- Offer Profile

- Rollon designs, engineers and markets a complete range for linear motion products. Our solutions are based on standard and customizable products to meet the specific needs of each application.

Linear Rails

- Linear and curved guides with ball and roller bearings, with hardened raceways, high load capacities, self-alignment and capable of working in dirty environments.

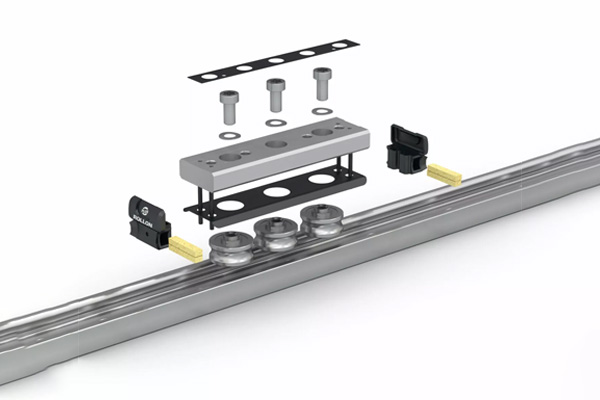

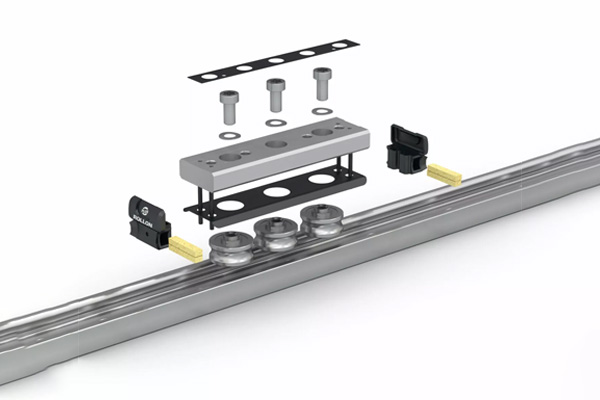

Compact Rail & Compact Rail Plus

-

Compact Rail PLUS

Very high load capacity roller guide. The most tolerant self-aligning system on the marketThe Essential

Skate equipped with new double-row ball bearing rollers. Increase in load capacity up to +65% in radial and +120% in axial direction, compared to

Compact Rail with identical dimensions.

Excellent reliability in polluted environments thanks to the generous dimensions of the rollers, the new protective side seals and self-aligning scrapers for optimal cleaning of the raceways.

Integrated lubrication system with progressive release felt

Single rail, “TG” type, which can accommodate 4 different versions of runners. C” profile rail, with convex raceways for greater rigidity.

Roller guide designed to be mounted on unmachined surfaces. Drastic reduction in cost and time required to mount the system

CF53 (or C43F) high performance steel track with induction hardened and ground raceways

Maximum reliability in industrial automation applications with demanding cyclical conditions

Linear accuracy of less than 0.1 mm for a rail length of 1000 mm

Operating temperature range between -20°C and +120°C, short peaks at +150°C accepted

Adjustable skate preload. Easily butt-jointed rails for unlimited travel

Suitable for use in polluted, humid, low and high temperature environments

X-Rail

-

Keep it Cost Effective

Linear bearings with bended C-profile.

Available in zinc-plated steel, stainless steel or hardened with Rollon NOX treatment.Cost effective

The use of bended steel profile makes X-Rail an efficient cost effective solution

Easyslide

-

Heavy loads with a compact solutionn

Linear ball rails with single slider or multiple sliders.

The system consists of an “C” shaped linear profile rail, and one or more internal sliders with caged recirculating ball bearings.Long lifetime

Induction hardened raceways

with 1.2 mm effective depth and

hardness between 58 and 62 HRC.

Curviline

-

Select your product

Download Catalogue

Download 3D Models

Curviline

Yes, It's Curved

Curvilinear rails with radial ball bearing rollers

Constant and variable radii in order to meet every application needLong lifetime

Curviline is available with

induction hardened raceways.

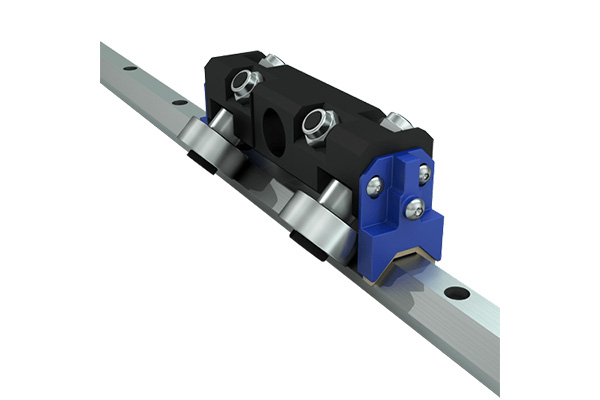

O-Rail

-

Design with No Limits

Modular linear guides with rollers.

Versatile for the highest flexibility of configurations.

The original shape of the FXRG guide features 3 raceways arranged at 90°, over which the R series rollers can run on any one of the 3 raceways.Versatile for

multiple configurations

The original shape of the FXRG guide

features 3 raceways arranged at 90°.

Prismatic Rail

-

The choice for heavy loads

Prismatic rails with bearings and induction hardened

v-shaped raceways.

Rails can be machined with two straight cuts, one straight and one slanting cut or two slanting cuts in order to create

joinable versions for longer strokes.Long lifetime

Thanks to induction hardened raceways.

Speedy Rail

-

Dirt and Contaminants Won't Stop It

Self-supporting linear rail in extruded aluminum with steel rollers covered in plastic compound.

No maintenance and lubrication required, total reliability even in dirty environments with uniquely quiet operation.Long lifetime

Up to 80.000 Km thanks to a deep hard

anodized surface treatment of the aluminum profile.

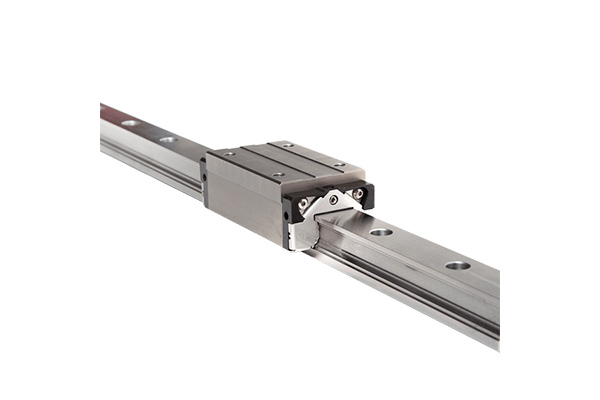

Mono Rail

-

High Precision under Heavy Loads

Re-circulating ball profiled rails with the highest degree of precision.

Four rows of balls run in the self-lubricated slider.Long lifetime

Mono Rail guides have always

induction hardened raceways.

MiniRoller Rail

-

An alternative to miniature ball guide rail

Adaptive design that saves space and installation time, with rollers, induction hardened and honed raceways.

Super smooth and silent operation and an adaptive design that is easy to customize and integrate into customer’s assemblies

Telescopic Slides

- Linear and curved guides with ball and roller bearings, with hardened raceways, high load capacities, and low bending, resistant to shocks and vibrations. For partial, total or extended extraction up to 200% of the length of the guide.

Telescopic Rail

-

The go-to for heavy duty

8 different series of telescopic linear rails with hardened raceways

for high load capacity.

Minimum deflection while under very heavy loads,

even when fully extended.

Telerace

-

Improves automation

Telescopic guides with ball bearings.

Thanks to the bearings Telerace telescopic guides are the Ideal solution for applications with variable stroke or vertical movements.

Light Rail

-

Light loads, High quality

Light telescopic linear guides with full or partial extraction.

Ideal for applications in which the mass of the rail is just as important as the deflection.

Hegra Rail

-

Extracting heavy loads

Steel, aluminum and stainless steel Telescopic guides available for partial, full and overextended applications.

Extremely sturdy profiles can extract heavy loads with minimum deflection up to 200% of the length of the guide in closed position.

Actuators

- Linear actuators with different guide configurations and drives, available with belt, screw or rack and pinion drives according to different needs in terms of precision and speed. Guides with bearings or ball recirculating systems for different load capacities and critical environments.

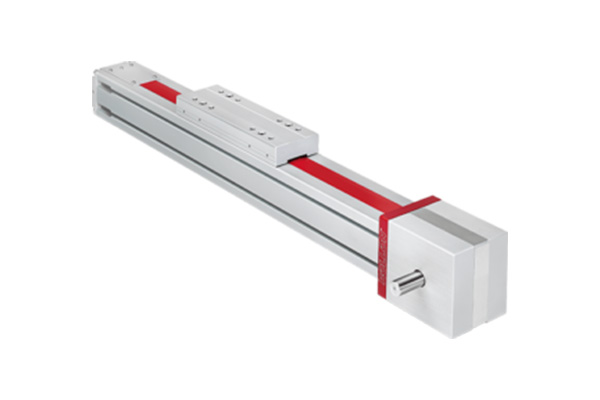

Plus System

-

The highest level of protection

High performance linear units with steel re-enforced

driving belt transmissions.

Exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration.High protection for dirty environments

A polyurethane sealing strip ensures complete protection of the belt drive and linear guide system against dust, dirt, chips, liquids and other contaminants.

Clean Room System

-

Designed for clean rooms

Belt driven linear actuators with aluminum profile.

A special vacuum system, prevents particles from being discharged in the environment where the linear unit is located.Clean room class ISO 3

Special vacuum system with:

• sealing strip alog the opening where the slide moves

• 0.8 vacuum pump connected to 2 vacuum pipes located inside

the drive head and the idle head

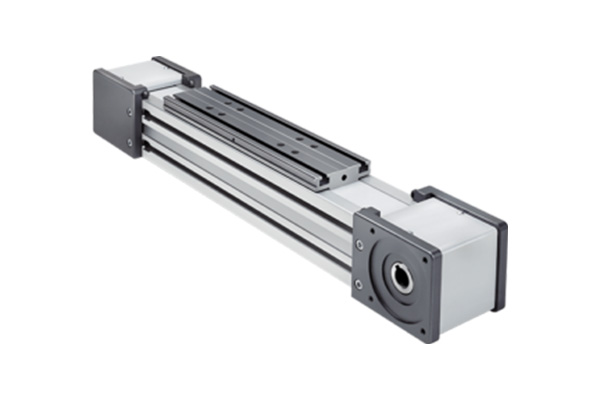

Smart System

-

High performance

and simple design

High performance linear units with steel re-enforced

driving belt transmission.

The ideal solution for those application where high dynamics and load capacities meet cost effectiveness.High Dynamics

• Speed up to 4 m/s

• Acceleration up to 50 m/s²

Eco System

-

Versatile linear unit

Versatile belt driven linear motion units.

Linear actuators made of a self-sustaining extruded aluminum frame and driven by a polyurethane belt with AT

metric profile steel inserts.High Dynamics

• Speed up to 5 m/s

• Acceleration up to 50 m/s²

Uniline System

-

Reliable inside and out

Compact belt driven linear motion units.

The motion system is made up of rails with

radial ball bearing sliders.Linear motion by Compact Rail guides

Rollon Compact Rail linear bearings are mounted

inside Uniline System actuators.

Precision System

-

For highest precision

High precision ball screw driven linear units.

3 different product series with repeatability up to 5 µmHigh repeatability and accuracy

Smart System actuators have a

repeatability accuracy of ±0,005 mm

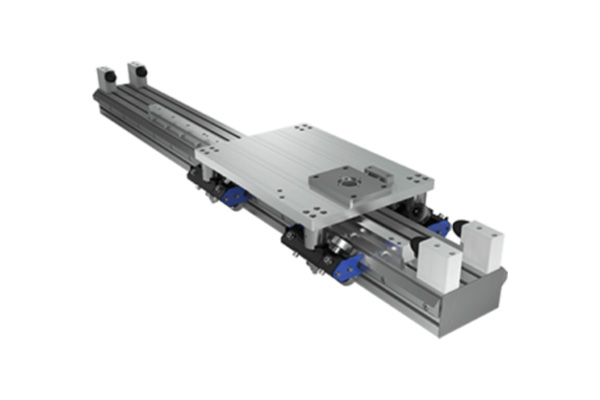

Tecline

-

Ideal for heavy load cartesian

multi-axes systems

Linear axes with rack and pinion transmission.

Rolling on trapezoidal or recirculating ball guides.

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg

with fast and silent functioning.High load capacity

Payloads from 10 to 2000kg

Modline

-

Long stroke with belt is possible

Linear axis with belt drive. Rolling on trapezoidal, round

or recirculating ball guides.

Ideal to be combined with Tecline actuators for creating

multi-axes cartesian systems.Patented short belt solution

for long strokes

Long strokes with belt axes is now possible

thanks to a Rollon patented solution.

Speedy Rail A

-

Life time up to 80.000 Km

Self-supporting linear rail in extruded aluminum

with steel rollers covered in plastic compound.

No maintenance and lubrication required for this motion system, total reliability even in dirty environments with uniquely quiet operation.Long lifetime

Up to 80.000 Km thanks to a deep hard

anodized surface treatment of the aluminum profile.

Telescopic Systems

-

Maximize productivity, minimize footprint.

Ideal for applications with limited space between machine and ceiling, where axis travel distance exceeds vertical clearance.

Actuator Systems

- Integrated actuators for industrial automation, they find applications in numerous industrial sectors: from machinery servo systems to high precision assembly systems, packaging lines and high speed production lines. It has evolved from Actuator Line series in order to meet the most demanding needs of our customers.

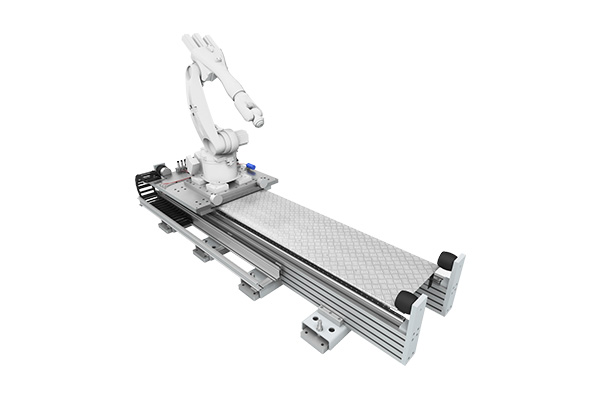

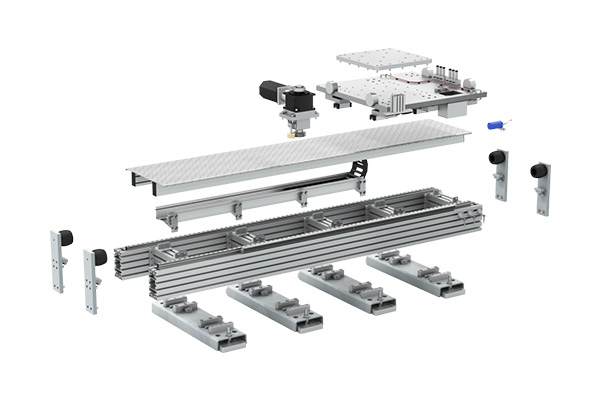

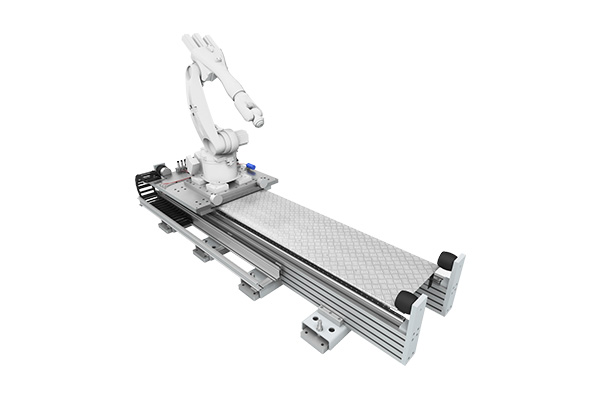

Robot Transfer Unit

-

Improve your robots’ reach

Shuttle system for moving robots and heavy loads

for long distances with high dynamics.

A complete range of 11 sizes for every model of robot:

6 sizes for robots from 140 kg to 1500 kg

5 sizes for robots and cobots up to 140 kgEasily integrated with any type of robot

A complete range guarantees simple integration,

for any type of robot, weighing up to 1500 Kg.

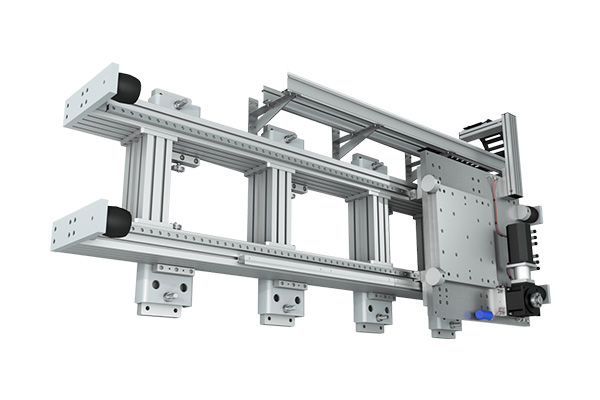

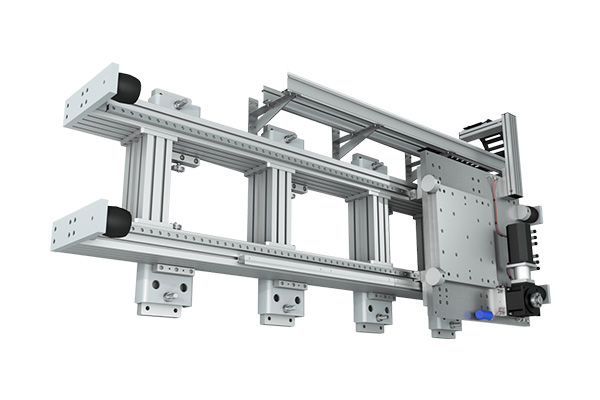

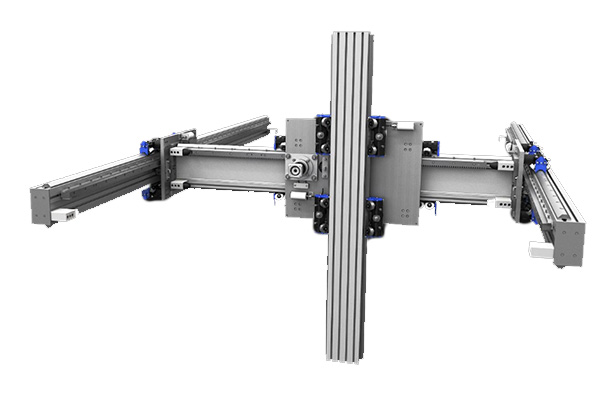

XYZ Multi-Axis

-

We build it for you

Versatile multi-axis systems designed

starting from your specific needs.

Different X/Y/Z configurations available and different

driving systems for any application.

Ready to use

All the advantages of a ready made solution designed for you with our 45 years expertise in linear motion:

• engineered and tested solution

• short assembly time and service

• low maintenance and additional warranties.

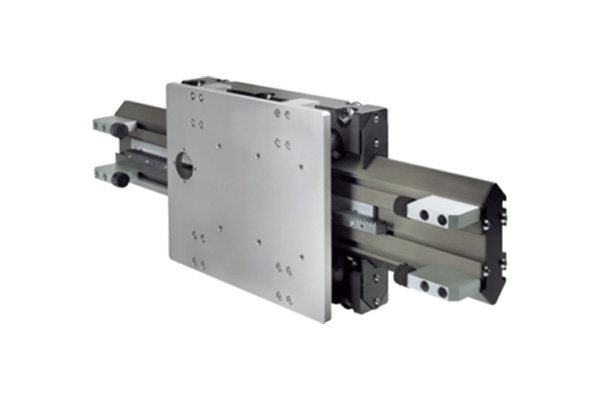

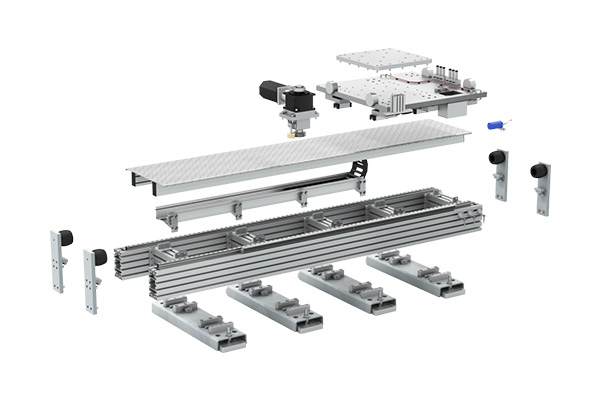

YZ Multi-Axis

-

We build it for you

Versatile multi-axis systems designed

starting from your specific needs.

Different Y/Z configurations available and different

driving systems for any application.All the advantages of a ready made solution designed for you with our 45 years expertise in linear motion:

• engineered and tested solution

• short assembly time and service

• low maintenance and additional warranties

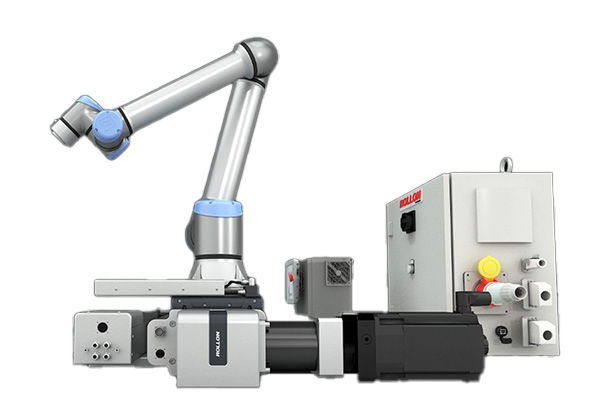

Cobot Transfer Unit

-

Plug and Play for UR Cobots

A full range of Transfer Units for improving the reach

of each size of UR Cobots.

Rollon CTU solution is certified by Universal Robots and includes a fully accessorized linear unit, Rollon URcap software, electrical cabinet, motor drive and gearbox, cables.

Industries

Intralogistics

-

Warehouse process optimization

In the Intralogistics market, even one second can make the difference. Rollon is highly specialized in improving the efficiency of warehouse process automation, developing industry-specific mechanical systems combined with customized components.

Through a wide range of products combined with a industry specific know-how, Rollon offers customized solutions that ensure reliability and speed within increasingly contained footprint. The perfect combination for an efficient warehouse

Industrial machines

-

Efficiency in any production process

Efficiency is a key concept for industrial machinery used in the production process: workstations, cutting machines, painting machines and wood or marble processing machines need to be able to operate correctly over a long period of time – often with high cycles, under critical conditions and when handling liquids, dust and chips from the process as well as pollutants and corrosive substances.

The application experts at Rollon are familiar with the requirements of machine and plant construction, and design every linear application for your industrial machines to the exact specifications you supply us with.

Railway

-

On-time and safe journeys

In the railway industry, transport efficiency and passenger safety are paramount. Each part of a train car (railway, underground or tram) must be designed to deliver the highest level of reliability, taking into account impacting factors, such as: harsh environments, corrosive agents, on-going vibration, and everyday wear and tear.

Rollon’s offer meets the car manufacturers requirements by developing sturdy components, compliant with performance and maintenance specifications that ensure long life, low maintenance, low operating costs and high reliability.

In the railway industry, telescopic guides and linear rails are used in many parts of the train. Like in other markets, Rollon stands out for being able to develop specialized, custom solutions that provide flexibility to all design requirements.

Packaging

-

Steady material flow

In the packaging sector, efficiency is measured in terms of productivity, reliability, performance and safety. The ability of an asset to support high-volume operations and reduced production time means immediate savings. The reliability of selected components also ensures the reduction of maintenance costs and increased plant productivity.

Rollon ensures efficiency in the Material flow and offers cost-effective solutions, modular automation systems and tailored implementation. The linear components are suitable for all applications in which dynamic processes are required, long travels must be covered or large loads are to be moved fast

Aerospace

-

Comfortable and smooth design

The aerospace industry constantly demands the most modern technology, services, materials and special solutions. When it comes to the interior design of aircraft, features such as lightweight construction, high load capacity, reduced dimensions, strength and ease of installation must be combined with high performance, good ergonomics and a long service life.

Reducing the weight of an aircraft component means cutting fuel costs. Installing a low maintenance product means reducing aircraft down-times caused by maintenance. Therefore, manufactures of aerospace components must focus on strength, high load capacity, compact size and, above all, weight.

Rollon has partnered with top aircraft cabin interior manufacturers for many years with special and custom designs, resulting in an extensive know-how in the field. It also supplies components for manufacturers of special vehicles and devices, and equipment used in airports.

Building and Furniture

-

The highest degree of project freedom

Sometimes, architects and interior designers need to take their projects to the next level. In order to do it, functionality, aesthetics and reliability need to go hand in hand. Rollon’s linear and telescopic rails are designed to ensure the highest degree of project freedom and perfromance for furnishing projects for retail stores, luxury brand boutiques, yachts, hotels, museums and theaters.

Rollon linear and telescopic rails can also be used in several construction industry applications. Their high performance makes them the ideal solution for handling extremely heavy loads or ensuring a high-quality motion in harsh environmental conditions. Rollon linear and telescopic rails are used in several interior design and architectural/construction applications.

The uniqueness of Rollon products and the company’s ability to offer customizable solutions make its products ideal for technically ambitious or demanding projects.

Special Vehicles

-

Robust and durable performance

Many applications in utility vehicles would not be possible without linear technology: it enables the adjustment of seats in excavators and road rollers, facilitates the handling of stretchers and trolleys in ambulances, or gives firefighters fast access to their equipment.

For the development of customized solutions for all types of highly specialized vehicles, all mechanical components must be carefully selected. This applies to moving parts such as telescopic rail extensions and linear rails. So, in construction vehicles, particularly dirt-resistant linear rails for seat adjustments, sliding doors or moving control panels are employed. A backlash-free run even at maximum load is guaranteed by the extremely robust telescopic extensions.

Rollon’s linear technology is characterized by high load capacity, accuracy and longevity. Even under harsh conditions, the compact motion systems work reliably and precisely, ensuring mobility even in confined spaces.

Healthcare

-

Positive patient experience

In an industry primarily linked to healthcare, the technology employed must deliver high performance and safeguard the well-being of patients and healthcare professionals.

Linear systems must be versatile enough to suit various working environments, adapting to the unique requirements of each application while functioning in strictly regulated settings. Rollon’s offerings can be pivotal in this regard.

Rollon has developed a suite of products that ensure precise and stable linear motion, aiding in the establishment of dependable and secure healthcare settings. Rollon’s solutions are capable of managing substantial loads while preserving compact sizes, making them ideal for use in confined areas.