- Offer Profile

-

Nabtesco Precision Europe GmbH – part of the Nabtesco Group – is the world’s largest and most recognised manufacturer of cycloidal gears. The special technology of these precision gears makes them robust and highly precise. The high-quality gears incorporate the entire engineering competence of more than three decades.

Business units of the Nabtesco Corporation:- Precision reduction Gears

- Hydraulic Equipment

- Railroad Vehicle Equipment

- Aircraft Equipment

- Commercial Vehicle Equipment

- Marine Vessel Equipment

- Packaging Machines

- Welfare Equipment

- Automatic Doors and Platform Doors

Your No. 1 for maximum precision, performance and efficiency.

- Precision gearboxes from Nabtesco stand for top quality, performance, safety, availability, durability and first-class customer service. They are used millions of times worldwide and ensure your future viability and competitiveness! As an established system provider and experienced solution specialist, we implement future-proof drive concepts for robotics & automation and support the industry on its way to greater efficiency, process reliability, cost-effectiveness and sustainability in production. You have the application - we have the solution.

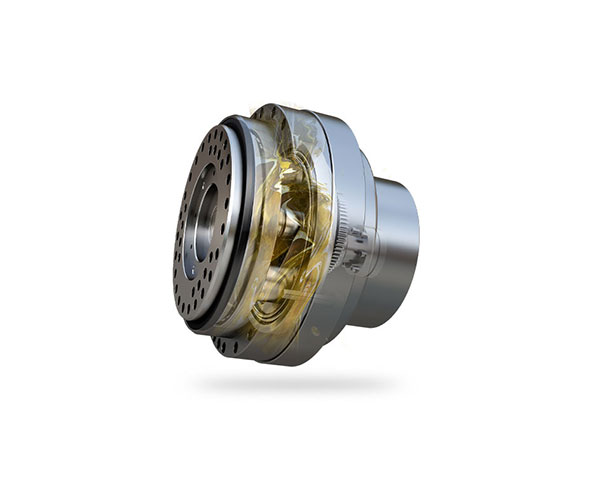

Cycloidal gears

Cycloidal gears for the highest demands

Precision cycloidal gearboxes are the key to greater productivity, efficiency and flexibility in production. Cycloidal gears use cam disks and rollers to transmit power. This ensures high efficiency, enormous resistance to shock loads and minimal backlash over the entire service life. Due to their special design, they are significantly more precise, dynamic and rigid than the rotary tables and standard planetary gears that are commonly used - and can therefore achieve considerable improvements in efficiency.

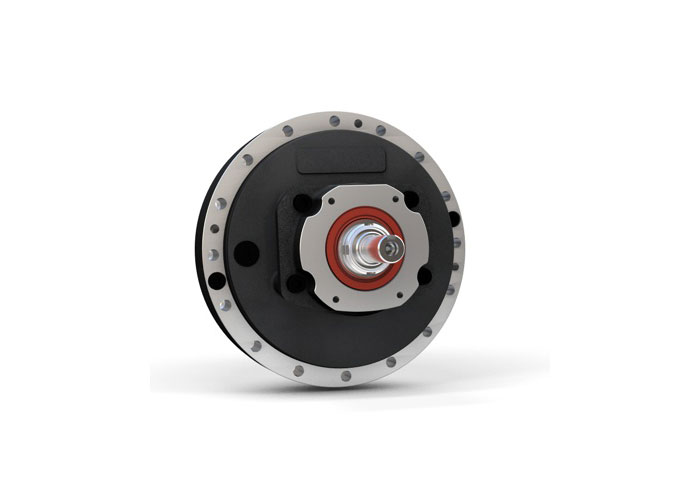

Neco® & Neco®HT

-

Functionality meets style: modular, dynamic, precise

The servo gearboxes in the Neco® series offer high power density, extremely effective corrosion protection and maximum flexibility in motor connection - all in an elegant design and compact construction. In addition, we have developed a modular system that allows customers to quickly and easily configure the gearbox of their choice. For large masses and forces, Nabtesco has expanded the Neco® series to include sizes for heavy-duty applications (high-torque gearboxes).

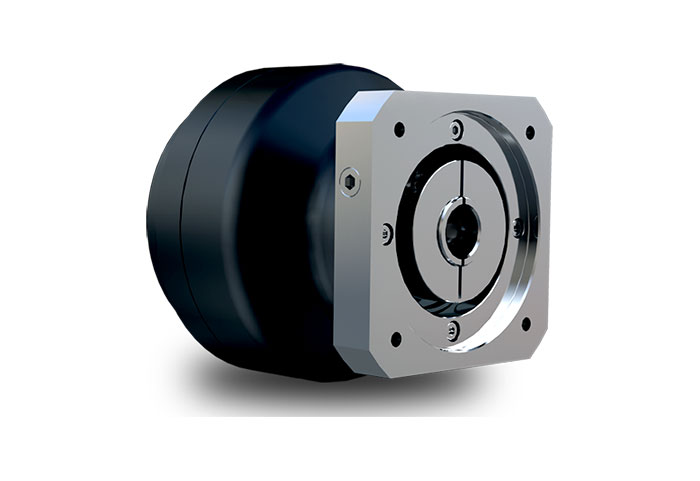

RV-N

-

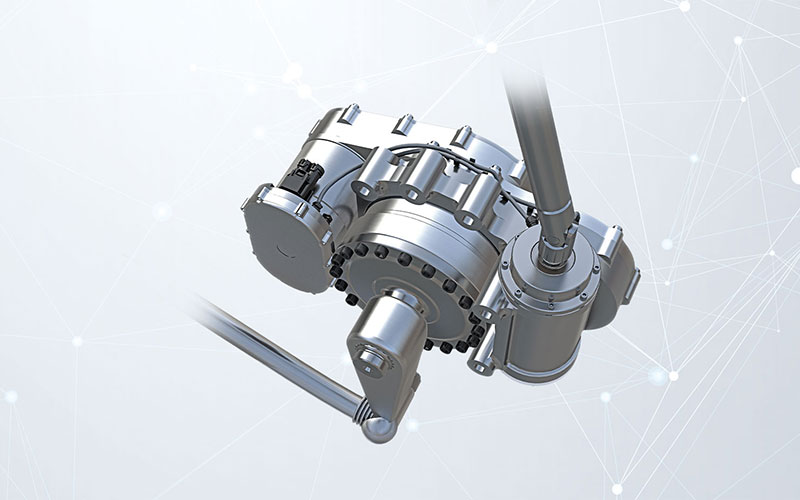

Compact design and reduced weight: ideal for robotics

With the component sets of the RV-N series, we have, we have developed particularly compact, lightweight and powerful solid shaft gearboxes. They are used wherever high torque performance is required but space is limited. Perfect for robotics!

The RV-N cycloidal gearboxes owe their compact design to the main bearing with integrated inner ring. The reinforcement of the eccentric shaft bearing results in a very high power density. We have also FEM-optimized all gearbox components and manufacture them using the latest production methods.

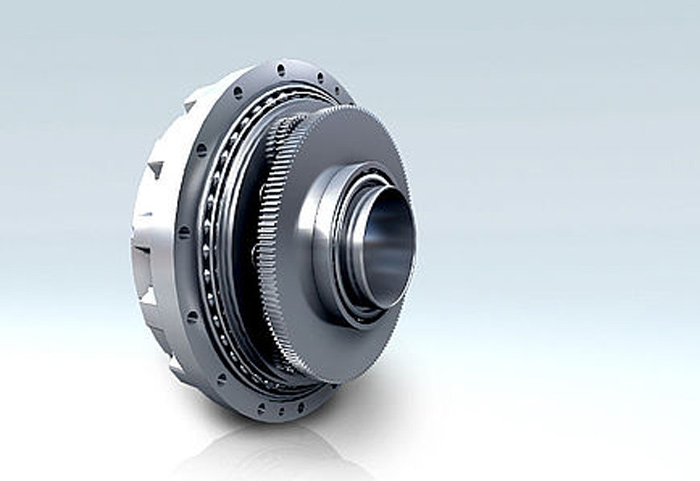

RV-C

- Power packs with an open center

The RV-C precision gearbox component sets are the right choice for demanding drive tasks. They have a hollow shaft through which supply lines, cables and drive shafts can be routed. The RV-C component sets have a very compact and lightweight design, but at the same time offer high performance and torsional and tilting rigidity.

The RV-C series component sets have an identical design and the same quality features as the RV-E eccentric gearboxes. The difference, however, is the hollow shaft with a diameter of up to 138 mm. Thanks to their design, the RV-C component sets achieve a particularly high repeatability and path accuracy with a hysteresis loss of less than 1 arc.min. In conjunction with the low vibrations, the RV-C series is therefore ideal for applications in robotics, medical technology, 5-axis machining centers (CNC) and also for antenna systems where maximum precision is required.

RD-C

- High performance design for supply lines

The precision gearboxes in the RDR-C, RDS-C and RDP-C series have a hollow shaft for feeding cables, hoses and lines through. Inside is an extremely compact and powerful RV-C gearbox of the latest design. The three versions differ in the way they are mounted.

While the RDR-C series is designed for right-angled mounting, the RDS-C series is suitable for direct mounting; finally, the RDP-C is a variant with belt drive. This allows fast, cost-effective installation and a wide range of applications: The powerful and extremely precise cycloidal gears are suitable for countless applications, from machine tools to applications in robotics and woodworking machines. The hollow shaft precision gearboxes in the RD-C series are always supplied pre-filled with lubricant and fully encapsulated. This means that nothing stands in the way of immediate installation in your system!

RD-E

- Precise and flexible, straight from the construction kit

The gearheads of the RD_-E series are more compact and versatile than ever. Three different models allow for numerous types of use, e. g. with the choice of the servomotor. A high-precision, extremely resistant and extra durable, latest-generation gearbox is concealed in the interior.

- Solid shaft, fast and cost-effective installation, completely enclosed, pre-filled with lubricant

- Coupling and flange for the most common servomotors included in the kit

- Straight mounting, right-angle mounting or pulley

- Solid shaft, fast and cost-effective installation, completely enclosed, pre-filled with lubricant

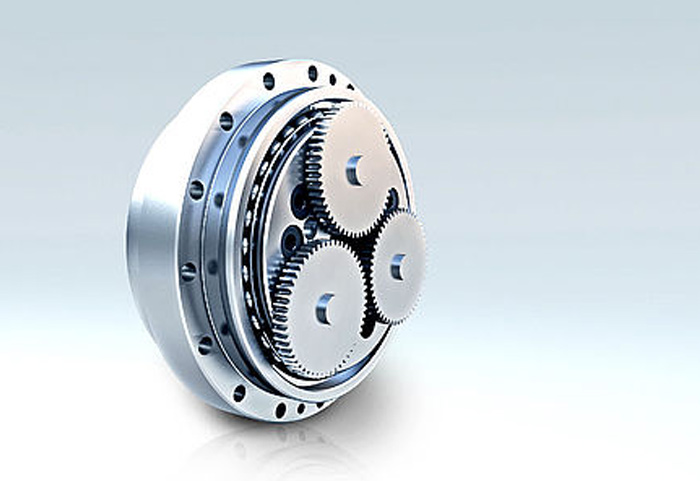

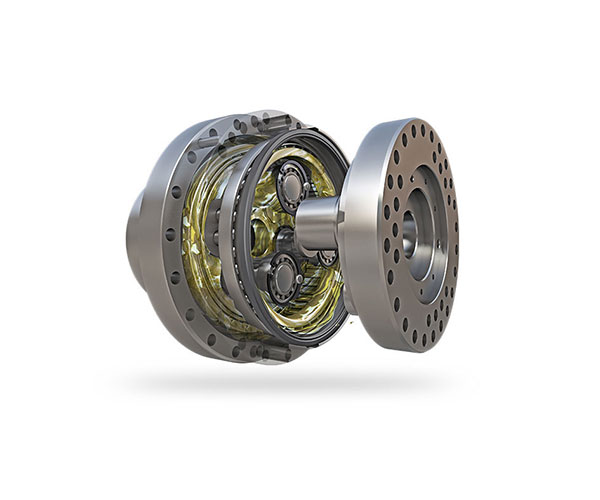

RV

-

The basis of our precision gearboxes

The RV series forms the basic version of our component sets and therefore the basis for our entire product range. It stands for high reduction ratios and low backlash. The output bearing can be determined individually.

Because the power transmission of the RV series eccentric gearboxes runs via rollers, they have a high level of accuracy with low hysteresis loss (< 1 arc.min). An angular contact ball bearing is not integrated in the RV component sets. The external bearing ensures a very compact design and high torsional rigidity. In conjunction with the self-determinable output bearing, this makes the RV series the ideal solution for integrated applications that exactly match your specifications!

The cycloidal gears transmit power via rollers. As a result, the efficiency of our RV gearboxes is high, the service life long and the backlash extremely low. The almost symmetrical gearbox design and the roller bearing support of all shafts guarantee constant operating behavior over the entire service life. They also allow short-term load peaks of up to 5 times the specified rated torque, as can occur in emergency stop situations, for example.

RF-P

-

High speed in a small space

We have designed the RF-P series solid shaft gearboxes for fast applications in the smallest of spaces. This makes them ideal for use in the arm axes of Delta and SCARA robots or in the wheel drive of automated guided vehicles.

The compact cycloidal gears of the RF-P series set new standards when it comes to high speed in a small installation space. They enable output speeds of 200 min-1 and work with extreme precision (hysteresis loss

Mecanum wheel

-

Omnidirectional mobility for mobile automation concepts

Whether turning on the spot, cornering in any radius or maneuvering in the tightest of spaces - thanks to the Mecanum wheel, driverless transport vehicles, conveyor vehicles or autonomous mobile robots can move freely in all directions like a hovercraft. Without any maneuvering or turning circles. This omnidirectional maneuverability enables limitless mobility and makes the Mecanum wheel a key component for modern, mobile drive concepts. Our drive units combine the Mecanum wheel with innovative cycloidal gear technology to guarantee the best performance with ultimate compactness.

RVW

-

Perfect drive concept for driverless transport systems

We have developed a drive unit with a Mecanum wheel for driverless transport systems. These special wheels allow a transport system to move freely in any direction. This fully integrated and decentralized drive concept, in which all necessary components are housed in the wheel unit, offers the user maximum design freedom in the construction of AGV solutions.

Especially for mobile automation solutions, Nabtesco offers a fully integrated and decentralized drive unit with Mecanum wheel, which combines the highest precision with maximum robustness, reliability and durability and thus meets all the requirements of modern automated guided vehicles (AGV). The RVW Mecanum wheel drives used allow high torque performance even in the smallest of spaces and have an integrated main bearing that optimally absorbs the radial and axial forces that occur. Thanks to the cycloidal gears, the compact and extremely robust drive concept is also completely maintenance-free. All necessary components are housed in the wheel unit. This offers the user maximum design freedom in the construction of AGV solutions.

Nabtesco makes you mobile:

- Fully integrated and decentralized drive concept

- Omnidirectional mobility thanks to the Mecanum wheel

- Precise, robust and durable cycloidal gears

- Compact design

- Completely maintenance-free

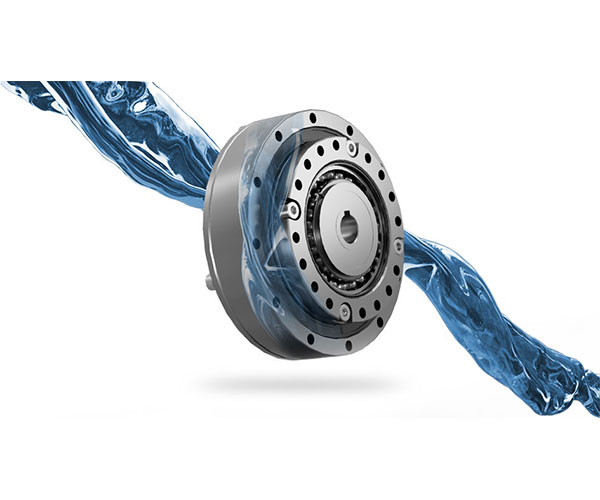

Strain wave gears

- Backlash-free strain wave gears in excellent quality

Strain wave gears are characterized by absolute zero backlash, excellent repeat accuracy and a high torque capacity - all with small dimensions and low weight. We can also design all strain wave gears individually and tailor the performance, geometry, material, interfaces and gearbox properties precisely to your application, including function, component and system integration if required. This means that you do not have to compromise on the design of your machine or robot. Our motto: It is not the application that has to be adapted to the gearbox, but the gearbox to the requirements.

Gear sets

-

Highly integrable strain wave gears

Our backlash-free component sets are available in various designs and sizes. They offer high dynamic torques, excellent transmission and repeat accuracy and maximum integration flexibility. The gearbox sets can be fully integrated into existing applications and form the basis for compact, powerful and efficient designs - an ideal solution for robotics and automation.

Gear sets are the simplest version of the strain wave gears. They consist of the components flex spline, circular spline and wave generator and are characterized by a high power density. The component sets are suitable for customers who want to integrate the gearbox into an existing application. Thanks to their single-stage reduction ratio, the backlash-free gearboxes enable the construction of extremely compact applications. A suitable high-performance lubricant is provided, as well as support with integration and assembly. Interfaces can be individually adapted. A central hollow shaft is available on request.

Gear sets Plus

- Strain wave gears with output bearing

In addition to the three basic components flex spline, circular spline and wave generator, the gear sets plus also have a tilt-resistant output bearing. This means they are ready for immediate installation and significantly reduce the design and assembly effort. The backlash-free gearboxes cover a wide range of torques and impress with the best performance data and maximum flexibility in terms of customization.

The gear sets plus are our tried-and-tested gearbox sets including a tilt-resistant output bearing. Cross roller bearings (CRB) are installed. These are able to absorb high tilting moments and thus ensure safe and reliable operation. The output bearings are perfectly matched to the respective gearbox set and contribute to the high load capacity of the strain wave gears. A coupling (Oldham coupling) is optionally available to compensate for any radial offset between the motor and gearbox input shaft.

Gear units

- Closed plug-and-play solutions

Our gearbox units combine cutting-edge technology and maximum user-friendliness in a compact design. The backlash-free plug-and-play solutions are fully enclosed and have components such as output and drive bearings as well as a sealing system already on board. Users benefit from outstanding performance, simple integration and absolute reliability with a long service life.

The gearbox units are based on the gearbox sets and, in addition to a tilt-resistant output bearing like the gear sets plus, also have a tilt-resistant input bearing and a sealing system. The fully enclosed strain wave gears are ready for immediate installation and very easy to handle thanks to the plug-and-play concept. The outstanding performance enables significant increases in performance and efficiency in your automation. Depending on the application, you can choose between a hollow shaft variant for the passage of external media or a solid shaft with minimal mass inertia.

Digital gearboxes

-

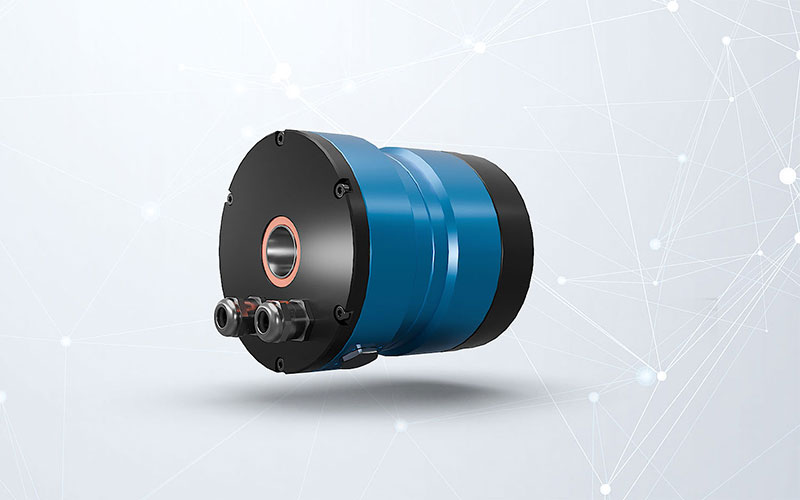

Digital gearboxes: Smart, backlash-free, installation space-neutral

Our digital gearboxes combine high-precision, backlash-free strain wave gear technology with smart sensor technology and artificial intelligence - without any change in size. The strain wave gears meet all the requirements for integration into intelligently networked and digital production processes and make a decisive contribution to increasing efficiency, optimizing performance, conserving resources and improving cost-effectiveness. All in all, this results in potential savings in the double-digit percentage range.

The digital gearbox integrates smart sensor technology with the same dimensions as a standard gearbox with comparable performance data and therefore offers a space-neutral solution for intelligent automation. Sensors determine torque, temperature and vibration. Combined with our practical experience, reliable conclusions can be drawn about the condition of the gearbox. Continuous condition monitoring makes it possible to calculate the actual service life of the gearbox, determine the gearbox fault, detect overloads, unsuitable operating points and cases of misuse and creates the conditions for sustainable optimization strategies and predictive maintenance concepts.

Actuators

-

Complete systems for your automation

Our compact actuators provide you with powerful complete systems that make your automation much easier. The unique design based on our backlash-free strain wave gears offers you high functionality, easy handling and unparalleled flexibility. All actuators are customized and precisely adapted to your application. The integration of digital functions is also possible.

Actuators are complete, pre-assembled drive systems and typically consist of a gear set, bearings, housing and electric motor with encoder. All components are perfectly matched and achieve unsurpassed performance with minimal space requirements. Whether hollow shaft or solid shaft, with or without brake, with or without power electronics, standard or high-voltage: our modular system includes a wide range of customizing options and leaves nothing to be desired. Depending on customer requirements, a wide variety of sensor types can be adapted and additional components such as torque sensors, temperature sensors, position sensors, etc. can be integrated. Our actuators are fully corrosion-protected and already achieve protection class IP65, so that they can be used directly without additional enclosures and seals.

Short gears

-

Short gears: Strain wave gear technology with impressive performance improvement

The Nabtesco strain wave gears have been equipped with new detailed designs through changes to the gearbox geometry. As a result, every core component has been optimized. Convince yourself of 120% power density, 140% service life (10,000h, market standard 7,000h) and all this with the same size. Specially developed for humanoid robots and cobots.

Rotary indexers: Strong, precise and compact

- An innovative alternative for servo-driven rotary indexers

rotary indexers (also known as rotary indexing tables or rotation tables) realize rotating movements. They are often installed as components in positioners, but are also used separately (e.g. if the application does not require a swivel axis). Our rotary indexers with integrated angular gears are based on cycloidal gear technology that has been tried and tested in robotics for decades and, thanks to their special design, are significantly more precise, dynamic and rigid than conventional solutions. This gives you an enormous increase in performance and efficiency in production.

RS

-

Positions even the heaviest loads with high precision

We have developed the RS series especially for positioning heavy loads. These precision gearboxes with hollow shaft have an integrated angular gearbox and a stable, durable design.

The high-precision RS series gearboxes with integrated angular gearbox are designed for axial loads of up to 9 tons. A cast-iron base ensures stable, hard-wearing floor mounting. The motor is mounted at a right angle and is therefore easily accessible. With this compact design and its exceptional power, the hollow shaft gearboxes of the RS series are clearly superior to conventional camshaft and worm gearboxes.

RSX-40K

-

Innovative solution for demanding positioning tasks

With the innovative combination of cycloidal gears in a rotary indexer including an integrated swivel axis, we offer you an economical plug-and-play solution for demanding positioning tasks. The RSX-40K rotary indexer scores with maximum accuracy, load capacity and durability and enables ergonomic working. The design is modular. This guarantees easy adaptation to individual requirements. Whether welding, gluing or laser cutting: The variable positioning unit can be used wherever parts need to be joined or cut.

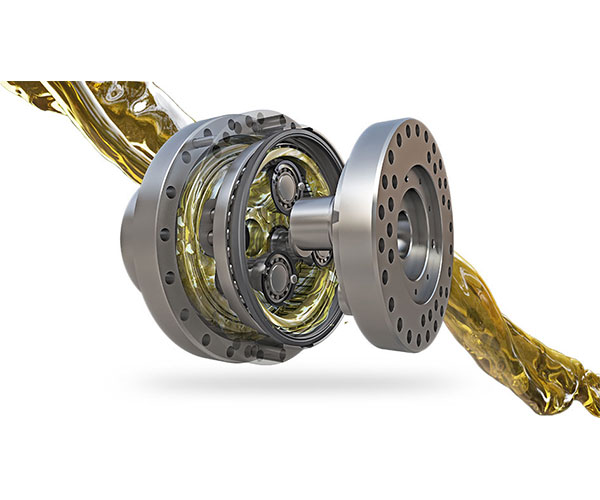

Lubricants

RV Grease LB00

-

Top-class high-performance lubricating grease: RV Grease LB00 is a further development of our lubricant Vigogrease RE 0. It offers an increased performance level and has been optimized in particular with regard to smooth running properties, low-temperature characteristics and resistance/durability. RV Grease LB00 is a combination of lithium soap, synthetic hydrocarbon oil, mineral oil and various additives. The special additives ensure excellent lubrication performance over a wide range of applications (temperature, speed, load) and guarantee smooth running and a long service life of the cycloidal gearbox. Perfect operation is guaranteed even at low temperatures.

Delivery forms and container sizes:

- 270 g tube

- 16 kg tin bucket

- 170 kg drum

Vigogrease RE 0

-

State of the art: Vigogrease RE 0 is the further development of our lubricant Molywhite RE 00. Like the tried and tested Molywhite lubricant, Vigogrease RE 0 also consists of a combination of synthetic and mineral oils as well as EP additives based on a lithium soap. However, thanks to the new, optimized formula, Vigogrease RE 0 has an increased viscosity. This has enabled us to improve the shear stability of the lubricant and the temperature behavior of the gearbox. Despite the increased viscosity, the starting efficiency of Vigogrease improved by 5 % compared to Molywhite.

Delivery forms and container sizes:

- 400 g tube

- 2 kg can

- 16 kg tin bucket

- 170 kg drum

Molywhite Grease RE 00

-

Our classic: The Nabtesco lubricant Molywhite Grease RE 00 is an EP lithium soap with excellent wear resistance. It is based on a combination of synthetic and mineral oils with an organic molybdenum compound. The lubricant is characterized by a very good pressure profile. Thanks to its low viscosity, Molywhite RE 00 flows easily into every corner of the RV gearbox's complex lubrication system. This effectively ensures the performance of the gearbox and increases its efficiency and service life.

Since 2008, we have been filling our gearboxes exclusively with the Molywhite successor Vigogrease RE 0, but you can still obtain Molywhite Grease RE 00 from us! Used Molywhite can also be mixed with Vigogrease.

Delivery forms and container sizes:

- 400 g tube

- 2 kg can

- 16 kg tin bucket

- 170 kg drum

Synthetic gear oil RV Oil SB150

-

Perfect for high speeds: We have responded to numerous customers' requests for an oil as a high-performance alternative to lubricating greases and now offer RV Oil SB150, a synthetic gear oil that best meets the requirements of the market. We have developed the lubricating oil together with users and a renowned German research institute with regard to high-speed applications, durability and use at high temperatures. These requirements were verified through numerous trials, analyses and field tests. Compared to lubricants, the gear oil offers a significantly better heat capacity and enables homogeneous heat distribution in the gearbox - and therefore has an effective cooling effect.

RV Oil SB150 is available in 20 l and 200 l containers and as a 1000 l IBC.

- Optimized: For use in cycloidal gears in machine tool construction, etc.

- Special additives: For a long service life and high precision over the entire service life of the gearbox.

- Service: Quick lubricant change in the field and rapid filling during initial assembly possible.

TMO 150

-

High-performance gear oil for optimum performance: Kyodo Yushi TMO 150 was specially developed for use in compact precision gearboxes. Thanks to maximum additivation with organic Mo compounds, the polyglycol gear oil has a very high viscosity index and is characterized by excellent abrasion resistance and low friction. It therefore guarantees high load capacity and effective wear protection, prevents seizure even in highly stressed steel applications and at the same time offers exceptional resistance to oxidation and thermal stress. These properties contribute to the overall efficiency of the entire drive train.

Delivery forms and container sizes:

- 10 l can

- 20 l can

- 209 l drum

- 1,000 l IBC

Turmogrease IFM blue

-

High-performance special grease: Turmogrease IFM blue is a special lithium soap grease based on synthetic oil. It offers outstanding wear and corrosion protection and has a pronounced metal affinity. Thanks to its excellent low-temperature properties, the lubricant ensures a low frictional torque and low starting resistance. Even in high-speed gearboxes, it causes only minimal heating and is therefore ideal for long-term and lifetime lubrication. An excellent solution for strain wave gears.

Delivery forms and container sizes:

- 20 x 400 g cartridges

- 6 x 1 kg cans

- 25 kg hobbock

Mechatronic systems

-

Mechatronic systems are the future

Mechatronic systems integrate mechanics, electronics, control technology and IT and are at the heart of innovative solutions. They enable completely new functions and pave the way for advanced technologies and revolutionary applications. The complex interplay between the various specialist disciplines requires a high level of expertise, experience and system integration. Nabtesco bundles mechanical, electronic and digital expertise within the corporate family and thus offers a unique pool of knowledge, experts and resources that is unparalleled on the market. The result is individual solutions with a high innovation factor, unique performance levels and impressive efficiency potential.

CV-EPS

-

Steer-by-wire platform for heavy commercial vehicles

CV-EPS (CV-EPS = Commercial Vehicle Electronic Power Steering) is a modular steer-by-wire platform for autonomous driving (mechanical construction kit with software-based customizing). The innovative steering actuators - developed in collaboration with adcos, a software and hardware expert and Nabtesco Group company - open up completely new possibilities in the development of pioneering transportation concepts and are an important building block for the mobility of the future.

Actuators

-

Complete systems for your automation

Our compact actuators provide you with powerful complete systems that make your automation much easier. The unique design based on our backlash-free strain wave gears offers you high functionality, easy handling and unparalleled flexibility. All actuators are customized and precisely adapted to your application. The integration of digital functions is also possible.

Digital gearboxes

-

Digital gearboxes: Smart, backlash-free, installation space-neutral

Our digital gearboxes combine high-precision, backlash-free strain wave gears technology with smart sensor technology and artificial intelligence - without any change in size. The strain wave gears meet all the requirements for integration into intelligently networked and digital production processes and make a decisive contribution to increasing efficiency, optimizing performance, conserving resources and improving cost-effectiveness. All in all, this results in potential savings in the double-digit percentage range.

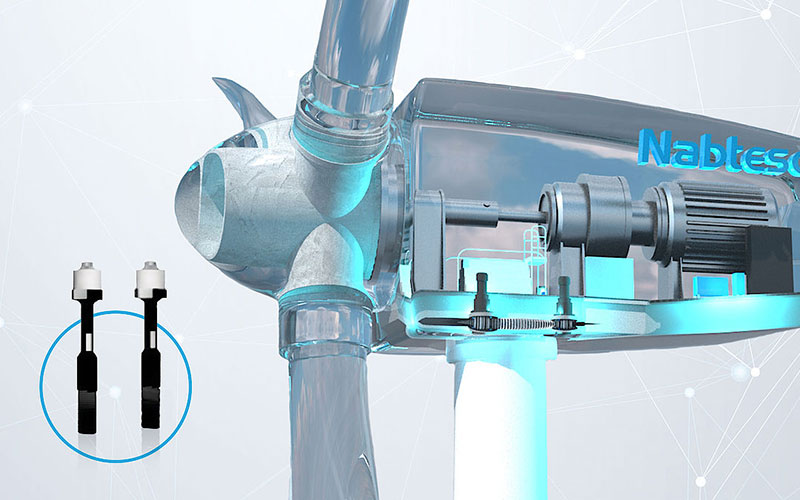

CMFS

-

Condition monitoring for the yaw drive system of wind turbines

The condition monitoring system with fail-safe function (CMFS) enables permanent, seamless condition monitoring of the yaw drive system of wind turbines - both during operation and in phases in which the yaw drive are not actively moving. It monitors the individual drive units, detects overload situations and automatically ensures even load distribution. This extends the service life of the wind turbines, prevents power generation failures and significantly reduces repair, maintenance and operating costs. A real game changer for the wind industry.

Solutions

-

Cycloidal gears from Nabtesco are used in diverse industries

A look at the diverse applications in which Nabtesco gears are used shows that they cut a good figure – and not only on paper. Whether in robotics or packaging technology, wind power installations or machine tools, antenna construction or medical technology: Our precision gears are used in applications that require exact positioning and absolute reliability.

Automation and handling

-

User-friendly gearboxes for automation & handling

Wherever components, workpieces, assemblies, semi-finished or finished parts need to be moved, maximum precision, dynamics and reliability are required. Our precision gearboxes stand for maximum performance, efficiency, safety and maximum availability and are the key to future-proof drive concepts and competitive manufacturing processes. We have developed economical plug-and-play gearboxes especially for automation and handling in small and medium-sized companies, which combine excellent power density with maximum user-friendliness.

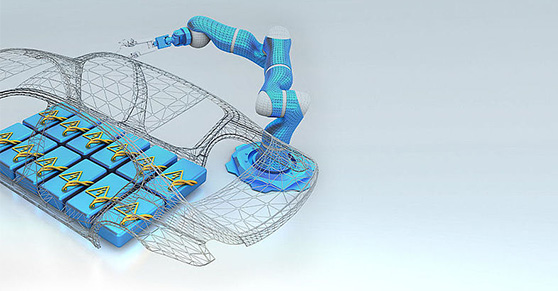

Electromobility

-

Our gearboxes get production in electromobility up to speed

Electromobility is picking up speed. As a long-standing robotics and automation partner, we are very familiar with the high demands made by the industry in terms of precision, quality, performance and process reliability. Wherever handling and positioning processes need to be automated and executed with high precision in production, our precision gearboxes make a significant contribution to greater efficiency and cost-effectiveness.

Medical technology

-

Safe high-tech gearboxes for the future of medical technology

Digitalization and automation are opening up new, revolutionary possibilities for diagnostics, treatment and care in the healthcare sector. We are an experienced, long-standing industry partner and have a high level of engineering and application expertise in the field of medical technology. Our innovative precision gearboxes and drive systems offer you maximum precision, safety, hygiene and reliability and form the basis for high-performance, efficient and fail-safe medical technology devices.

Robotics

-

Nabtesco gearboxes for robotics: resilient, precise, powerful

Gearboxes are a core technology in the design of robots. As converters of torque and speed, they are a central component in the drive train and have a decisive influence on the performance data of the kinematics - particularly in terms of accuracy, reproducibility and service life. The following applies: Every robot is only as good as its gears. We are an established system provider, experienced solution specialist and close development and design partner for robotics, working with all recognized robot manufacturers and reliably supporting the growth of our customers. Our innovative precision gearboxes offer high performance in the tightest of spaces and ensure maximum productivity and robot availability. With our many years of experience and in-house engineering, we help you to solve your problems together. We love a challenge and will find a solution for every requirement.

Woodworking

-

Powerful gearboxes for automatic woodworking

Wood is one of the most important renewable raw materials and is extremely versatile - be it for building houses and furniture, as a basis for paper production or as a source of energy. In view of the increasing demands on productivity, product individuality, variant diversity, cost-effectiveness, digitalization and sustainability, the wood industry is increasingly relying on the use of robot technology and automation solutions. Precision, efficiency, resilience and reliability are of central importance here. With our gearboxes, you are a decisive step ahead. The cycloidal gearboxes and strain wave gears combine the expertise and experience of over 35 years with innovative, future-oriented approaches and ensure efficient and precise wood processing.

Food technology

-

Hygienic gearboxes for food technology

The level of automation in food technology is constantly increasing. Innovative robots, intelligent sensor solutions, advanced gripper technologies, smart image processing systems and adaptive control systems are expanding the application horizon and opening up new possibilities. We are a long-standing partner to the food industry, an experienced automation specialist and the global market leader in the field of robot gearboxes, combining unique industry, technology and application expertise. Our gearbox and drive solutions are state-of-the-art, exceptionally powerful, extremely reliable and easy to clean and support food technology in meeting the growing demands for productivity, efficiency, availability, food safety, hygiene and sustainability.

Machine tool construction

-

Gearboxes for the highest demands in machine tool construction

Precision is a top priority in machine tool manufacturing. After all, blanks, workpieces and tools need to be positioned with micrometer precision to ensure high production quality and efficiency. Our gearboxes have been used in a wide variety of machine tools for decades and have proven themselves millions of times over. They meet the highest accuracy requirements, ensure enormous increases in production efficiency and at the same time improve the cost-effectiveness of machine tools many times over - features that are valued by leading manufacturers in the automotive industry and numerous other sectors worldwide.

Packaging technology

-

Packaging technology: Innovative gearboxes for peripherals and robots

In order to remain internationally competitive, high productivity, efficiency and reliability are required in packaging technology. Gearboxes play a key role in this. We have more than 35 years of experience in robotics & automation and make the industry fit for the future with innovative drive concepts. Whether high numbers of cycles, fast movements or changing load conditions: Our solutions set standards in terms of precision, dynamics, installation space, durability and reliability and form the perfect basis for building high-performance systems with a small machine footprint - be it packaging machines, filling systems, picking solutions, handling and palletizing robots or automated guided vehicles (AGVs) for internal transport.

Welding

-

Spot and path-accurate welding thanks to high-precision gears

The use of robots and automated systems in welding leads to higher productivity, improved quality and considerable cost savings. With our gearboxes, you can fully exploit the potential of welding automation. The cycloidal gears and strain wave gears offer maximum precision, dynamics and reliability and guarantee exact positioning of workpieces, components and welding heads. Users benefit from consistently high weld seam quality, minimal reworking and shorter production times.

Mobile transport systems

-

Compact gearboxes for mobile transport systems

Mobile transport systems such as automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) ensure an efficient, smooth flow of materials and goods and have long been an integral part of flexible production and logistics processes. Precision, dynamics, reliability and compactness are among the basic requirements. Home game for our gearboxes . The cycloidal gearboxes and strain wave gears offer top performance in the tightest of spaces and get your transport logistics up to speed!