- Offer Profile

- AMI Förder- und Lagertechnik

GmbH is one of the leading providers of high performance conveyors for

material handling, from incoming goods to production, picking and final

inspection to despatch. Our product range stretches from light conveyors to

heavy-duty conveyors for loads of up to 2,500 kg.

To you, this means that planning, engineering, production and installation of ma-chines and equipment are all provided from one single source. Based on detailed analyses, we plan and produce turnkey conveyor systems or upgrade existing equipment. Intensive and continuous consultation throughout the project is a matter of course.

CONVEYER TECHNOLOGY

Manual light conveyor technology

-

Manual light conveyor technology for optimum efficiency

Manual light materials handling systems enable the efficient transportation of light goods in areas such as production, storage, assembly and distribution. These flexible solutions use gravity-driven incline transportation and are ideal for applications that require high adaptability and fast changeover times. The flow of goods is optimized and efficiency is increased – without the need for complex automation systems. The systems are characterized by easy handling, high reliability and the possibility of individual adaptation to specific requirements. Discover tailor-made solutions that optimize your processes and increase productivity.

Discover our versatile light conveyor systems:

- Smooth-running roller conveyer

- Smooth-running roller can

- All-side roller conveyer

- Ball roller table

- Accessories

Powered light conveyor technology

-

Maximum efficiency thanks to powered lightweight conveyor technology

Powered light materials handling systems offer a modern solution for the transportation of light goods in areas such as production, storage and assembly. The targeted use of powered systems ensures a fully automatic, continuous flow of goods, which significantly increases the efficiency of your processes. With state-of-the-art control technology, these systems enable a smooth flow without manual intervention, optimizing productivity. Powered solutions are ideal for applications where consistent, fast and automated transportation of goods is required. They offer a high degree of flexibility and can be easily integrated into existing production and logistics processes to efficiently master complex transportation requirements.

Discover our versatile powered systems at a glance:

- Belt conveyer

- Driven roller conveyer

- Inclined roller conveyer

- Scissor roller conveyer

- Hooist lifts

- Turntables

Manual heavy-duty conveyor technology

-

Efficient and reliable: Manual heavy-duty conveyor technology for demanding loads

Manual systems for heavy-duty applications enable controlled, safe transportation – even with heavy loads. The robust design, simple handling and high load capacity make this technology particularly efficient. In operating environments with changing requirements or a limited degree of automation, manual systems offer an economical and reliable solution. With a clear structure and flexible application options, manual heavy-duty conveyor solutions can be seamlessly integrated into existing processes. Stable processes, reduced material handling effort and ergonomic working are thus effectively supported.

Discover our versatile manual heavy-duty systems:

- Heavy-duty roller conveyer

- Pallet loading station

- Pallet removal station

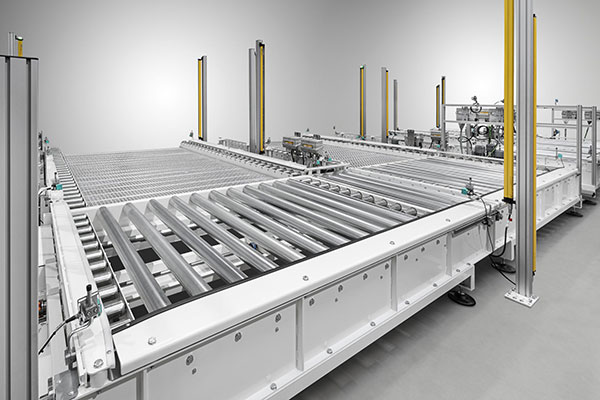

Powered heavy duty conveyor technology

-

Powered heavy-duty conveyor technology for demanding industrial applications

Driven systems for heavy loads enable the safe and efficient transportation of large or particularly heavy loads. They are designed for industrial environments with high demands on load capacity, availability and process reliability – for example in mechanical engineering, automotive manufacturing or heavy industry. The design is based on heavy-duty components such as reinforced frame profiles, powerful gear drives and durable idlers or chain elements. The modular design allows flexible adaptation to individual loads, routes or cycle times. Coupled with intelligent control technology and optional integrated sensors, the systems enable a continuous material flow – even under harsh operating conditions and high weights. This reduces manual intervention, speeds up processes and significantly increases operational safety.

Our powerful powered heavy-duty systems at a glance:- Roller conveyor

- Chain conveyor

- Powered heavy-duty travelator ASVW

- Pallet tipping station

- Pallet inspection station

- Driven pallet dispenser APA 15

Automation technology

-

Automation technology for the targeted optimization of your conveyor system

AMI offers a wide range of products in the field of automation technology – independent modules that can be used specifically to optimize conveying and material flow processes. These components can be flexibly integrated into existing systems and individually adapted. Whether lifting, stacking, destacking or buffering – our automation units reliably perform recurring tasks and reduce manual intervention in the process. The use of modern control technology enables precise, needs-based process control. All products have a modular design, grow with your requirements and contribute to greater efficiency, safety and consistent quality in operation.

Discover our versatile automation technology systems:- Dynamic goods memory

- Automatic capping machine

- Label removal station

- Stacking/de-stacking machine

- Cardboard turning station

OUR COMPONENTS

-

Each conveyor system, and each intralogistics system, is only as good as the individual components it contains. This is the foundation of the mission we at AMI have made our own. With our system components, we can bring a high level of efficiency to your material flow. AMI offers a high degree of vertical integration at 87 percent, outstanding “Made in Germany” product quality, a modern machine fleet and a well-trained team of employees.

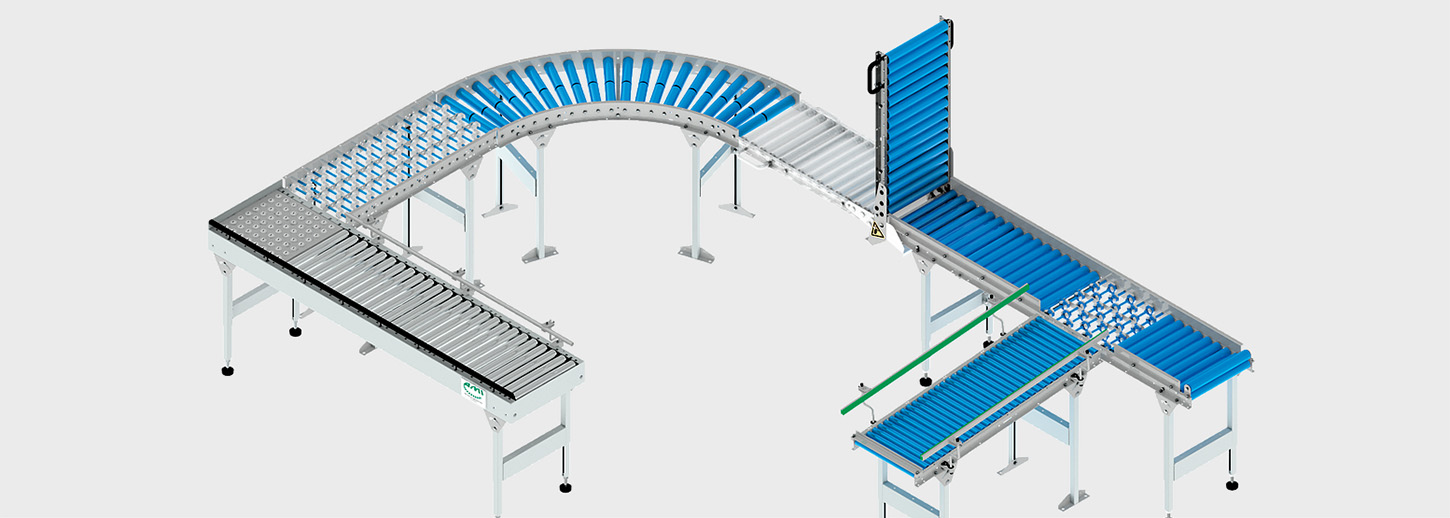

AMI components and modules for intralogistics are in use across sectors in many different departments for small and mid-sized industry and trading companies, as well as in large companies. Our system modules offer you an extensive range of power-operated components such as roller conveyors, curved roller conveyor sections, converters, push units, belt conveyors, vertical conveyors and power-operated accordion roller conveyors. In addition, technical information on the products allows customers to directly select the right components. Integrated into your intralogistics systems, AMI components can be used to transport your products, such as cardboard boxes, containers and empty drink crates reliably and efficiently.

With proven system accessories such as supports lateral guides and end stops, customers can design a system for almost any application easily and economically.

MANUAL LIGHT CONVEYOR TECHNOLOGY

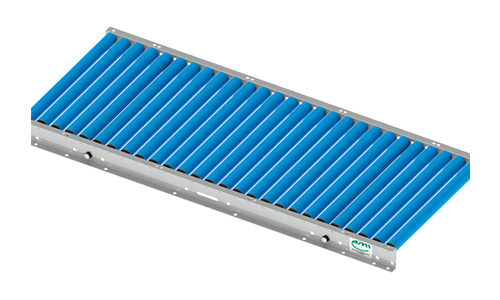

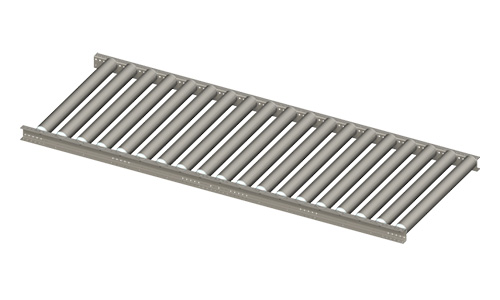

Smooth-running roller conveyor

-

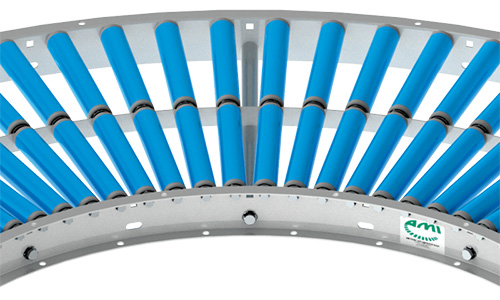

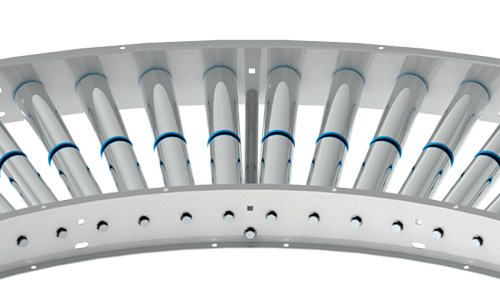

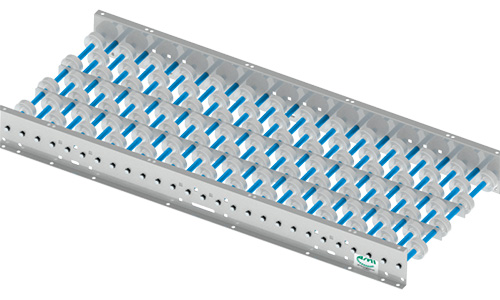

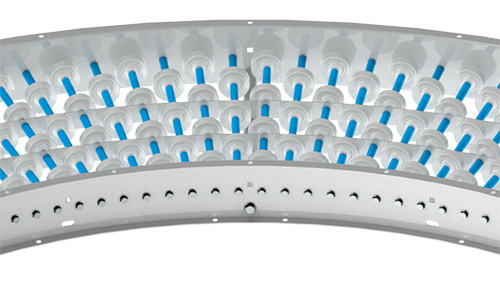

Smooth-running roller curves – efficient and flexible for your logistics processes

The smooth-running roller curves are manual conveyor system solutions that enable efficient changes of direction in the material flow. They are used in areas such as warehouse logistics, production facilities and order picking. With plastic or steel rollers and an incline of 2-5%, transportation is carried out by gravity without the need for additional drives. This makes the smooth-running roller curves particularly low-maintenance and cost-efficient.

Smooth-running roller cam

-

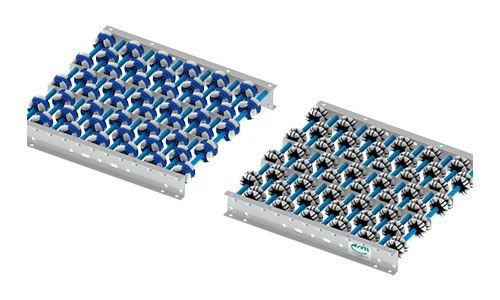

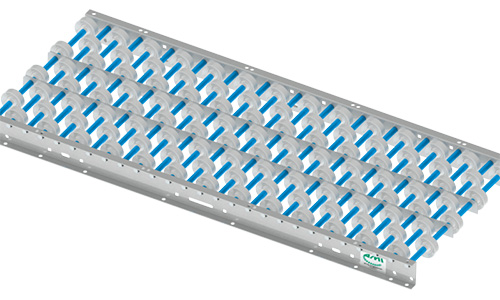

The AMI all-round roller conveyor – open in all directions

The AMI all-round roller conveyor consists of sturdy barrel rollers that are attached to a robust U-profile frame. These innovative barrel rollers make it possible to move goods manually in all directions. This means that almost all conveyed goods can be easily and flexibly pushed, pulled or even rotated from one point to another. This high degree of freedom of movement opens up numerous application possibilities in light conveyor technology.

The AMI all-round roller conveyor is the perfect solution for a wide range of requirements in modern conveyor technology. Our all-round roller conveyor is particularly suitable for manual order picking, work stations and sorting stations. Whether in storage and dispatch areas or in the assembly and manufacturing industry – the AMI all-round roller conveyor ensures efficient and ergonomic handling of a wide range of conveyed goods. Simple integration into existing roller conveyor systems optimizes the material flow and significantly improves the overall workflow.

All-side roller conveyor

-

The AMI all-round roller conveyor – open in all directions

The AMI all-round roller conveyor consists of sturdy barrel rollers that are attached to a robust U-profile frame. These innovative barrel rollers make it possible to move goods manually in all directions. This means that almost all conveyed goods can be easily and flexibly pushed, pulled or even rotated from one point to another. This high degree of freedom of movement opens up numerous application possibilities in light conveyor technology.

The AMI all-round roller conveyor is the perfect solution for a wide range of requirements in modern conveyor technology. Our all-round roller conveyor is particularly suitable for manual order picking, work stations and sorting stations. Whether in storage and dispatch areas or in the assembly and manufacturing industry – the AMI all-round roller conveyor ensures efficient and ergonomic handling of a wide range of conveyed goods. Simple integration into existing roller conveyor systems optimizes the material flow and significantly improves the overall workflow.

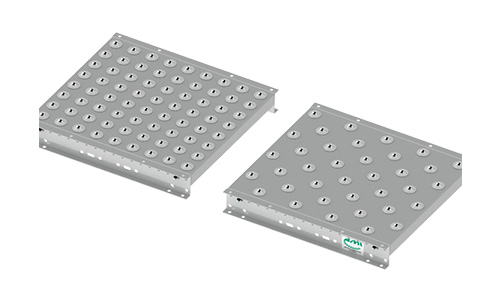

Ball roller table

-

The AMI ball transfer table – versatility in motion

The AMI ball transfer table is a versatile conveyor system that is used to move or divert conveyed goods in different directions. The ball transfer table consists of a large number of ball rollers that enable the conveyed goods to be moved almost frictionlessly in all horizontal directions. Due to the point load acting on the bottom of the conveyed goods, unit loads can be maneuvered easily and precisely. This ball transfer table is particularly suitable for areas where flexibility and maneuverability are crucial, such as warehousing, manual order picking, sorting and packaging.

Accessories

-

Manual light conveyor technology – The right accessories for your logistics solutions

With the right accessories, you can make your manual light conveyor technology even more flexible and efficient. We offer you a wide range of high-quality accessories that can be seamlessly integrated into your existing conveyor systems. Whether you need bipod supports, side guides or end stops – we have the right solutions to optimize your logistics processes.

Powered light conveyor technology

-

Maximum efficiency thanks to powered lightweight conveyor technology

Powered light materials handling systems offer a modern solution for the transportation of light goods in areas such as production, storage and assembly. The targeted use of powered systems ensures a fully automatic, continuous flow of goods, which significantly increases the efficiency of your processes. With state-of-the-art control technology, these systems enable a smooth flow without manual intervention, optimizing productivity. Powered solutions are ideal for applications where consistent, fast and automated transportation of goods is required. They offer a high degree of flexibility and can be easily integrated into existing production and logistics processes to efficiently master complex transportation requirements.

Belt conveyor

-

AMI belt conveyors – Optimum conveyor technology for every application

Belt conveyors are efficient and reliable solutions for powered conveyor technology and offer a wide range of applications for a wide variety of industries. They consist of an endless belt conveyor that is driven by a motor. The belt conveyors are particularly suitable for transporting goods of different sizes and shapes, as the belt conveyors can be customized in terms of width and length. We select the right conveyor belt based on the specific requirements of the application area and determine the ideal belt. Various materials such as PVC or PU are used to ensure the optimum belt for each conveyed product.

We also offer a wide range of drives and drive arrangements that can be optimally adapted to the respective application. In addition to the classic drum motor and center drive stations, we also offer numerous other solutions that are designed for different requirements and space conditions. Our flexible drive concepts enable efficient use of space while ensuring high operating efficiency – ideal for a wide range of application scenarios, even in confined environments.

Driven roller conveyor

-

AMI roller conveyors: Wide product range – Versatile application

AMI roller conveyors are versatile and reliable conveyor systems that are ideal for transporting goods in various industries. They are designed so that no protruding edges or screws are visible, which facilitates cleaning and maintenance. The support rollers integrated into the side panels can be easily maintained or replaced if necessary. Designed as low pressure accumulation conveyors as standard, the roller conveyors can easily be converted to a zero pressure accumulation version. The extensive AMI system accessories include components such as diverter systems, various side guides and suitable curves. Each type of AMI roller conveyor is also available as a curve, which enables even more flexible adaptation and optimization of the conveyor system. These extend the application range of the roller conveyors and improve the transportation and handling of a wide variety of conveyed goods.

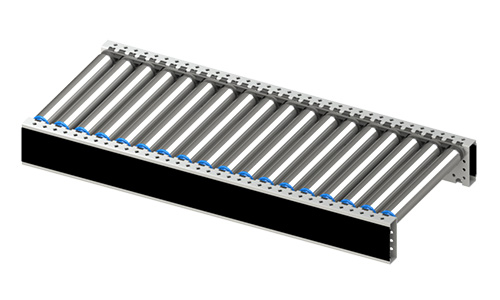

Inclined roller conveyor

-

Inclined roller conveyors – Precise alignment for safe transportation

The inclined roller conveyor is an efficient and precise solution for transporting and aligning conveyed goods in modern intralogistics systems. The inclined rollers align the conveyed goods to the side of the conveyor, while an additional roller side guide ensures that the product not only remains securely on the track, but is also conveyed in a targeted and stable manner. This combination enables reliable product alignment, even with inclined transportation.

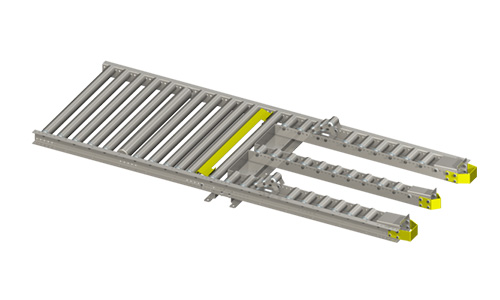

Scissor roller conveyor

-

Scissor roller conveyor – The flexible solution for your requirements

The scissor roller conveyor from AMI is a versatile conveyor system from the category of powered light conveyor technology that has been specially developed for the internal transportation of goods. The extendable frame construction with rollers enables flexible adjustment of the track length, while the scissor mechanism allows it to be used in a straight, curved or even circular shape. This flexibility makes the scissor roller conveyor particularly suitable for goods handling centers, production facilities and all logistical areas that place frequently changing demands on the conveyor line.

Hoist lifts

-

Reliable connection between conveying levels – AMI’s lift systems

Lifting devices play an important role in the material flow when goods need to be moved safely and in a controlled manner between different conveyor levels. They enable a seamless vertical transition – for example from a floor transport section to a higher conveyor line or between floors in multi-storey systems.

Even within complex production environments, lift systems ensure smooth processes and create connections across different process levels – for example in automated buffer zones, transfers to machines or the transition from manual to automated conveyor lines.

AMI lifts are robustly constructed, precisely controllable and available in various designs – suitable for different conveyed goods, load capacities and installation environments. They can be seamlessly integrated into existing systems and provide a space-saving, vertically aligned material flow solution.

Turntables

-

Full control at every turn – turntables from AMI

Turntables play a central role in automated conveyor processes when it comes to guiding conveyed goods in other directions or transporting them in a defined position. They ensure smooth transitions between lines, enable direction changes without complex conversions and are ideal for designing space-saving and flexible conveyor lines. Products can also be rotated by 180 degrees within production lines – for example for further processing or correct alignment for subsequent process steps.

Whether for turning cardboard boxes or containers – AMI rotary tables are available in various designs and can be perfectly integrated into existing systems. With precise control, a reliable drive and robust design, they are suitable for a wide range of applications, e.g. in logistics, production and assembly.

Manual heavy-duty technology

-

Efficient and reliable: Manual heavy-duty conveyor technology for demanding loads

Manual systems for heavy-duty applications enable controlled, safe transportation – even with heavy loads. The robust design, simple handling and high load capacity make this technology particularly efficient. In operating environments with changing requirements or a limited degree of automation, manual systems offer an economical and reliable solution.

With a clear structure and flexible application options, manual heavy-duty conveyor solutions can be seamlessly integrated into existing processes. Stable processes, reduced material handling effort and ergonomic working are thus effectively supported.

Heavy-duty roller conveyor

-

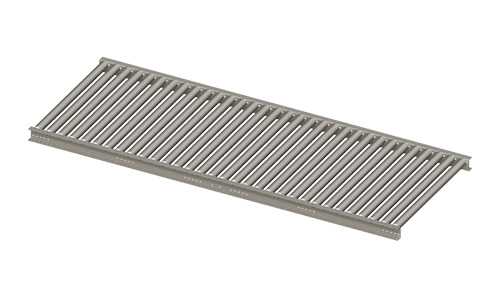

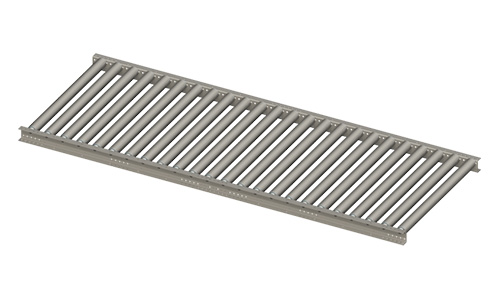

The AMI heavy-duty roller conveyor – high-performance conveyor technology for heavyweights

The AMI heavy-duty roller conveyor is a robust conveyor system designed for transporting heavy loads and bulky goods under the most demanding conditions. The solid construction made of high-quality materials ensures a long service life and reliable operation. Precision-manufactured rollers ensure a smooth, gravity-driven material flow and are ideal for handling heavy loads.

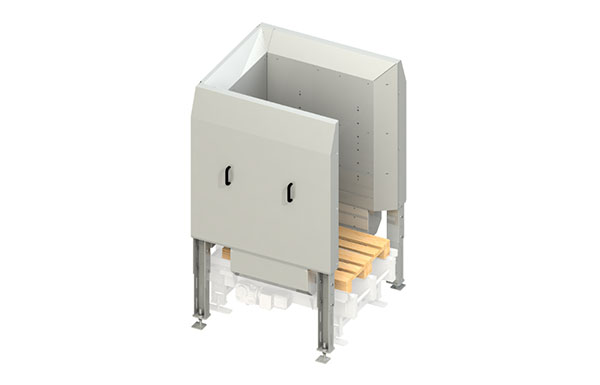

Pallet loading station

-

Reliable pallet feeding for smooth conveying processes

Manual pallet loading stations are crucial for efficient logistics processes. They enable precise and safe positioning of pallets on conveyor lines. These stations are used to place standard Euro pallets manually with hand or electric pallet trucks and forklift trucks at the start of a conveyor line or at transfer points and to control the material flow.

Thanks to a wide range of accessories, such as centring devices, collision protection, end stops and other customization options, pallet loading stations can be adapted to your specific logistics requirements. This ensures a reliable and efficient solution for various applications in production, storage and distribution.

Pallet removal station

-

Reliable pallet removal for smooth processes

Manual pallet removal stations are indispensable for efficient logistics processes. They enable the precise and safe removal of standard Euro pallets at the end of a conveyor line. These stations are used to remove pallets manually using hand or electric pallet trucks and forklift trucks and to ensure a smooth transition from the conveyor line to other processes.

Thanks to different versions, the manual pallet removal station can be flexibly adapted to your specific requirements. This guarantees a reliable and adaptable solution for various applications in production, storage and distribution.

Powered heavy-duty conveyor technology

-

Powered heavy-duty conveyor technology for demanding industrial applications

Driven systems for heavy loads enable the safe and efficient transportation of large or particularly heavy loads. They are designed for industrial environments with high demands on load capacity, availability and process reliability – for example in mechanical engineering, automotive manufacturing or heavy industry.

The design is based on heavy-duty components such as reinforced frame profiles, powerful gear drives and durable idlers or chain elements. The modular design allows flexible adaptation to individual loads, routes or cycle times.

Coupled with intelligent control technology and optional integrated sensors, the systems enable a continuous material flow – even under harsh operating conditions and high weights. This reduces manual intervention, speeds up processes and significantly increases operational safety.

Roller conveyor

-

Heavy-duty roller conveyors – robust, precise, reliable

Heavy-duty roller conveyors from AMI are specially designed for transporting particularly heavy and bulky goods. They are used wherever stability, load capacity and reliable conveyor technology are required – for example in steel processing, in mechanical and plant engineering or for the in-house transportation of massive components.

The modular design allows flexible adaptation to individual requirements and spatial conditions. High-quality components, reinforced frame constructions and robust roller elements ensure a safe and controlled material flow.

Chain conveyor

-

Chain conveyors: Maximum strength for bulky products

AMI chain conveyors offer efficient and reliable solutions for transporting heavy and bulky goods, such as pallet cages, which cannot be transported using conveyor systems with idlers. These systems are indispensable in many branches of industry as they transport unit loads over long distances using roller chains. Depending on the design and application, various strand configurations are possible, for example as a 3-strand or multi-strand variant.

Powered heavy-duty travelator ASVW

-

Powered heavy-duty transfer carriages – robust, flexible, reliable

AMI’s powered heavy-duty transfer car is the ideal solution for the horizontal transportation of goods on load carriers such as pallets. With its precise drive technology, the heavy-duty carriage moves along defined travel paths and can move to different positions and efficiently close gaps in conveyor lines over long distances. Particularly in complex production and logistics processes, such as in steel processing, mechanical engineering or the automotive industry, the heavy-duty transfer carriage is a crucial component for a smooth process.

By using this precise drive technology, which enables flexible movement on defined travel paths, the heavy-duty transfer car can serve several conveyor lines and easily cover different distances between the transport stations. In combination with other driven components such as roller and chain conveyors, pallet corner transfer units and turntables, there are numerous additional options for continuously optimizing the material flow and ensuring the onward transport of conveyed goods.

Thanks to its robust design, powerful drive technology and simple integration into existing systems, the heavy-duty transfer carriage is an indispensable component for industrial applications where precision and flexibility are required.

Pallet tipping station

-

Pallet tipping station – For precise and efficient pallet unloading

The pallet tipping station from AMI is the ideal solution for gently and precisely tipping goods packed on Euro pallets onto conveyor belts. The tipping device ensures that the goods are deposited in a controlled and safe manner without being damaged. Particularly in sectors such as logistics, the automotive industry or food processing, the pallet tipping station makes a decisive contribution to ensuring a smooth material flow.

The robust design and precise control enable goods to be transported safely on conveyor belts, resulting in efficient further processing of the materials.

Pallet inspection station

-

The pallet inspection station – customized quality inspection for pallets

The AMI pallet inspection station is a specially developed system for the quality control and inspection of pallets in intralogistics. It was developed to ensure that pallets meet the highest quality standards and are suitable for use in various logistics processes. The compact, automatic pallet inspection station checks the quality and dimensional accuracy of both delivered and circulating Euro pallets.

Driven pallet dispenser APA 15

-

Powered pallet dispenser – Technological innovation for efficient pallet handling

The powered pallet dispenser from AMI simplifies the stacking and unstacking of pallets. It enables the automatic separation or grouping of pallets and ensures an efficient material flow in production and logistics processes. The pallet dispenser can be easily combined with roller or chain conveyors to transport pallets safely and reliably across existing conveyor lines and further optimize the material flow.

Automation technology

-

Automation technology for the targeted optimization of your conveyor system

AMI offers a wide range of products in the field of automation technology – independent modules that can be used specifically to optimize conveying and material flow processes. These components can be flexibly integrated into existing systems and individually adapted.

Whether lifting, stacking, destacking or buffering – our automation units reliably perform recurring tasks and reduce manual intervention in the process. The use of modern control technology enables precise, needs-based process control.

All products have a modular design, grow with your requirements and contribute to greater efficiency, safety and consistent quality in operation.

Dynamic goods memory

-

Flexible and ergonomic for smooth processes – Dynamic goods storage

The dynamic goods storage system from AMI enables the intermediate storage of conveyed goods such as polybags, small packages and parcels. A special feature is the automatic height adjustment, which ensures that the conveyed goods are ready for removal at an ergonomically favorable height. This enables convenient handling without having to lift or grip in an awkward position, which relieves strain on the back and improves working comfort.

The dynamic goods storage unit is also mobile and space-saving. When not in use, it can simply be folded up and stored separately – ideal for flexible and efficient use of space.

Automatic capping machine

-

Automatic capping machine for maximum efficiency in lid handling

The automatic capping machine from AMI enables the fully automatic closing of plastic containers with lids – efficiently, reliably and precisely. An innovative gripper system removes the lids individually from a stack and places them precisely on the containers. The automated lid feed line ensures a continuous supply to the process, thus avoiding interruptions.

The flexible integration into existing conveyor lines makes the automatic capping machine highly versatile. It contributes to automation, particularly in warehouse logistics, production or in the dispatch area, when fast and reliable capping processes are required. The result: consistently high process quality and optimized workflows.

Label removal station

-

Label removal station – Automated solution for fast label removal

The label removal station from AMI enables the fully automatic removal of labels from plastic containers. During the conveying process, the containers are guided past two blow-off hoods arranged one behind the other, with a precise positioning system ensuring exact alignment. The labels are precisely removed and collected in a collection box. The label removal station is suitable for various plastic container sizes and can be easily integrated into existing conveyor systems.

Stacking/de-stacking machine

-

Efficient and automated – the automatic stacking/destacking machine

The automatic stacking/destacking machine from AMI is an innovative solution for the automatic handling of KLT containers. Integrated into your conveyor line, this machine enables precise stacking and unstacking of containers without the need for additional manual intervention. Each stack of containers is loaded and unloaded via a separate conveyor line, making the process efficient and safe.

The simple integration into existing conveyor systems makes this machine ideal for applications in warehouse logistics, production or order picking. The stacking/destacking machine ensures constant handling of containers, which significantly increases your productivity and efficiency.

Cardboard turning station

-

Efficient and automated – the carton tipping device

The carton tilting device from AMI enables efficient and automated handling of cartons in the packaging process. The precise alignment of the cartons ensures fast and safe filling, with the product sliding directly into the carton. The tilting station automatically aligns the cartons so that exact positioning is achieved. In combination with a robot that removes the cartons from a carton magazine, the entire process is further optimized and automated. Thanks to its flexible integration into existing conveyor lines, the tilting device can be easily adapted to the individual requirements of your packaging process. Manual intervention is reduced, while the material flow is optimized by speeding up the process. In combination with a robot, which removes the cartons from a carton magazine and inserts them into the device, the entire process is further automated and made more efficient.

Order picking machines

-

The SMART-FLEXDEPOT – The new dimension in automated order picking

The SMART-FLEXDEPOT is a highly developed solution for modern warehouse logistics that helps companies and facilities to significantly optimize their storage and picking processes. The flexible and adaptable technology combines semi-automatic and fully automatic storage functions, enabling intelligent, space-saving storage and fast, precise picking of your goods. With seamless software integration, ease of use and a modular design, the SMART-FLEXDEPOT can be individually adapted to your requirements.

The SMART-FLEXDEPOT includes a range of flexible models tailored to the different needs of sectors such as industry, retail, logistics, pharmacies, hospitals and many more. From compact single cabinet systems to models with cooling functions – each system maximizes efficiency, flexibility and space utilization. Intelligent storage logic, such as chaotic storage and adjustable storage heights, ensures optimum space utilization in every model – even where space is limited. In addition, the system enables convenient storage of a wide range of goods. Permanent stock reconciliation between the system and your merchandise management system helps to prevent stock shortages.

Smart-FlexDEPOT Classic

- The SMART-FLEXDEPOT Classic offers a reliable semi-automatic solution for the efficient picking of a wide variety of items. Particularly suitable for applications with regular access and varying product sizes, this model supports manual processes with targeted automation steps. Items are conveniently stored using a barcode scanning system, which enables fast and error-free recording. The simple handling and structured warehouse organization significantly reduce the daily workload – ideal for companies that want to optimize their processes without relying on full automation.

Smart-FlexDEPOT Premium

- The SMART-FLEXDEPOT Premium is the fully automated version for the highest demands in terms of speed, throughput and process reliability. Particularly in dynamic storage environments with high volumes, this model offers fully automated storage and retrieval – including automatic detection and processing of a wide range of goods formats via a storage conveyor. The SMART-FLEXDEPOT Premium ensures a fully automated storage process without any manual intermediate steps. The intelligent process control optimizes workflows, saves time and achieves a high level of precision in storage and picking. The Premium model is ideal for facilities that want to make their logistics processes efficient and future-proof.

Smart-FlexDEPOT Compact

- The SMART-FLEXDEPOT Compact is the ideal solution for companies and facilities that require a compact and space-saving storage solution. Thanks to its modular design, the vending machine can be flexibly adapted to a wide variety of room configurations. The single cabinet system makes it possible to create maximum storage capacity even in confined spaces. Its small footprint makes it particularly suitable for smaller warehouses or rooms with special structural requirements, without having to compromise on efficiency and flexibility. This system is available in Classic and Premium versions.

Smart-FlexDEPOT Fresh

- The SMART-FLEXDEPOT Fresh is the ideal solution for companies and facilities that need to store temperature-sensitive goods such as food, chemicals or pharmaceuticals safely and efficiently. This refrigerated order picker is specially designed to store items at constantly low temperatures under optimum conditions. With advanced technology, the system ensures reliable temperature control while meeting the requirements of a controlled refrigeration environment. The automation meets the specific needs of temperature-controlled stock, providing an ideal solution for a wide range of applications. This system is available in the Classic version.

Smart-FlexDEPOT Market

- The SMART-FLEXDEPOT Market enables secure access to goods – around the clock, even outside regular opening hours. It was specially developed for companies and facilities that require continuous availability of goods, for example in retail, logistics or healthcare. Even after closing time, authorized access to the system is possible in order to retrieve items in a targeted and controlled manner. The dispensing process is secure and reliable – ideal for operations without permanent staff. The SMART-FLEXDEPOT Market is available in Classic and Fresh versions.

High-speed depot

-

Optimum picking speed for your logistics

The AMI HIGH-SPEEDDEPOT was developed to optimize your logistics processes with maximum speed and precision. Specially designed for the storage and picking of goods in folding boxes, it provides a highly dynamic and flexible solution for fast-moving warehouse environments. With innovative technology, you can increase your efficiency and achieve a new dimension in storage speed.

The High-SpeedDEPOT works with two perfectly coordinated storage zones that make optimum use of the available space. The specially developed chutes, also known as slots, allow the items to be stored by type. A precise sliding mechanism ensures fast and error-free removal. The integrated conveyor belt transports the picked goods seamlessly out of the machine and feeds them directly into the next logistics processes, so that fast and smooth further processing is guaranteed.

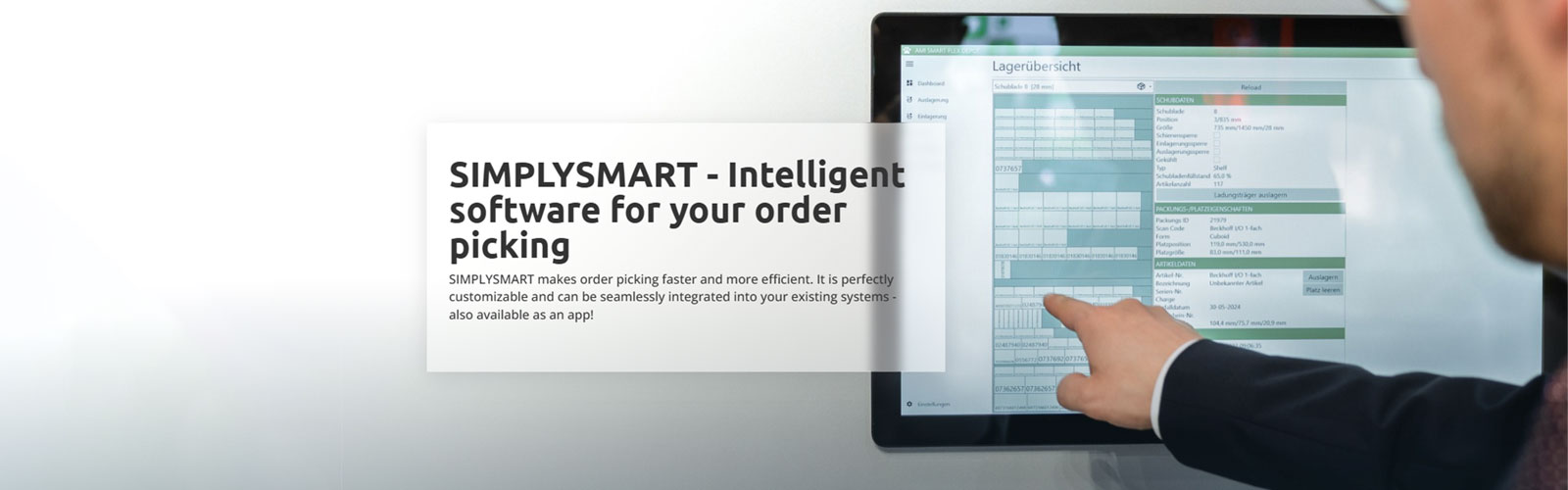

Simply SMART operating Software

-

SIMPLYSMART – The ideal solution for your warehouse management

The SIMPLYSMART operating software is the ideal solution for efficient and uncomplicated warehouse management. With a user-friendly interface, storage and retrieval functions are significantly simplified. The software can be flexibly adapted to your existing systems and easily expanded with additional interfaces. This means you benefit from fast and reliable control of your logistics processes at all times.

The most important features at a glance:- Overview of all orders & warehouse key figures: Clearly structured display of all open orders and important key figures such as storage depth, storage time and occupancy for optimal planning.

- Emergency mode for all cases: Continuation of your processes even in an emergency with flexible handling.

- Expiry date notification & batch recording: Automatic notification of products with an expiry date and complete batch and stock removal documentation.

- Pack tracking and inventory: Complete traceability from orders to stock removal and fast implementation of inventory processes.

- User-friendly operation & notebook: User-friendly interface for quick familiarization and an integrated notebook for relevant measurements and data.

- Interfaces to other systems: Flexibility through seamless integration with your existing systems.

- Detailed statistics: Evaluations of performance and efficiency as well as a quick overview of current processes and their status.

Software

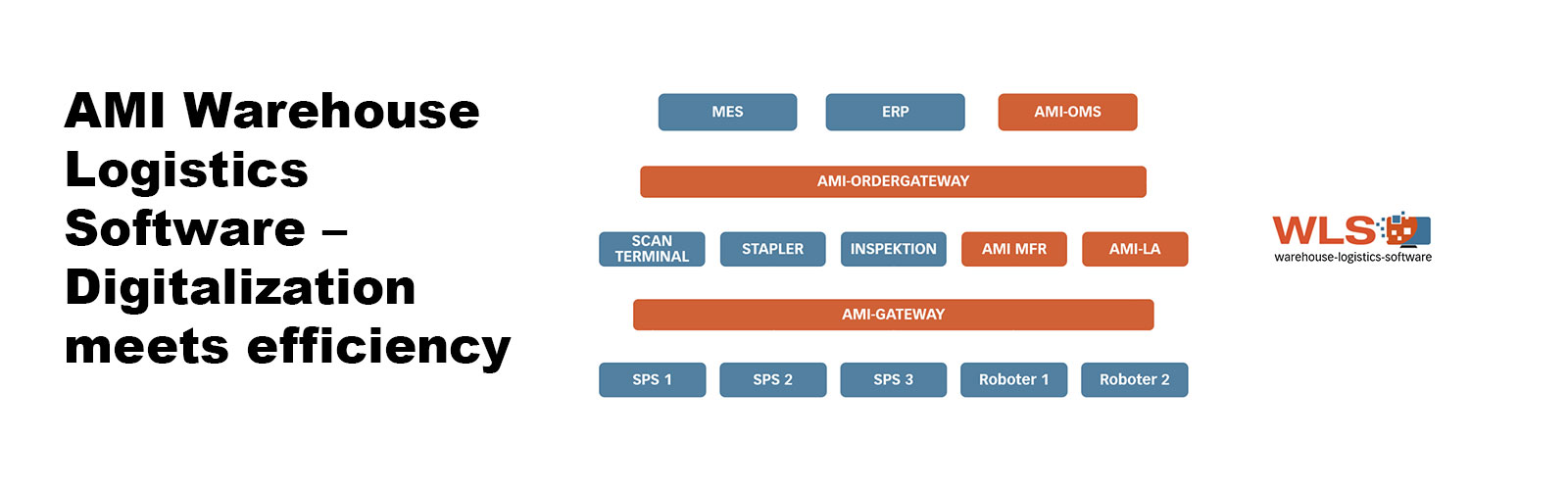

Warehouse Logistics Software (WLS)

-

AMI Warehouse Logistics Software – Digitalization meets efficiency

In modern intralogistics, the smooth flow of information is just as crucial as the physical flow of materials. With AMI-WLS, our powerful warehouse management software, you create the basis for digitally networked and future-proof intralogistics. The modular platform offers maximum flexibility and can be adapted precisely to your existing processes and systems – from a simple visualization tool to powerful middleware for complex system structures.

AMI Gateway

-

AMI Gateway – The translation level for your networked intralogistics

In modern intralogistics processes, a wide variety of systems come together – from programmable logic controllers (PLCs) to complex IT backends. The AMI gateway acts as an intelligent interface that connects these worlds. It translates communication protocols, separates networks physically and logically and significantly reduces the integration effort.

AMI line analyzer

-

AMI line analyzer – For more performance in automation

Efficient production starts with sound insights. The AMI Line Analyser is a powerful software for diagnosing and optimizing automation systems. Based on the PackML state model and calculated OEE data, the system analyzes your processes seamlessly and uncovers hidden potential – regardless of manufacturer or machine type.

The service-oriented architecture enables flexible integration into existing infrastructures – whether conveyor technology, robots, palletizers or lifts. This creates a complete picture of your system – at any time, from any location and across all platforms.

Material flow computer

-

AMI material flow computer – The clock generator for automated logistics processes

Modern intralogistics requires precise processes and smooth communication between systems and machines. The material flow computer from AMI takes on precisely this task: as a central control unit, it generates transport orders from higher-level systems such as ERP or warehouse management and coordinates their execution – from conveyor lines and robots to storage and retrieval machines and automated guided vehicles (AGVs).

By integrating its own AMI order management system, orders are efficiently accepted, managed and translated into actual transport movements. The material flow computer thus becomes the link between the planning level and physical execution – for maximum transparency and efficiency in the internal material flow.

AMI inspection

-

AMI inspection – precision in image processing for the highest requirements

AMI Inspection is a specially developed software solution for the seamless integration of camera systems into your intralogistics solutions. It enables customized image processing that is specifically tailored to your requirements and tasks. The flexibility of this solution allows you to precisely control object detection processes in order to implement various tasks efficiently and error-free.

From 1D/2D code scanning and pick & place applications for robots to real-time object detection – AMI inspection optimizes your entire infrastructure. Especially in challenging environments, such as the detection of objects in highly reflective areas or high-speed processes, this solution offers customized results that take your logistics processes to a new level.

Order management

-

AMI order management – optimal management of your orders in real time

In an automated logistics system, the consistent provision and management of orders is crucial. AMI order management acts as a central instance for recording, storing and distributing order information – independently of the source system.

Incoming orders from ERP or MES systems are processed here in a standardized way, completed by requests to other systems if required and made available for further processing – for example for the AMI material flow computer or other control systems. Completed orders are also confirmed centrally via the order management system – for maximum transparency and reliable communication between all levels.