- Offer Profile

- SensoPart is one of the leading manufacturers of photoelectric sensors and image processing for factory automation. Our aim is to remain one step ahead to be able to offer our customers the most innovative products on the market. In this way we help them to pave the way to the digital factory. In order to maintain our ability to offer the latest technologies, we invest more than usual in research and development and work together with renowned universities and research institutes. Successful products, now considered indispensable for modern factory automation, have been created from the many futureoriented ideas of earlier days. But we do not simply rest on our laurels – because we still have many ideas for the future.

Detect the difference.

- With our innovative sensors and vision cameras we accompany your transformation into a digital factory. Whether for the identification or inspection of objects, positioning tasks in the robotics industry or numerous other sensor tasks, we offer simple and reliable solutions using state-of-the-art technologies, designed with modern interfaces for the integration into future-oriented infrastructure.

VISOR® vision sensors for factory automation

Image processing can be so easy.

Highlights

- Perfectly in tune: A combination of sophisticated hardware and easily configurable software

- Connectivity: Comprehensive protocols (e.g. PROFINET, Ethernet/IP) for seamless integration into your environment

- Flexibility: One of the most extensive vision sensor families on the market offering solutions tailored to your applications

- Scalability: Select your VISOR® to suit to your own requirements.

Hardware + Software = VISOR®

With our portfolio of vision solutions, we cover a wide spectrum of industrial image processing. A high-performance smart camera fitted in a compact and light-weight housing forms the heart of our VISOR® vision sensors. They feature innovative solutions, such as a target laser for simple mechanical alignment or motorised focus for automatic adjustment to your individual operating distance.

The hardware is optimally enhanced by the VISOR® software, which enables the set up of applications in a few simple steps and the adjustment of process parameters. Thanks to the software, the process can also be continuously monitored.

SensoPart vision sensors have proven themselves to be extremely flexible – the VISOR® comes with diverse resolutions of up to 5 megapixels and three different fields of view (narrow to wide). One variant for special applications allows the additional installation of an external lens.

All VISOR® sensors are equipped with a universal interface for installation in your machine, which is further facilitated by integrated standardised transmission protocols (PROFINET, Ehternet/IP).

SensoPart offers the VISOR® with a package of integrated detectors and functions tailored to the application:- Standard: To solve simple image processing tasks

- Advanced: An extended scope of functions for more challenging applications

- Professional: The complete detector package suited to even very complex tasks

The VISOR® vision sensor family offers the right product for every application:

VISOR® Code Reader

-

Reads whatever is printed, dot-peened and lasered.

Highlights- Reliably reads barcodes as well as printed and directly marked data matrix codes, and even several codes simultaneously and mixed 1D/2D codes

- Supplementary object detection for characteristics other than codes

- Evaluation of quality parameters according to ISO/IEC 15415 and AIM DPM 2006

Typical VISOR® Code Reader

The VISOR® Code Reader from SensoPart easily reads bar codes of numerous types as well as printed and direct marked data matrix codes according to the ECC 200 standard, regardless of the carrier materials (metal, plastic, paper, glass).

The sensor even easily deciphers skewed or distorted codes, or those attached to convex, reflective or transparent surfaces.

Built-in early warning system

The VISOR® Code Reader evaluates the quality of your printed and direct marked data matrix codes on the basis of standardised quality parameters according to ISO and AIM standards.

Scope of detectors according to the application:- Standard: Reliable reading of printed codes and labels

- Advanced: Reading of printed and directly marked codes on all backgrounds

- Professional: The complete package, including optical character recognition (OCR)

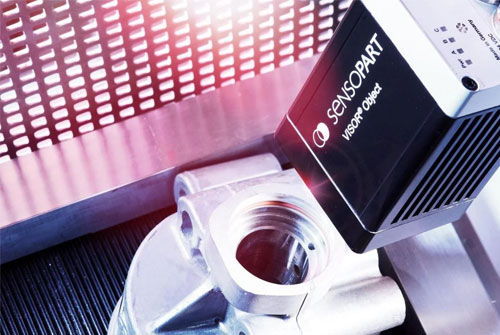

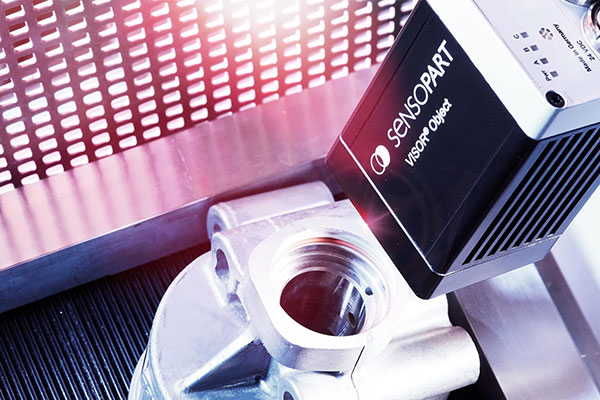

VISOR® Object AI

- Detects the right part in the wrong place and vice versa

Highlights- Detectors for presence and completeness checks, position control and simple measurement tasks

- Precise position determination: x/y-position and orientation

- Easy to use calibration for measuring tasks. Conversion into mm and correction of distortion and perspective

Typical VISOR® Object

Objects that sometimes appear in unexpected positions and have complex shapes and details – classic switching sensors would be completely overwhelmed by such detection tasks.

Not the VISOR® Object from SensoPart: it always maintains its overview, detecting defective parts, parts in the wrong position,

wrong orientation, wrong sequence or a combination of them all – in an instant. The comprehensive calibration functions range from a simple scaling factor to the correction of image and lens distortions at a mouse click. With its highly precise position and orientation detection, our VISOR® Object is one of the best in its class.

An expansive range of detectors is available for inspection tasks and evaluations: pattern matching, contour detection, calliper, BLOB, brightness, grey threshold and contrast detection. Position tracking offers reliable detection of those features that do not repeatedly appear in the original position taught.

All evaluations take place relative to the current part position and orientation, without them having to be defined for every possible position of an individual feature. The color version features detectors for color detection, enabling VISOR® to also distinguish between the finest nuances in shade. This powerful tool allows you to solve even demanding applications confidently!

Scope of detectors according to the application:- Standard: Detectors for simple presence detection, measurement tasks and color identification

- Advanced: Additional comprehensive preprocessing filters and enhanced position tracking for position control and completeness checks. Optional result calculation, and complete palette of tools for your color application

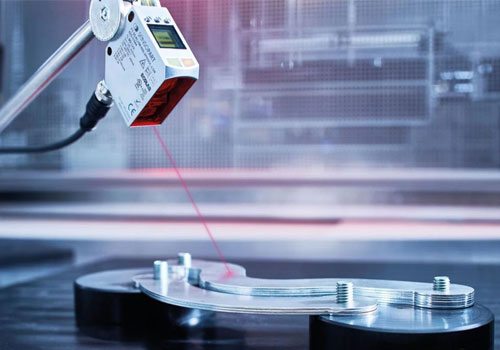

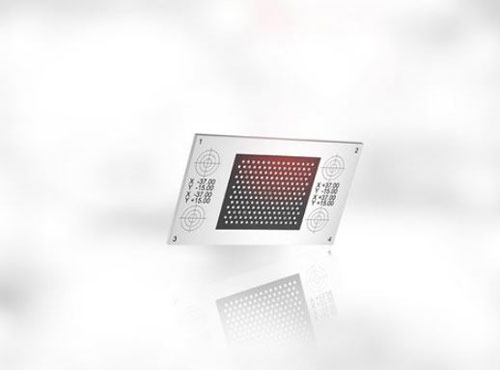

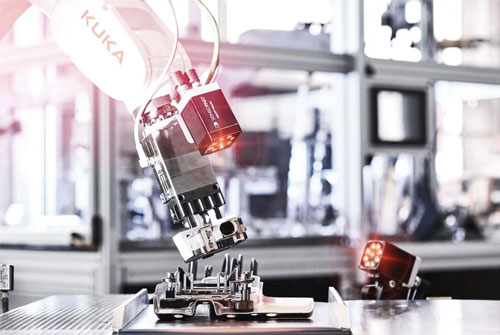

VISOR® Robotic

- An eye on everything – the vision sensor for robotics applications

Highlights- Calibration methods tailored to the application

- Target Mark technology provides 3D object poses in no time Simplified installation through 3D grip point transformation

Typical VISOR® Robotic

Expectations of today’s robotics solutions are steadily rising in the context of Industry 4.0, paired with a simultaneous desire for greater ease-of-use. And this is precisely where the VISOR® Robotic demonstrates its outstanding ability. Available in several versions, it offers the perfect solution for a variety of automation tasks. Designed with integrated and standardised interfaces, VISOR® Robotic can be easily incorporated in existing installations and systems, and thanks to different calibration methods and flexible data structures, it is also suited to a diverse range of procedures.

Scope of detectors according to the application:- Advanced: To solve common image-guided robotics applications

- Professional: Extended scope of functions for identification, enhanced calibration methods and localisation in 3D

VISOR® Allround

-

Object detection in color plus identification united in one device

Highlights- All detectors of VISOR® Object and VISOR® Code Reader united in one device

- Multishot function reveals minimal height differences and suppresses printed markings

- Calibration function for measurement tasks and robotics applications

Typical VISOR® Allround

The VISOR® Allround is the latest member in the VISOR® family and a real multi-talent among vision sensors. In the new allround version, the device unites the functions of the object sensor (i.a. calibration, pattern matching, contour, calliper, BLOB) with the powerful tools of the code reader (bar code, datamatrix and optical character recognition). When feeding parts in correct alignment or positioning components, additional data matrix codes for example can now also be read. With a resolution of up to 5 megapixel even the smallest details are reliably detected and evaluated.

In addition to the monochrome version, the VISOR® Allround is also available as a color version with up to 5 megapixel. Thus additional “Detectors” are available for color evaluation. Even the subtlest nuances in shade can be reliably detected. The relevant object colors, for example, can be taught-in quite simply by push of a button or - thanks to the intuitive color histogram - set graphically for each channel in the colour space. The authorised color tolerances can be defined by the user.

Scope of detectors according to the application:- Advanced: Color detection and object identification within in one device

- Professional: To also solve robotics applications

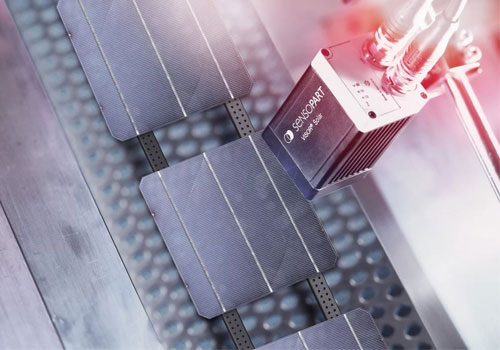

VISOR® Solar

- Vision sensor for automatic detection of wafer and cell geometry

Highlights- Easy integration

- Precise position detection

- Detection of breakouts and holes

Typical VISOR® Solar

SensoPart has expanded its range of vision sensors with the VISOR® Solar in order to combat rising cost pressure in the production of solar cells. The compact sensor detects the position and any damage to wafers and cells. It allows robots to pick up and lay down wafers accurately. Wafers and solar cells with fine breakouts can be directly rejected during this step, before they can completely break up and damage other material.

These sensors can also be integrated in existing lines – as easily as a light barrier. Before a cell is printed, the sensor checks it for damage that could lead to breakage during the print process, preventing costly machine breakdowns.

Optical sensors

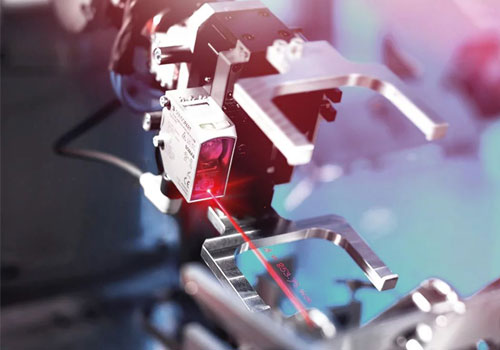

Distance sensors

- Accurate and non-contact distance measurement for automation technology

Highlights- Fast and accurate measurement, precise positioning and detection of a wide range of materials

- IO-Link sensors can be operated in IO-Link mode or standard I/O mode

- Our distance sensors cover a wide range of applications:

- Triangulation sensors for near-field applications

- Time-of-flight sensors for long working distances

Distance sensors for all operating ranges

Triangulation for close range

The measurement principle of optical triangulation is suitable for the precise determination of distances at close range. With the help of special receiver optics and a position-sensitive detector (e.g. a photodiode line), the sensor can determine the object distance regardless of its reflectivity (see illustration below). The color and surface properties (e.g. highly reflective) thus have practically no effect on measurement accuracy.

Time-of-flight for long distances

SensoPart uses time-of-flight technology to measure longer distances (up to 250 m). The sensor emits pulsed laser light that is reflected by the target object. The distance to the object is determined by the time taken between emission and reception of the light. The use of pulsed light provides reliable background suppression and very high immunity to ambient light.

Color & Contrast sensors

- A broad spectrum

Highlights- Efficient part detection Accurate and high-speed detection of the subtlest differences in color and grey values as well as non-colors Accurate and fast printing mark detection Numerous outputs and interfaces for easy integration in machine control systems IO-Link sensors can be operated in IO-Link mode or standard I/O mode

Color & contrast sensors

The attachment of color marks that are then evaluated with a color or contrast sensor is a proven method for identifying objects in industrial production. Even objects with differing shapes and surface properties can be very reliably detected in this way.

Color sensors- Sorting packaging or checking different labels

- Detecting colors and color ranges on packaging and film

Contrast sensors- Detecting printing marks with the subtlest variations in grey values in the printing and packaging industry

- Checking labels and stickers in the printing industry

Luminescence sensors- Detecting labels on glass bottles

- Detecting invisible printing marks for object alignment

Photoelectric sensors

- By far the best object detection

Highlights- Sophisticated laser technology - small, precise laser light spots for highly-accurate small-part detection

- Wide variety of setting options: potentiometer, teach-in, external control cable or fixed pre-setting

- Different transmission light sources for a wide range of requirements: laser, LED or infrared light transmitters

- Intelligent mounting solutions for easy installation and adjustment

Photoelectric sensors and diffuse sensors - Performance and quality made in Germany

Photoelectric sensors and diffuse sensors are the standard sensors in automation technology. At SensoPart you will find the right sensor for almost every conceivable application. Our product portfolio offers a comprehensive selection of differing sizes, ranges and switching variants. Regardless of whether you choose a sub-miniature sensor for restricted machine conditions or a large housing with a particularly long range or scanning distance – all our sensors share excellent performance data, high reliability and solid workmanship “made in Germany”.

Our photoelectric sensors and diffuse sensors offer, for example, precise background suppression, extremely accurate small-part detection or reliable detection of transparent objects. And they operate extremely reliably in harsh industrial conditions: our current sensor series have tightly sealed (IP 69 / IP 67) plastic housings and are immune to cleaning according to the Ecolab standard.

Optical sensors - Series

The right model for every application

F 10

- Sub-miniature sensors

- Sub-miniature sensor for installation in the smallest of spaces and in moving machine parts

- The world’s smallest laser sensor with background suppression, adjustable via teach-in

- Sensors as LED or laser versions

- F 10 BlueLight: specially designed for scanning solar wafers and strongly light-absorbing objects

- User-friendly set-up via electronic teach-in key or control line

- Well thought-out mounting accessories for rapid and simple integration

F 25

- Miniature sensors

Highlights- Choice of LED or laser light (class 1)

- Most comprehensive sensor family on the market

- User-friendly teach-in key (alternative: fixed focus)

- Best black/white shift on the market in this sensor class

- Precise background suppression thanks to ASIC microchip

- Auto-detect – automatic adjustment of the switching output (PNP/NPN)

- Long ranges with compact miniature housing

- Robust glass-fibre-reinforced plastic housing (IP 69 & IP 67, Ecolab)

- Robust sensor design with metal connector, and mounting holes reinforced with metal inserts

F 55

- Compact class

Highlights- Precise laser distance sensors with operating ranges of up to 1 m for diverse applications

- Time-of-flight sensors for distance measurement and reliable object detection in front of any background, with a range of up to 5 m

- High-end color sensor FT 55-CM: high performance and ease of use

- All laser versions are laser class 1 – for optimum safety

- Precise background suppression and minimal black/whiteshift

- User-friendly operation of all “energetic” variants via electronic teach-in key or control line

F 50

- The reliable standard series

Highlights- Universal use in numerous automation applications

- Autocollimation variants with high precision and no blind zone

- Precise background suppression

- Laser, LED or infrared light transmitter options

- Simple adjustment via potentiometer, with numeric display

- Rotatable plug (270°)

- Well thought-out mounting accessories

FR 85 RailPilot

- Distance sensor for collision prevention

- Measurement range: 0 … 6 m

- Wide detection cone

- 2x2 detection zones

- 1 input

- 2 PNP outputs

- RS485 interface

- Detection zone adjustable externally

- Reliable suppression of foreign objects (girders, pillars)

Barrel type

- All-round performance

Highlights- Robust housings

- Very easy installation

- Straight or angled optics options

- Metric threads in 5 sizes: 4, 5, 12, 18 or 30 mm

- Red-light / infrared LED or laser light options

- FMF 18 for detection of liquid limit levels

- FT 04 and FT 05 the smallest sensors with IO-Link

Fiber-optic sensors

- For a wide range of applications

Highlights>- Sub-miniature FL 20 housing for simple integration in machines

- Powerful & variable FL 70 fibre-optic cable sensors

- Powerful FMS series for extreme demands

- Wide range of fibre-optic cables for standard applications or individual customer requirements

Fork sensors & optical windows

- Experts in small part detection and counting tasks

Highlights- Simple and robust housing

- Metal or plastic housing options (FGL) or robust metal housings (FG)

- High resolution for precise small part detection

- Easy, rapid mounting without complicated adjustment

Ultrasonic sensors

Reliable detection of objects with critical surfaces and highly transparent objects

- Highlights

- Reliable detection of objects with critical surfaces and highly transparent objects

- Available in cubic (32 x 20 x 12 mm) or barrel type (M12/M18/M30) housing options

- Simple adjustment via teach-in, control input or display

Typical Ultrasonic sensors

- Ultrasonic sensors may be a useful alternative where optical sensors come up against their physical limits. This applies, for example, for objects with uneven surfaces or under difficult ambient conditions, or with highly transparent media as well as moving, highly reflective liquid surfaces.

Typical uses of ultrasonic sensors are therefore checking the presence of highly transparent foils and measuring the filling levels in liquid containers. A major advantage of ultrasonic sensors is the absolutely reliable background suppression resulting from their sound time-of-flight measurement principle.

Inductive sensors

The metal detectors

- Highlights

- Reliable detection of metallic objects

- Product versions for standard or increased switching distances

- Robust housing variants in metal, plastic or completely made of stainless steel

- Different designs for flush, quasi-flush and non-flush mounting

- Variants with IO-Link 1.1 or analog output – IO-Link sensors can be operated in IO-Link or standard I/O mode

Accessories

Meeting all needs

A sensor rarely comes unaccompanied: accessories supporting their mounting, commissioning and use are of considerable importance for the reliable functioning of an automation solution. The characteristic practical orientation of SensoPart products is thus also evident in a particularly versatile and user-friendly range of accessories.

Illumination

- Surface lights, ring lights, spot lights, light strips, coaxial lights, DOM, laser line

Robotics

- Calibration plates and target marks for VISOR® vision sensors

Cables

- Power supply cables, Ethernet cables, data cables, cables for illumination

Mounting

- Brackets, mounting angles, mounting rods, clamps, mounting joints

Optical accessories

- Lenses, intermediate rings for c-mount, filters, protective casing and polarizer glasses

Peripherals

- Electrical accessories, Interfaces, Software, Switching devices

SmartPlug

- SmartPlug saves you from using expensive timing elements or supplementary control elements because SmartPlug makes the sensor smarter. Connected with SmartPlug, your sensor takes over additional control functions. As a timer, counter or inverter, for monitoring frequency, or for on-delay or drop-out delay. Adjustment takes place using teach-in via a control line.

SmartPlug is suitable for sensors from all producers with standardised M12 plugs; a special adapter cable is available for connection to an M8 plug. SmartPlug accommodates its refined electronics in a small, easy-to-handle 60 x 20 mm plug housing. With its maximum output current of 400 mA, the SmartPlug can also be used as a switching amplifier. SmartPlug: plug-in intelligence!

Applications

Detection

- You might think detecting presence is straightforward, but we know the challenges you face are anything but. Our products excel in reliably identifying and signaling the presence of objects, no matter how simple or complex their shapes and surfaces. With our optical sensors, you can trust that your production processes will run smoothly, ensuring your peace of mind.

Identification

- Continuously monitoring parts and products through code tracking is becoming increasingly vital in industrial operations. Typically, parts are marked with one-dimensional barcodes or two-dimensional data matrix codes. These codes are applied either by printing, dot-peen, or laser marking technologies (known as direct marking). With our VISOR® Code Readers, you're equipped to read all standard industry code types accurately, keeping your operations seamless and efficient.

Distance Measurement

- In numerous automated procedures, you need fast and accurate measurements, precise positioning, and the ability to detect various materials. SensoPart's distance sensors, utilizing either triangulation or time-of-flight technology, are crafted to meet these exact needs, enhancing the accuracy and efficiency of your operations.

Positioning

- Using robots for part positioning is a key element in automated manufacturing. Whether a component needs to be picked up, placed, or further processed, precise guidance of robots is crucial. Our VISOR® Robotic vision sensor keeps the position always in your view. Its automated calibration and user-friendly interface provide you with exact robot coordinates, streamlining your operations and boosting your productivity.

Classification

- Using robots for part positioning is a key element in automated manufacturing. Whether a component needs to be picked up, placed, or further processed, precise guidance of robots is crucial. Our VISOR® Robotic vision sensor keeps the position always in your view. Its automated calibration and user-friendly interface provide you with exact robot coordinates, streamlining your operations and boosting your productivity.

Inspection

- We know delivering high-quality products is your top priority. Our VISOR® Object (AI) vision sensor ensures error-free assembly of every component. If an issue does arise, our sensors immediately detect and prevent further complications, helping you maintain the highest quality standards in your products.

Industries

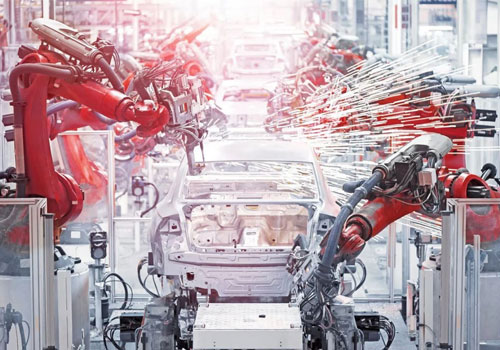

Automotive industry

- For the love of automation

The automotive industry has always placed extremely high demands on quality and process reliability, with automated tasks that are becoming more and more challenging. Sensors from SensoPart satisfy all the expectations of both manufacturers and suppliers.

Thus, the VISOR® Object is ideally suited to check components for completeness, for example, while the VISOR® Robotic acts as the "eye" of handling and assembly robots. The VISOR® Code Reader enables the identification of directly marked components such as car body sheets. Our optical sensors, especially our distance sensors such as the FT 55-RLAM, are also ubiquitous in automotive production processes, e.g. to control the position of parts.

Assembly & handling

- Every part in the right place

There’s no-one in sight, everything is moving as if by magic: conveyor systems are rumbling, robot arms are gyrating, workpieces are being separated, picked up and put down, and then transported on conveyor belts and finally assembled. SensoPart sensors ensure that all these procedures are carried out seamlessly and without any human intervention.

We have the right sensor for every task in our portfolio: our fork sensors in a robust plastic housing are suited for detecting small parts on vibrating conveyors; for applications in confined spaces, our F 10 series of sub-miniature laser sensors are the solution – these tiny sensors can even be fitted on a robot gripper arm. Our VISOR® Object vision sensors are ideal for complex inspections of the position and completeness of components, while our VISOR® Robotic is the best choice for seamless cooperation and communication with handling robots.

Robotics

-

Image-guided robotics - the "eyes" of the robot

Automation is unimaginable without robots in many sectors of industry today: collaborative robot systems (cobots) in particular, which can work side by side with people, have become widely used over recent years. Vision sensors from SensoPart serve as the "eyes" of cobots.

Our robotics expert VISOR® Robotic supplies the robot with all the necessary information on the position of parts. This data is converted into robot coordinates within the sensor before transmission so that the robot can accurately seize the part. Special functions, such as gripper space check and gripper point offset, offer further safety for the automation of handling tasks. Distance sensors can be used in addition if necessary: Our range extends from the sub-miniature sensor FT 10-RLA – the smallest optical distance sensor in the world – to the particularly versatile model FT 55-RLAM. This ensures that the robot can always accurately grasp parts despite variations in shape and position.

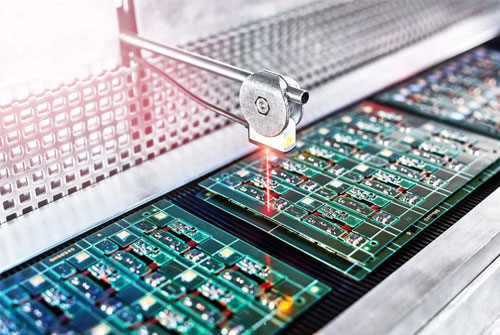

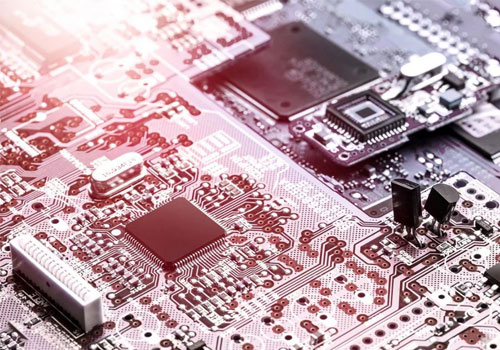

Electronics

- Reliable detection of small parts and colors

The handling and assembly of sensitive electronic components requires utmost precision. Switching sensors and vision sensors from SensoPart guarantee smooth procedures and error-free results.

We have a suitable sensor for every stage of production: A photoelectric proximity sensor from the F 10 sub-miniature series or a fork sensor from the FGL-RK series checks the presence of components that are supplied loose; an FT 25-C color sensor sorts them by color code; a VISOR® Robotic vision sensor supplies the necessary position information to the handling robot so that the latter can accurately grip each part and deposit it in a tray. Our vision sensors also prove valuable during quality control of electronic assemblies, as unlike standard color sensors, they can recognise active colors from fluorescent objects, such as LEDs.

Food & beverages

- Clean and safe production

Is the right juice in the right bottle? Are the cookies the required shade of brown? Has the use-by date been added to the packaging? SensoPart sensors supply reliable answers to these and many other questions.

For example, when filling drink bottles: The laser scanners from the FT 25-RGO series are specially trained in the detection of (transparent) bottles, while the color sensor FT 55-CM or the vision sensor VISOR® Object Color unequivocally identify whether the bottle lid is in the right position and of the right color. At the end of the production chain, our VISOR® Code Reader scans the packaging and checks the codes and plain text information. Many of our sensors also come in a particularly robust and hermetically-sealed stainless steel housing (IP 69 K), perfect for use in hygiene environments: When an industrial meat processing plant is cleaned with a powerful steam jet at the end of a shift, the sensor can also enjoy a good wash.

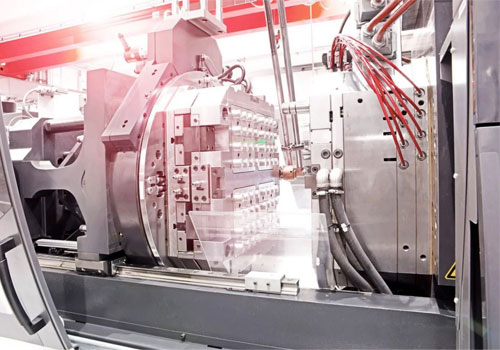

Plastics technology

- Higher quality, lower costs

Like many other sectors, the plastics processing industry is under growing cost pressure, while the trend for more frequent batch changes with smaller quantities is causing increasingly complex process cycles. SensoPart sensors enable widespread automation of production and quality assurance processes, and help sharpen a company’s competitive edge.

Applications in the plastics sector are diverse: BlueLight photoelectric proximity sensors reliably detect small black parts, such as transparent PET bottles; miniature color sensors from the FT 25-C series sort plastic parts on vibrating conveyors by color; and image-processing vision sensors from the VISOR® series identify manufacturing defects, such as short-filled moulds, burrs, color streaks, surface defects or faulty insert moulding. Early error detection during the manufacturing of injection moulded parts avoids complex reworking and costly rejects.

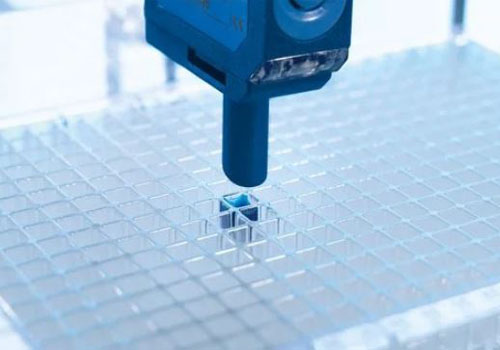

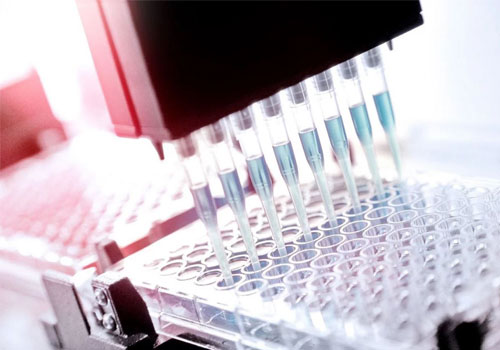

Laboratory automation

- Precision and safety in all processes

Whether in the handling of liquids of any kind or the preparation and analysis of test tubes, SensoPart sensors help laboratories prevent errors and contribute to efficient processes.

Precise measurement of fill levels in microtiter plates is essential in many applications, e.g. when analysing blood samples or dispensing chemical substances. This is where our BlueLight photoelectric proximity sensors from the F 10 series or our UT 20 Soundpipe ultrasonic sensors prove their worth. The size, shape and color of a test tube cap play an important role in the subsequent analysis process – vision sensors from our VISOR® series can inspect these characteristics in one image. Finally, the VISOR® Code Reader can reliably identify and track every sample in an analysis process due to its ability to interpret all standard one- and two-dimensional codes as well as plain text. Errors can be excluded almost entirely.

Pharmaceuticals & cosmetics

- Flawless products

The production of pharmaceuticals is a sensitive matter, as people’s health is at stake. SensoPart sensors conscientiously check contents and packaging.

An identifying feature frequently used for correct placement and packaging is color: Our vision sensor VISOR® Object Color can reliably detect whether a tablet of incorrect color has found its way into the blister pack. And our FT 50 UV luminescence sensor will spot if an information leaflet is missing. With cosmetics, it might be less dramatic if a bottle does not contain the correct shampoo, but this can be avoided by inspecting the bottle lid and/or product color with the aid of our color sensors FT 25-C or FT 55-CM. For use in hygiene environments, many of our sensors also come in a robust, hermetically sealed stainless-steel housing (IP 69 K) specially designed to withstand water jets or chemicals.

Solar industry

- Fully automatic and error-free

Production and quality assurance of solar cells is largely automated for reasons of cost efficiency, and switching sensors and vision sensors from SensoPart play an important role.

The presence of wafers or wafer boxes must be registered at numerous stages in the production of solar panels. Our laser photoelectric proximity sensors from the sub-miniature series F 10 are perfectly suited for this type of application and can be easily integrated in installations, even in cramped spaces. Position detection requires that robots pick up and put down wafers or cells with utmost precision – a task for the VISOR® Solar vision sensor, which can detect the position of wafers with ± 50 µm accuracy. In addition, the sensor can also identify even the smallest of damage, such as edge breakouts, thereby avoiding the possible breakage of wafers further down the production line, and any subsequent related contamination or costly machine downtimes.

Packaging technology

- The right sensor for every task

Numerous production steps are necessary before merchandise is packed ready for shipment – involving just as many different detection tasks along the packaging line. Sensors from SensoPart guarantee the smooth overall functioning.

One typical example is chocolate bars: They are usually packed in flow pack wrappers that are supplied from a coil in the form of an endless tube. FT 55-RLAM laser distance sensors continually monitor the thickness of the coil, and the tension of the material, to ensure a seamless feeding process. A multi-color contrast sensor from the FT 25-RGB series uses registration marks to identify where the coil has to be cut into single packs, while an FT 25 RH photoelectric proximity sensor detects the precise position of the individual wrappers before they are filled. Thanks to high-precision background suppression, reliable results are guaranteed regardless of extraneous light and reflections.

In focus

Distance sensors

-

Accurate and non-contact distance measurement for automation technology

Highlights

- Fast and accurate measurement, precise positioning and detection of a wide range of materials

- IO-Link sensors can be operated in IO-Link mode or standard I/O mode

- Our distance sensors cover a wide range of applications:

- Triangulation sensors for near-field applications

- Time-of-flight sensors for long working distances

BlueLight Technology

-

Blue misses nothing

Developed specifically for recognising objects that are difficult to detect, BlueLight sensors are true all-rounders. The BlueLight series offers much greater detection efficiency than standard optical sensors in challenging applications – whether with extremely shiny, strongly light-absorbing or highly transparent objects.

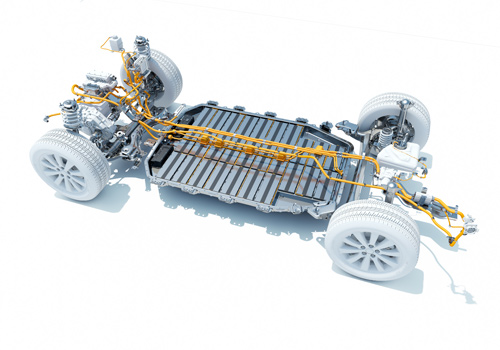

e-Mobility

-

Efforts to reduce fossil fuel consumption are leading to a rapid rise in e-mobility. Electrically powered cars, bicycles and even scooters are becoming increasingly popular.

These modes of transportation all require battery power, which means the market for battery pack manufacturing is growing alongside the e-mobility sector.

As with any assembly line, there are various challenges in battery pack manufacturing, especially with automated processes in production. Sensors, such as vision or distance sensors, play a crucial role here. Be it in the context of object inspection, reading individual component serial numbers before assembly or guiding robots.