Güdel

Videos

Loading the player ...

- Offer Profile

- Components, modules and

system solutions are the main pillar of our product strategy. With our

know-how, we are among the leading automation systems companies in these

fields. Our local presence in key markets guarantees availability and

technical support world-wide.

We have made it our commitment to continue setting the standards in these markets.

Product Portfolio

Mechanical Components

- New High Precision and High Performance Gearboxes

Linear guideways

- • Guideway System for heavy duty applications

The guideway system for heavy duty applications is based on standardized roller supports with three integrated roller bearings, guideways with and without racks, drive units and tubular steel profiles with guideways. the system is especially suited for high axial and radial loads, high moment ratings, high rigidity and quiet operation.

• Guideway System for medium duty applications

The guideway system for medium duty applications is based on standardized guideway rollers and vee bars. The system is especially suitable for applications requiring high velocities, low friction, exact positioning and quiet operation.

Gear units

- • Standard worm gearbox

This range of gearboxes have been designed and built with today’s market demands in mind. The design gives excellent heat dissipation, universal mounting, different coupling options, and a wide range of versions. All gearboxes are lubricated for long life.

• High Performance Servo Worm Gear Units

The AE-range of compact high performance gearboxes is available in 6 model sizes and 10 standard ratios. The gearbox size is identical to the centreline distance.

• Planetary Gear GSP

Güdel supplies complete solutions for power trains that require high dynamics using planetary gear reducers. In the project planning phase, our sophisticated methods of calculation enable us to predetermine the best suited components for your system.

• Low Backlash Positioning and Drive Units

Low Backlash Positioning and Drive Units are based on the Duplex worm gear principle. The two worm and worm gear each have a different lead.

• Bevel Gear Units

Bevel Gear Units PV: for Small Loads

Bevel Gear Units HKF: for Medium Loads

Bevel Gear Units FK: for Heavy Loads

Racks and gears

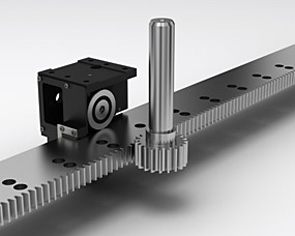

- • Racks and Pinion

Our racks and pinions are available in various designs and qualities, but we can also produce custom-made models on request. Thus we can provide products that are perfectly tailored to each industry and application.

• Spur Gears

Our standard range of pinions contain a large variety of models in different qualities and materials such as steel, stainless steel and plastic.

We are also able to produce special products to your designs.

• Worm Wheel Sets

Our standard range of worm and worm gears contains seven sizes. Each size is available with 8 ratios. Precision cut, tolerance of teeth: 8f24.

You may select between hollow worms or worms with shaft.

• Bevel Gear Sets

As one of the leading manufacturers of drive components our bevel gear range contains a large variety of materials, load capabilities and qualities:- Gears manufactured in steel, stainless steel, graphite cast iron, brass,

zinc and plastic:

- Straight, helical and spiral teeth

- in precision cut, hardened and ground and injection moulded

- Our bevel gear range includes 3 specifications:

- Gears for low loads

- Gears for medium loads

- Gears for high loads

- Gears manufactured in steel, stainless steel, graphite cast iron, brass,

zinc and plastic:

Linear axes

1-Axis: Type EP

- The single-axis module type EP by virtue of it’s high

modularity and its wide range of payloads lends itself to applications in

diverse industries. The assigned roller and guideway system ensures very

quiet running and low sensitivity to environmental cleanliness. The rack and

pinion drive system permits excellent dynamic motion with high accuracy.

Due to its modular and compact structure, the single-axis module type EP is particularly suited for use as an auxiliary axis in complete systems. Frequently they are used as a fast and accurate positioning axis.

2-Axis: Type ZP

- Our new Gantry System enables the flexible positioning of the Legs of the Gantry beam. This means a huge advantage in the planning phase, when frequently the exact dimensions of machines and space needed for some processes in the automatic production line can only be determined at the last moment. The legs can be freely positioned within a grid of 100 mm. The entire rear side of the beam is threaded and can be fitted with drip trays, cable ducts etc. The stroke movements can be varied with the free placements of shock absorbers in steps of 100mm. They are mounted in the bore holes on the front side.

3-Axis: Type CP (Cantilever)

- The portal gantry type CP fits a broad range of applications: Regardless

of required stroke, load, accuracy or rigidity, with the FP range of modules

you will find a suitable solution.

Cantilever portal gantries type CP with rack and pinion drive have applications in extremely diverse industries such as Injection Moulding Machines, Pressure Casting Machines, Machine Tools and Machining Centres.

As well as process oriented applications: Packaging, Palletising, Joining (Glueing, Welding, Screwing), Cutting, Mounting and Verifying.

3-Axis: Type FP

- Portal gantries type FP with rack and pinion drive have applications in extremely diverse industries such as logistics, machine industry, aerospace, medical technology, automotive etc. Type FP portal gantries are especially suited to applications where large work areas must be covered with a high degree of accuracy.

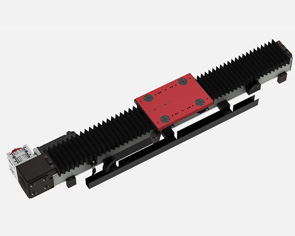

1-Axis: Type MLB

- Modular linear axis MLB with belt drives are specially

suited for general handling applications for packaging and logistics, as

well as for the food and medical industry. MLBs by GÜDEL are characterized

by highly dynamic and low-noise linear guidance systems built on an

aluminium profile. They are very compact with an integrated drive unit (GÜDEL

High-performance worm gear) as well as being rigid with high precision.

Linear axes are available in lengths up to 6000mm.

The stationary drive unit and motor reduce the moving mass to a minimum and in many cases make complex power transmission with chains unnecessary. The functions: guidance, drive and positioning are combined in a single unit which makes it easy to integrate into a complete system and make it possible to mount in any position.

Trackmotion: Type TMF

- Modular linear axes with rack and pinion drive for use in

diverse applications such as welding machines, plasma-arc cutting,

mechanical processing, pouring, packing etc. TrackMotion linear axes are

well-proven in applications such as logistics, aerospace and in the

automobile industry. Select your trackmotion by robot type.

GÜDEL Trackmotion modules are very insensitive to dirt, and show extreme rigidity and stiffness due to the large rollers and guideways used. The welded steel framework provides an optimal distribution of load on the rails, so that extremely quiet running is achieved. The modules can be manufactured in segments and can therefore easily be extended in length. Stroke lengths up to 100m are easily and reliably realized.

Trackmotion: Type TMO

- Trackmotion moves robots overhead The overhead-trackmotion

TMO from GUDEL completes the well proven series of floor-mounted

trackmotions type TMF. They allow mounting of a robot in a ceiling

orientation (hanging), wall-mounted (sidewise) or in an elevated position

(above floor, robot on top).

E (Elevated)

W (Wall)

C (Ceiling)

Rotary axes

Rotary axes for linear axes

- Capable of handling components weighing up to 3 tonnes with extreme accuracy, speed and repeatability. Güdel’s linear robots can be supplied with up to 5 axis of motion. They have been developed as a standard robot line for easy integration with other automatic machining, welding or robot assembly equipment.

Hand wrist (2+3 rotary axis)

- Capable of handling components weighing up to 3 tonnes with extreme accuracy, speed and repeatability. Güdel’s linear robots can be supplied with up to 5 axis of motion. They have been developed as a standard robot line for easy integration with other automatic machining, welding or robot assembly equipment.

Robots

Linear robots

- Capable of handling components weighing up to 3 tonnes with extreme accuracy, speed and repeatability. Güdel’s linear robots can be supplied with up to 5 axis of motion. They have been developed as a standard robot line for easy integration with other automatic machining, welding or robot assembly equipment.

Curved gantry robots

- roboLoop

The roboLoop system was launched as a world’s first at the 1998 Hannover Fair. Developed and patented in-house by Güdel. It was, and still is the only curved-track gantry and transfer system on the market.- Multiple independent robo-carriers per loop

- On-board pneumatic or hydraulic supply unit

- Radio-control

- Rack driven system giving high positioning accuracy

- Curved-track conveying system

- Multiple robo-carriers per loop

- Autonomous robo-carriers

- Switching station and buffer station

- Closed circulation system

Robots (5 rotary axes, 1 linear axis)

- 5-Axis Overhead Robot on a Linear Travelling Axis

The overhead robot roboFlex manufactured by Güdel is an innovative robot concept. It consists of a 5-axis robot arm which is fitted in a suspended position on a linear travelling axis. Thanks to the overhead robot roboFlex it is nowadays possible to position workpiece grippers and operating heads in any axes direction and angle required. The small mass guarantees very high dynamics and maximum rigidity and accuracy.

ABB IRC5 robot controller

- IRC5 is ABB’s fifth generation robot controller. It sets

new standards with its modular concept, a completely new ergonomically

designed portable interface unit, the FlexPendant and fully synchronous

multiple (up to four) robot control through the MultiMove function.

IRC5 has the ability to control multiple robots with the potential to reduce costs, improve quality, increase productivity and expand robot applications. MultiMove allows applications that were previously impossible – all thanks to the perfect coordination of complex motion patterns.

KMC - Kuka Motion Control

- It has proven itself to be particularly reliable, multifunctional and easy to use. So good, in fact, that our engineers felt that it would be a shame if it could only be used with KUKA robots. Consequently, the KUKA controller has been expanded for General Motion Control tasks and made available for everyone in the field of automation. The result is KUKA Motion Control, or KMC. In the future, you will only need to invest in a single, comprehensive hardware and soft- ware solution.

Industry Solutions

By industries

Press Automation

- Güdel provides highly efficient automation systems

designed for use in tandem press lines and transfer presses. Our press

automation systems are based on our well proven standard components and

modules.

For the automation of presses, Güdel combines innovative mechanics with the most modern control and servo technologies.

Food, Beverages

- Your profitability is of the utmost importance to us: Güdel systems are particularly impressive because of their low life-cycle costs. We take into account the total cost of ownership – starting with the facility’s purchase and ending with its disposal. Due to the high percentage of components manufactured in-house, we have this objective in mind right from the production stage. We optimise your costs and identify any savings potential.

Non-Food

- The cost effectiveness of your system is our objective: Güdel systems feature low life cycle costs. We strive to keep your total costs as low as possible – from purchase to disposal. Because such a high share of our products is manufactured in-house, we are able to address cost efficiency while your system is still in production. Our product range is designed to offer you the best solution for your production conditions, without compromise.

Green tire handling

- A great deal of knowledge and excellent mechanical engineering is needed to produce a green tire. Storing the green tire afterwards and then transporting it requires precision handling and excellent dynamics. Güdel offers solutions which meet all of these requirements and which can be implemented quickly and at a low cost.

Finished tire

- The cost effectiveness of your system is our objective: Güdel systems feature low life cycle costs. We strive to keep your total costs as low as possible – from purchase to disposal. Because such a high share of our products are manufactured in-house, we are also able to address this in the production phase.

Solar/Photovoltaic

- Production of solar modules

Within the photovoltaic (PV) industry, «grid parity» is the magic word. It means that the costs for generating PV power are reduced to the level of conventional energy production. On the Automatica 2010, 3S Modultec and GÜDEL present two brand-new machines for different stations in the production process, that bring manu-facturers of solar modules closer to this goal.

Aerospace

- Güdel designs, develops and manufactures all its products in house utilizing our extensive engineering capability to deliver quality controlled products from one supplier. Our modular and standardised range of Cartesian equipment enables us to offer a range of flexible, and reconfigurable solutions to meet the demands of the Aerospace manufacturing sector.

Composites

- Güdel offer a range of flexible re configurable equipment for Composite Manufacturing and assembly. Our solutions are based upon utilizing our proven Cartesian and Robotic technology and many years’ experience of designing, developing and manufacturing bespoke solutions to suit industry requirements.

Glass handling

- Güdel linear modules with rack-and-pinion drives are successfully used in applications for handling glass. We are specialized in the development and production of standardized linear modules. For this application, we developed a solution for handling glass panes with our single-axis and multi-axis linear modules.

Wood

- With long years of experience, a wide range of products, and continuous technological improvements – Güdel will help you find the right solution to efficiently tackle the various tasks in the area of wood processing.

Bending

- Bending processes place high demands on robotic systems. The robot itself forms an integral part of the bending cell, which means that the robot significantly affects the cell's precision and productivity. In addition, the bent parts are often large and heavy, so that in addition to featuring high accuracy, the robotic system must also meet demanding requirements for load capacity and flexibility.

Cutting

- Güdel linear guideway systems and Güdel racks are used on

plasma, laser, and water jet systems. Our products are characterized by

outstanding reliability, even in extreme environments. Maintenance and

downtimes are kept at a minimum.

By processes

Machine tending

- In addition to the process costs of the machine tool, an

increasingly important cost driver is the handling and storage of parts.

Based on the in-house manufactured modular system, Güdel has developed various package solutions for such applications. The high level of standardization in the components,- Gantry robot

- Gripper systems

- Storage and transport technology

Handling in frozen environments

- Güdel linear modules with rack-and-pinion drives are

successfully employed in applications for handling frozen goods.

We are specialized in the development and production of standardized linear modules. The application shown is based on our standard two-axis and multi-axis linear modules. In this case, we developed a solution that enables the axis to operate smoothly even at - 28 ° C. The payload of the commissioned containers can vary between 500 and 700 kg.

Palletising

- The well-conceived Güdel modular system and the

space-saving design that characterizes the entire product range will enable

you to construct a solution tailored to your requirements.

The Güdel gantry robots can be realized in a scale that corresponds to your performance specifications and requirements. That means, no compromises have to be made, and the system will deliver exactly the required performance.

Storage

- For payloads of up to 500 kg, Güdel storage and retrieval

devices offer high performance to accelerate your warehouse throughput

speeds.

The entire drive train for your storage and retrieval devices will be made of racks, pinions, and gears manufactured by Güdel. This drive train offers you the advantage of minimized life cycle costs and helps you maintain performance, even in a rough environment.

The modular system designed by Güdel lets you choose the appropriate solution for your space requirements, flexibility and performance. s

Glueing

- Robotic systems for bonding processes must meet exacting

requirements. The workpieces often have large dimensions, and large amounts

of adhesive have to be applied in a short time and with high accuracy.

Güdel offers innovative robotic concepts which meet all of these requirements and can be implemented quickly and at a low cost. The modular design of Güdel linear axis systems and Güdel drive axes allows rationalized solutions. The robust design makes it possible to precisely position dosing and mixing heads as well as allowing direct conveyance of the heavy containers for the adhesive components.

Güdel products are successfully employed to apply adhesive in the following processes:- Rotor blades for wind turbines

Welding

- On the one hand, the automation of welding processes

requires robust and reliable concepts in the area of robotics. On the other,

it requires concepts that are precise and dynamic.

Güdel offers solutions which meet all of these requirements and which can be implemented quickly and at a low cost.

The modular design of our robot drive axes and our multi-axis linear systems provide simple solution concepts. The robust design makes it possible to directly carry heavy wire barrels and also to construct compact systems.

Güdel products are successfully used in the following welding applications:- Spot welding

- MIG/MAG welding

- Laser beam welding

- Electron beam welding