- Offer Profile

- A pioneer in the production of Switchgear, E. Dold & Söhne KG is one of the leading European manufacturers and is certified to ISO 9001.

The precision manufacture of Dold products is in keeping with the best of Black Forest traditions. This private owned company has been producing relay products for some 80 years and is currently managed by the third generation of the Dold family. Dold currently employs over 400 employees, many of them have been with the company for more than two decades and freely associate themselves with Dolds quality driven policies. This creates a depth of knowlege that comprises of something far greater than the often-used buzz word ”Know how”.

Innovations and highlights

-

Three-stage enabling switch - RE 6906

The enabling switch serves as an enabling device acc. EN 60204-1 and meets the requirements for enabling devices with three positions as determined in EN 60947-5-8.

The enabling switch features two normally open contacts controlling the safety function. When the enabling switch is activated both contacts are closed and the plant is released. If the enabling switch is pushed through resp. released the safety function is triggered and both contacts open up.

Enclosure series KV 4600

-

Full functionality at the front

Ready for the future - the electronic enclosure KV 4600 sets new standards in modularity and function. All functionality is integrated into the front of the enclosure and thus offers a high degree of flexibility for your electronics.

During development, special attention was paid to mechanical stability. This also enables the device to be used in mobile applications. Reduce your installation effort - only a few enclosure components make up the finished device. Increase your degree of automation - the push-in terminals fulfil the high requirements of the reflow soldering process. The modular enclosure system with construction widths from 12.5 mm enables a tailor-made realisation of a large number of customer-specific applications. As an option, common communication interfaces can also be integrated.

Highlights:

- Full functionality at the front panel

- Optional sealable, hinged front cover

- Modular widths from 12.5 mm and various construction depths available

- Use of up to two printed circuit boards per enclosure width

- High signal density due to push-in terminals with 3.5 or 5 mm pitch

Relay modules

-

Relay modules, Safety relay modules

Dold develops, manufactures and distributes high-quality components and complete solutions for functional safety, electrical safety and drive technology worldwide

In the area of functional safety, monofunctional safety switchgear, such as emergency stop modules, standstill monitoring and speed monitoring, multifunctional safety switchgear and safety systems ensure fast and reliable shutdown of machines and systems. Innovative monitoring solutions additionally ensure electrical safety in grounded and ungrounded power supplies by means of residual current monitors, insulation monitoring devices as well as measuring relays and monitoring relays. Intelligent motor starters, soft starters and solid-state relays or solid-state contactors comprise the drive technology product range. The switching devices ensure reliable switching, control and monitoring of motors. Control technology, timing technology and installation technology round off Dold's extensive product portfolio.

Safety Technology

-

Functional safety, Safety relay modules

SAFEMASTER - from monofunctional safety relays to multifunctional, configurable safety systems as well as wireless safety solutions

The safety relays of the SAFEMASTER series monitor safety functions such as emergency stop, safety gate, light barrier, two-hand control, safety mat or light grid as well as other functions. The solutions for safe drive monitoring ensure increased productivity and operator safety by combining safe speed, standstill or frequency monitoring, optionally also sensorless. The multifunctional safety solutions enable safe monitoring of all safety circuits of machines and systems through modular and configurable safety systems. In addition to the safe mobile radio emergency stop system and wireless enabling switches of the SAFEMASTER W family, Dold also offers a safe, bidirectional radio safety system.

Safety relay modules, safety relays

-

The right safety relays for reliable monitoring of the functional safety of your machines and systems - SAFEMASTER

Safety relays monitor various safety functions such as emergency stop or emergency stop, safety door monitoring, two-hand control, safety mat, light barrier as well as other safety functions. The classic, monofunctional safety relays are characterized by quick and easy commissioning and diagnostic functions directly on the safety relay, with convenient plug-in connection technology (push-in) and positively driven contacts. Minimum installation widths from 17.5 mm as well as different housing designs round off the wide product range of Dold safety relays. If you only want to monitor a few safety functions, the safety relays of the SAFEMASTER series are the optimal safety solution.

Safety relays of functional safety are certified according to IEC/EN 61508 up to SIL 3, IEC/EN 62061 up to SIL CL 3 and EN ISO 13849-1 up to Cat. 4 / PL e and can be used worldwide. For the use of safety relays in operating modes with a low demand rate (low-demand mode), we provide additional safety-related characteristic data depending on the device.

Extension / delay time / interface modules

-

Multipled contacts, specific shut-down or switching of functions

Expansion, delay and coupling modules from DOLD allow for cost-effective contact multiplication as well as for the specific shut-down or switching of functions.

Speed monitor, speed monitoring

-

Speed monitors - safe and convenient standstill and speed monitoring, optionally also without sensors - SAFEMASTER S

The SAFEMASTER S series standstill and speed monitors are used for safe standstill and speed monitoring of drives. The speed monitors detect and signal the standstill and speed of machines and systems in automatic as well as in setup mode. Dold offers efficient and economical solutions for safe sensorless speed monitoring, sensorless frequency monitoring as well as drive monitoring via proximity switches.

The standstill and speed monitor is used in machines and systems where machine movements or moving parts can pose a risk to man and machine. For example, safe monitoring of the reduced operating speed in setup mode increases the safety of the operating personnel. It also increases productivity by preventing unnecessary shutdowns.

Multifunctional safety solutions

-

Multifunctional safety solutions save space and costs

Alongside a multitude of monofunctional safety switching devices, DOLD also offer high-performance multifunctional safety switching devices and systems. In doing so, DOLD integrates increasing functionality with constantly sinking space requirements. The multifunctional safety switching devices offer you optimal solutions for many areas of use in machinery and system construction. SAFEMASTER C, which is configurable without additional hardware, is one option here just like the modular safety system SAFEMASTER M, which allows you a cost-effective and software-free adjustment of the safety functions to the respective task. With SAFEMASTER PRO, you receive a safety system that you can tailor to the application using variable expansion modules.

Wireless Safety System

-

SAFEMASTER W - Maximum mobility and flexibility with the highest degree of safety

The Wireless Safety System from DOLD in the SAFEMASTER W family allows the safe operation and shut-down of systems with hazardous areas, such as in automatic operation (e.g. troubleshooting, lubrication, calibration work) or in set up operation (e.g. putting into service, machine settings, maintenance). The high availability of your machines and systems is only one of many advantages of this solution. The Wireless Safety wins points with its wear- and maintenance-free radio technology, the flexible and mobile use and a high degree of user-friendliness.

Special devices

-

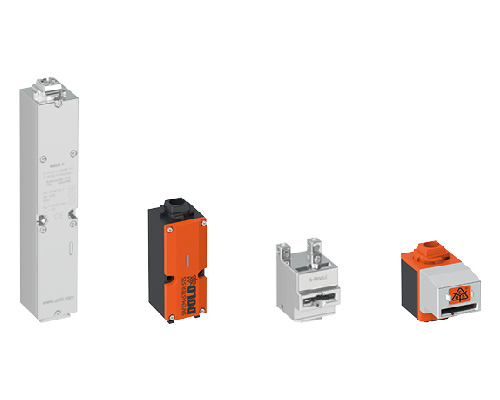

The special devices from DOLD include emergency stop monitors as well as buttons and magnetically coded safety switches

Special devices from DOLD include emergency stop monitors for the fast localisation of actuated emergency stop buttons, emergency stop devices and magnetically coded safety switches. The DOLD emergency stop monitors help to quickly and easily located actuated emergency stop buttons. This can significantly reduce the standstill times of machines and systems. Emergency stop devices from DOLD deactivate machines and/or place them in standstill. This thus reduces dangers to persons or damage to machinery as well as the manufactured products. With the coded magnetic switches from DOLD, the position of movable, rotatable or removable safety doors is monitored. The contactless devices can also be used for doors that are difficult to move or that are imprecisely positioned.

Monitoring devices

-

Electrical safety - residual current and insulation monitoring

Solutions for residual current monitoring, insulation monitoring, insulation fault location and for the detection of electrical and physical quantities in earthed as well as unearthed systems

Dold offers you a comprehensive product range in the field of electrical safety of residual current monitors, insulation monitoring devices, insulation fault location systems as well as measuring relays and monitoring relays for unearthed (IT systems) and earthed power systems (TT and TN systems).

The devices detect and report at an early stage when critical limit values of electrical quantities, such as current, voltage, power, insulation resistance, etc., are exceeded. Hazards for man and machine can thus be reliably avoided. Furthermore, the availability of your machines and systems is increased and production downtimes are minimized. The portfolio ranges from standard devices for monitoring individual measured variables (residual current monitors, insulation monitors, etc.) to multifunctional devices and flexible fault indication systems.

Residual current monitors

-

Residual current monitoring in grounded power supplies (TT and TN systems) - VARIMETER RCM

Residual current monitors (RCM) measure and monitor residual currents in grounded power supply systems (TN and TT systems). Here, residual current monitoring is carried out according to the principle of residual current measurement and serves primarily to avoid expensive downtimes and to prevent fire hazards that are latent due to creeping insulation faults. Residual current monitors are used in systems in which, in the event of a fault, a message is to be sent but no shutdown is to take place. Compared to residual current circuit breakers (RCD), which trip at certain rated residual currents and cause immediate shutdown, residual current monitors indicate a residual current at an early stage and signal insulation deterioration via an output contact, for example.

Early detection of insulation faults, as well as preventive maintenance and servicing outside of operating hours, can prevent unexpected shutdowns of machines and systems, thus avoiding unwanted interruptions in operation, property damage and high costs. Residual current monitors of the VARIMETER RCM (Residual Current Monitor) series are available as pure AC currents and pulsating DC currents DC (type A according to IEC/TR 60755) as well as all-current sensitive residual current monitors (type B) AC currents, pulsating and smooth DC residual currents DC.

Insulation monitors

-

Insulation monitoring of unearthed power supplies (IT systems) - VARIMETER IMD

Insulation monitors, also called IMD (Insulation Monitoring Device), monitor the insulation resistance in unearthed AC, AC/DC and DC power supplies (IT systems). This involves measuring the insulation resistance of the IT system to be monitored against earth. These systems are protected by insulation monitoring devices, the use of which is required by law in IT systems by the "Safety of Machinery" standard. Insulation monitoring devices are used to prevent accidents in the event of insulation faults, to prevent failures and generally to protect against fire and accidents.

Equipment for insulation fault location

-

Insulation fault location during operation in unearthed power supplies (IT systems) - VARIMETER EDS

Insulation fault locators enable fast and precise fault location of insulation faults in unearthed power supplies (IT systems) during operation. The insulation fault location system of the VARIMETER EDS series, consisting of a test current generator and an insulation fault locator, quickly and reliably locates the source of the fault in complex isolated AC/DC systems (IT systems). Differential current transformers (measuring current transformers) are used to record and evaluate the generated test current signals.

A device for insulation fault location, also called IFLS (Insulation Fault Location System), enables insulation faults to be located within a very short time and is used in addition to an insulation monitor. In the event of a fault, it impresses a test current between the live conductors and earth. Components that are pre-damaged with regard to insulation can be located as quickly as possible and replaced before a failure occurs, i.e. there is no need to shut down the system. DIN VDE 0100-410 also recommends for IT systems that an initial insulation fault be rectified as quickly as possible.

Measuring relays / Monitoring relays

-

From monofunctional measuring relays / monitoring relays for monitoring individual measured variables to multifunctional measuring relays, Dold offers a wide range of relay modules - VARIMETER

The measuring relays and monitoring relays are used wherever electrical safety is a priority. They monitor physical parameters such as voltage, phase failure, current, insulation faults, active power, frequency, standstill etc. In addition to monofunctional measuring and monitoring relays, the extensive relay programme also includes multifunctional and universally applicable measuring relays.

Fault annunciators

-

Interference suppressor systems for systems and buildings

Dold interference suppressors of the INFOMASTER family use lamps, signals or text notifications to inform about interferences and the conditions of electrical systems in industrial settings and buildings. In addition, they are also used to define maintenance intervals for preventive maintenance. Especially in the event of interferences in complex machine and systems, they can decisively reduce the length of the search for interferences. This minimises standstill times of the production system and helps to save on costs. The compact Dold interference suppressor ensures a cost-efficient monitoring of small machines without SPS, such as compressors. Thanks to it modular construction, it can grow with the system through expansions.

Power electronics

-

Drive technology, Motorstarter

Solutions for smart drive technology monitoring with softstarters, motorstarters, solid state relays / solid state contactors as well as motor braking devices and reversing contactors

In the field of smart drive technology, Dold offers powerful and flexible device solutions such as softstarters and softstop devices, smart motorstarters, motor braking devices, reversing contactors as well as solid state relays / solid state contactors and speed controllers or phase controllers. In today's machines and systems, the most commonly used drive is the three-phase asynchronous motor. Processes such as starting, reversing and braking motors are among the main tasks of electronic switching devices. Where high switching frequencies or high switching cycles are required, solid-state switching devices have proven themselves in industry. With their long service life due to wear-free switching, they solve switching and control tasks in specific applications in a particularly economical way.

Solid state relays / Solid state contactors

-

Wear-free, noiseless switching with solid-state switching devices - POWERSWITCH

With the solid state switching devices of the POWERSWITCH series you get solid state contactors and solid state relays with real added value. For decades, Dold has been developing and producing solid-state switching devices for industrial switching technology. Thanks to the extensive portfolio from a single source, Dold solid-state relays and solid-state contactors offer the possibility to switch loads in a wide range of applications. Plug in, connect, ready! The ready-to-use design, due to the optimally adapted heat sink, allows a quick and easy commissioning in just a few steps.

Where high switching frequencies and cycles are needed, our solid state switching devices are the ideal solution. Once installed, the devices remain operational almost indefinitely. Regular time-consuming and cost-intensive device replacement is therefore unnecessary. The POWERSWITCH series is characterized by wear-free and silent switching and is able to safely and reliably withstand repeated loads as well as high temperatures. This makes our solid-state relays and solid-state contactors particularly suitable for use in medical technology applications, stage technology and in other applications such as heating or lighting.

Reversing contactors

-

POWERSWITCH - High functionality in the smallest space

DOLD reversing contactors of the POWERSWITCH series are used to change the direction of rotation in alternating current motors, start them gently and/or to monitor their load. Various diagnostic functions inform you constantly about the operating condition of the motor. The DOLD reversing contactors save space and have few wires as all functions are combined in a single housing. Costs can also be saved as an alternative to a frequency converter. The devices are universally usable, e.g. for extruders, pumps, actuators or conveyors.

Softstarters

-

MINISTART - Intelligent, flexible and high-performance!

DOLD soft start devices of the MINISTART family ensure that your machines start up gently and smoothly and/or minimise a wide variety of problems such as mechanical wear during the direct start of drives, the tipping or sliding of loads on transport belts, pressure surges in the lines of pump systems and much more. They reduce the wear on and increase the service life of your motors and mechanical drive components. DOLD soft start devices offer additional advantages as a simple and space-saving installation, provide flexible configuration options and relieve the supplying grid through reduced starting current.

Motor brake relays

-

MINISTOP - High-performance and flexible device solutions

The factors of safety and efficiency are an important argument for the motor braking devices of DOLD. The wear- and maintenance-free devices can be easily installed, even in existing systems. The configurable braking current allows an optimal adjustment to machines and systems. Asynchronous motors up to 160 kW are reliably braked with the DOLD braking devices of the MINISTOP series. This allows your machine to be brought to a standstill in only ten seconds in accordance with the EU Machinery Directive and European standards.

Speed controller / Phase controller

-

Simple speed controlling of fans and pumps

The speed controllers from DOLD especially serve the simple speed controlling of pumps and fans to adjust the load on the drive machine. In comparison to frequency converters, they provide with substantially few EMC problems because no shielded wires are necessary. Possible applications are the speed controlling of exhaust fans for large kitchens.

Motorstarter

-

Smart motor starters, multifunctional motor starters

Smart motor starter with current monitoring up to 4 kW with a width of only 22.5 mm - MINISTART

The smart motor starters, often referred to as hybrid motor starters or electronic motor starters, switch and invert 1- and 3-phase motors up to 4 kW quickly and reliably in a space-saving compact enclosure with a width of only 22.5 mm. The motor starters combine up to 7 functions in one control cabinet enclosure and thus enable space savings of up to 80 % compared to the use of conventional devices. The smart motor starters of the MINISTART series offer a combination of motor control functions such as reversing function (counterclockwise rotation / clockwise rotation) or soft start / soft stop and monitoring functions such as current monitoring or motor protection functions as well as galvanic mains isolation. The motor starters ensure low-wear and gentle starting of machines and systems and are suitable for demanding drive tasks such as door and gate controls, conveyor systems as well as bridge and actuator drives and that in efficiency classes IE1, IE2 and IE3.

In addition to classic motor starters, multifunctional motor starters with Modbus RTU interface, phase sequence monitoring and phase failure detection are also available. The phase inverter with automatic rotating field correction also joins the wide product range of electronic motor starters.

Control devices

-

Control technology for all requirements

DOLD is a pioneer in the field of control technology and present the first SPS in a standard housing in the automobile and tool machine industry in 1978. Benefit from this experience. DOLD offers you a universal portfolio of safe, efficient solutions for control technology that is tailored to your needs. A comprehensive palette of field bus-capable input and output modules are available for you.

Latching / interface / switching relays

-

Links between logic and load

The DOLD toggle, coupling and switch relays are the first choice for all interface applications in demanding control systems. They connect the highly sensitive logic level of the SPS, a shelf system or process computer with the raw operation of the power levels of a machine. Installation and maintenance of the relays can be conducted in a time-saving manner with the snap-on plug-in sockets on the top-hat rail. Your additional benefit: They are not sensitive to overcurrent and/or overloads and are significantly less expensive that semiconductors with medium to low switching frequency.

Power supply units

-

Switch power supply units with a wide voltage range

DOLD switch power supply unit and/or switch mode power supply units have diverse uses thanks to a wide voltage range. Their task is to convert unstable input voltage into a constant output voltage. They save space in the control cabinet thanks to their compact construction. They are in accordance with the standard IEC/EN 60950 and EN 61558, are highly effective and feature a short circuit and overload protection.

Programmable logic controllers

-

Flexible applications for safety and automation simply realised

The increasing complexity of control technology in machines and systems as well as strong trend towards decentralisation result in an increased communication need between control technology and peripheral equipment in machine and system control. The field bus-capable SPS from DOLD is available with a comprehensive palette of field bus-capable input and output modules with which flexibly applications for safety and automation can be simply realised. The input and output modules (I/O modules) represent peripheral components of an SPS in the bus system. Both analogue and digital DOLD bus modules are available for the field bus system CANopen.

I/O Modules

- Flexible applications for safety and automation simply realisedThe increasing complexity of control technology in machines and systems as well as strong trend towards decentralisation result in an increased communication need between control technology and peripheral equipment in machine and system control. The field bus-capable SPS from DOLD is available with a comprehensive palette of field bus-capable input and output modules with which flexibly applications for safety and automation can be simply realised. The input and output modules (I/O modules) represent peripheral components of an SPS in the bus system. Both analogue and digital DOLD bus modules are available for the field bus system CANopen.

Timers

-

Time relay, Timers

Time relays for applications with high demands

DOLD has been a renowned, innovative manufacturer in the field of timer technology for decades that has continued to set standards with its developments. Time relays, that is, relays with specific time response, help you to cost-effectively realised start-up and shut-down delays in industry and building technology. The timer technology from DOLD includes both electro-mechanical and electro-pneumatic time relays as well as electronic devices on the basis of modern microprocessor technology.

Multifunction relays

-

Universally usable - maximum function in minimum width

Multifunctional relays are universally usable thanks to the selection of the corresponding function. They also belong to the group of time relays with which you can cost-effectively realised specific time functions. A multifunctional relay can be used as a flasher relay, clock, impulse former, start-up and/or shut-down relay as well as contact and recurrence delay. You can simply set the respective function on the device.

Flasher relays

-

Control of malfunction notifications and position lights

DOLD flasher relays are used on cranes, wind power systems as well as airfield lighting where they control position lighting. The control of malfunction notifications on machines, lighting, fans, et cetera is an additional task of these devices. Impulse time and pause time are identical with flasher relays.

Cyclic timers

-

Impulse and pause times configurable independent from each other

Clocks from DOLD are important components of traffic light control systems, automatic ovens, et cetera. They have the same function as flasher relays with the difference that the impulse and pause times for time-dependent control systems are different from each other and can thus be set separately.

Fleeting action relays

-

Input and output wiping relays for time-dependent control systems

Machines and systems such as dosing systems and rinsing systems are where wiping relays are used. DOLD wiping relays are available as both input as well as output wiping relays. While the input wiping relays immediately switch the operating voltage to the work position after installation, output wiping relays are placed over the voltage control contact on the control input. If this is open, the relay immediately switches to the work position. Both relay types switch back to resting position immediately after the expiration of the set wiping time.

Timers on delayed

-

Time relays with contact delay for forward switching

With contact delayed time relays, the start is triggered by the activation of the operating voltage. The relay switches to the work position after the expiration of the configured delay time. Contact delayed time relays from DOLD are used for forward switching, e.g. pre-heating, or for delay times in switching systems such as for the delayed activation of system parts in burner controls, escalators and elevators.

Timers off delayed

-

Time relays with recurrence delay for forward switching

For time relays with recurrence delay, we distinguish between devices with and without auxiliary voltage. While devices without auxiliary voltage are only realisable for short times, those with auxiliary voltage are also suitable for longer periods of time. Repress delayed time relays from DOLD are used for follow-on switching (e.g. fans), lighting control systems (e.g. stairwell lighting) or for the delayed switching to an emergency power generator and/or an emergency lighting system.

Installation electronics

-

Innovative installation devices so that you aren't left standing in the dark

DOLD offers you a wide palette of products for installation technology. These basic devices for modern building automation ensure that you aren't left standing in the dark or ensure that energy is reasonably saved over the scope of the lighting controls. Alongside timers and remote switches, energy-saving switches and load shedding relays, additional installation devices, such as Venetian blinds switches, network relays or the innovative hybrid switch relays round out the coordinated DOLD programme of installation devices.

Time switches

-

Timer for saving energy and costs

With DOLD timers, you can save energy and costs by avoiding unnecessarily long activation times for lighting and other electricity consumers. The usage spectrum for timers is vast and ranges from stairwell and hallway lighting to courtyard lighting to follow-on controls for bathroom ventilation fans. Additional cost benefits from space savings result from the compact construction of the device. The continuous lighting function ensure that lighting is not interrupted during longer activities.

Remote control switches

-

Switch lighting on and off from any number of locations

In large office buildings, factories, hospitals, schools, public buildings, et cetera, one often has to individual turn different lamp groups on or off. At the same time, it should be possible to turn all lamps on in the morning or off at night with a central control command, possibly only by authorised personnel. You can realise central and group switching very easily with remote switches from DOLD. You can connect any number of unlit push buttons to a remote switch. The distances between the push buttons and the remote switch barely plays a role.

Specific installation devices

-

Special installation devices for building technology

This product group from DOLD includes the energy-saving switch, the hybrid switch relay and the network relay. You can save energy and costs with the energy-saving switch which is a combination of a timer and remote switch. With it, you can turn off the lighting in a controlled manner before the expiration of the time configured. Alongside lighting, it also makes sense for fans, dryers and other electricity consumers that seldom have to be immediately turned back on after being used. The hybrid switch relay is used in heating, ventilation, air conditioning and lighting technology for the switching of strongly inductive and/or capacitive loads such as energy-saving lamps. Electro-smog can be avoided with DOLD net relays. They are used to deactivate the power supply of electrical circuits in bedroom or other rooms sensitive to electro-smog.

Safety relays | PCB relays

-

The extensive product portfolio includes safety relays with forcibly guided contacts, miniature relays, card relays as well as bistable relays

Dold is one of the leading manufacturers in the field of PCB relays and offers the right electromechanical relay for a wide range of application areas. The wide product range includes miniature relays, card relays, bistable relays and safety relays with forcibly guided contacts. As a specialist in PCB relays, we stand for quality and reliability from a single source. To meet the highest quality requirements, we rely on a high vertical range of manufacture, state-of-the-art production facilities and a combination of experience and know-how. Our PCB relays are available in a wide range of contact variants and designs and guarantee maximum switching reliability with minimum dimensions.

Safety relays with forcibly guided contacts

-

Relay with mechanically forcibly guided contacts according to DIN EN 61810-3

Safety technology is becoming increasingly important in mechanical and plant engineering. Safety modules or even safety controllers are used everywhere. Despite the increasing use of semiconductors, electromechanical relays are still an important component. The so-called safety relays, i.e. relays with mechanically forcibly guided contacts according to DIN EN 61810-3, are used wherever people, machines and valuable goods have to be protected against damage and injury. Such a relay consists of at least one normally closed contact and one normally open contact and is constructed in such a way that the normally closed contact and the normally open contact are never closed at the same time. For example, if a normally open contact fails due to opening failure, the associated normally closed contact cannot close when the supply voltage is switched off. This behavior enables easy diagnosis and fault detection when monitoring the positively driven feedback contact.

PCB relays

-

PCB relays with one or two contacts, in different installation heights and with different contact materials

PCB relays, also known as plug-in/print relays, are used for galvanic separation of circuits as well as for signal adaptation and signal strengthening. Our vertical and horizontal designs enable optimum adaptation to your application. Dold PCB relays, with max. continuous currents up to 16 A, are available with one or two contacts, in different installation heights and with different contact materials.

Miniature relays

-

Highest switching safety on smallest space

If it is necessary to switch heavy currents reliably in a small space and galvanic separation of control and load circuits is also required, there is no better answer than the compact miniature power relays available in SMD (Surface Mount Device) form and in DIL (Dual In-Line) form. With the smallest of dimensions, at around 20 mm long and 10 mm wide, they can be inserted into conventional 16-pole IC sockets.

All miniature relays are optionally available as versions with one NO contact or with one changeover contact. Different technologies, contact materials and contact configurations show their strengths in various applications.

Bistable relays

-

Bistable relays – Energy-efficient and reliable switching

Bistable relays can be used to switch applications in a reliable and energy-saving manner. They retain their switched position if supply voltage fails, preventing loss of information on the current switching status. Bistable relays allow for two stable switch positions even when powered down. In comparison to monostable relays, just a short switching impulse of a few milliseconds is enough to switch the relay into a defined switch position. Only a low nominal power level is required. This saves energy and reduces heat generation. In addition, the relays have high vibration and shock resistance. The bistable relay OB 5623 with forcibly guided contacts was developed for special, safety-related applications such as in railway and signal technology.

Enclosures

-

Electronic enclosures for top hat rails

With the wide range of switch cabinet enclosures, distribution enclosures and mounting rail bus system, you will find the right DIN-rail enclosure for every application from a width of 6.2 mm and upwards

Our enclosure series includes a wide range of different switch cabinet enclosures, distribution enclosures and a mounting rail bus system (in-rail bus). Whether multifunctional, compact, modular or customized enclosure solution, Dold offers you an extensive product portfolio of thermoplastic DIN rail enclosures. The modular enclosure concept allows the use of different connection systems such as plug-in terminal blocks with screw or spring terminals (push in). Flexible construction widths from 6.2 to 200 mm enable a finely graduated size adjustment to any application.

The integrated DIN rail bus (in-rail bus) ensures fast and reliable data and energy transmission. Instead of complex wiring, the module connection is made by simply snapping it onto the top-hat rail.

Switch cabinet enclosures

-

Switch cabinet enclosures | Electronic enclosures

Wide range of switch cabinet enclosures from 6.2 to 200 mm width with selectable screw or spring-cage terminal (push-in) connection technology

Our extensive product portfolio offers 7 different switch cabinet enclosure series for installation in switch cabinets. The universal, modular enclosure systems in widths from 6.2 to 200 mm allow the use of all common terminal technologies (up to 30 connections on 3 terminal levels possible at 22.5 mm width). In addition to conventional screw terminals, the plastic switch cabinet housings can also be equipped with power terminals up to 50 A, cage clamps or modern spring-loaded terminals (push-in). In addition, the techniques are also available with pluggable terminal blocks and in different installation depths of 97 or 118 mm.

The large-area and stable front allows an individual design with plenty of space for operating and display elements as well as programming interfaces. For linking and communication with other devices and systems, a wide variety of connections can of course be realized, such as BUS connections, KNX (EIB), RJ-45, etc. The enclosures are designed for both top-hat rail and screw mounting. The surface is also ideally suited for laser marking or printing.

Enclosure Series KS 4400

-

More space for your ideas

Modern electronics demands innovative enclosure solutions. From design, through production to final supply, the KS 4400 Series is an ideal platform for numerous applications from stand-alone devices to full system integration offering more decentralised distribution functions. This universal enclosure system, in modular widths from 6.2 mm to 90 mm and optional In-Rail-Bus assembly, provides the user with extensive design and assembly space. Its distinctive, aesthetically appealing design and high functionality, enable the realisation of your individual ideas.

Enclosure Series KO 4300

-

Space-saving and with selectable connection system

With their electronic enclosures of the compact range KO 4300, DOLD supports the trend towards miniaturisation - without any compromises in the connection convenience. Apart from conventional screw-type terminals, the enclosures can also be equipped with advanced spring-loaded terminals, for example. They considerably reduce the time required for the device connection. In addition to this, both designs are available with plug-type terminal blocks which provide additional advantages and savings potential. With such detachable terminal blocks the user not only benefits from an easier installation, but also from a faster device replacement with fixed wiring in the case of service. Also a pre-assembly without device is possible.

Enclosure Series K 70

-

Enclosure system with many widths proved in various applications

This consistent enclosure range allows for an especially fine graded adjustment to the size of the electronics. Thus, this enclosure system not only covers the common widths from 22.5 mm to 150 mm, but also provides intermediate sizes such as 32.5 mm or 55 mm. These enclosures are suitable for both DIN rail mounting and screw mounting.

Enclosure Series KO 4030

-

Dynamic enclosure system with detachable terminal blocks

The electronic enclosures of this variable system excel by their detachable terminal blocks. They are available in different designs while maintaining the same overall dimensions. You can choose from terminal blocks with plug-type box terminals in a variable quantity or with solderable heavy-duty terminals, for example. Because any combination of the different terminal blocks is possible, the enclosures can be easily tailored to specific applications.

Enclosure Series KO 4000

-

Versatile enclosure system with high modularity

Electronic enclosures of this very diverse range are available in a variety of sizes. From the 22.5 mm wide compact enclosure with 8 terminals up to the 200 mm wide large enclosure with up to 132 terminals. For devices that require more space, the 200 mm wide version can also be delivered with a height of 123 mm apart from the standard height of 73 mm.

Enclosure Series KO 4070

-

Innovative compact enclosures for space-saving devices

The electronic enclosures of this compact range are the perfect shell for space-saving devices. Available in widths from 12.5 mm to 28 mm, they provide up to 16 terminals. Guides inside the enclosure allow for a convenient accommodation of PCBs in up to three tiers. PCBs can be reliably connected on mechanically solderable double pins of the terminal blocks.

Enclosure Series KO 4900

-

Versatile enclosure series for individual requirements for advanced building

automation

These enclosure ranges meet all the requirements for advanced building automation. Their design variety allows you to also solve individual requirements without any problems. The enclosure size can also be adjusted to specific applications by fine steps. Thus, the enclosure ranges cover all common widths from 8.8 mm to 140 mm. Apart from conventional captive screw-type terminals, cage clamps are also available for the device connection, which allows for a very efficient device installation. And if higher current intensities are possible, you can use heavy-duty terminals up to a rated current of 50 A. For the connection and communication with other devices and systems, a variety of connectors are, of course, also available such as bus connectors, KNX (EIB), RJ-45, etc. These enclosures are designed for both top-hat-rail mounting and screwtype mounting.

Enclosure series KV 4600

-

Full functionality on the front of the housing

Ready for the future - the electronics housing KV 4600 sets new standards in modularity and function. All functionality is integrated into the front of the housing and thus offers a high degree of flexibility for your electronics.

During development, special attention was paid to mechanical stability. This also enables the device to be used in mobile applications. Reduce your installation effort - with just a few housing components to the finished device. Increase your degree of automation - the push-in terminals meet the high requirements of the reflow soldering process. The modular housing system with overall widths from 12.5 mm enables tailor-made implementation of a large number of customer-specific applications. Common communication interfaces can also be integrated as an option.

Distribution enclosures

-

Distribution enclosures, electronic enclosures

Large product range of distribution enclosures and building installation enclosures from 8.8 to 140 mm construction width as well as different construction depths of only 55 and 70 mm

The extensive Dold enclosure program also includes 3 complete families of distribution enclosures or installation enclosures. While the compact enclosures of the KU 4000 and KU 4500 series are content with an installation depth of only 55 mm, the distribution enclosure series KU 4100 offers even more capacity for your electronics with an installation depth of 70 mm. Both series offer enclosure widths from 8.8 to 140 mm and up to 64 or 96 connection terminals (for KU 4000 or KU 4100). In addition to selectable connection terminals, various BUS connections are also available for the distributor enclosure.

Enclosure series KU 4000

Enclosure series KU 4100

Enclosure series KU 4500

In-Rail-Bus

-

In-Rail-Bus, Mounting rail bus system

Smartest solution for a reliable and quick transmission of signals, data and energy

The IN-RAIL BUS system is based on a carrier section. It can be easily integrated in the 35 mm standard DIN rail and accommodates the BUS pcb that can be individually configured. With its high flexibility, this concept allows a variety of custom solutions. The In-Rail Bus replaces the costly individual wiring by an uninterruptible and flexible system solution. It is safely integrated in a standard 35 mm top-hat rail. Perfectly fitting carrier sections allow the use of standard rails with a height of 7.5 mm or 15 mm.

Safety switch, Guard lock, Key transfer

-

Electromechanical safety switch with and without solenoid interlock, key transfer and safety command device

The SAFEMASTER STS product range includes electromechanical safety switches, solenoid interlocks (safety switches with guard locking), key transfer and safety command devices and is used for reliable safeguarding of movable guards on machines and equipment.

The SAFEMASTER STS modular interlocking system is type-tested in accordance with the legal requirements and is suitable as a stand-alone system for use in safety applications up to Cat. 4 / PL e in accordance with EN ISO 13849-1 without fault exclusion. The safety switch and key transfer system is available as a reliable FRP version or as a highly robust stainless steel version. Find your suitable safety switch with or without solenoid interlock - in combination with safety relays, Dold offers complete solutions from a single source.

Safety switch

-

Electromechanical safety switches with separate actuator for guard door monitoring

Safety switches of the SAFEMASTER STS series reliably protect accesses and safety doors or flaps on machines and systems and are suitable for safety applications up to Cat. 4 / PL e in accordance with EN ISO 13849-1 without fault exclusion. Electromechanical safety switches (type 2) with separate actuator are ideally suited for safeguarding safety guards that can be rotated, removed or moved sideways and only provide the required safety when closed.

When the safety guard is opened, dangerous movements must be switched off immediately and secured against restarting. The dangerous machine can only be restarted when the safety guard is closed. The very narrow and robust design of the safety switch also allows space-saving mounting on movable guards.

Guard lock

-

Electromechanical solenoid interlocks prevent unauthorized opening of accesses and safety guards

Solenoid interlocks of the SAFEMASTER STS family combine the functional principle and the advantages of electromechanical safety switches with a 2-channel guard locking function. Guard locking ensures that rotating, removable or laterally movable protective devices such as safety guards, hoods, protective grids remain closed as long as a dangerous condition or risk of injury to persons exists. This includes, for example, safety applications with overtravel movements of a machine or system in which, for example, high temperatures or pressure prevail.

However, solenoid interlocks are also used in process protection where opening of the safety guard is not desired, such as unauthorized interference in the production process. Electromechanical solenoid interlocks act together as a link between the higher-level control system (PLC) and safety relay devices such as standstill and speed monitoring or safety time relays. In addition, different coding levels, very high locking forces and extensive diagnostic options enable use in almost any safety-relevant application.

Key transfer

-

The key transfer system combines the advantages of none wiring, mechanical safety with electrical safety

The basic principle of the key transfer system ensures that a machine or system is in a safe state before an access can be made. A further safety aspect is that a key is inserted either in a safety switch or can be used for opening a door lock. This property can be used to force a certain operating sequence, which can not be deviated from. As a result, a high safety level is achieved and a large number of different danger areas can be ensured.

Individual moduls

-

Flexibly, individually and perfectly adapted to your applications

The modularity of the SAFEMASTER STS allows individual adaptions to the corresponding applications. By means of bayonet locks (see accessory) any number of units can be mounted of only a few basic modules. The function of the units are defined from the way and arrangement of the modules, whereby several unities form a system. The possible combinations of the composed unities determine the individual functions of the total system.

Command devices

-

Safe communication between man and machine

The robust stainless steel option module expands the modular safety switch and key transfer system SAFEMASTER STS with variable command, indication, selection and emergency stop functions. This turns the system into a true "control centre" from where command functions, status displays, release signals, main and maintenance access points can be controlled. The option module is form-fitting and can be installed directly underneath safety switches or hold closed units thus enabling direct command execution at the access points for machines and systems. It can also be installed as a standalone command device. You too can benefit from the high degree of system flexibility.

Load isolator with interlock

-

Power Interlocking - switching off with safety!

Power Interlocking of the SAFEMASTER STS family enables the simple integration of a load-break switch into the safety switch and key transfer system. It enables the direct separation and safety-related interlocking of the power supply of machines and systems. The safety system thus reliably protects persons entering the hazardous area.