- Offer Profile

-

OMRON Industrial Automation’s Long-Term Vision

Enriching the future for people, industries and the globe by innovative automation.

The manufacturing industry is at a historical turning point, and the role of automation, a driver of progress in the industry, is also undergoing dramatic change. Manufacturing today has to do more than just pursue material abundance and industry growth: it must also be sustainable. It has to be able to build a sense of purpose and increase work satisfaction among factory workers, and help preserve the Earth's environment.

- Automation that drives industrial development to generate technological innovation.

- Automation that allows people to unleash their full potential and feel fulfilled in their work.

- Sustainable automation that co-exists with the global environment.

Delivering this kind of automation requires a deep understanding of society, the manufacturing industry, the production site, and the people working there.

We at OMRON strive to create new means of automation by marshaling our years of experience confronting difficult challenges on the manufacturing site and applying the problem-solving capabilities we have developed along the way. Through these efforts, we will contribute to create a future society that allows both people and our planet to continue to flourish, while enabling the sustainable industrial progress foundational to prosperous living.

Automation Systems

Industrial PC (IPC)

-

Industrial PCs (IPC) or Industrial Computers are designed to provide a powerful, reliable and scalable computing platform for industrial automation in harsh industrial environments.

Industrial PCs can control and monitor diverse industrial processes, enabling real-time data acquisition, analysis, and decision-making.

By leveraging the power of IPCs, manufacturers can optimize operational efficiency, boost productivity, and enhance overall reliability.

NYB - Industrial Box PC

-

Compact design that offers flexibility, expandability and easy maintenance for applications in factory automation environments.

- Based on Intel® Atom® to Xeon® including Intel Core® i3,i5,i7 Industrial 11th Generation Processors.

- Windows 10 IoT Enterprise 2021 LTSC or without operating system

- Open operating system allows running customised software and hardware

- Giga Ethernet ports to segregate access to your IT and OT systems.

- Optimised form factor: 1 or 2 layer body with or without fan.

- 15.4 , 12.1 and 18.5 inches Industrial monitor

- Industrial Box PC and Industrial Panel PC (Industrial Box PC + Monitor integrated) types

- Display Port

- Optional Additional Video and or RS-232 Ports.

- PCI Slot Expansion Option.

- Models available with NY Monitor Link interface for connectivity up to 100 m between IPC and Monitor

- Optional Hardware RAID

NYP - Industrial Panel PC

-

Compact design that offers flexibility, expandability and easy maintenance for applications in factory automation environments.

- Based on Intel® Atom® and Intel Core® i3,i5,i7 Industrial 11th Generation Processors.

- Windows 10 IoT Enterprise 2021 LTSC or without operating system

- Open operating system allows running customised software and hardware

- Giga Ethernet ports to segregate access to your IT and OT systems.

- Optimised form factor: 1 or 2 layer body without fan.

- 12.1, 15.4, and 18.5 inches Industrial monitor

- Display Port

- Optional Additional Video and or RS-232 Ports.

- PCI Slot Expansion Option.

- Models available with NY Monitor Link interface for connectivity up to 100 m between IPC and Monitor

NYE Series - Basic Industrial Panel PC

-

Basic Industrial Panel PC for 24/7 Excellence

- Based on Intel® Atom® Quadcore E3940 Industrial Processors.

- Windows 10 IoT Enterprise 2021 LTSC operating system.

- 7, 9, 12, 15 inches Resistive display.

- Ethernet LAN x2 ports.

- USB 2.0 2 x Ports ,USB 3.0 1x Port.

- RS-232 x 1 Port.

- More than 16 million colour display for all models and 1280 x 800 high resolution display for the 12 and 15-inch.

- 24 Volts Powered.

- Optional Software

NY5 - IPC Machine Controller

-

Hybrid controller which combines Sysmac machine control and IT technology

- Intel Core i5 Quad-core processor

- Windows 10 IoT Enterprise 2019 LTSC

- Open operating system allows running customised software and hardware

- Functions: Logic sequence, Motion and NC

- Built-in EtherNet/IP port for your IT systems and machine to machine communication

- Sysmac machine controller inside

- 500 μs system cycle time

- Up to 64 synchronized axes

- Built-in EtherCAT port for up to 192 synchronized slaves

- NC functionality available on Industrial Panel PC*: Ideal for XY cutting, milling, lathe and any other path-following application such as dispensing, bending, grinding and forming machines

NYM - Industrial Monitor

-

Display and touch interface for the Industrial PC Platform.

- 12.1, 15.4 and 18.5 inches models

- Multi-touch, using the latest projected capacity technology

- False touch detection (palm rejection, water and cleaning)

- Glove operation (When using gloves, ensure to use gloves that are functional with this touchscreen)

- Easy built-in supportive mounting

- Models available with NY Monitor Link interface for connectivity up to 100 m between Box PC and Monitor

Machine Automation Controllers

NX7 - Sysmac Controller

-

The NX7 series is a high performance CPU that includes two synchronized motion cores controlling up to 256 axes.

- Fastest cycle time: 125 µs

- Number of axes: 256, 128

- Two synchronized motion cores

- Functions: Logic sequence, Database connection, AI and Motion

- Database direct connection: SQL client for server Microsoft SQL, Oracle, IBM DB2, MySQL, Firebird, PostgreSQL

- Database direct connection in V2.0 is expanded with stored procedure calls and secure communications functionality

- AI Functionality: AI engine included in the controller enables real time utilisation of machine learning model

- AI Predictive Maintenance Library enables non-stop equipment

- Multi-tasking

- Built-in EtherCAT and two EtherNet/IP (1 Gbps) ports

- IoT Ready: OPC UA server built-in as standard feature, variable structures are supported

Different variants available.

NX1P

-

The NX1P completes the NX/NJ machine controllers family offering same functionality in a compact design. The NX1P provides synchronized control of all machine devices such as motion, I/O, safety and vision under one Integrated Development Environment.

- Fastest cycle time: 2 ms

- Functions: Logic sequence and Motion control

- Up to 8 axes (4 synchronized axes)

- Built-in I/O: 40 or 24 I/O points

- Up to 8 local NX I/O units

- Built-in EtherCAT and EtherNet/IP ports

- Up to 16 EtherCAT slaves

- Up to 2 option boards can be connected to add serial communications or analog I/O functionality

- EtherCAT Ring topology is supported to maintain communications and control in case of a broken cable or device failure

- NX1P supports MQTT (S) communication using MQTT Communication Library

NYJ5 - Sysmac Controller

-

The NJ5 series is a machine controller for logic sequence and motion that includes CPU options for advanced functions such as robotics and database connection.

- Fastest cycle time: 500 µs

- Number of axes: 64, 32, 16

- Synchronized motion core

- Functions: Logic sequence, Motion, CNC, Robotics, Database connection, SECS/GEM and OPC-UA

- Database direct connection in V2.0 is expanded with stored procedure calls and secure communications functionality

- Database direct connection: SQL client for server Microsoft SQL, Oracle, IBM DB2, MySQL, Firebird, PostgreSQL

- Delta, SCARA and Cartesian robots control

- CNC functionality: Ideal for XY cutting, milling, lathe and any other path-following application such as dispensing, bending, grinding and forming machines

- Multi-tasking

- Built-in EtherCAT and EtherNet/IP ports

- EtherCAT Ring topology is supported to maintain communications and control in case of a broken cable or device failure

Different variants available.

Programmable Logic Controllers (PLC)

-

A Programmable Logic Controller (PLC) is a specialized hadware designed to manage control tasks in industrial settings.

A PLC is a special kind of digital computer that plays a crucial role in industrial automation. It has a CPU that runs the control program and manages other components.

CJ2

-

CJ2 PLC: High performances modular controller

Due to his high flexibility in configuration CJ2 is the ideal solution to be used in a wide range of machines in various application ranges from Packaging, Food and commodities to Digital and Automotive. Connectivity with most of the industrial communication networks in the market is a key factor to use CJ2 controller in all applications that need a data exchange between machines. Scalability between CJ2M and CJ2H CPU’s enables an exact match between functions required and HW to use to always provide a perfect ratio Price/Performance in each application. Robustness of the solution and proven quality complete the value of those products.

- Always accessible through standard USB support

- Standard Ethernet port with EtherNet/IP Data Link function

- High program capacity from 5K steps up to 400K steps

- Higher precision for machine operation and processing quality

- Immediate refreshing of basic I/O ensures real-time processing

- High data memory capacity of up to 832K words

- Serial option board

- Dedicated function block memory ensures efficient execution of function block software modules

CP2E

-

CP2 Series Compact Controller

The Micro PLC designed for compact Equipment which can support data collection and Machine 2 Machine communication. A powerful and effective solution for stand-alone machines produced in series where Price/Performance ratio is a key. CP2E series controller offers an efficient solution for a flexible production where traceability and machine key assets monitoring can be used to get operational excellence.

- Reduced wiring cost and improved communication performances those values are available thanks to built-in 2-ports Ethernet Switch and dedicated Function Blocks. You can save cost of additional hardware and simplify Ethernet connectivity with a daisy chain Ethernet wiring for Machine 2 Machine communication.

- Data collection, Control and Monitoring of serial devices is easy: up to 3 serial ports are available.

- Improve design efficiency and productivity reducing development time with a modular conception of the machine. CP2E includes 4-axis positioning functions with linear interpolation and Omron Libraries for positioning, Machine 2 Machine communication and predictive maintenance.

- Install and forget. Omron CP2E can supply a reliable solution for all environmental conditions: extended operational temperature range, Battery free operation, Input/output terminal LED indicators for quick troubleshooting, Automatic Recovery by electric interferences.

- Complete your configuration with NB HMI for a perfect match.

CP1L

-

When it comes to controllers for compact machines, our CP1L series offers the compactness of a micro-PLC with the capabilities of a modular PLC. It provides all the functionality you need to control your machine, including outstanding positioning capability. On top of this some CP1L models have an embedded Ethernet port with socket services functionality to give you flexible connectivity for monitoring, operating, logging and remote access. The CP1L is completed with a range of optional boards for serial communication or analogue I/O and further expansion units in case more I/O is needed. As the CP1L series shares the same architecture as the CP1H, CJ1, and CS1 series, programs are compatible for memory allocations and instructions.

4 axes PTO I/O line driver

Different variants available.

CS1D

-

The dual-redundant PLC system for never-fail control

CS1D adds a number of dual-redundancy options to the well-proven CS1 architecture to ensure around-the-clock operation without minimal downtime. Duplex CPUs, with or without loop control functions, are continuously cross-checked for errors, without the need for special programs to be written by the user. An even simpler way to increase system availability is to use dual power supply units. Hot swapping of CPUs, power supplies and I/O units allow system maintenance with little or no process interruption.

- Choose the level of redundancy needed; CPU, power supply, communication

- No special programming or software tools required

- Hot-swapping of I/O units

- All standard CS1 I/O units can be mounted

- Ideal for control of power generators, water supply utilities, 24/7 production.

Input and Output (I/O)

NX I/O Series

-

Performance and practicality for machine control

Modern machine control requires system-wide synchronisation of motion axes with microsecond accuracy. The NX I/O system offers this timing accuracy and repeatability for a wide variety of in- and outputs. Its ultra-fast internal bus system is synchronised with the Distributed Clock of the EtherCAT network, resulting in system-wide deterministic I/O operation.

- Ideal match with Sysmac Machine automation controllers and CJ2-series PLC's

- Synchronous I/O updates, system-wide, with less than 1 μs jitter using EtherCAT

- High density: up to 16 digital or 8 analog signals in 12 mm width

- Removable wiring terminals for easy system assembly and testing

NXR Series

-

Remote IP67 IOs over Ethercat and Ethernet/IP networks with IO Link master functionality

The NX series streamlines commissioning and maintenance of production equipment. A simple, easy and quick IP67 solution that increases availability, flexibility and improves quality in machines and applications.

- Just One Unit for multiple applications thanks to fully configurable ports in the NXR Series

- Just 30 secs. Quick Switch Feature enables the option for quickest replacements with no PC required

- Just One Click for IO-Link configurations

- Just One Cable for flexible, simple and modular machines

- Just One Controller. Full integrated solution by OMRON

- Led Port indicators per signal and master unit for visual maintenance and diagnosis

- NXR Hubs to extend Digital IOs to be connected per device

GX-ILM

-

IO-Link master unit for water and dusty environments

IO-Link makes communication down to the sensor level visible

- Machine downtime can be reduced.

- Abnormality detection for shortest recovery time.

- Condition monitoring for predictive maintenance.

- Individual identification for reduction of man hours.

- GX Series master unit with IP67 protection class for watery and dusty environments as well as NX Series master unit with IP20.

- Up to 8 sensors can be connected with one GX Series IO-Link master unit.

- Photoelectric and Proximity sensors available.

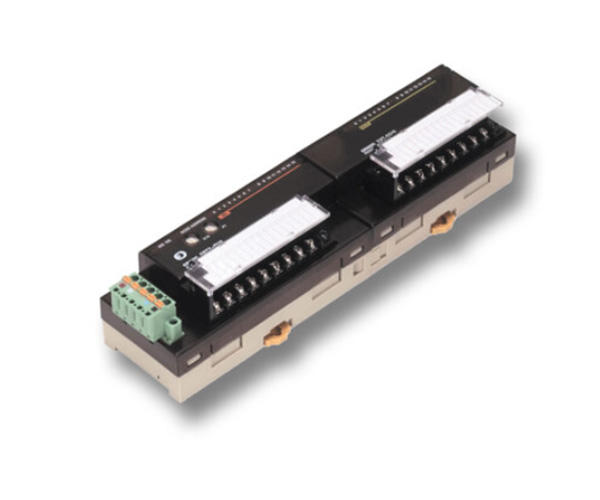

GX

-

When speed counts: EtherCAT I/O

EtherCAT is an extremely fast industrial automation network, which uses standard Ethernet cabling. It makes very efficient use of the standard Ethernet transmission frame, with each node accessing the entire frame on the fly. This reduces the delay in each slave to microsecond level. Its deterministic nature makes EtherCAT extremely suitable for motion control. Omron provides PLC-based as well as stand-alone motion control solutions based on EtherCAT. The GX-series I/O units provide the basic in- and outputs for such systems, including high-speed encoder inputs which can feed position information into the controller.

- Compact size IP20 housing

- Expandable digital I/Os

- Detachable I/O terminal blocks

- Selectable high-speed input response time

GI-S Series

-

Safety I/O Terminals for CIP Safety™

- Safety Remote Digital Blocs

- Individual Test Pulses for better diagnostics

- CIP-Safety on EtherNet/IP is Supported

- Standard-feature EtherNet/IP Communications Port

- Separate Power supply for Logic and S-I/O's

- Can work as remote Safety I/O's in combination with NX-SL5000 series with NX-CSG320 or NX102 using port 2 A/B

SmartSlice

-

The smartest modular I/O system

Omron's SmartSlice I/O system is compact, intelligent and easy. When used with Omron's CS1/CJ1 DeviceNet master units it is plug-and-work, no configuration tool is required. By using built-in functions such as pre-scaling, totalising, differentiation and alarming in analog I/O units, PLC programming can be minimised. Preventive maintenance data can be accessed using CX-Integrator software, standard PLC function blocks or NS-series Smart Active Parts.

- Most compact in the market (84 mm high)

- Easy set-up, backup and restore functions

- Diagnostics and preventive maintenance data at I/O level

- Detachable terminal blocks allow hot-swapping without re-wiring

- 3-wire connection with 'push-in' technology, no screwdriver required for installation

DRT2

-

Smart DeviceNet I/O

Compact DeviceNet I/O units with extensive diagnostic functions. Data regarding power supply status, I/O response times, operation counters and on-time are continuously recorded and checked against user-defined limits. Any deviation is reported to the control system, as indication to perform machine maintenance and prevent unplanned downtime. Smart DeviceNet I/Os are supported by PLC Function Blocks and HMI Smart Active Parts, allowing program-less visualisation and monitoring from the CJ1 PLCs and NS operator terminals.

- Compact size IP20 housing

- Expandable digital I/Os

- Built-in diagnostics and preventive maintenance functions

- Detachable I/O terminal blocks

- Analog I/O with data pre-processing and alarm functions

Different Variants available.

Human Machine Interfaces (HMI)

NA Series

-

NA Series -The Sysmac HMI

As part of the Sysmac automation platform, Omron NA HMI transforms machine data into information, shows information and controls devices based on requirements at FA manufacturing sites. The NA Series enables faster, more efficient control and monitoring. With a widescreen displaying 16,770,000 colors, the HMI that is dynamic, intuitive and predictive makes industrial machines more attractive and competitive.

- Proactive operator/ machine relationship

- Design based on real applications and customer requirements

- Future-proof, scalable platform

- Allows quick reaction

- 16,777,000 display colors (24 bit full colors)

- High resolution display

- 1,280x800 resolution for 12-inch and 15-inch models

- 800x480 resolution for 7-inch and 9-inch models

NB Series

-

Ideal HMI for Compact Automation

The combination of high quality and rich features offers outstanding value for an economy-class HMI. The V1 model's hardware upgrade significantly improves the user experience with a faster CPU across all models and enhanced brightness and resolution in the 5” and 10” screens.

- More than 65,000 display colors TFT touch screen

- Available in sizes ranging from 3.5 to 10 inches

- Long-life LED backlight

- Serial, USB or Ethernet communication

- Vector and bitmap graphics

Additional Automation Systems

Remote Access Solution

-

Secure and Easy Remote Access to your machines

The RT1-series SiteManager operates in the Secomea's PRIME platform, ensuring efficient maintenance, cost savings, and increased production output.

- DIN mountable industrial router that you install in machine control panels to provide option for remote access for on-demand, real-time servicing of industrial equipment

- Security certified and built-In firewall

- Troubleshooting and remote programming of the complete range of Omron Automation System

- Improve responsiveness, reduce the impact of emergencies, optimize the workload of engineers and maximize machine availability and productivity

- Minimized environmental impact and increased sustainability by reducing Travels for Machine maintenance

Industrial Ethernet Cables and Connectors

-

XS5 XS2 XS6 Series

Omron XS5 XS2 XS6 Series are offered to provide an extensive portfolio of Industrial Ethernet Cables and Connectors to work over EtherNet/IP™, EtherCAT® and other Industrial Ethernet Networks

- One-touch Smartclick connections

- Environmental resistance to enable reliable connection quality

- From Cat5/5e to Cat6/6A (up to 10 GBASE-T)

- RJ45 connectors for in-panel wiring and M12 Connectors with IP67 protection for wiring outside the panels

- Cable bending test data for robot cables

Industrial Robots

-

Industrial robots and robotics are at the heart of innovative manufacturing. These intelligent and programmable machines can automate repetitive production and material handling tasks, such as assembly, pick and place, packaging, and inspection. Manufacturing robots bring speed, strength and precision to production processes, and enable flexible manufacturing. OMRON robotics solutions include various industrial robot types for a total automation solution. In addition to fixed robot arms placed on manufacturing lines with integrated robotics control, OMRON also offers other types of robotics solutions, such as autonomous mobile robots (AMRs) and collaborative robots or cobots.

Fixed Robots

i4H

-

Gain more out of production with a higher payload and faster cycle time

Achieve more by seamlessly integrating the robust i4H into your production line today. With an updated robust design, the i4H can achieve a more meaningful and efficient production for your factory needs.

- 15 kg payload capacity

- 650 mm, 750 mm, and 850mm reach options with floor, wall and ceiling mounting options

- Robot Integrated Controller NJ-R with EtherCAT connectivity

- Stand Alone Ethernet models

- Options: IP65, Food Grade, ESD and Clean Room

- Fast cycle time with an unprecedented range of movement and repeatability

- Advanced and robust industrial design

- Lowest total cost of ownership

- Optimize your line with maximum uptime by means of interactive maintenance alarms and an RGB dome light

Different Variants available.

iX3

-

Parallel robot ideal for use in the food and beverage, pharmaceutical, and healthcare industries

We have taken efficiency to the next level with the iX3 parallel robot. This powerful robot supports integrated high-speed conveyor tracking, powerful vision guidance, and easy-to-use application software created specifically for the packaging market.

- EtherCAT connectivity to the Omron NJ501-R controller and programming through the familiar IEC 61131-3 programming language or scripting (ev+).

- Tracks up to a conveyor speed of 1.4 m/s

- Designed with a high payload to support multi-hand (multi-picking)

- Supports fast Pick & Place on a fast conveyor • Helps reduce mounting cost and robot vibration • Maximum working diameter 1,130 mm

- Working height 425 mm

- Maximum payload 8 kg

- Weight 52 kg

Different Variants available.

eCobra

-

SCARA robot for precision machining, assembly, and material handling

Our newest family of 4-axis robots. The eCobra SCARA robot features 600 and 800-mm reach and is available in two different models, EtherCAT and Ethernet.

- High repeatability suitable for material handling and precision assembly.

- High payload for screw-driving tools.

- The amplifier and controller built into the robot reduces the number of cables.

- Overhead mounting configuration for efficient use of space.

- Reach: 600 and 800 mm models.

- 5.5 kg max. payload.

- IP20 protection class (IP65 as option for 800 mm models).

- Clean room C10 as option.

Viper

-

Articulated robot for machining, assembly, and material handling

Our newest family of 6-axis robots. The Viper Articulated robot features 650 and 850-mm reach and is available in two different models; EtherCAT and Ethernet.

- Programmable through ACE software and eV+ language, or through the familiar IEC 61131-3 when using ePLC Connect.

- Diagnostics display enables faster trouble shooting

- Available in two different models; EtherCAT and Ethernet.

- High-resolution, absolute encoders to provide high accuracy, superior slow-speed following, and easy calibration

- New EtherCAT models to be used with the Robot Integrated Controller NJ-J

- High-efficiency, low-inertia Harmonic Drives and a lightweight arm to deliver maximum acceleration

- Reach 650 mm for Viper 650 and 855 mm for Viper 850

- Maximum payload 5 kg

- Weight 34kg for Viper 650 and 36kg for Viper 850

- 3D Bin Picking Solution integrated with ACE Software

Hornet

-

Parallel robot ideal for use in the food and beverage, pharmaceutical and healthcare industries

- Ethernet capability to control the robot through the familiar programming language (IEC 61131-3) of NX/NJ machine controller

- The amplifier and controller built into the robot reduces the number of cables

- Tracks up to a conveyor speed of 1.4 m/s

- Designed with a high payload to support multi-hand (multi-picking)

- Helps to reduce mounting cost and robot vibration

- 1,130 mm working range

- Up to 8 kg max. payload

- IP65 protection class

Quattro

-

Four-axis parallel robot achieves high speed and high precision

- Ethernet capability to control the robot through the familiar programming language (IEC 61131-3) of NX/NJ machine controller

- Four-axis arm evenly distributes the load on the robot

- Fast and high-precision conveyance and assembly

- Designed with a high payload to support multi-hand (multi-picking)

- 650HS model is USDA accepted for primary food handling

- 1,300 and 1,600 working range models

- Up to 15 kg max. payload

- IP65 protection class (IP66 for HS model)

X-Delta 2+1

-

The design concept with a minimum of mechanical components results in a high quality robot

- Robot control integrated in the NJ robotics controller

- Control of up to 8 robots by one controller

- Degrees of freedom: 2 + 1 (rotational axis optional)

- Up to 200 cycle per minute

- Models from 800 to 1,500 mm working range

- Payload range: 3 to 35 kg

- TWIN model for applications that a long gripper is required

- IP65 protection class

- ISO mount gripper interface

- Low maintenance, easy access to components

Different variants available.

Autonomous Mobile Robots (AMR)

-

How can fully autonomous mobile robots help transform manufacturing, warehouse automation and intralogistics to facilitate flexible manufacturing? With AMRs, you can connect and easily scale up production lines, ensure just-in-time delivery or pick-up of materials, reduce health and safety risks on the warehouse and manufacturing floors, as well as improve the quality and traceability of products. The robots are equipped with sensors and guided by a smart software so they can reach their destination freely and independently, safety avoiding any obstacles in their path. AMRs can also be used in many other industries and applications, from vertical farming to healthcare and hospitality.

LD-series

-

Fully Autonomous Mobile Robots

OMRON mobile robots are autonomous mobile robots (AMRs) designed to dramatically increase productivity in manufacturing and logistics operations. Our mobile robots increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. What’s more, unlike traditional AGVs, our mobile robots navigate by the natural features of the facility and require no expensive facility modification.

The Omron LD Mobile Robot is a self-navigating Autonomous Mobile Robot (AMR) designed for dynamically moving material in challenging environments that may include confined passageways as well as dynamic and peopled locations.

OMRON mobile robots are easy to get up and running, requiring no construction such as the installation of magnets, and minimal programming. In addition, our software integrates with your other systems so you can get the solution up and running in minimal time.

- he dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

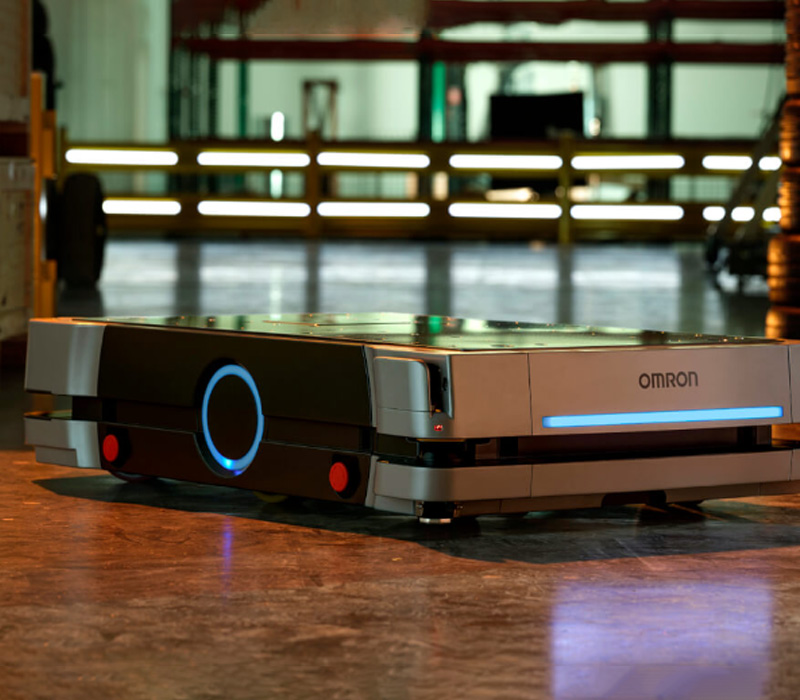

MD-series

-

Powerful mid-sized mobile robot with cutting-edge performance and safety

The OMRON MD-series mobile robot adds 650kg and 900 kg payload options to an industry proven line of OMRON autonomous mobile robots with payloads ranging from 60 kg to 1500kg. Designed for industrial manufacturing and warehouse logistics operations, the MD-series can work collaboratively with humans and is an ideal choice for pallet-moving applications where pickup and drop-off stands can be used. Designed with a global audience in mind, the MD-series can accommodate European, US, and Asian pallet sizes.

- 650 kg or 900 kg payload capacity.

- Based on the same proven technology used in the HD series.

- 360° safety coverage with LiDAR technology.

- Eight-hour runtime with less than 30-minute charging time (5%-95%).

- Top speed of 2.2 m/s (MD-650) and 1.8 m/s (MD-900).

- Capable of autonomous reverse navigation.

- Switchable footprint.

Looking for safe and more efficient ways to move products and materials around your facilities? OMRON's mobile robots can provide a safe, fast and reliable solution with payloads ranging from 60 to 1500kg, including the best in the industry safety and fleet management tools. The OMRON MD-650 and MD-900 medium-duty mobile robots complete the portfolio with payload options for 650 and 900 kg, for handling a wide variety of parts and materials while maintaining a small footprint

- The dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

HD-series

-

Our strongest Fully Autonomous Mobile Robot

The HD-series boasts a payload capacity of 1,500 kg and allows customers to lead and transport the heaviest of objects. Designed for industrial manufacturing, reduce the need for forklifts and do more with less equipment.

The 1,500 Kg payload Omron HD-1500 mobile robot handles the performance of simple transport, delivery, and routing operations so your employees can perform higher-value jobs.

The HD-1500 also takes advantage of Omron’s ability to customize the fleet with accessories that improve performance, such as HAPS and LiDAR.

- Charge from 5% to 80% in 35 minutes.

- 9 hours of run-time with a full payload.

- 12,5 hours of run-time unloaded.

OL-series

-

Versatile and efficient mobile robot designed to streamline cart transport operations with cutting edge safety technology and performance

OMRON’s innovative low-profile, omni-directional OL-450S represents a significant advancement in the field of automation. Its exceptional performance, characterized by high speed and impressive lifting capacity, combined with its advanced safety features, makes the OL-450S a versatile solution for a wide range of applications.

- 450 kg payload capacity.

- Omni-directional drive capabilities.

- 360° coverage with LiDAR technology.

- ISO 3691-4 compliance (except clause 4.12).

- Five-hour runtime with 45-minute charging time (20%-80%).

- Lift deck height of only 108mm.

- Ready to work out-of-the-box.

Cobots (Collaborative Robots)

-

How can collaborative robots (cobots) improve industrial operations and enable human-robot collaboration to drive productivity and safety?

Cobots are smart robots that make work easier, safer and more efficient. Cobots are designed to work harmoniously alongside humans. Unlike traditional robots that require safety barriers, cobots are equipped with advanced sensors and built-in safety features. They can take care of repetitive or hazardous tasks, improving workplace safety and freeing workers for more strategic roles.

From manufacturing, logistics to healthcare and food and beverage, collaborative robots are boosting productivity, flexibility, and precision. They streamline tasks like assembly, material handling, and quality inspection, while adapting to changing business needs.

TM

-

Collaborative robots assembly, packing, inspection and logistics

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011 and ISO/TS-15066

- Fast changeover using TMvision and Landmark

- Advanced collaborative control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

Features

Faster set-up with built-in visionThe OMRON TM Collaborative Robot features a built-in vision system. The integrated camera localizes objects in a wide field of vision, and the image-enhancement light enables object recognition under almost any conditions.

Different variants available.

TM S

-

Next generation of collaborative robots with advanced hardware options and expanded safety features

The OMRON TM S series collaborative robots are designed to increase safety of robot operations in proximity with humans and automating repetitive tasks. The next generation of OMRON cobots offer an easy-to-use programming interface, enabling engineers of all skillsets to successfully develop robotic solutions. The built-in vision system and calibration tool will relocate the cobot to different workplaces in addition to the usual vision tools for pick and place, machine tending, material handling, palletizing, and many other applications.

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011 and ISO/TS-15066

- Fast changeover using TMvision and Landmark

- Advanced collaborative control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

Certifications:

- ISO 13849-1, Cat.3, PL d

- ISO 10218-1:2011

- UL & CSA Safety Certification

Protections:

- IP54 rating for Robot Arm, AC control box, Robot Stick and TM screen.

- ISO Class 3 for the Cleanroom

- Enhanced oil resistant covers for joints

Different variants available.

Additional OMRON Robots

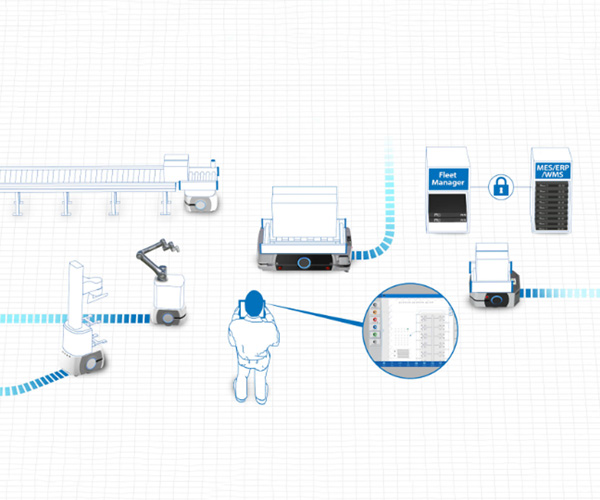

FLOW Core Fleet Manager

-

Centralize your AMR control and monitoring with the Fleet Manager. Optimize your workflow with FLOW Core.

The industry’s leading autonomous mobile robot fleet management solution for factory and manufacturing applications. Automatically manages AMR traffic and tasks based on your priority. Deploy flexibly with secure, scalable virtualization options.

Our solution for setting up, integrating and managing autonomous mobile robot (AMR) fleets within a factory environment. FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. FLOW Software encompasses the following features:

- FLOW iQ

- Integration Toolkit (ITK)

- MobilePlanner 6

- MobilePlanner Tablet Call Button

- Selectable Autonomy

- Dynamic Obstacle Tracking

- Cell Alignment Positioning System (CAPS)

- Fleet Simulator

Robotics Integrated Controller

-

For applications requiring high-speed processing for machine control, safety, reliability and maintainability.

Our Robotics Integrated Controller perfectly synchronizes automation technology so that customers can improve the speed and accuracy of their production, simulate entire production line, simplify maintenance, and reduce time-to-market.

- Up to 8 robots control per CPU

- Integration of Robotics, Logic, and Motion in one CPU

- Conforms to IEC 61131-3 (JIS B 3503) standard programming and PLCopen function blocks for motion control

- Conforms to IEC 61131-3 (JIS B 3503) standard programming and traditional V+ scripting for robot and motion control

- Programming with variables allows users to create complex programs efficiently

- Models with SQL DB Functionality

- Offers speed without compromising on reliability and robustness expected from PLCs.

- Linear and circular interpolation.

- Electronic gear and cam synchronization.

- Fast and accurate control by synchronizing all EtherCAT devices, such as vision, servos, robots, and IO with the controller.

- Offers speed without compromising on reliability.

Features

The Robotics Integrated Platform is the next revolutionary step in the SYSMAC ecosystem that seamlessly integrate the full ORT Fixed Robotics product line.

Total Integration (Control): Unified control automation + robotics

Process Integration (Faster Time-to-market): Applications can be developed from design through commissioning, operation, and continuous improvement

Supply Chain Integration (Flexibility): Users can easily reprogram (PLC and robots), modify, or scale production, providing flexibility to adapt to fluctuating demands The NJ-R machine controller with new Robot Integrated CPU supports up to 8 robots as well as independent motion axis control.

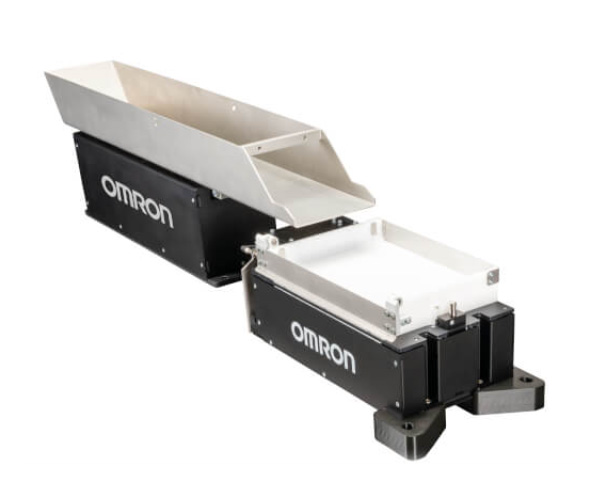

Industrial Part Feeder

-

New OMRON Feeder System

- Pick and place applications, assembly line material feeding, and primary packaging.

- Modular design with many flexible options.

- Suited for automotive, electronics, pharmaceutical, agricultural, or medical component manufacturing applications.

- Feeds parts and components from 5 mm to 150 mm in size.

- Patented 3-axis vibration technology can move parts in all directions and ensures parts do not accumulate in a corner or on an edge.

- Gently handles delicate parts through precise tuning of frequency and amplitude.

- Fully integrated and supported by the powerful & easy-to-use ACE software tool for fast deployment of pick and place solutions.

Feautures

- Compatible with 99% of types of parts and geometries

- Short cycle times

- Pre-orientation and gentle separation of components thanks to 3-axis system

- Easy settings and integration

- Compact and flexible feeder with integrated controller

- Reduced production changeover time

- Omron quality product with no maintenance required

Complete range of Industrial Part Feeders for components from 5mm to 150mm

Different variants available.