- Offer Profile

- Zasche handling was founded

in 1932 as a company specializing in steel and crane construction and

evolved into the market leader for handling technology.

Its portfolio encompasses a wide of products, range starting from simple manually operated manipulators to semi-automated manipulators, jib cranes, light crane systems, lifting devices or steel construction.

Manipulators

Pivot arms

- These pivot arms are combined with rope balancers. An

extremely comfortable handling for the machine operator is achieved by

mounting the hoist on the column, whereby only the low mass of the secondary

arm needs to be moved.

The operator can choose between different model series - depending on the component weight - to achieve the optimum ratio between payload and moving mass.

Especially for low payloads we can recommend our carbon series. Compared to the steel version, the dead mass is reduced by 75%. This considerably increases the productivity, joining accuracy and worker acceptance of your employees.Technical specifications

- max. 160 kg

- max. 2000 mm

- max. 4000 mm

Design variations

- floor-mounted on a column

- ceiling-mounted stationary

- ceiling-mounted and traversable in a suspension crane or rail system

Control options- one, two or multiple load balancing control

- up/down control with and without no-load balancing

- intuitive hand force detection control

- safety functions, such as gripper release

- and many more

Options- pneum./electr. brakes

- maintenance unit

- slewing angle sensor

- mobile base plate

- endless rotation at the column

- and many more

Parallelogram Manipulators

- Our parallelogram devices combine a pneumatic hoist with

a parallelogram. This technology allows the equalization of torsional forces

and therefore enables the picking up of workpieces outside their center of

gravity.

Parallelograms have a standard working radius of up to 3,200 mm. Those dimensions can, however, be extended or shortened according to the task at hand.

We also offer a very compact version of our parallelogram for light- weight applications. This version excels through its optimized cross section and greatly reduced dead weight.Technical specifications

- max. 350 kg

- max. 1600 mm

- max. 3500 mm

Design variations

- floor-mounted on a column

- ceiling-mounted stationary

- ceiling-mounted and traversable in a suspension crane or rail system

Control options- one, two or multiple load balancing control

- up/down control with and without no-load balancing

- intuitive hand force detection control safety functions, such as gripper releaseand many more

Options- pneum./electr. brakes maintenance unit slewing angle sensor lifting lock mobile base plate and many more

Lifting axes

- Lifting axes are usually pneumatically powered and

perform a linear stroke. They are used for the rigid, off-centered guidance

of the load. They allow for the loads to be comfortably and safely guided

due to the direct transmission of the applied hand forces onto the load.

They excel through their low dead weight and their ease of movement.

The guidances consist of hardened and ground recirculating ball bearing guides in machine tool quality. These are being combined with low maintenance recirculating ball bearing guide sleds, which require low manual forces for the stroke movement

To enable the handling of higher payloads of up to 1000 kg the lifting axes can also be equipped with a chain hoist.Technical specifications

- max. 1000 kg

- max. 1200 mm

- max. 2500 Nm

Design variations- ceiling-mounted and traversable in a suspension crane or rail system

- floor-mounted in combination with a heavy duty pivot arm

Control options- one, two or multiple load balancing control

- up/down control with and without no-load balancing

- inuitive hand force detection control

- safety functions, such as gripper release

- and many more

Options- pneum./electr. brakes

- maintenance unit

- position scanning

- lifting lock

- travel drive in x/y axis

- and many more

Telescopic lifting devices

- Telescoping lifting devices are moved up and down by

electrically actuated chain hoists using internally or externally running

chains. They are available in two different design variations: With a square

column as a square telescope (TV) or with a round column as a round

telescope (TR). Both versions are available as single telescopic and double

telescopic.

Telescopes are especially suitable for handling heavy workpieces up to 1,500 kg. They can handle large torques of up to 5,000 Nm. The maximum available stroke is 2000 mm, depending on the version. They can be installed either in a rail system or on a floor- mounted Z-K2 heavy duty pivot arm.

With the double telescopic design, they can also be used in low ceiling rooms.Technical spefications

- max. 1500 kg

- max. 2000 mm

- max. 5000 Nm

Design variations

- ceiling-mounted and traversable in a suspension crane or rail system

- floor-mounted in combination with a heavy duty pivot arm

Control options- up/down control

- safety functions, such as gripper release

- and many more

Options- pneum./electr. Brakes

- position scanning

- travel drive in x/y axis

- and many more

Stacker crane

- Off-centered pick-up positions and large strokes outside

the machine operator's reach - these are the core strengths of a stacking

trolley. The control unit remains ergonomically irrespective of the long

distances between the pickup and the stacking position.

Lifting capacities and torques can be specially adapted to your application.Technical specifications

- max. 500 kg

- max. 3000 mm

- max. 2500 Nm

Design variations

- ceiling-mounted and traversable in a suspension crane or rail system

- floor-mounted in combination with a heavy duty pivot arm

Control options- up/down control

- safety functions, such as gripper release

- and many more

Options- position scanning

- travel drive in x/y axis

- and many more

Floor-guided handling devices

- A special form of manual handling equipment are handling

devices on the ground. They are used in situations where it is not possible

or desirable to attach a handling device to the floor or ceiling.

A another advantage is that a mobile solution can work independently of a specific installation point.

Mobile handling devices can be operated purely mechanically, electrically (e.g. battery), hydraulically or pneumatically.Technical specifications

- max. 200 kg

- max. 800 mm

- max. 1500 mm

Design variations

- electric, hydraulic or pneumatic strokes available

- design according to customer requirements

- with or without a gripper

Control options- up/down control using a button or foot pump

- and many more

Options- brakes

- and many more

Lifting equipment / rope balancers

Pneumatic rope balancers

- The pneumatic rope balancer is especially suitable for

positioning loads with great sensitivity and for complex joining and

assembly tasks. The payload suspended on the rope is balanced using

compressed air via a rope drum. This allows components to be positioned with

extremely high precision.

Technical specifications

- max. 100 kg

- max. 2000 mm

Design variations

- ceiling-mounted and traversable in a suspension crane or rail system

- floor-mounted in combination with a pivot arm or slewing crane

Control options- one, two or multiple load balancing control

- up/down control with and without no-load balancing

- intuitive hand force detection control

- safety functions, such as gripper release and many more

Special features- precise and smooth positioning of loads

- intuitive hand- guidance directly on the workpiece

- fast transfer of loads with short cycle times

- compact design, control and drive all in one housing

- speed limiter as safety device: prevents unacceptably high lifting speeds

Electric rope balancer

- The electric rope balancer is especially suitable for

demanding tasks when positioning workpieces with great sensitivity and with

no pneumatical air supply available. With it, all tasks for picking up,

transporting and positioning loads can be carried out precisely. While using

the joining mode, the machine operator can position and join the component

directly, without actuating any additional control buttons.

Technical specifications

- max. 100 kg

- max. 2000

Design variations

- ceiling-mounted and traversable in a suspension crane or rail system

- stationary when mounted on a pivot arm

Control options- continuous up / down control via hand force control

- intuitive hand- guidance directly on the workpiece

Special features- freely parameterizable operating modes for guiding and joining

- ergonomic control handle for fatigue-free working

- high safety through permanent load monitoring

- easy-to-service through plug & play connections

- electronic control via D-Grip incl. connection cable for PC and parameterization software (CD)

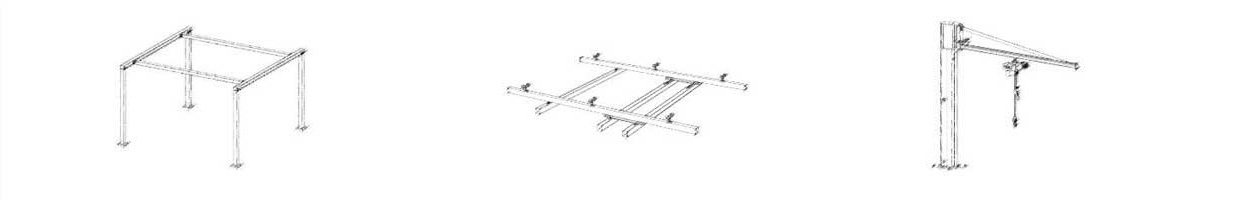

Suspension crane systems

Steel superstructure/crane suspension system

- In case you need a steel superstructure for the operation

of suspended crane systems or ceiling-mounted handling equipment we are

happy to plan and implement this for you. We have in-house specialist

engineers, certified welding experts and suitable equipment in our

production facilities exactly for this purpose.

Design variations

- according to requirements

Light crane systems

- We can offer you a large number of tailor made single or

double girder crane systems from various steel or aluminum profiles from a

comprehensive modular system.

Design variations

- according to requirements

Slewing cranes

- Wall- or floor-mounted slewing cranes are used in

conjunction with rope balancers or chain hoists for very simple handling

operations. They are equipped with jib arms made of steel or aluminum

profiles, which have a low dead weight in relation to their range of

outreach and load capacity. This makes the jib arm easy to move by hand.

Design variations

- floor-mounted

- wall-mounted with a mounting console

Control options- one, two or multiple load balancing control

- up/down control with and without empty load balancing

- hand force detection control

- safety functions, such as gripper release

- and many more

Lifting gear- chain hoist

- rope balancer (electrical or pneumatical)

Options- maintenance unit

- main switch

- slewing angle limitation

- and many more

Suspension crane systems

Semi-automation

- In today’s market a handling device must not only

guarantee high process reliability. Flexibility and versatility, shorter

cycle times and repeat accuracy are increasingly in the forefront. For

difficult and sensitive handling tasks, often in combination with limited

space, purely hand-operated applications are reaching their limits. Limited

space is an additional reason for semi-automation.

In hand-held automatic operation, applicable standards for fully automated systems are not applied, meaning that the space required by protective devices such as fences and light curtains is completely eliminated. However, the machine operator can still actively intervene in the handling process and initiate manual process steps through his perception.

Whether small loads with a high cycle time of cycles or high loads in the range of more than 1.000 kg: Thanks to our in-house expertise, we are able to offer you semi-automatic systems for every load range.Design variations

The manipulators are configured according to your requirements. Depending on those requirements, linear or rotary drives with internal measuring systems or laser measuring are used for positioning the system and the process sequence is programmed accordingly.

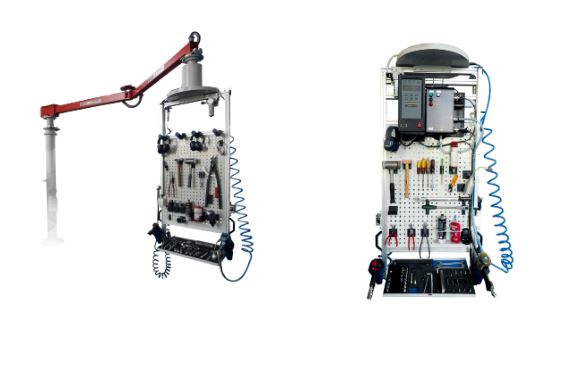

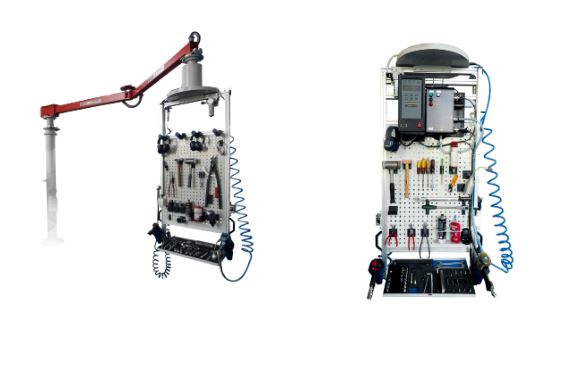

Tool handling / tool panels

- Whether it is tool or fixture handling, we can provide

the optimized tool panel for you and your process.

An ergonomic and efficient workplace design allows you to reduce the tool supply to a minimum. The risk of tripping that is caused by loose cables and hoses is thereby avoided and the rapid accessibility of tools, power supply, small parts and attachments as well as fixtures is guaranteed. This shortens your cycle times thanks to a reduction in travel distances.Technical specifications

Design variations- floor-mounted

- wall-mounted with a mounting console

Media supply- compressed air e

- lectricity

- EDV

- nutrunner controls

- process monitoring

- scanner

- and many more

Options- pneumatic brakes on all pivot bearings compressed air supply incl. maintenance unit (pressure reducer, fine filter, oil separator) tool panel compatible with all common operating equipment suppliers comprehensive range of tool holders, clamps, trays and boxes endless rotation at column and side arm end and many more

Solutions

Automotive

- Whether classic manipulator, semi-automatic installation device or simple lifting aid, Zasche handling implements both individual and standard solutions for your application in the automotive sector. Whether in component production, body- in- white, pre-assembly or final assembly - ZASCHE handling manipulators can be found at all well-known automobile manufacturers as well as their suppliers.

Electric Mobility

- ZASCHE handling can also boast a high level of competence in this sector of automobile production. Resort to our experience in manufacturing components and the assembly on the vehicle, whether it is storage systems, electric drives, control and cooling technology or the powertrain.

Construction – Stones – Ground soil

- Due to the robust and low-wear construction of our devices, manipulators of Zasche handling can also be used under the most demanding conditions. They support your employees and contribute to the reduction of illness-related losses due to musculoskeletal disorders to a minimum.

Chemicals industry

- Whether it is in the production or processing of high-purity silicon or the handling of liquid, solid or gaseous substances, the manipulators of Zasche handling provide you with equipment for a process that is both reliable and safe for your personnel.

Printing industry

- Pick & Place is the classic application in the printing industry. As shown here, paper stacks are inserted into the machine for binding and further processing. High cycle times and payloads of up to 150 kg are not uncommon.

Casting industry

- Molds and sand cores usually have a very high dead load combined with a very vulnerable surface structure. The challenge for the handling device or the gripper is usually the selection of the gripping points in a way that the component can be handled abrasion-free in harsh environmental conditions.

Logistics

- The simple and fast transfer of goods from an ergonomic point of view is becoming increasingly important. We counter the increasing strain on your employees with both ergonomically and technically sophisticated equipment and thus ensure an increase in output with high worker acceptance.

Machine building industry

- Manipulators are often used in machining centers as tool changers for large and bulky tools and as devices for loading and unloading machining parts. With a manipulator from Zasche handling, your employees can perform these tasks ergonomically and quickly with high precision, repeat accuracy and component protection.

Wood / Furniture

- You will find our equipment wherever you need to relieve your employees. We will always find the ideal handling device for you and your application.

Metal processing

- Metal processing requires handling of bulky and heavy semi-finished products. These can also be sharp-edged, hot and unwieldy. A lifting tool or manipulator from Zasche handling will guarantee safe transport under these circumstances.

Textiles

- The focus in textile production often lies on the fast and safe handling of bobbins and yarns or the associated spinnerets. The product must not be contaminated by outside influences or the operator should be protected from the thermal treatment in the production process. Also, interruptions in production when changing production equipment can be reduced to a minimum using handling equipment from Zasche handling.

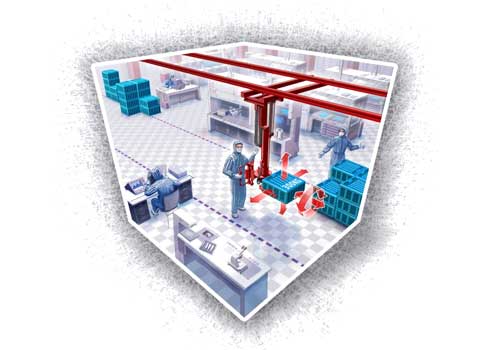

Clean room

- Zasche handling also enables you to carry out manual handling tasks in a clean room setting that exceed that exceed the muscle strength of the employees. Different precautions can be taken to meet your needs with regard to the requirements of your clean room class.