a tribology test bench, investigates the wear conditions of piston rings and cylinder segments. With variable loads, temperatures and precise dosing of media, it enables comprehensive simulation of demanding test conditions. The data collected can contribute to the optimization of engine components, which in the long term leads to a reduction in downtime and operating costs and improves overall efficiency in the area of engine development.

Function test stand for foot lever mechanism and brake booster

- Testing of foot lever mechanisms and their individual pedals, brake boosters, wheel brakes and clutch actuation systems in combination with the various consumers, such as volume transducer brake system, wheel brakes, clutch slave cylinder test device and transmission housing with clutch and clutch slave cylinder. Concrete detailed specifications: Tests under extreme temperature conditions (possible in the temperature-controlled chamber)

Test stand for carrying out individual and endurance tests on axial joints

- The axial joint test stand carries out individual and endurance tests on various axial joints, whereby load spectra, angular movements, temperature and humidity can be variably adjusted. The test stand can test up to 4 axial joints simultaneously and uses hydraulic cylinders to apply axial force and angular movement. Each test station has individual test adapters for simultaneous testing of different axial joints. Axial play is measured and, in the event of defects, the corresponding cylinder is switched off, with downtime and other data being logged.

Radiation measuring device for drums with radioactive waste: Precise and safe

- The radiation measuring device was specially developed for the precise inspection of 200-liter drums with radioactive waste and enables a thorough measurement of dose radiation. It can be used flexibly for drums with different diameters and can be transported through a 900 mm wide door. The device has a robust design, is easy to load and has 12 gamma sensors that can detect and record the dose rate during a complete rotation.

Service life test bench for rack and pinion steering systems with integrated web server

- This test bench can be used to carry out service life tests on manual and servo-assisted rack and pinion steering systems. Static and dynamic tests up to 30 Hz tie rod load are computer-controlled. The drive unit can be adjusted in 4 axes and the load unit in 2 axes. The status of ongoing tests can be queried from any computer via the TCP/IP interface.

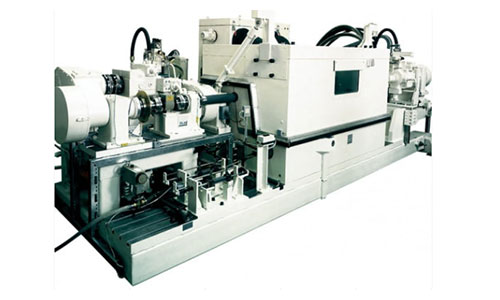

Power steering test bench for 100 % test in assembly line

- The power steering test bench carries out automatic functional tests on hydraulic steering gears in rack and pinion design. It automatically recognizes the steering types and enables efficient model changes with minimal manual effort, thereby increasing productivity.

Rack and pinion steering test bench for endurance tests

- This rack and pinion steering test bench enables service life tests on manual and servo-assisted rack and pinion steering systems with static and dynamic tests up to 30 Hz rack load. The tests are computer-controlled and the status can be queried from any computer via a TCP/IP interface.

Power steering test stand for 100 % tests in production lines

- The power steering test bench enables 100 % testing of rack and pinion power steering systems in production lines by automatically feeding, docking and testing the test specimens, storing the test results on data carriers and network servers and allowing model changes without manual intervention.

Friction dynamometer

- Two friction power test benches have been developed to investigate the effects of various engine component design features on engine friction power. These test benches can test individual components or complete 6-cylinder engine blocks and are equipped with torque measurement, speed control and data acquisition. The systems have an output of 47 kW and an oil supply unit that supports temperatures from 20 °C to 135 °C. They are designed for three-shift operation. They are designed for three-shift operation and offer a wide range of measurement and control options.

Camshaft test bench

- The camshaft test bench is used to test engine components, in particular the camshaft drive, for their friction performance and enables tests of individual parts or complete 6-cylinder engine blocks at various speeds up to 8000/15000 rpm, whereby torque and speed can be measured and controlled. The test bench has a 34 kW drive motor and an oil supply unit for temperature control, and the mounting plate is height-adjustable and complies with DIN 876, grade 3.

Gearbox test bench

- The transmission test bench is used to test and determine the control characteristics of automatic transmissions with hydraulic and electronic control. Continuously variable automatic transmissions, automatic stepped transmissions and special transmissions can be tested. The test bench enables static and dynamic operating modes as well as a driving simulation without having to install the test specimen in a vehicle. The drive and output units are equipped with safety devices and the measurement is carried out with high speed and torque dynamics with low mass inertia.

Inspection system for round parts, stud measuring device (dimension and surface)

- The inspection system for round bolts with a diameter of 45-75 mm and a length of 40-130 mm enables the inspection of surface defects and dimensional deviations using a CCD camera and ultrasonic and eddy current technology, with cycle times of 2.5-5 seconds per part depending on size.

Testing system for round parts, bolt measuring device (dimension)

- The semi-automatic testing system for studs with a diameter of 10-35 mm and a length of 15-70 mm enables dimensional testing of the outer diameter, crowning, taper and length with high precision and cycle times of 1.5-2.5 seconds per part, depending on the size.

Bolt measuring device, round parts measuring system (ultrasound and eddy current)

- The fully automatic stud measuring device enables the inspection of studs with a diameter of 10-35 mm and a length of 15-70 mm for surface cracks, dimensions (outside diameter, crowning, taper), and enables multiple sorting by size with cycle times of 1.5-2.5 seconds per part depending on size.

Laser measuring station

- A laser measuring station was developed to monitor cylindrical shafts during production. The requirements include a diameter range from 4 mm to 120 mm, lengths from 5 mm to 700 mm, short measuring times, easy handling and the possibility of subsequent automation. The laser measuring device uses a helium-neon laser beam for precise measurements of diameter, concentricity, cylindricity and lengths. It achieves high measurement accuracy in the micro range and requires no complex adjustment. A sliding carriage, cantilever arms and roller blocks allow the test specimens to be positioned for various measurements.

Stud measuring device (surface)

- The semi-automatic stud measuring device enables the inspection of studs with a diameter of 10-35 mm and a length of 15-70 mm with regard to their surface quality, outer diameter, crowning, taper and length with high precision and cycle times of 1.5-2.5 seconds per part, depending on size.

Steering gear test bench with double drive shaft

- The steering gear test bench with double drive shaft enables manual and computer-controlled function tests on mechanical and hydraulic steering gears, including rack and pinion and recirculating ball steering systems. The clamping fixtures and docking units offer flexibility for model changes. The test bench is equipped with two measuring lines to measure torques ranging from 0.5 Nm to 750 Nm and enables a variety of functional tests, including steering angle, pressure, leakage oil loss and strength tests.

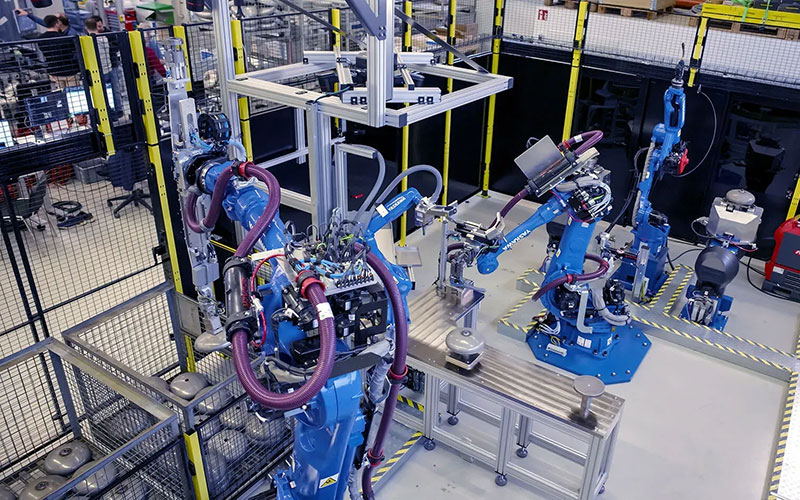

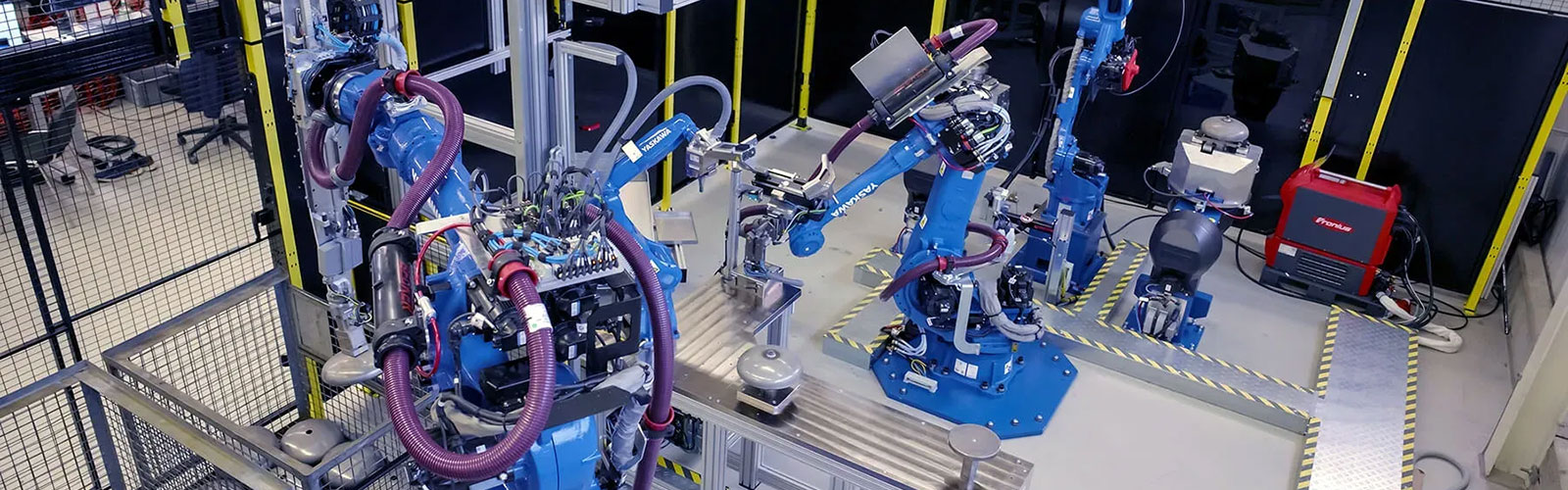

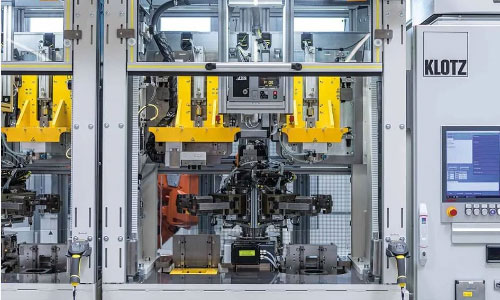

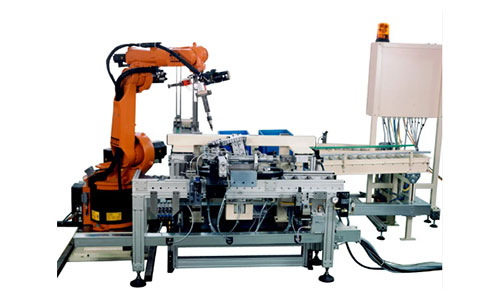

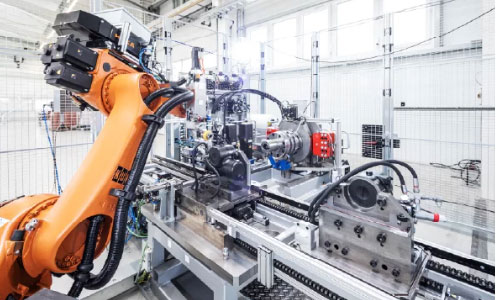

Robotics

-

KLOTZ uses the synergy of robotics, classic mechanical engi- neering, IT, sensor technology, electrical engineering and computer science to construct highly developed mechatronic special machines.

This holistic approach enables the creation of highly complex and customized machine solutions for a wide range of applications.

End-of-line test bench for car steering systems

- These fully automated end-of-line (EOL) test benches for electromechanical car steering systems enable efficient, precise and flexible end-of-line testing and adjustment. This solution integrates testing and adjustment processes in one system and ensures high accuracy and efficiency. The test bench can set up and contact fully automatically, perform vibration analyses and enable customer-specific adjustments. The EOL test benches offer a cost-effective solution to the challenges of modern car steering production.

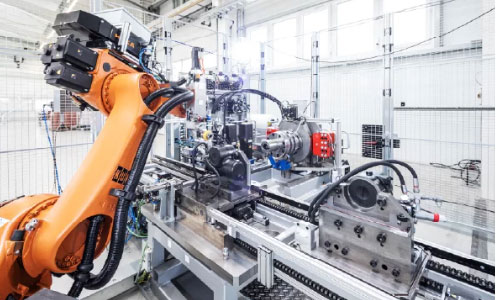

Fully automatic joining device for steering valves

- The fully automatic joining device for steering valves is precisely designed for insertion into rack-and-pinion steering systems. With the help of an industrial robot, imaging and force torque sensors, force-monitored assembly takes place with greasing of the rack and feeding of the support bearing. This system integrates seamlessly into existing production lines, ensures high quality with a cycle time of just 23 seconds per steering valve and thus improves efficiency and quality assurance.

End-of-line testing for high-performance electric motors

- Special test benches for high-performance electric motors enable fully automatic set-up, contacting, leakage and performance tests and autonomous operation. They offer flashing, residual bus simulation, customer-specific software installation as well as vacuum and overpressure leakage tests. With robotic or manual loading, high flexibility and efficiency with cycle times under 20 seconds.

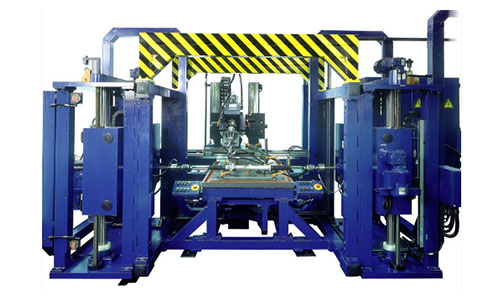

Assembly Equipment

- From simple mounting devices to fully-automated assembly lines. And especially where special measuring, testing or monitoring requirements are closely linked with the assembly.

Final assembly and testing of servo-electric steering drives

- The assembly line for the final assembly and testing of servo-electric steering drives includes tasks such as joining and bolting the motor and ECU, welding contacts, surface pre-treatment, gluing the protective cover, flashing the ECU, leak testing and functional testing, whereby strict requirements for technical availability, cleanliness and ESD must be met.

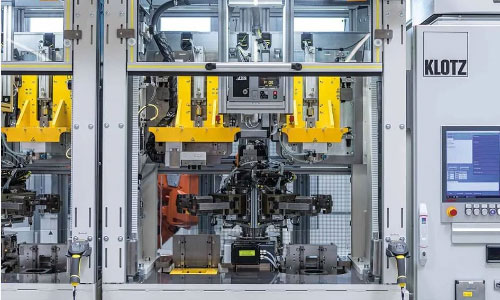

Semi-automatic assembly press for seals and bearings in the steering housing

- The semi-automatic assembly press enables radial shaft sealing rings, roller bearings and wipers to be pressed and greased into commercial vehicle steering housings, with sensors monitoring the placement and position of the components. Force- and displacement-monitored joining processes with graphic display ensure quality assurance. The press can be converted to different housing, bearing and sealing ring types, with tools and holders coded to prevent mix-ups.

Fully automatic joining device for steering valves

- The fully automatic joining device for steering valves is precisely designed for insertion into rack-and-pinion steering systems. With the help of an industrial robot, imaging and force torque sensors, force-monitored assembly takes place with greasing of the rack and feeding of the support bearing. This system integrates seamlessly into existing production lines, ensures high quality with a cycle time of just 23 seconds per steering valve and thus improves efficiency and quality assurance.

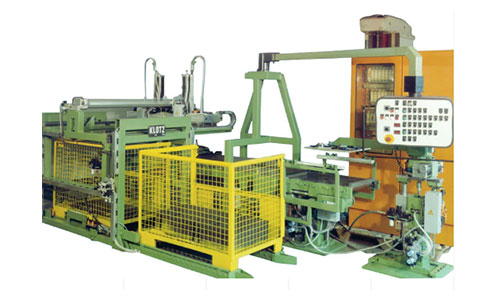

Assembly line for commercial vehicle steering systems

- This assembly line is used for the manual assembly and testing of power steering systems for commercial vehicles.

Fully automatic screwing, measuring and adjustment stations in steering assembly

- The steering assembly machines enable the screwing of housing covers, the measurement of axial play and the presetting of the friction torque for commercial vehicle steering systems in the assembly line, whereby automatic recognition of the steering types enables a smooth model change without manual intervention and the workpiece feed takes place via a conveyor belt.

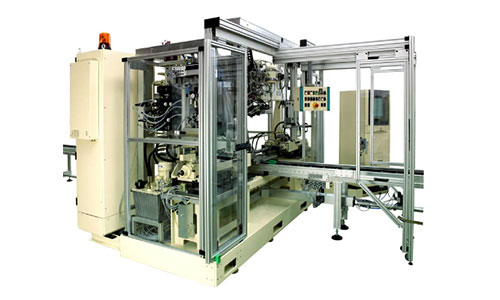

Fully automatic assembly machine for decorative and trim rings

- The fully automatic assembly machine for decorative and trim rings was developed to enable high flexibility and increased productivity in the assembly of these rings. The system can process up to six different sizes of rings without retooling and offers simple operation and a high degree of automation. It is equipped with state-of-the-art drive and control systems and enables the production of high-quality products with minimal manual effort.

Software Solutions

-

With over 40 years of experience, KLOTZ develops first-class soft- ware solutions for testing and special machine construction. Flexible solutions for automation and testing applications, compatible with real-time systems such as TwinCat, CtrlX and TiaPortal, are in use worldwide.

Our automation framework KinRig is also based on this experi- ence. It uses standardized software libraries that are fully tested with state-of-the-art tools. In our framework, high-level languages and PLC software grow together. KinRig is a product of our subsidiary of Kinmatec GmbH.

Kinmatec

- In addition to special machine construction, technical software is also one of our core competencies. With KinRig, Klotz has created a flexible product for both plant operators and plant manufacturers, with which automation and testing tasks can be implemented quickly and in a standardized manner.

Handling Technology

- Whether industrial robots or special solutions - always independent, always specially tailored to your needs. You can rely on us.

Mold gripper for interim storage of radioactive waste

- A gripper system has been developed for handling radioactive waste in molds that operate at high temperatures of around 600 °C. This gripping system is characterized by its robust design, insensitivity to radiation, simple operation without auxiliary energy and good centering with different diameters. It offers the possibility of combining up to three functions, requires no lubricants and is easy to decontaminate.

Handling system for oven loading and unloading of baking trays

- The handling system is designed to remove enamel powdered baking trays from a trolley train, rotate them 180 degrees and place them on a firing chain, with flexible three-phase drives, electric swivel movements and pneumatic grippers that can be automatically adjusted to ensure precise handling with high adaptability. The system has been designed to withstand the heat load at 100°C on the part and enables accurate part delivery.

Lifting and centering table for enamel powder-coated baking tubes

- Lifting and centering table for enamel powder-coated baking tubes

Ultrasonic testing device with handling for series production

- Ultrasonic testing device with handling for series production

Insulation mat gripper with support

- The system was developed to remove insulation mats from Euro pallets and place them on dishwasher doors, using special grippers with kinematic properties to safely separate and precisely place the mats. The conveyor belt plays a crucial role in feeding material and positioning the mats to ensure a continuous workflow.

Truck steering systems

- KLOTZ has been active in the assembly and testing of recirculating ball steering systems for many years. Innovative, comprehensive solutions and close cooperation with customers result in the quality that KLOTZ industrial partners expect from us. You can expect.

Final test bench for commercial vehicle steering systems

- The final test bench for commercial vehicle steering systems carries out a comprehensive 100 % test of commercial vehicle steering systems at the end of an assembly line, including checking friction torque, efficiency, reverse torque, valve characteristics and internal leakage, as well as adjusting and testing final limiting valves.

Assembly line for commercial vehicle steering systems

- This assembly line is used for the manual assembly and testing of power steering systems for commercial vehicles.

Fully automatic screwing, measuring and adjustment stations in steering assembly

- The steering assembly machines enable the screwing of housing covers, the measurement of axial play and the presetting of the friction torque for commercial vehicle steering systems in the assembly line, whereby automatic recognition of the steering types enables a smooth model change without manual intervention and the workpiece feed takes place via a conveyor belt.

Vehicle steering systems

-

Klotz steering test benches for passenger cars and commercial vehicles are used by many well-known manufacturers: end-of-line test benches, test benches for quality assurance, development test benches and final assembly systems for servo and recirculating ball steering systems. For example, performance, tightness, acoustics, fatigue strength, load capacity and other criteria are tested.

In addition to systems for hydraulic steering systems (HPS), Klotz has also been building assembly and testing systems for EPS and EPAS steering systems and their components since 2006. Klotz has a strong team and a comprehensive library of solutions in the field of test bench software. Residual bus simulation for FlexRay and CAN systems are an integral part of many systems.

Klotz has realized test benches and assembly systems for both Rack-EPS (R-EPS) and Column-EPS (C-EPS).

Klotz systems offer very high availability in continuous operation (24 h).

The assembly and testing systems are in use worldwide, e.g. in Brazil, China, Germany, France, Russia and the Czech Republic.

Final assembly and testing of servo-electric steering drives

- The assembly line for the final assembly and testing of servo-electric steering drives includes tasks such as joining and bolting the motor and ECU, welding contacts, surface pre-treatment, gluing the protective cover, flashing the ECU, leak testing and functional testing, whereby strict requirements for technical availability, cleanliness and ESD must be met.

End-of-line test bench for car steering systems

- These fully automated end-of-line (EOL) test benches for electromechanical car steering systems enable efficient, precise and flexible end-of-line testing and adjustment. This solution integrates testing and adjustment processes in one system and ensures high accuracy and efficiency. The test bench can set up and contact fully automatically, perform vibration analyses and enable customer-specific adjustments. The EOL test benches offer a cost-effective solution to the challenges of modern car steering production.

Service life test bench for rack and pinion steering systems with integrated web server

- This test bench can be used to carry out service life tests on manual and servo-assisted rack and pinion steering systems. Static and dynamic tests up to 30 Hz tie rod load are computer-controlled. The drive unit can be adjusted in 4 axes and the load unit in 2 axes. The status of ongoing tests can be queried from any computer via the TCP/IP interface.