- Offer Profile

- We are a leading supplier of resin metering systems and specialist for automation and dispensing technology.

Material Preparation & Feeding Systems

-

Homogeneous and bubble-free when the right preparation and feeding system is used

A good dispensing system is only as good as the material preparation and/or feeding system used. Only the correct preparation and feeding unit can provide homogeneous feeding of potting media that is optimized to the particular application. An advanced preparation and feeding system can even compensate for interruptions, breaks and errors during dispensing or in downstream production steps without compromising quality. Scheugenpflug AG offers material preparation and feeding systems for all 1C and 2C potting materials with viscosities ranging from 50 to 1,000,000 mPa∙s. With these systems you are also well equipped for tomorrow’s potting media challenges. Compact Preparation and Feeding Systems

-

Cartridge or pressure tank feeding

The models of the A90 compact preparation and feeding system product line provide an entry into automated material feeding. These systems are the right choice for applications with a very low material consumption and for potting materials that do not place high demands on homogenization, heating and evacuation. Suitable models and options are available for various requirements.

A90 C: small, compact and easy to use

-

Ideal for Semco and Euro Cartridges

The A90 C system is the right choice for providing material via standard Semco or Euro cartridges, depending on the cartridge size. The system works with compressed air, which pushes the cartridge trigger and feeds the material from the cartridge to the dispenser. At the same time, the piston of the pneumatic cylinder moves the cartridge trigger over the surface of the workpiece, ensuring smooth dispensing of the material. The various colored LEDs notify the operator when the cartridge fill level drops below a defined minimum value (

Advantages- Space-saving design

- Easy to use

- Interference-free feeding of even small quantities

- Suitable for the assembly to portal axles

A90 CV

-

Material Feed with Vacuum Docking

Apart from the conventional functions, this model of the A90 C also features the new vacuum docking function. It enables the automated ventilation during cartridge changes and thus an absolutely bubble-free docking process between the material cartridge and the dispensing system. With it, the material waste per cartridge change can be reduced by up to 90 percent. Users not only benefit from absolute process reliability but also from considerable cost savings - especially in the case of expensive dispensing media.

For the vacuum docking process, Scheugenpflug specifically designed an innovative docking sleeve with filter insert. The sleeve is manually put on the filled material cartridge, which is inserted into the cartridge mount of the A90 CV afterwards. The ejector of the cartridge expulsion unit then evacuates the air within the docking sleeve. The integrated filter prevents the introduction of dispensing material into the ejector line.

A90 B: wherever higher performance is needed

-

The Ideal Choice for High Viscosity Media

If highly filled, high density materials are used or the feeding pressure of an A90 C cartridge expulsion unit is not sufficient, the use of a material preparation system with pressure booster is necessary. The A90 B system is the right choice in such cases. The proven Scheugenpflug piston pump acts as a booster and is filled by the A90 C cartridge expulsion unit, enabling the piston pump to increase the feed pressure and consequently accelerate filling of the dispensing system.

Advantages- Space-saving design

- Easy to use

- Continuous material feed possible

- Perfect for feeding high viscosity media

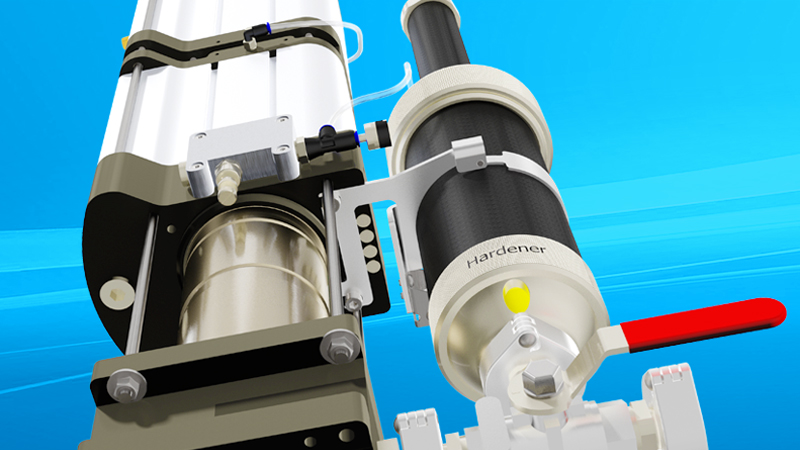

Systems for Feeding from Hobbocks

-

Reliable, clean and bubble-free feeding of high viscosity materials from hobbocks

The heavy-duty A220 and A280 material feeding systems are used for high viscosity and, depending on the pump model, non-abrasive or highly abrasive 1C or 2C potting compounds. The original drum (hobbock, pail) is placed in the hobbock drawer and the control unit starts the docking process after the safety door is closed. This lowers the patented vacuum follower plate into the drum, where the follower plate automatically and quickly (< 5 min.) attaches itself (docks) to the material without air pockets. Material feeding starts fully automatically. After removal, the empty drum is discarded together with the follower plate. Docking the next drum with a new vacuum follower plate avoids the risk of introducing residual material into the drum, as often happens when conventional rubber follower plates are used incorrectly.

A220 Follower Plate Pump

-

Reliable feeding of high viscosity materials from the hobbock

The A220 follower plate pump is used for feeding high viscosity, non-abrasive potting compounds. The reciprocating piston pump used in this system ensures a continuous supply of material, which is pumped during both the downward and upward stroke, making it a rugged, cost-effective system.

Advantages- Long service life thanks to a rugged, durable reciprocating piston pump

- Very easy to use

- High process reliability due to fully automated pressure and vacuum control

A280 Follower Plate Pump

-

Reliable feeding of abrasive materials from the hobbock

The A280 follower plate pump, which shares the basic design of the A220, features a reliable Scheugenpflug dual-piston pump. This pump comes in contact with the material on only one side, while a barrier fluid on the reverse side prevents abrasive fillers from adhering to the seals. This gives the material preparation system an unsurpassed service life when feeding highly abrasive, paste-like media.

Advantages- Long service life thanks to a rugged, durable dual-piston pump

- Very easy to use

- High process reliability due to fully automated pressure and vacuum control

Vacuum Follower Plate

-

Bubble-free feeding of high viscosity potting material

The patented vacuum follower plate was designed specifically for feeding high viscosity potting material from a hobbock or pail and is used in the A220 and A280. The vacuum follower plate is made of polypropylene (PP), which guarantees appealing sliding and manufacturing characteristics that aid in the production process. In addition, PP provides exceptional material compatibility with the most frequently used potting media.

Advantages- Bubble-free docking

- Cost-effective solution thanks to almost complete emptying of the drum

- Fast drum changes without transferring material residue

Systems for Self-Leveling Materials

-

Moisture and air bubbles are now a thing of the past

When working with sensitive materials that react to moisture or need to be prepared in a vacuum, for instance, our preparation and feeding systems for self-leveling potting media are the right choice. Using system processes such as homogenization, heating, circulation and evacuation, it is possible to control the processing properties of the materials and establish the basis for the function and reliability of your workpieces.

LiquiPrep LP804 Material Preparation and Feeding Unit

-

Pump UP your material quality!

There’s no denying it: Electronic components have to work. An optimal dispensing performance as well as an absolutely homogeneous and bubble-free material are the prerequisites for this. The new LiquiPrep LP804 system incorporates the process engineering know-how of 30 years of market activity and allows for reliable preparation and feeding of self-leveling adhesives and potting materials with a viscosity of up to 70,000 mPa∙s. Processes such as homogenization, tempering, circulation and evacuation can be used to specifically influence the processing properties of the medium. The heart of the system is a novel, intelligent diaphragm feed pump. State-of the-art sensors individually determine the degree of filling here. This ensures a continuously high feeding performance. The diaphragm feed pump also offers significantly increased wear resistance and thus a long service life.

Advantages

- Absolutely homogeneous and bubble-free potting material

- Consistently high feeding performance

- Long service life thanks to intelligent diaphragm feed pump

- Convenient maintenance and operation

Barrel Agitator Station

-

Moisture and bubbles in large drums are a thing of the past

The barrel agitator station developed for 200 l barrels is used in applications with high material consumption. It provides homogenous and tempered potting material and also allows the comprehensive preparation of moisture-sensitive materials from large containers. The basic model is operated in combination with the LiquiPrep LP804 material preparation and feeding system and is ideal for agitating and tempering self-leveling media. Optionally, the barrel agitator station can be equipped with an eccentric screw pump. In addition to feeding highly viscous media up to 70,000 mPa∙s, this variant also allows the dispenser to be directly fed with potting material without the need of an additional preparation stage by the A310 system.

Advantages- Bubble-free processing of 200 liter containers

- Also suitable for moisture-sensitive media

- Consistently homogeneous potting material, even after production breaks

- Optional: Vacuum potting at up to 100 mbar possible even without intermediate preparation

Dispensers

-

Automated Precision Fluid Dispensers

Scheugenpflug liquid and adhesive dispensers – economical, reliable, accurate

Process reliability is critical in the manufacturing industry and directly depends on selecting the right dispensers. Since adhesive bonding or potting usually take place towards the end of the process chain, mistakes have a particularly wide-ranging impact.

You're in good hands with the rugged adhesive bonding, dispensing and potting machines from Scheugenpflug. Our equipment has proven its worth over several decades. From precise and repeatedly accurate application of 1C and 2C materials to multi-piston dispensers for batch production, we have the right dispenser for all your needs.

Volumetric Piston Dispensers

-

Versatile liquid and adhesive dispensers for a wide range of applications

Volumetric piston dispensers are the “jack-of-all-trades” among dispensers. They can be used for very low-viscosity media, for high-viscosity materials and even for the application of filled and/or abrasive materials such as 1C and 2C thermal conductive gels and gap fillers. These dispensers offer a wide range of possible applications: Volumetric piston dispensers are used both for potting and sealing applications and for tasks related to adhesive bonding, insulation and thermal management.

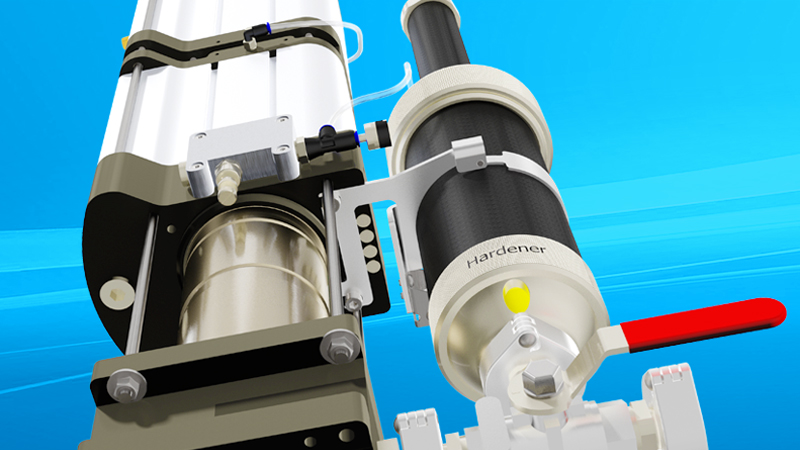

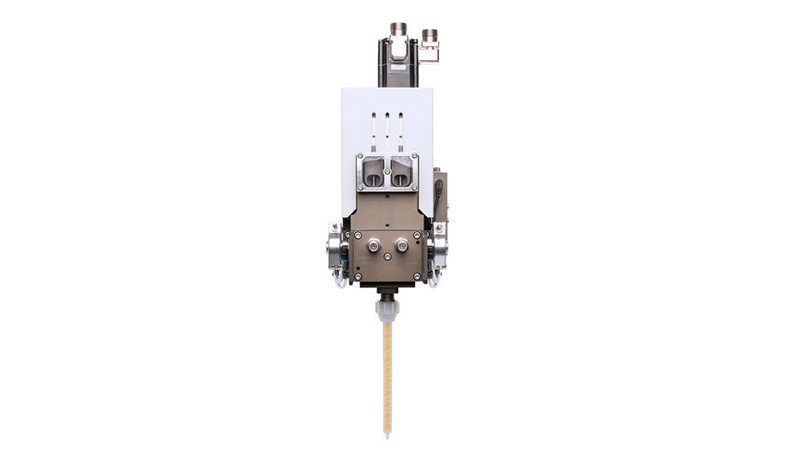

DosPL DPL2001

-

Maximum flexibility from even the smallest volumes

The increasing miniaturization of components in the automotive electronics, industrial electronics, medical electronics, and consumer electronics requires new, innovative dosing solutions. The DosPL DPL2001 piston dispenser takes precise and high-precision dosing to a new level.

The new Low Volume Dispensing enables displacement-free micro-dispensing for the application of smallest points, finest lines and micro-fillings down to the μl range.

Application benefit:

- Application of smallest volumes up to the μl range

- Highest precision

- Flexible dispensing rates and wide volume range

- Comprehensive process monitoring options

- Suitable for filled and abrasive materials

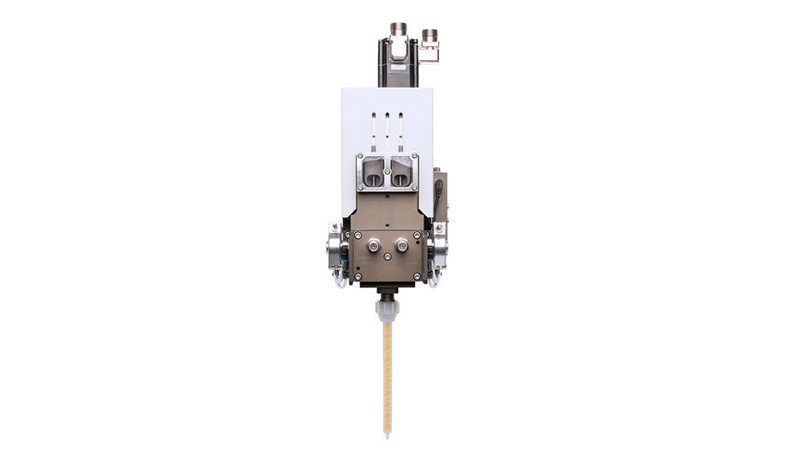

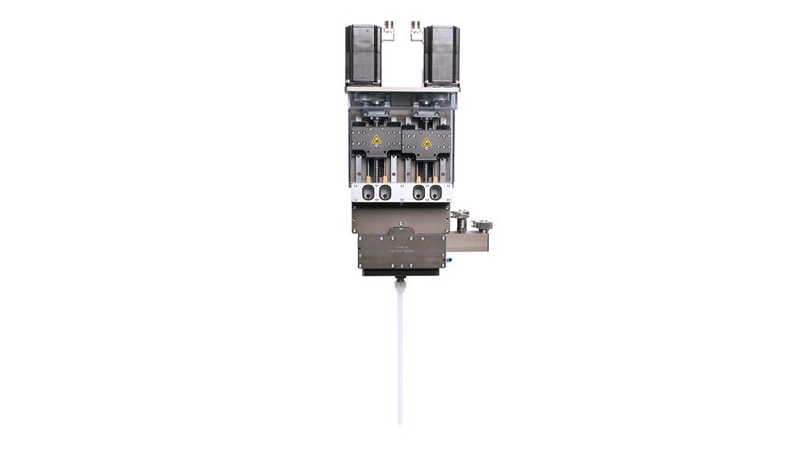

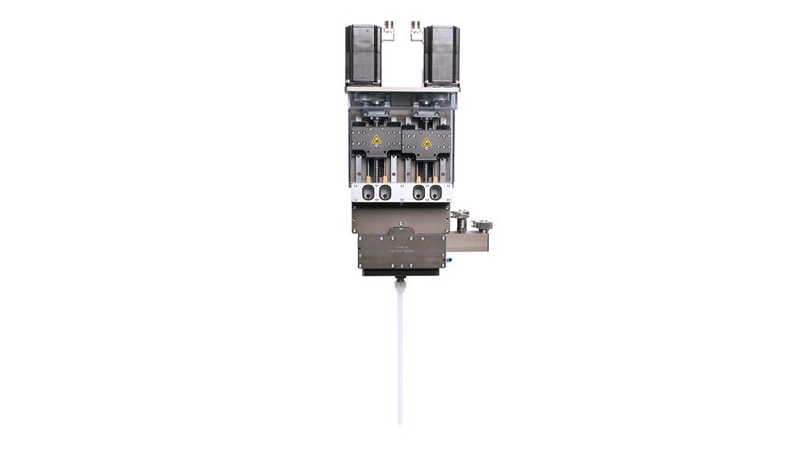

Dos P Volumetric Piston Dispensers

-

Accurate, rugged, durable

The Dos P016 / 050 / 100 / 300 / TCA piston dispensers are high-precision volumetric dispensers designed to process 1C and 2C materials and cover a wide range of applications. Precisely dimensioned dispensing cylinders provide the ability to obtain reproducible material volumes. When 2C materials are used, the mixing ratio is kept constant by simultaneously discharging both cylinders into the shared mixing tube, ensuring the highest level of process reliability. At the same time, potting media that are sensitive to pressure, moisture or shearing are fed carefully through the dispenser, eliminating potential worry of changes to the material. Users also benefit from their fast and easy maintenance, long service life and significantly reduced servicing costs. Thanks to optional features such as valve monitoring, mixing tube heating and dispenser heating, these systems can be adapted flexibly to any requirement.

Advantages- Dispensing accuracy does not depend on temperature, pressure or viscosity

- Constant mixing ratio at all times due to parallel evacuation of dispensing cylinders

- Wide spectrum of applications (material and task)

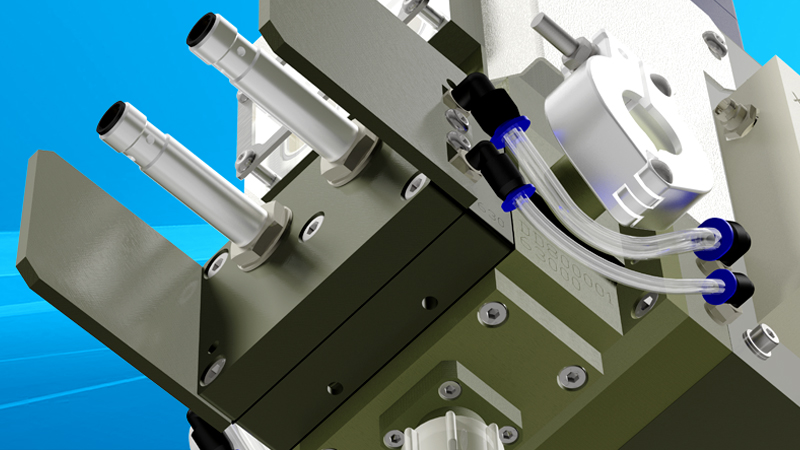

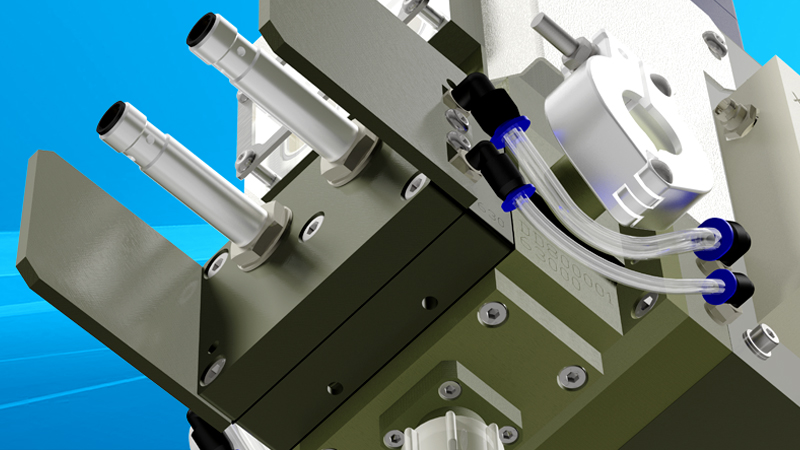

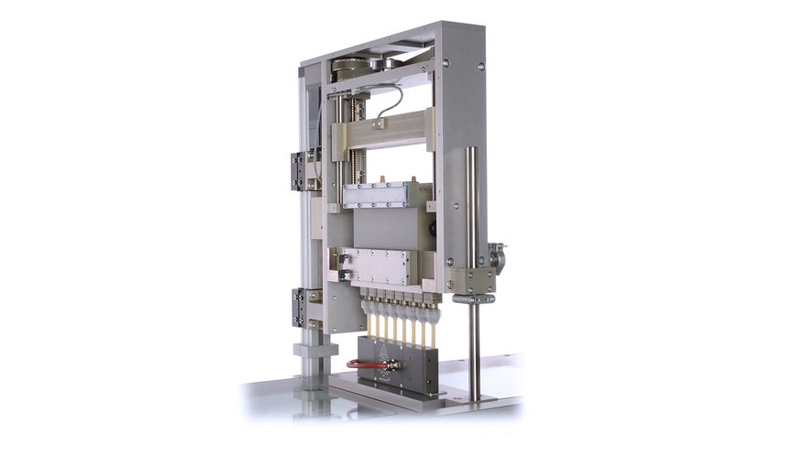

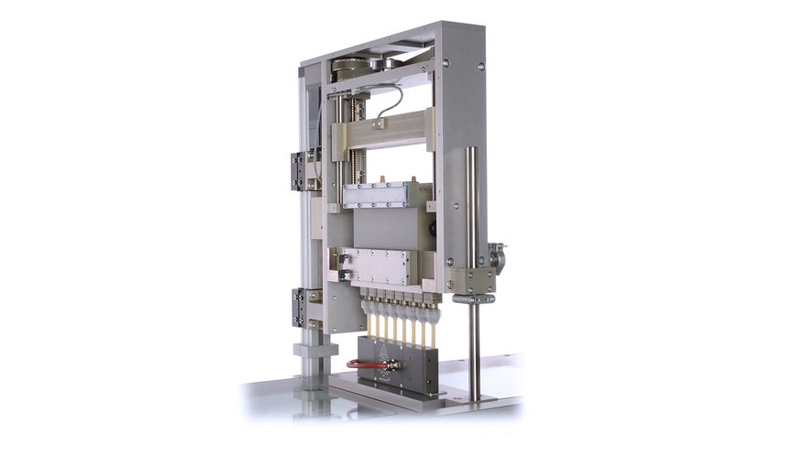

Dos P-X Multi-Piston Dispenser

-

Ultimate performance with a small footprint

Multi-piston dispensers are used for the output of large batch quantities and for short cycle times. These systems can pot several workpieces in a single potting cycle. They are particularly suited for potting a large number of small workpieces, especially when dispensing in a vacuum. Their unrivaled performance is the result of distributing the filling, evacuation and ventilation time among many workpieces. Multi-piston dispensers are made of several functionally interconnected single dispenser outlets. Each outlet is controlled by individual inlet/outlet valves and monitoring sensors. A shared lifting unit guarantees absolutely simultaneous and identical dispensing from all outlets. One or more nozzles can be disabled by controlling individual valves for more flexibility in the event that not all of the holders contain workpieces. These systems achieve perfectly precise dispensing accuracy combined with a long service life, regardless of the number of single outlets used.

Advantages- High part throughput per unit of time (up to 48 nozzle potting possible)

- Consistent quantity and mixing ratio through common lifting mechanism

Dos P-A Alternating Volumetric Piston Dispenser

-

Uninterrupted potting of large quantities

The Dos P-A is the system of choice when large quantities have to be applied quickly. In this design, one cylinder pair is loaded while the other is discharged. This makes it possible to output large quantities of dispensing material within a very short amount of time. Filling time is no longer an issue. This system is therefore ideal for filling large quantities or applying long beads of sealants or adhesives.

Advantages- Seamless production through alternating discharge and filling of both cylinder pairs

- Ability to process large quantities in short time

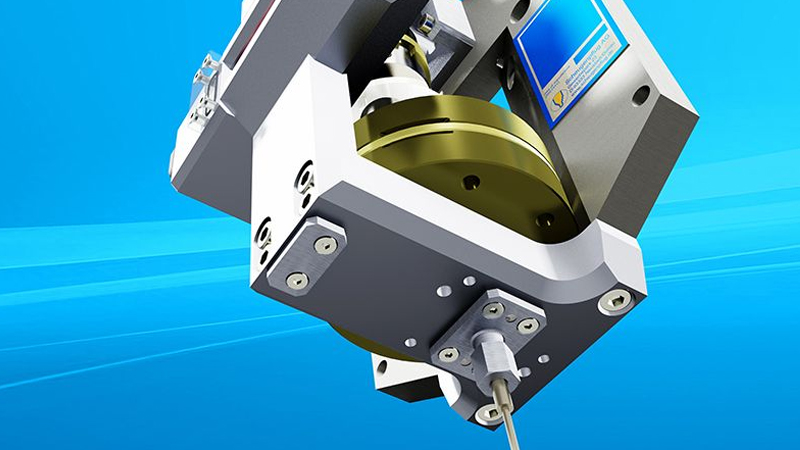

Gear Pump Dispensers

-

Gear Metering Pump: Specially Designed for Continuous Bead Application

Dos GP gear pump dispensers

Gear pump dispensers are volumetric dispensers specifically designed for the continuous application of low to high viscosity potting materials. Application options include applying sealing beads to component housings or applying adhesives as part of joining processes.

Dos GP gear pump dispensers

-

Rugged, fast and consistent – even with high inlet pressures

Dos GP systems are the first choice for applications requiring 1C or 2C, high viscosity, unfilled, non-abrasive potting material, making them the best choice for applying continuous beads. The dispensing process is absolutely continuous and consistent. A special swivel needle is also available for DOS GP gear pump dispensers to handle 2D/3D contours. These systems work fast and accurately – even on complex workpiece geometries.

Advantages- Seamless bead application of large material quantities

- Swivel needle (optional) allows for the application of contours on steep slope angles

- Fast and even application - even at high inlet preassure

Dispensing Systems

-

ECONOMICAL, RELIABLE, ACCURATE

Process reliability is critical in the manufacturing industry and directly depends on selecting the right dispensers. Since adhesive bonding or potting usually take place towards the end of the process chain, mistakes have a particularly wide-ranging impact.

You're in good hands with the rugged adhesive bonding, dispensing and potting machines from Scheugenpflug. Our equipment has proven its worth over several decades. From precise and repeatedly accurate application of 1C and 2C materials to multi-piston dispensers for batch production, to small quantity and micro dispensing, we have the right dispenser for all your needs.

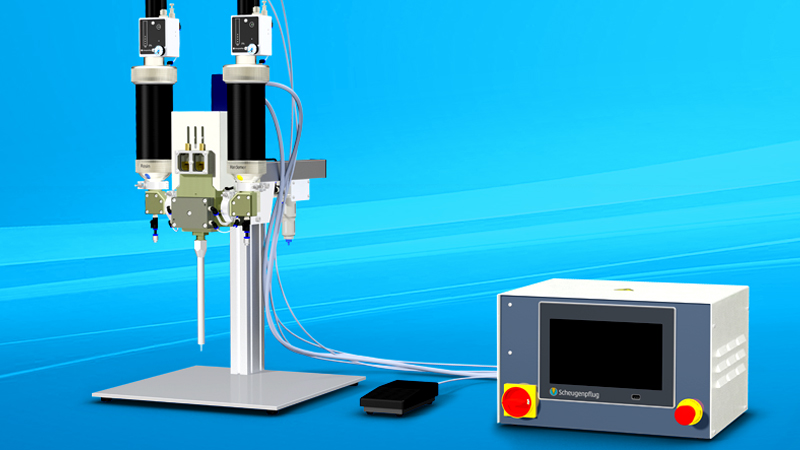

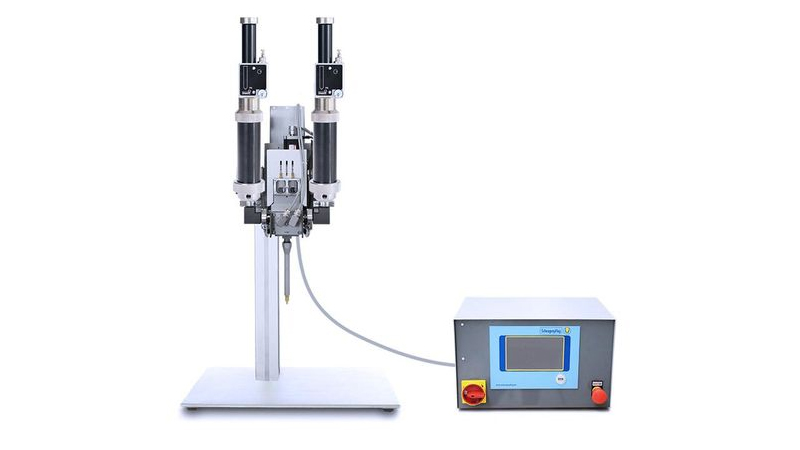

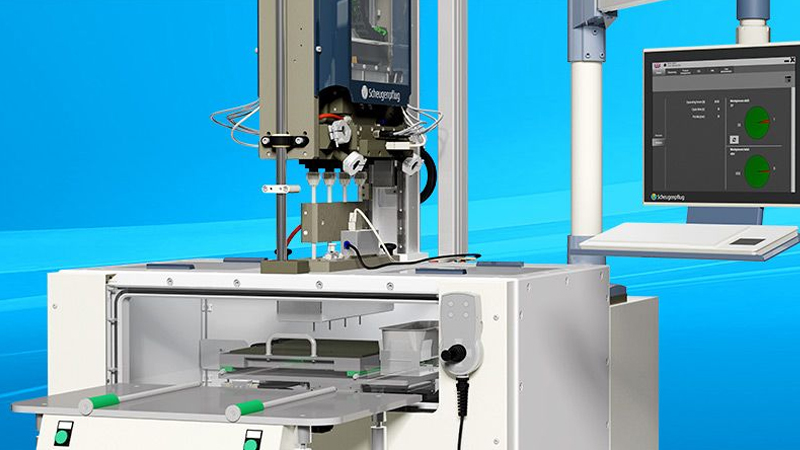

Manual Work Stations

Manual Work Stations

-

Highly flexible at an affordable price

The Dos manual work stations are a budget-friendly, reliable entry-level solution for simple potting tasks and small batches. They consist of standard modules of varying performance classes. The basic model includes a material preparation system and feeding system and a dispenser with stand. Thanks to the proven Scheugenpflug modular system, all modules can be easily combined and flexibly adapted to the particular process requirements. In addition to using the manual work station, these systems can also be expanded to form an automated standalone system. It is also possible to easily integrate existing production lines, since the standard, documented interfaces significantly reduce the otherwise typical programming involved.

Advantages- Optimized entire system with efficient individual components

- Easy and fast exchange of component and series

- Easy and economical handling of small batches

- Sustainable through flexible integration

Dispensing Cells

-

Optimized for any application

Dispensing cells are the ideal solution for medium to large-sized batches and for most applications. Since adhesive bonding and potting tasks usually have specialized requirements, Scheugenpflug AG offers a modular system which allows users to customize their system precisely to the requirements of the respective application. However, regardless of the dispensing cell: these systems offer a high level of productivity despite the good value for the price. The effective support of process standardization worldwide and a high level of security in planning and investment through simple system expansions are also important factors in today’s market.

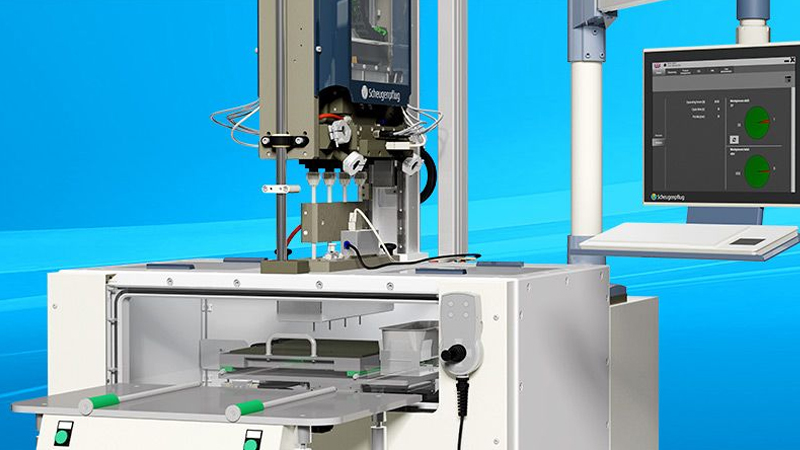

Multifunctional Cell DispensingCell DC803

-

Scale UP your performance!

The casting of changing components, changing capacities or lack of space in production: The requirements for adhesive bonding, sealing and potting processes are becoming increasingly individual. Against this background, the ability to adapt the dispensing system efficiently and economically plays a decisive role. The new, high-performance DispensingCell DC803 is available for demanding dispensing tasks. The further development of the proven CNCell has been specially tailored to the requirements of industrial series production with short cycle times and high quantities. Its modular design and numerous equipment options allow flexible configuration and rapid adaptation to changed processes and series sizes.

The DispensingCell DC803 is part of our new system solution.

Advantages

- Highest performance for series production

- Flexible configuration in terms of equipment features and degree of automation

- High usability thanks to intelligent machine control unit

- Numerous options for quality assurance and process monitoring

DispensingCell

-

The Entry-Level Solution for Dispensing Applications

The system includes a 3-axis-system and a light curtain as well as the proven Dos P016 and the cartridge expulsion unit A90 C with filling level monitoring.

Advantages

- Fast start of production

- Unrivaled service life

- Short delivery times

LeanCNCell

-

Focusing on small and medium-sized batch production

The LeanCNCell is specially designed to handle dispensing and potting of small to medium-sized batches. It combines all the advantages of the CNC system plus a high-precision axis controller with attractive performance for the price. This makes it particularly suited for applying seals or conformal coating of electronic assemblies and housings with 1D, 2D or 3D contours. A wide selection of dispensers is available for use with the LeanCNCell. It represents an alternative to the DesktopCell wherever other model sizes or process monitoring capabilities (scales, needle status measurement, heater, etc.) are required.

Advantages- Full CNC functionality

- High-precision axles

- Attractive price-performance ratio

CNCell

-

Ultimate performance and scalability

Where high flexibility for medium and large batch production is required, the CNCell is the system of choice. This multi-functional cell is based on standardized modules and it is tailored to customer specifications. The wide range of available dimensions, production processes, parts handling options and material flow or machine control units allows for a completely customizable set-up of a system tailored to specific needs. All modules perfectly match, so that they can be easily swapped or used together. The equipment can be used almost immediately thanks to the system’s scalable, modular design, which also allows for short planning and implementation times as well as quick adaptation to changes in process and batch size. The CNCell offers superior performance and high-level planning and investment security, and effectively supports the standardization of processes worldwide.

Advantages- High axis speeds allow for short cycle times

- Flexible configuration and diverse possibilities for expansion

- Highly effective through automation option

- Quality control with options to monitor processes

- Wide range of applications

Processing Modules

Processing Modules

-

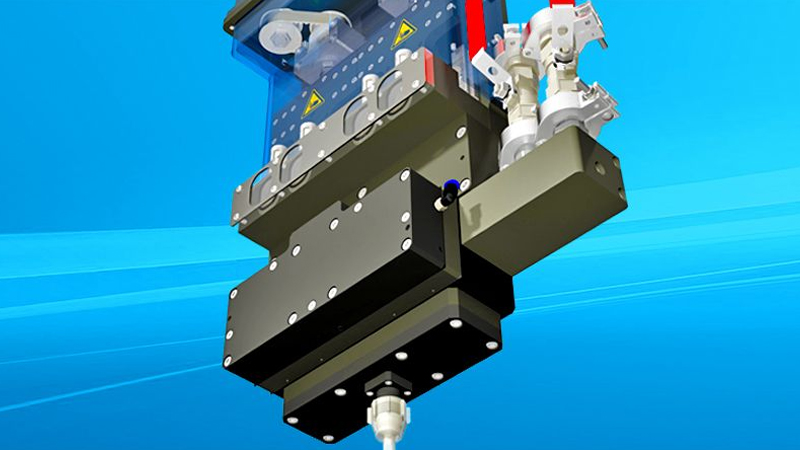

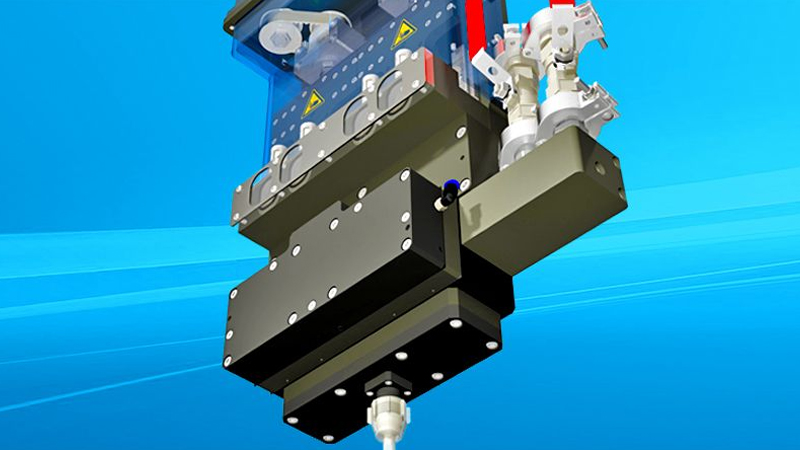

Superior processing technology for easy integration

The Scheugenpflug ProcessModule allows systems integrators and automation providers to leverage the benefits of the strictest processing technology standards in their production lines or cells. The system can be quickly and safely integrated into new or existing production lines or cells as easy as “plug-and-produce”. This ensures that all parameters and processes related to adhesive bonding and potting are accurately matched to each other, independently of the rest of the machine. The Scheugenpflug ProcessModule offers the optimal solution for a wide range of process requirements.

Thanks to powerful axis and motor technology, the ProcessModule offers high traversing speeds and thus short cycle times in matrix, bead and filling applications. It was developed for maximum economy and optimized for simple and flexible integration. This is made possible by the large traversing range, which enables the dispensing of adhesives and sealants as well as potting media on several parts in a single operation. Further characteristics are the high flexibility with regard to process and part parameters and the simple use of conveyor belts.

Advantages- Fast integration through plug-and-produce

- Optimal usage of space

- Time and cost efficiency thanks to optimally matched components and interfaces

Vacuum Potting Systems

-

The solution for the strictest requirements

Many electronic components today have a wider range of functions and must fulfill strict reliability and functional durability requirements. Once installed, they are usually very difficult to replace. Often they are not even meant to be replaceable and are designed to perform their function throughout their entire lifespan. At the same time, component geometries are becoming ever more complex, particularly with the advancement of miniaturization.

Entry-Level Models

-

Economical entry-level models for vacuum potting

Increasing quality requirements and workpiece complexity, new degrees of freedom in design and engineering are just some of the many reasons to choose the vacuum potting process. Customers are particularly looking for systems that offer budget-friendly quality vacuum potting. The compact LeanVDS B and LeanVDS U models from Scheugenpflug are particularly suited for potting small to medium-sized batches, for lab applications and for eliminating unreliable, time-consuming sub-processes such as re-evacuation. For this purpose, bubble-free preparation of the potting medium is handled by one of the A310 preparation and feeding systems.

Lean VDS U

-

Reliable vacuum potting for medium-sized batches

The LeanVDS U(niversal) is available to users as a budget-friendly, entry-level model for reliable vacuum potting. Unlike the basic LeanVDS model, the LeanVDS U, in sizes starting from 420 x 420 mm, is equipped with up to three motion axes, allowing for precise, bubble-free filling, dabbing and bead application without CNC functions. This makes the system particularly suited for small to medium-sized workpieces in medium-sized batches. Potting takes place in a vacuum with up to 5 mbar of absolute pressure; parameters can be configured as usual. All LeanVDS U modules are equipped with the proven Dos P piston dispenser. Whether working with difficult workpiece geometries, more complex potting programs or a wide range of parts, users are able to handle anything when they use the LeanVDS U.

Advantages

- Higher component reliability and life-span due to improved impregnation

- Size of the vacuum chamber allows for potting of varying component dimensions

- Superior product quality for affordable investments

Lean VDS B

-

Optimized for large workpieces

The VDS B(asic) model is specifically suited for the bubble-free potting of large to extra large workpieces. The VDS B does not include axes, since in this case it is not necessary or not possible to move the workpieces. This in turn makes the vacuum chamber more easily scalable.

Advantages

- Higher component reliability due to improved impregnation

- Reliable vacuum potting of big components

Large Vacuum Chambers

-

Quality and performance for the most demanding requirements

Increasing quality requirements and workpiece complexity or added degrees of freedom in design and engineering are just some of the many reasons to choose vacuum potting. Scheugenpflug vacuum dispensers were designed for cost-effective batch production at the highest levels of quality. All VDS systems feature a dispensing unit for 1C or 2C potting media, depending on your needs. To ensure bubble-free feeding of the potting medium, one of the LiquiPrep LP804 preparation and feeding systems is used. Powerful vacuum pumps evacuate the entire space around the component or components. This guarantees bubble-free and homogeneous filling of the components in order to achieve the required potting quality even for the most difficult dispensing tasks. To meet this requirement, various cost-effective models are therefore available both as standalone systems or for integration in a production line.

VDS B

-

Optimized for large workpieces

The VDS B(asic) model is specifically suited for the bubble-free potting of large to extra large workpieces. The VDS B does not include axes, since in this case it is not necessary or not possible to move the workpieces. This in turn makes the vacuum chamber more easily scalable.

Advantages- Higher component reliability due to improved impregnation

- Reliable vacuum potting of big components

VDS U

-

The versatile system for a wide range of applications

In electronics manufacturing, flexibility is the domain of universal systems, which allow a quick reaction to product changes. The Universal vacuum dispensing system, which usually features three motion axes and an automatic cup position, is the ideal solution for volume production of medium-sized and large workpieces. Whether working with difficult workpiece geometries, complex potting programs or a wide range of parts, with this system you are prepared for any challenge.

Advantages- Short cycle times by potting multiple components per evacuation

- High component quality despite complex geometries and programming

- Indispensable for safety-relevant and highly functional components

VDS P

-

Power to make time less of a limitation

Time can be a limiting factor for many reasons. This problem can be easily overcome with the VDS P(ower) vacuum dispensing system, which is usually equipped with three motion axes, an automatic cup position and a multi-piston dispenser (2 to 8 nozzles, depending on required performance; other sizes available upon request). In a single evacuation cycle, as many components as possible are processed at the same time on an even grid so that one dispensing stroke processes several workpieces at once. This system is the perfect solution for fast, premium quality potting of medium-sized or small components at very high production volumes.

Advantages- Short cycle times by simultaneously potting multiple components per evacuation and stroke

- Short evacuation times due to powerful vacuum pump

- Indispensable for safety-relevant and highly functional components

Control Units & Systems

-

Easy control and visualization of potting processes

In today’s systems, control concepts and software greatly influence efficiency, since they affect the system’s usability, performance, and networking capability, and as a result also its future viability.

Therefore, in addition to processing technology, Scheugenpflug has established comprehensive expertise in software development and control engineering to fulfill both current and future requirements. These systems make it possible to ideally match user guidance and system programming to the specific requirements of the adhesive bonding, dispensing and potting task at hand.

Even with regard to networking, Scheugenpflug systems have you covered: whether for interlinking equipment, data acquisition and evaluation, process and pot life optimization, or communication with other systems and/or master control systems.

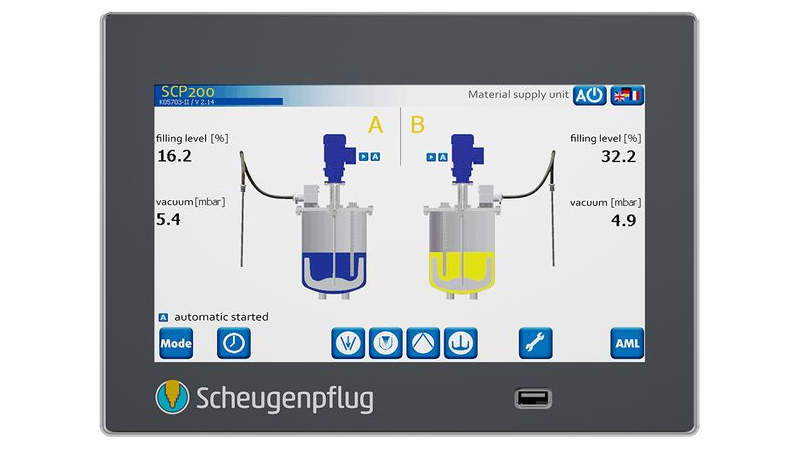

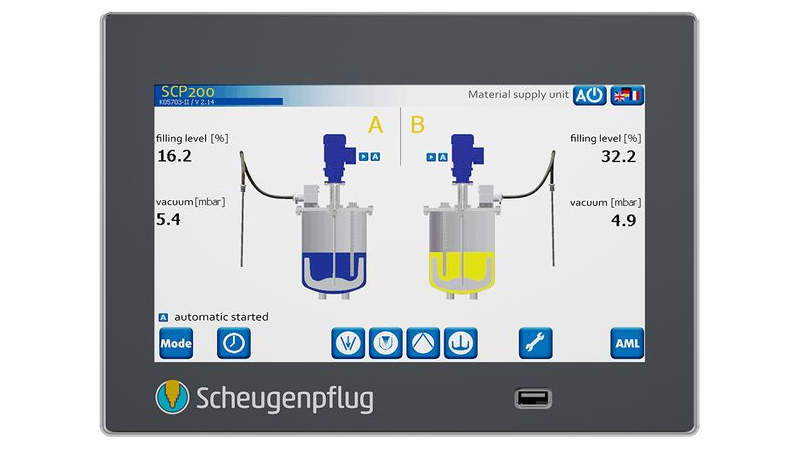

SCP210 and SCP210+

-

For material preparation and feeding units and for simple dispensing systems

Control and operating concepts have a major impact on the cost-effectiveness and efficiency of partially or fully automated systems. Thanks to our modularity concept, the system represents lean control technology. The SCP210 or SCP210+ microcontroller and visualization units enable easy, intuitive operation of our material preparation and feeding systems, manual workstations and dispensing cells with a lower degree of automation. The new EViS control unit represents a continuation of the SCP210 and is currently used in the LiquiPrep LP804.

Advantages

- High usability thanks to capacitive 10″ multi-touch display (prepared for the use of multi-finger gestures)

- Powerful processor

- Regular updates via USB interface

- Intuitive operation

- Fast and efficient dispensing program setup (SCP210+)

- Easy cleaning thanks to scratch-resistant real glass pane

EViS

-

New control unit for the LiquiPrep LP804

The EViS control unit concept supports simple system operation in times of increasing digitalisation. Thanks to the new design, which is graphically based on the UVIS5, EViS not only offers an improved user experience. In addition to easy adjustment of process parameters, it also allows continuous monitoring of system performance. The collected data can then be evaluated, analysed and used for further process optimisation.

Advantages

- Intuitive operation

- Fast activation of functions

- Customizable user administration

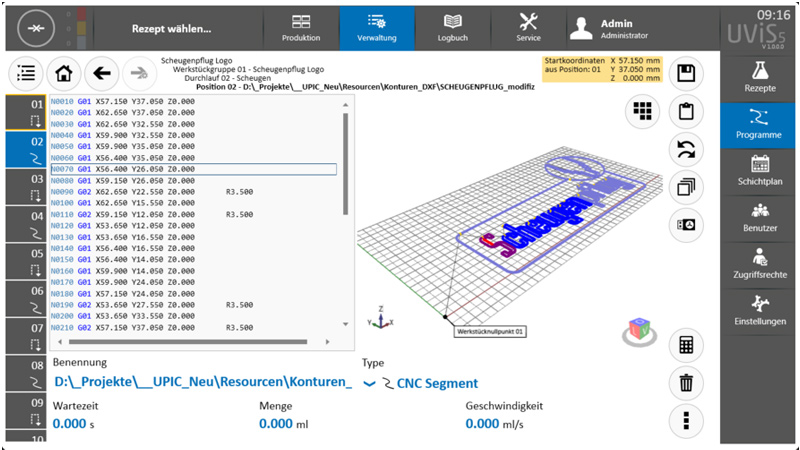

UVIS and UPIC

-

For highly functional dispensing systems and vacuum chambers

The effectiveness of a controller is determined at least as much by its user interface as it is by the hardware. The UViS5 interface software was developed specifically for the Scheugenpflug ProcessModule, the dispensing cells and vacuum potting systems. The UPiC5 is a supplementary tool that allows users to create dispensing programs quickly and easily without having to rely on programming specialists.

UViS5

-

Powerful software specifically for dispensing applications

The UViS5 (= Universal Visualization) software is a powerful user interface, tailored to the application and available to all Scheugenpflug cells, vacuum potting systems and the ProcessModule. The visualization of the dispensing and potting systems is thus optimally solved. For all processes and the associated monitoring, maintenance and analysis tasks, the user has a continuous overview of the relevant data on a 15.6" multi-touch display.

Advantages

- Customizable, clearly arranged user interface in modern tile look

- Fast and convenient operation

- Comprehensive user navigation

- Good ergonomics thanks to full graphics capability and touch operation

- Long-term availability of support and updates

UPIC5 programming tool

-

Programming without specialists

The UPiC5 (= Universal Programming Interface) supplements and extends the UViS5 user software. With this tool, users can create dispensing programs without having to rely on specialists. You can choose between creating a DIN-based CNC program or a direct CNC matrix program. Practical features such as a copy-paste function or the quick duplication of a created contour using a raster function ensure simple operation.

Advantages

- Fast and efficient creation of dispensing programs

- Optimum contour quality thanks to convenient control functions