- Offer Profile

-

Your specialist for vacuum

handling technology and more!With vacuum lifting devices from FEZER, you not only streamline your manufacturing processes, but also increase the operational safety and ergonomics of your workplaces at the same time.

The individual workpieces can not only be transported horizontally, but also rotated, swiveled or turned. The vacuum lifters ensure safe and, above all, absolutely gentle handling of automotive components.

AUTOMOTIVE

-

Vacuum lifters in the automotive sector Molded parts, body parts, built-in parts or entire front, side and roof elements handled easily and safely.. With vacuum lifting devices from FEZER, you not only streamline your manufacturing processes, but also increase the operational safety and ergonomics of your workplaces at the same time.

The individual workpieces can not only be transported horizontally, but also rotated, swiveled or turned. The vacuum lifters ensure safe and, above all, absolutely gentle handling of automotive components.

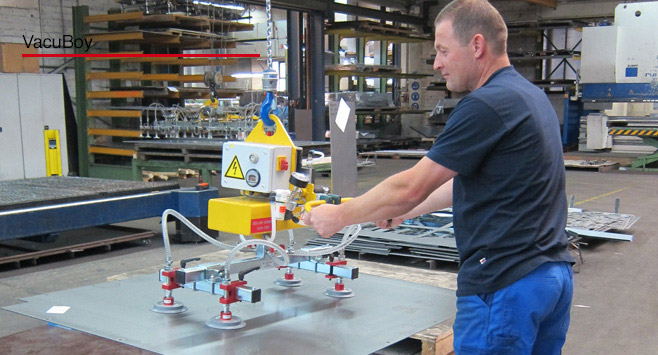

For handling processes that are carried out using on-site crane systems, the VacuBoy device series in particular is available. This device series is characterized by its robust design and its clever modular system, which makes it easy to adapt to individual requirements.

VacuBoy

-

VacuBoy — The universally applicable

vacuum lifter for maximum efficiency

and safetyWith our vacuum lifters from the VacuBoy series, components of all types up to 2,000 kg can be lifted effortlessly. The VacuBoy series opens up a universe of possibilities: Whether you're transporting materials horizontally, performing 90-degree swivels or need a full 180-degree turn, our vacuum lifters can handle any challenge, making them the ideal partner for working with bus back panels, RV floor elements or entire front panels.

And because we know how important safety is in assembly lines, we naturally offer additional safety features such as bottom grippers for all models - so you are always on the safe side.

These are the areas of application of the VacuBoy series:- Built-in cabinets and kitchen elements of mobile homes

- Truck floors

- Windshields of cars and trucks

SHEETS | METAL

-

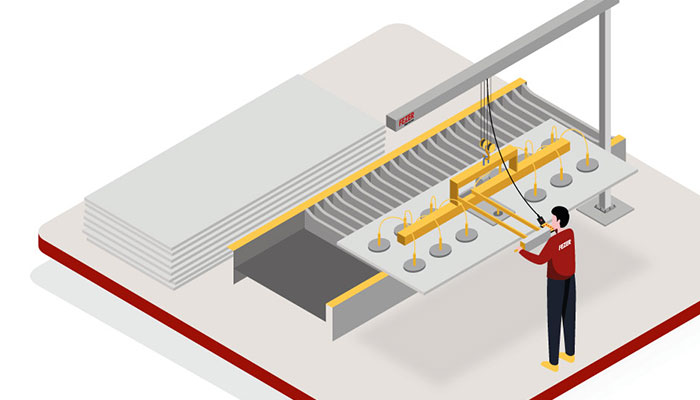

Ergonomic vacuum lifters for

more comfort in sheet metal handlingWith FEZER sheet metal lifters, you not only increase the efficiency of your production processes, but also increase the ergonomics of your workstations at the same time.

Thanks to their modular design, the vacuum lifters can be easily adapted to your individual production requirements and move loads weighing several tons simply, effortlessly and absolutely safely.

This not only reduces the physical strain on your employees, but also increases their motivation with significantly lower sick leave.

VacuBoy — Universal vacuum lifters

-

With these vacuum lifters, all vacuum-tight plates up to 2,000 kg can be moved as required. Whether you need to load and unload CNC horizontal or vertical processing machines, commission or restack plates, or even turn them over - the Vacuboy series offers the right solution. The vacuum lifters are absolutely gentle on the material and guarantee maximum operational reliability.

In addition, the devices are available in "ACCU" design and can thus be used completely independent of the mains.

Some examples of its application areas:- Feeding of CNC laser and waterjet systems

- Picking of plate-shaped materials

- Transportation of drums and heavy containers

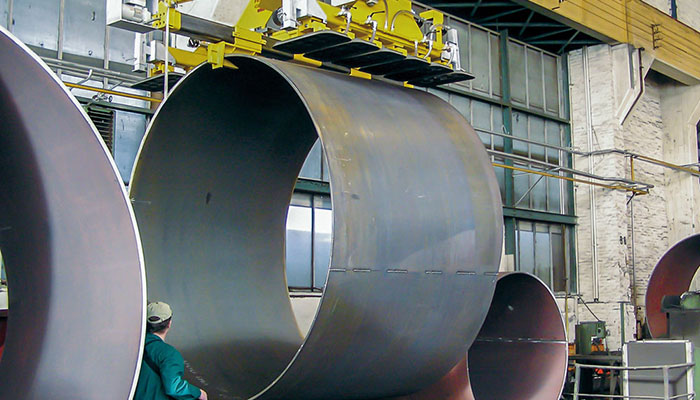

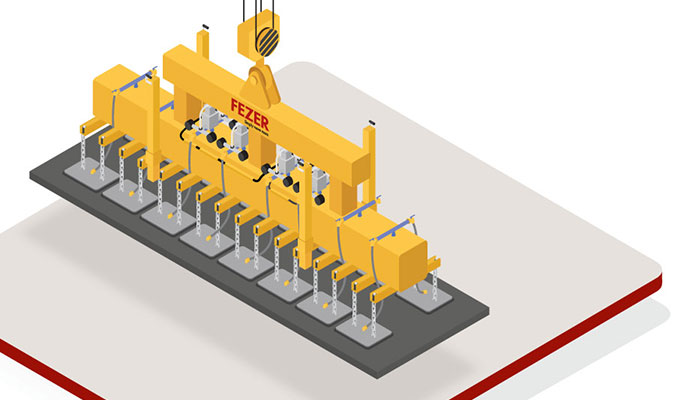

Vacu Giant — easy handling for loads up to 40 tons

-

Moving loads weighing tons safely, gently and quickly? The VacuGiant series supports you in coping with these requirements on a daily basis! Loads can not only be transported horizontally, but also swiveled and turned.

The robust design and the individual adaptation of the devices guarantee you an optimal product design to improve and optimize your production processes.

These are the areas of application of the VacuGiant series:- Aluminum and steel rolling mills

- Sheet metal commissioning in steel trade

- Truck bodies

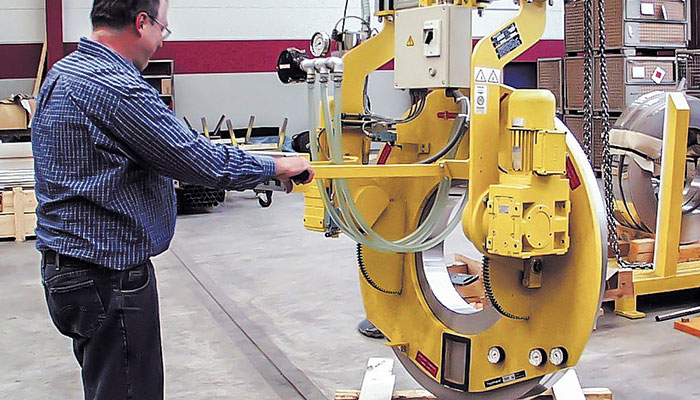

COILS | SPLIT STRIPS

-

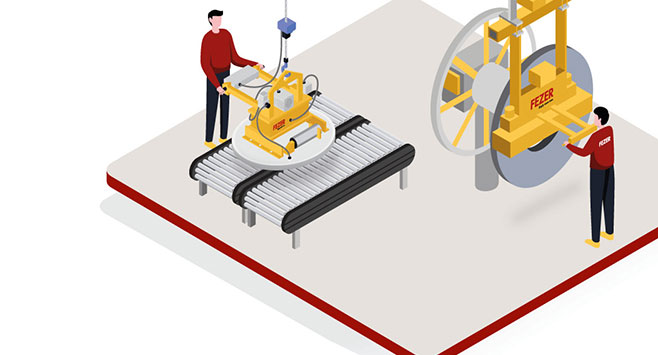

Our slit strip lifters and coil lifters

make work easier in the warehouseWhether in the automated process or in manual handling technology. For transporting and swiveling coils and slit strip rings, you can rely on the qualities of the VacuCoil device series.

Whether for loading reel mandrels, separating cut slit strip rings or for automatic picking and storage - the "VacuCoils" impress with their robust design and intelligent safety concept. Loads of up to 10 tons can be effortlessly transported or swivelled. FEZER relies on its proven safety features. Largely dimensioned vacuum accumulators and intelligent control and monitoring systems ensure absolutely safe handling of coils and slit strip rings.

In addition, all manually controlled vacuum handling equipment features the unique main switch monitoring system. FEZER thus sets new standards for the safety of your employees.

FEZER also offers you special solutions for special handling tasks. For example, suction plates in "flattened design" can always pick up standing slit strips with different outer diameters centrically. With the "transparent suction plate", the operator always has a clear view and always hits the center. In addition, the coil lifters can also be equipped with centering mandrels or mechanical undergrippers if long transport distances have to be covered in large halls.

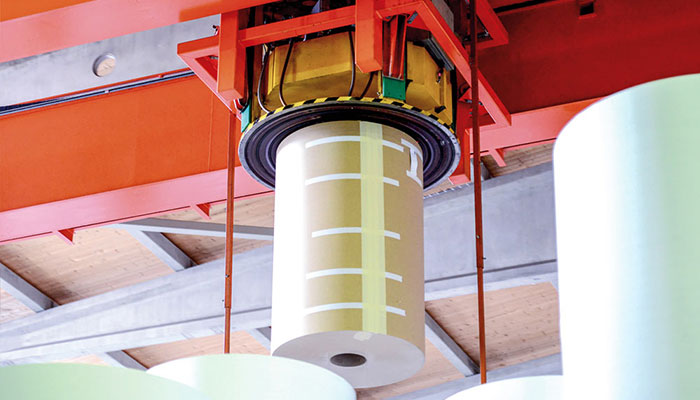

VacuCoil - trouble-free handling of coils, slit strip rings and paper rolls

-

The VacuCoil series was specially developed for handling coils and slit strip rings and supports you when restacking, picking or loading reel mandrels. The units are made of a sturdy steel base construction that withstands even the most robust operating conditions and ensures a long service life.

Largely dimensioned vacuum generators and safety accumulators ensure high operational reliability, even with very narrow or awkwardly wound slit strips.

Some examples of its applications:- Picking coils and slit strips

- Relocation, storage and retrieval

- System solutions for robot use and linear axes

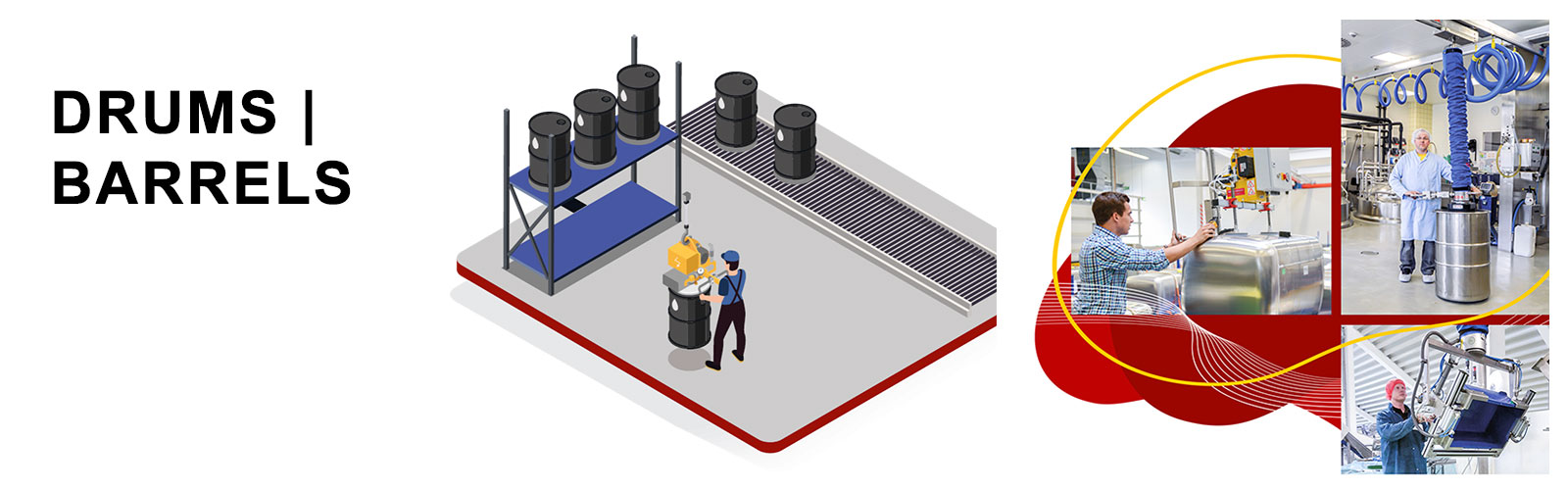

DRUMS | BARRELS

-

For the lifting of barrels, canisters

and containers FEZER offers you

several handling solutions at your disposal.These use the vacuum not only for suction but also for lifting the drums, canisters and containers. As a result, they do not require additional lifting aids such as chain hoists or rope balancers. Furthermore, FEZER also offers you solutions in which the loads can be picked up purely mechanically using clamps or lower grippers.

This is particularly recommended for canisters and containers that have no or too small a suction surface.

VacuBoyMini - Small but powerful

-

The compact VacuBoyMini is ideal for handling heavy drums. Due to the robust design, high safety standards and adaptability of the suction pads, it enables the simultaneous handling of several drums, canisters or containers. This optimizes cycle and throughput times. In addition, each of our manually controlled vacuum handlers offers a unique 'main switch monitoring' feature, allowing FEZER to set new safety standards for your employees.

Some examples of its applications:

- Loading and unloading CNC machines with small parts

- Small, compact and inherently stable workpieces

- Barrels, crates and containers

- Glass and window elements

- "ACCU" version for mains-independent operation

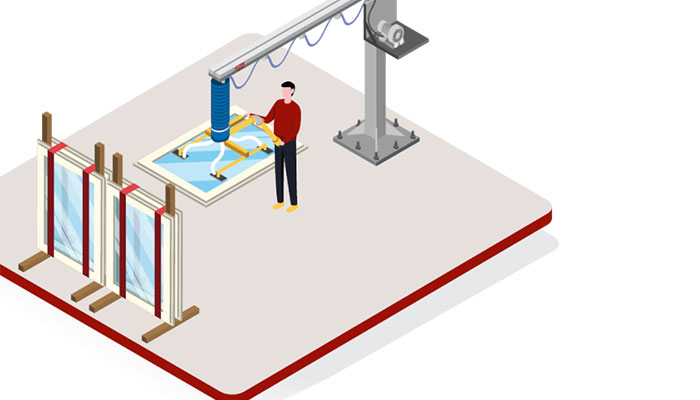

GLASS

-

Glass and window elements are absolutely vacuum-tight and therefore ideally suited for handling with vacuum technology.

That is why FEZER offers you a wide range of application options for the automated and manual transport of these materials. Regardless of whether glass elements have to be transported horizontally, rotated or swivelled.

FEZER offers you the ideal handling devices for glass elements with the VacuBoy, Mobilift and VacuPowerLift device series. These device series are so variably designed that they cover almost every requirement. Even for use on construction sites, FEZER offers you redundant device versions with dual-circuit vacuum systems in accordance with DIN EN 13155.In addition, all manually controlled vacuum handling devices have the unique "main switch monitoring". FEZER thus sets new standards for the safety of your employees.

Customised suction spiders are available for automated production processes, which can be flanged to robot systems and linear axes. Depending on the requirements, the suction spiders are designed with simple control via solenoid valves up to bus control via valve terminal technology.

Common to all handling tasks are FEZER's high safety requirements. Largely dimensioned vacuum reservoirs and intelligent monitoring of the vacuum circuits via electronic vacuum switches guarantee safe and rational transport with maximum operational safety.

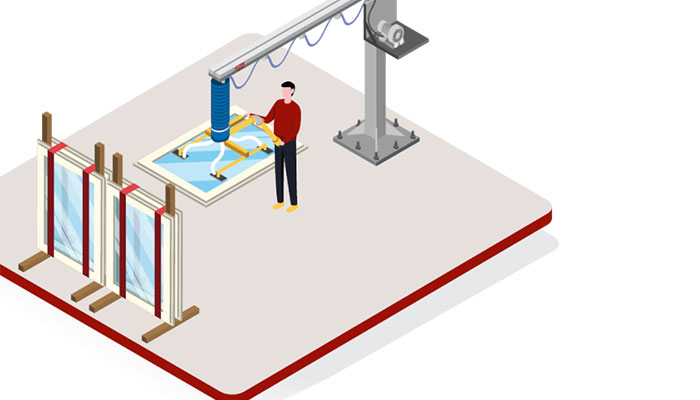

VacuBoyWindow - Our specialist for breakable.

-

With the VacuBoyWindow, we present a specially adapted device series that revolutionises your handling of window elements. The devices offer you the possibility not only to suck in window elements vertically, but also to turn them effortlessly to the left and right - and all this both electrically and manually.

As a special highlight, our units additionally offer the ability to swivel your window elements by 90 degrees or even turn them by 180 degrees.

Some examples of its areas of use:- Handling of window elements

- Restacking of glass panes

- and many more...

VacuPowerlift - the powerhouse for loads up to 200 kg.

-

With our innovative VacuPowerLift product series, suctioning almost any workpiece is child's play. Specially designed for glass elements, VacuPowerlift enables easy, safe and efficient lifting and transporting - all with just one hand. Experience the ease in your work with VacuPowerLift!

These are the areas of application of the VacuPowerlift tube lifters:- Cardboard packaging and logistics industry

- For drums and containers in the chemical and pharmaceutical industry

- Window and solar industry for glass panes and finished components

- Wood, plastic and sheet metal industry for panel material

- Construction industry for stones and concrete parts

- Loading of CNC machines of all types

- Handling of finished machines and machine parts

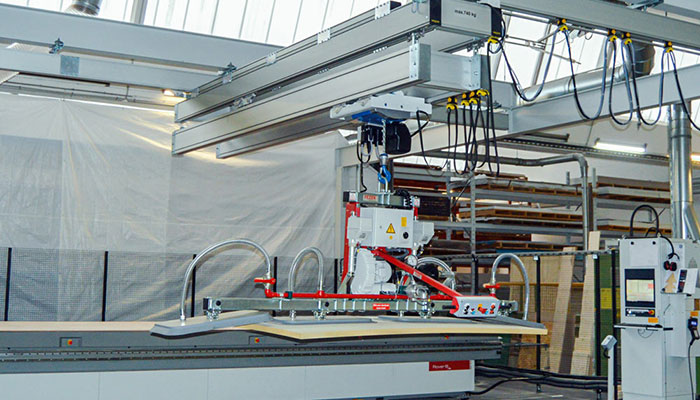

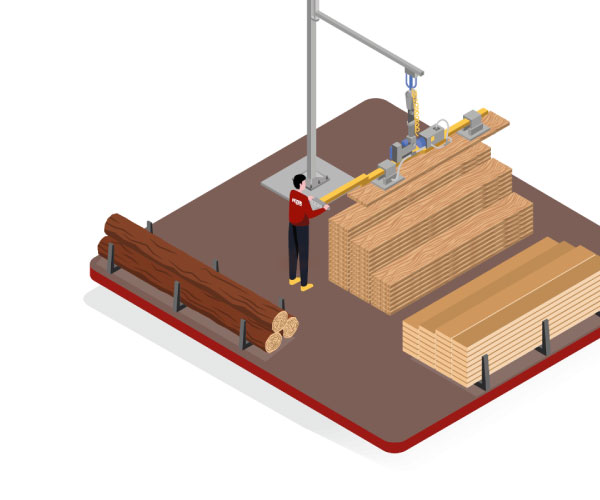

WOOD

-

For the handling of dense or porous wooden elements, FEEZR offers you several device series with which these workpieces can be handled safely and reliably.

With the VacuWood, planks, timbers and glue-laminated beams up to over 24 m in length can be handled. The vacuum is generated by dry-running vacuum pumps, which means that no oil residues can remain on the wood. This device series is particularly suitable for the safe restacking and commissioning of planks, timbers and glue-laminated beams.

In addition, all manually controlled vacuum handling devices feature the unique "main switch monitoring". FEZER thus sets new standards for the safety of your employees.The VacuPoro series is suitable for transporting chipboard, MDF and OSB panels. Thanks to the powerful blower, these porous materials can be sucked up and transported absolutely safely. In addition, the unit series is also available with a swivel drive, which means that the panels can be picked up lying down and transferred to upright processing machines or vice versa. In addition, chipboard, MDF and OSB boards can also be handled with the VacuPowerlift tube lifter. The tube lifter is characterised above all by its fast working speed. Because it uses the vacuum not only for suction but also for lifting the panels, it does not need any additional lifting aids such as chain hoists or rope balancers.

VacuPoro - for the ergonomic handling of porous materials.

-

Let yourself be surprised by the impressive capabilities of our VacuPoro series. Because anyone who previously believed that porous materials could not be lifted with vacuum is now being proven wrong.

Thanks to high-performance vacuum blowers, the VacuPoro series generates impressive air flows that make it possible to lift even non-vacuum-tight workpieces safely. Forget conventional limitations and discover a new dimension in handling porous materials.

Whether wood, polystyrene, plaster or other porous substances - the VacuPoro series makes lifting and transporting an effortless and efficient process.

Lift safely and efficiently:- Porous wood boards such as MDF, chipboard and OSB boards

- Styrofoam or plasterboard

- And many more...

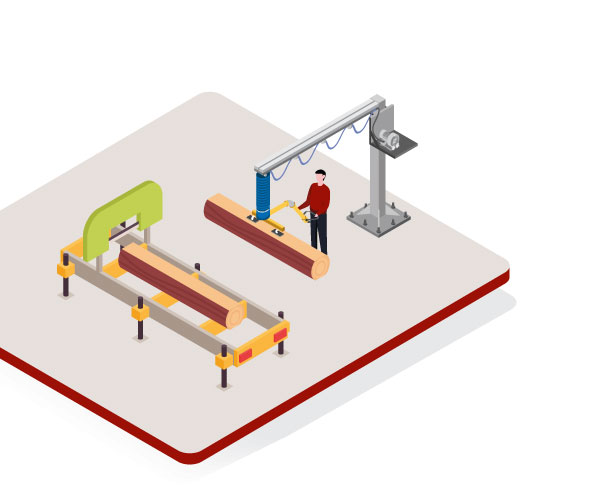

VacuWood - The specialist for wood, glue beams and planks up to 24 metres length

-

Experience the powerful efficiency of the VacuWood series: Equipped with a series of suction plates in longitudinal direction, it is specially designed for transporting wood and boards. Even glulam beams with considerable lengths of over 24 metres are no challenge for VacuWood. Transport timber, glue-laminated beams and planks efficiently and effortlessly!

Some examples of its areas of use:- Removal of the wood after frame sawing

- Storage and retrieval of wood

- Timber picking

VacuPowerlift - the powerhouse for loads up to 200 kg.

-

Discover the limitless versatility of our VacuPowerLift product series. Suctioning almost any workpiece becomes child's play with ease. The VacuPowerLift is also a powerhouse in the wood industry. Effortlessly and without compromise, even wooden planks weighing up to 200 kg can be transported safely and efficiently - and all with just one hand. Learn more about the unsurpassed power that our VacuPowerLift series offers you.

Its areas of use are:- Wood, plastic and sheet metal industry for panel material

- Packaging and logistics industry for cardboard boxes

- For drums and containers in the chemical and pharmaceutical industry

- Window and solar industry for glass panes and finished components

- Construction industry for stones and concrete parts

- Loading of CNC machines of all types

- Handling of finished machines and machine parts

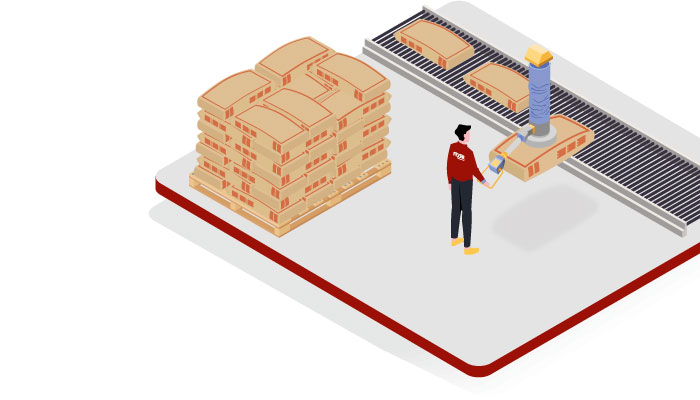

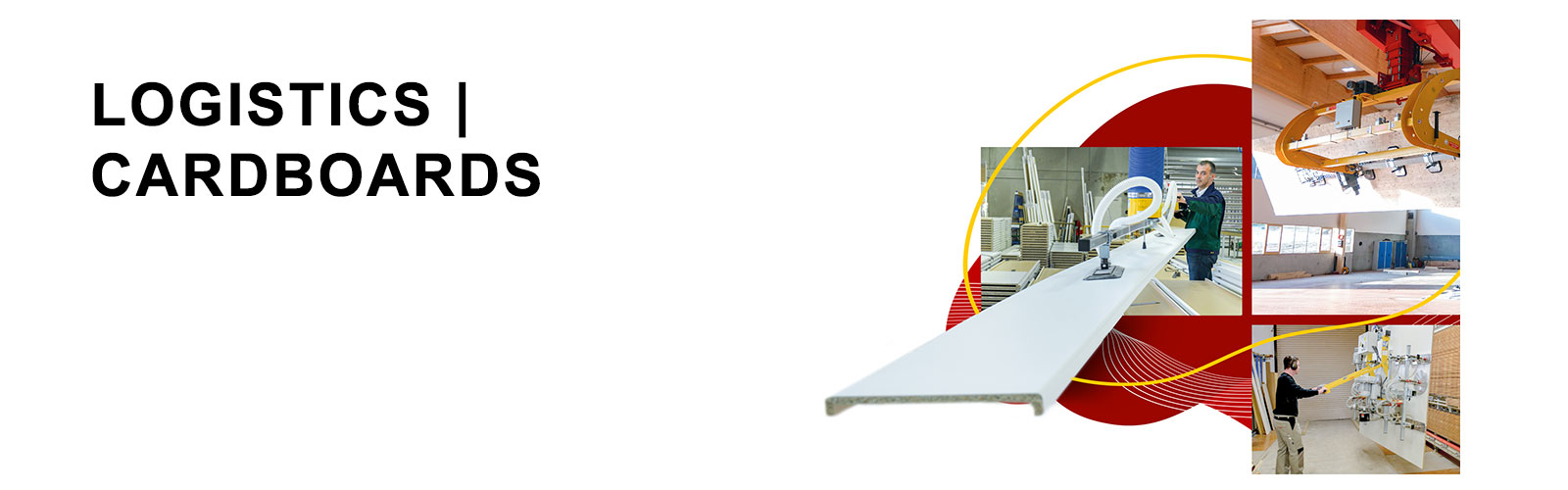

LOGISTICS | CARDBOARDS

-

The vacuum tube lifters from FEZER are your perfect choise for handling cardboard boxes.

Due to the powerful vacuum generators, the tube lifters achieve lifting speeds of up to 1 m/s. In order to also operate these speeds safely, both tube lifters have intelligent and extremely sensitive control units that allow the operator to operate the devices with ease.

In addition, FEZER offers you a wide range of accessories and options for the two vacuum tube lifters to adapt them to your individual needs and thus ensure maximum efficiency and ergonomics for your production processes.

VacuQuicklift - the vacuum lifter for loads up to 70 kg.

-

With the VacuQuicklift tube lifter, workpieces weighing up to 70 kg can be handled absolutely safely, without damage and extremely quickly. Short suction times, lifting speeds of up to 50 m/min and the patented "Quick Release System", with which loads can be released in seconds, guarantee maximum process reliability with the shortest cycle times.

And the best thing is: Your employees don't even have to bend their backs to do it! All they have to do is operate a lever - the VacuQuicklift does the rest virtually by itself.

Some examples of its areas of use:- Picking, storage and retrieval of cardboard boxes

- Handling of canisters, containers and smaller drums

- Handling of baggage during flight check-in

- Handling bags and containers

VacuPowerlift - the powerhouse for loads up to 200 kg.

-

Handling loads of up to 200 kg safely, gently and particularly quickly is no easy task. But Fezer has the right solution for this too. With the VacuPowerlift, cardboard boxes, plates, stones, sacks and much more can be moved effortlessly and very easily - and with just one hand.

If necessary, the workpieces can also be rotated, swivelled or even turned. The modular system of the VacuPowerlift always offers a suitable solution for your workflow. If there is nothing suitable, we will be happy to design a customised solution for you.

These are the areas of application of the VacuPowerlift tube lifters:- Cardboard packaging and logistics industry

- For drums and containers in the chemical and pharmaceutical industry

- Window and solar industry for glass panes and finished components

- Wood, plastic and sheet metal industry for panel material

- Construction industry for stones and concrete parts

- Loading of CNC machines of all types

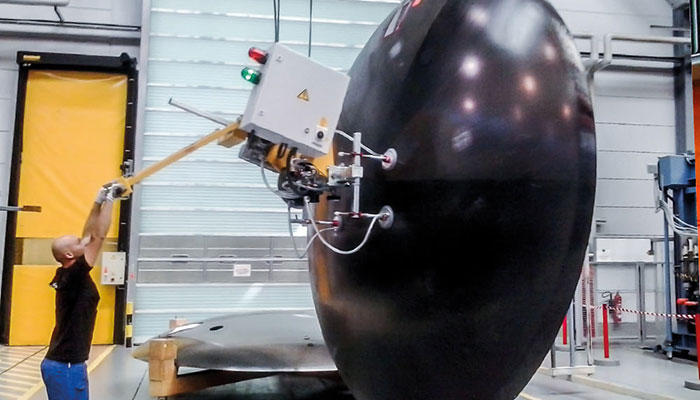

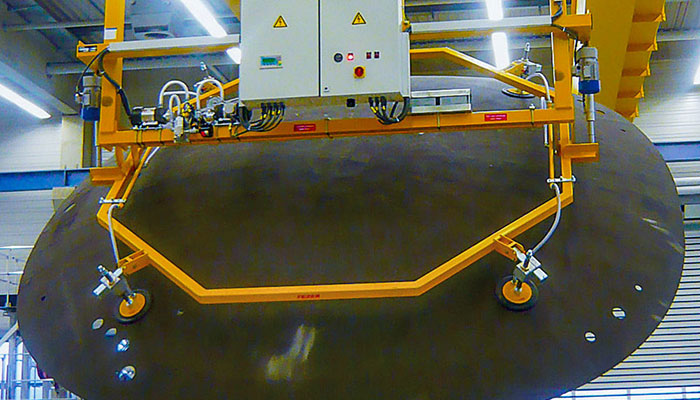

AEROSPACE

-

No matter whether loading covers, pressure domes, chambered wing parts or 40 m long aluminium plates have to be transported - FEZER offers special vacuum handling devices for aerospace technology that absolutely meet the high requirements of this industry.

Because here, after the safety of the operating personnel, very high attention is also paid to the safety of the components.

The components of aerospace technology have an enormous material value and the smallest damage or deformation can lead to the exclusion of the components. VacuBoySystem: The optimal solution for transporting large and heavy loads in aerospace.

-

The requirements of the aerospace industry are complex and demand flexible, adaptable solutions. This is exactly where our VacuBoySystem products come in. They easily master high load capacities and complex geometries.

These are the areas of application of the VacuBoySystem series:

In addition, our customised variants of the VacuBoySystem series are able to meet individual needs and leave nothing to be desired.- Aircraft elements

- Pressure domes

- etc.

SACKS

-

No matter whether you need to stack bags into or out of storage, commission them or make them available for packaging purposes. The vacuum tube lifters VacuQuick and VacuPowerlift guarantee absolutely safe handling of bags at maximum speed.

Thanks to the powerful vacuum generators, the tube lifters achieve lifting speeds of up to 1 m/s. In order to also operate these speeds safely, both tube lifters have intelligent and extremely sensitive control units that make it child's play for the operator to operate the devices.In addition, FEZER offers you a wide range of accessories and options for the two vacuum tube lifters in order to adapt them to your individual needs and thus ensure maximum efficiency and ergonomics for your production processes.

VacuPowerLift - The multitalent for ergonomic handling of bags

-

Discover the incredible versatility of VacuPowerlift: from small workpieces to heavy bags, our device effortlessly sucks up and moves everything with ease. Even lifting and transporting bags with just one hand becomes child's play with our VacuPowerlift, all while maintaining the highest safety standards.

Moreover, the versatility of our VacuPowerlift goes even further: it is even suitable for use in potentially explosive areas. Increase your efficiency without compromising on safety!

STONE | CONCRETE

-

For manual handling, in addition to the vacuum tube lifters, various vacuum handling devices are also available with which stones and concrete parts can also be swivelled and turned. And this for weights up to several tonnes. The devices are characterised by a high operational safety, even with extremely rough surfaces. Thanks to special suction pads and sealing profiles, these devices hold the stone and concrete parts securely for a sufficient time even in the event of a power failure.

In addition, all manually controlled vacuum handling devices feature the unique "main switch monitoring". FEZER thus sets new standards for the safety of your employees.

FEZER provides highly effective and above all intelligent vacuum components for automated processes for transporting, swivelling and turning stone and concrete parts. Powerful vacuum generators build up the necessary vacuum.

Robust and precise vacuum switches monitor the vacuum and provide feedback in case of malfunctions. In this way, process and operational safety can be increased and high availability guaranteed.

VacuPowerLift - Turns heavyweight into lightweight.

-

Discover the power of the VacuPowerlift: our versatile product line revolutionises the handling of workpieces of all kinds. With a special focus on stone materials in all shapes, the VacuPowerlift offers a handling solution that meets the highest safety standards as well as impressive efficiency. Lift and transport even the heaviest elements effortlessly - and all with just one hand!

But the VacuPowerLift is not only the ideal companion for lifting stone and concrete parts.

Other areas of use are:- Cartons / Logistics

- Sacks

- Glass

- etc.

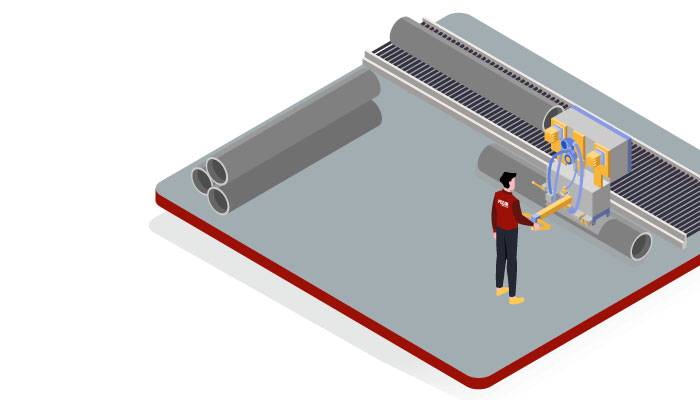

PIPES | TUBES

-

FEZER offers you special suction pads for this purpose, which can also accommodate a range of diameters of different sizes. This saves you high set-up and adjustment costs. No matter whether you have to handle the tubes, rods and profiles manually or in automatic mode. In addition, FEZER offers you a wide range of options to adapt the tube and bar lifters to your personal production processes.

This means that different suction circuits can be set up for variable pipe lengths, which switch themselves on or off automatically based on the existing lengths. This is done by means of built-in flow valves that automatically switch off the suction pads when they are not in use or by means of an intelligent system solution with vacuum monitoring and valve terminals.

VacuBoyTube - The expert for round geometries

-

The ideal solution for transporting tubes and bars is called: VacuBoyTube. Our specially developed suction plates adapt perfectly to the diameter of your transport material and allow effortless suction of workpieces of different weights and shapes.

Whether it is lighter and smaller diameters or heavy and larger steel pipes - VacuBoyTube offers the ideal solution for air pick-up transport of pipes and long goods.

Some examples of its areas of use:- Moving concrete pipes

- Feeding aluminum strips

- Handling of pipes with different diameters

CRANES

-

For loads up to 500 kg, we offer you a self-developed aluminium rail system for particularly smooth running of the column-mounted slewing cranes. For higher loads, stable steel rails are used, which guarantee our pillar-mounted slewing jib cranes maximum load capacity with minimum deflection. In addition to the column-mounted slewing crane, you will also find the matching chain hoists with two speeds and corresponding control bulb at FEZER.

The FEZER Pillar-mounted slewing crane at a glance: - smooth running aluminum profile up to 500 kg

- Highest operational reliability due to optimally matched components

- stable and robust brackets

- for higher loads with electric swivel and trolley drive

- Direct attachment to the floor without intermediate plate

- mobile base plate for free placement and arbitrary positioning with a lift truck

- Version with telescopic and lockable column

FEZER crane systems Lightweight. Robust. Powerful.

-

An efficient vacuum lifter requires an equally powerful crane system. So that you can get everything from a single, reliable source, we have developed our own cranes. Our cranes, consisting of extremely smooth-running aluminium profiles, cover a wide range of applications - whether for tube lifters, chain hoists or as a stand-alone solution.

Our crane systems include:

At the same time, our user-friendly crane systems are available in numerous designs and are just waiting to optimise your processes.- Pillar jib cranes

- Wall-mounted jib cranes

- Ceiling-mounted jib cranes

- Overhead conveyor systems

FEZER's wall-mounted slewing jib cranes perfectly complement FEZER's vacuum technology. They are also robust and smooth-running and, thanks to their special bracket design with plain bearings and transport trolleys with large running wheels, offer efficient workflows under various conditions. For loads up to 500 kg, wall-mounted slewing jib cranes with an aluminium rail system are available. For higher loads, sturdy steel rails are used to ensure maximum load capacity with minimum deflection. Matching chain hoists with two speeds and control bulb are also available.

The wall-mounted slewing jib cranes offer a smooth-running aluminium profile up to 500 kg, maximum operational safety thanks to optimally matched components, stable and robust brackets with plain or ball bearings and an electric slewing and trolley drive for higher lifting capacities.