- Offer Profile

- Solutions: As individual

as our customers

Nowadays innovative concepts in production, material flow and logistics are vital competitive factors. High efficiency flat belts, conveyor belts and processing belts often play a pivotal role here.

So leading manufacturing companies all over the world count on Forbo Siegling specialists as competent partners in developing groundbreaking solutions in power transmission, conveying and manufacturing.

The result:

comprehensive, industry specific product ranges for our customers.

CONVEYOR BELTS AND PROCESSING BELTS

- Siegling Transilon conveyor belts and processing belts

for speeding the flow of goods and for economic processing in the light

materials handling industry.

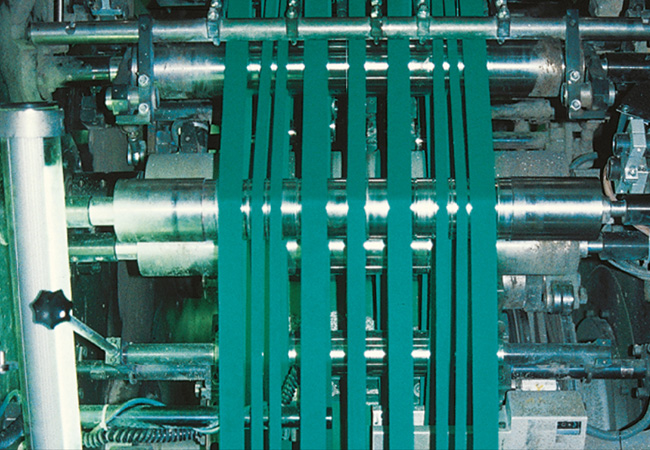

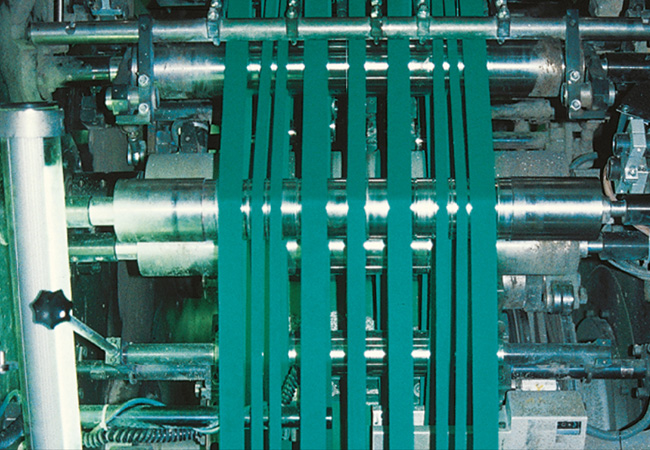

Certain conveying and processing tasks require mechanical, physical or chemical belt properties which are made possible only by special production processes, combination of materials or finishing. SIEGLING TRANSILON CONVEYOR BELTS AND PROCESSING BELTS

-

Siegling Transilon conveyor belts and processing belts for speeding the flow of goods and for economic processing in the light materials handling industry.

Efficient Conveying and Processing

Certain conveying and processing tasks require mechanical, physical or chemical belt properties which are made possible only by special production processes, combination of materials or finishing.

The standard Siegling Transilon construction consists of polyester fabric as tension member with synthetic or elastomer coatings. Siegling Transilon is used successfully in industrial, commercial and service companies worldwide. The standard product range includes over 160 various conveyor belt types and constructions for the most diverse of application requirements.

We offer special product ranges for numerous industries and applications.

Horiyontal conveying

-

Even a conveying task which seems quite simple can require a whole host of belt properties. Forbo Movement Systems has the best belt type for various goods, conveying speeds, reversing systems, stop & go and accumulation conveying, and other operating conditions. Some examples of the diverse features of Siegling Transilon include:

- troughable to particularly laterally stiff types

- exceptionally low-noise to flame-retardant

- pyrolysis-resistant to suitability for conveying unpackaged food

- non-antistatic to highly conductive and ATEX-approved

- surfaces suitable for accumulation conveying and especially good grip.

Inclined conveying

- Goods can be conveyed at an incline even on smooth belt surfaces. The conveying angle is dependent on a variety of factors such as the type of goods being conveyed, the top face coating and external factors like dust, moisture, etc.

For large conveying angles and for the conveying of small pieces and bulk goods, Forbo Movement Systems offers patterned belts or belts equipped with lateral profiles.

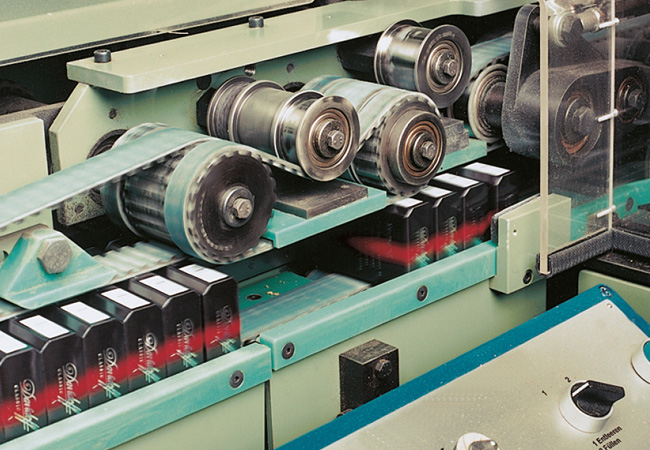

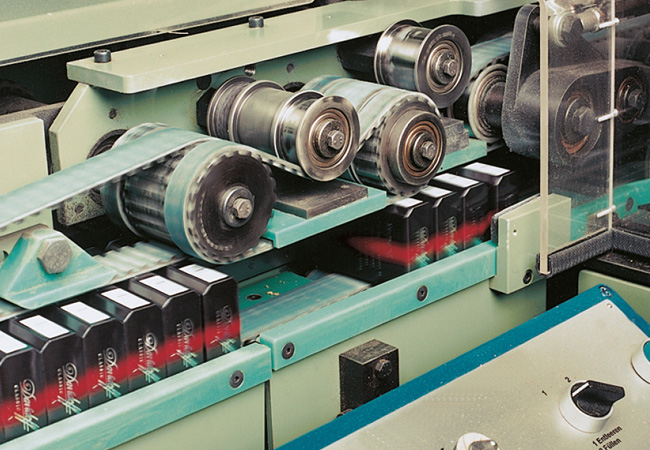

In the Picture one can see inclined conveying in the tobacco industry. In this area, conveying angles of up to 22° are possible for belt types with smooth surfaces.

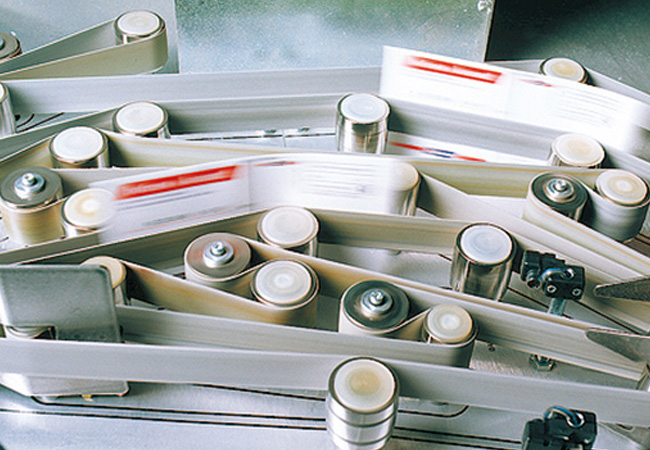

Curved Belts

- Thanks to their fabric design, Siegling Transilon curved

belts are exceptionally flexible, both laterally and longitudinally,

ensuring an optimal distribution of forces within the belt.

Depending on the application, either conical or cylindrical drums are used, or in some cases even knife edges or rolling knifge edges.Curved belts can be fabricated from one or more segments. Fabrication from several segments improves the distribution of forces within the belt. Curved belts can be equipped with perforations or eyelets along the edges so they can be attached to tracking systems later on.

Collection and distribution

-

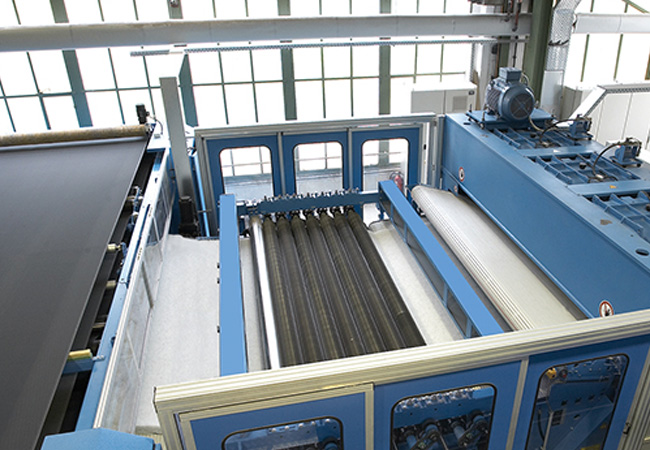

When pushers and ploughs are used, the belt’s laterally stiff design guarantees that it will lie flat and continue to run in a straight line reliably. The lateral loading and discharge of goods is achieved by using very smooth, wear-resistant surfaces. Lateral sorters (e.g. carrier cells), on the other hand, require very thin, flexible belts whose surfaces have high coefficients of friction. Their special tension member construction means that they have very low energy consumption.

The image shows a lateral sorter in a distribution centre. The high acceleration requires the belt surface to have an extremely high coefficient of friction.

Processing belts

-

With Siegling Transilon, the gap is often bridged between the classical conveying function from “A” to “B” and an active function in the production process.

For example, in the textile industry our processing belts stack thin layers of web, in large bakeries they form balls of dough, in the wood industry they compress chip mat in the pre-press, in dairies milk is coagulated on the belts to form cheese. Here are just a few examples of process operations.

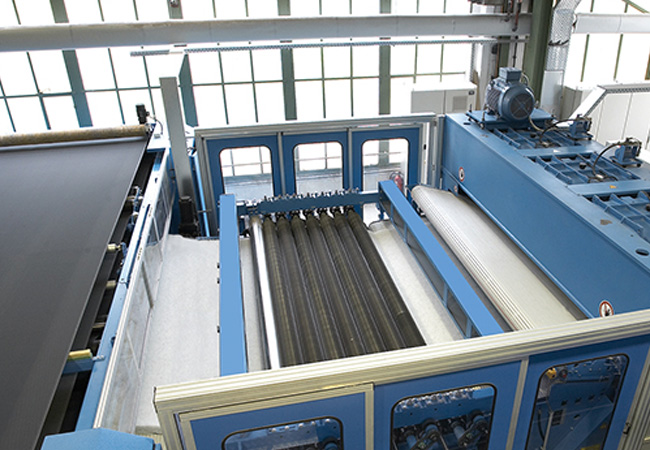

Cross-lapping of web layers in the nonwoven industry. High production speed and accele ration of masses while the web is guided directly between the belts places extremely high demands on the processing belts.In large bakeries for example, balls of dough are formed as a result of differing belt speeds.

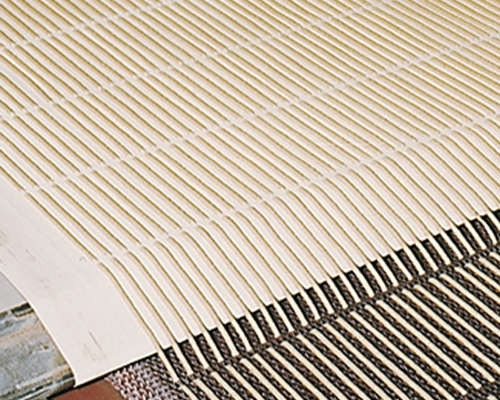

Profiles and Sidewalls

- Conveyor belts equipped with profiles are used for the

inclined conveying of bulk goods and small items.

Profiles are available in various shapes and sizes, and in some cases can be supplied as roll material.

Sidewall profiles are used – often in conjunction with lateral profiles – to contain bulk goods on the sides of the belt.

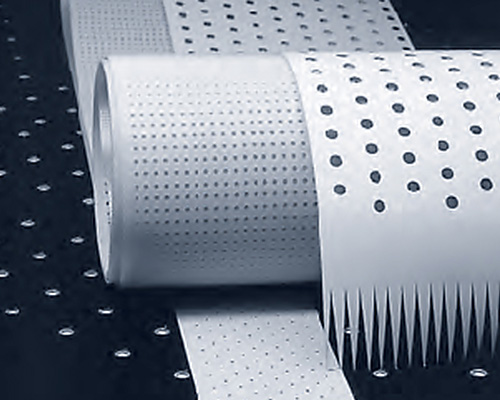

Top Face Patterns

- Siegling Transilon patterned belts guarantee good grip or

good release properties, depending on the design and goods conveyed.

Conveying angles of up to 30° can be achieved without profiles with certain patterned belts.

So patterned belts are not just an affordably-priced alternative to profile belts. The combination of patterned belts with longitudinal or lateral profiles is often possible.

Patterns can be peeled off from the belt edge up to a width of 150 mm (e.g. for clamps in swan-neck conveyors).

Modifying Belts

- Applying Free Forms

By precisely milling the surface of the belt and cutting virtually any types of perforations, Forbo Siegling offers a range of new options for many production processes. We can supply more detailed information on request.

Modifying Belts with Lasers

Positioning and control markings, logos, graphics, technical information and much more can be lasered into the surface of the belt. No material is added, a different colour is merely applied to the surface of the belt. Because of its extreme durability, precise positioning and crisp printing results, this process opens up new ways of using belts.

Belt Edge Sealing

- Belt edge sealing prevents oil, grease, water, foreign

bodies and bacteria from penetrating the belt. At the same time, it

increases the service life of the conveyor belt.

This additional protection can be applied to virtually every Siegling Transilon conveyor belt. You can find detailed information on the combinations possible in our data sheets.

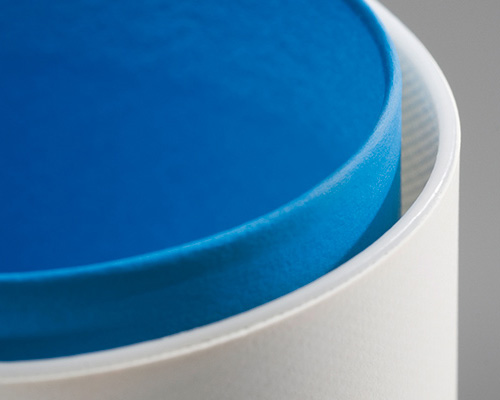

Knife Edge Belts

- Due to their fabric design, Siegling Transilon knife edge

belts are especially flexible longitudinally and rigid laterally. They are

suitable for use on knife edges as of 3 mm radius.

Even wide belts run flat, so even lightweight goods remain in position.

With their high coefficients of thermal conductivity, knife edge belts are exceptionally well suited for use as cooling tunnel belts. They are physiologically harmless, largely imper-vious to oils and greases and meet BfR, EU and FDA stipulations for the conveying of unwrapped foodstuffs. They can also be supplied in blue and white HACCP design.

Antistatic Belts

- Antistatic Siegling Transilon belts are equipped with an

electrically conductive static inhibitor that is abrasion-protected and

embedded in the belt.

It effectively prevents static build-up from the running belt. Antistatic belts do not always guarantee discharge of previously statically-charged conveyed goods, e.g. in the nonwovens industry, when conveying plastic or electronic components. In these cases HC belts should be used, particularly when they have to be ESD safe.In line with DIN-EN-ISO 284 thresholds, the electrical resistance measured on the inside (lengthways) RDi, according to ISO 21178, is less than 3 x 108 Ω.

NA (Non-antistatic)

- Siegling Transilon NA belts are

produced without an electrically conductive antistatic element. Tested

according to ISO 21178 the electrical surface resistance RDi is more than 3

x 10^8 Ω.

Combined with the coating materials appropriate in each case, NA belts guarantee smooth operation when using in electro-magnetic fields such as machine components with high frequency, X-ray and microwave applications.

NA belts in many different coatings with specific properties for particular products provide a high safety standard, in particular because of stringent quality controls, in the food and tobacco, chemical, pharmaceutical and particle board industries. In this way sensitive metal detectors for example can be used to an optimum with Siegling Transilon NA belts.

HC (Highly-conductive)

- Siegling Transilon HC belts (Highly-conductive) are

particularly antistatic due to a conductive top face and underside. Measured

in line with ISO 21178, the electrical surface resistivity of the top face

and underside is ROA < 3 x 10^8 Ω. In the majority of belt types, the

surface resistivity ROA of the top face and underside is even less than 1 x

10^7 Ω and as a result falls significantly short of the threshold stated in

DIN-EN ISO 284.

Numerous belt types also have an electrical volume resistance RD < 1 x 10^9 Ω, verified in accordance with ISO 21178.

HC belts are particularly suitable for conveying electronic components and anywhere where, if the belts and the goods conveyed are charged, there is a detrimental effect on product quality e.g. in the nonwoven or chemical industries.

Accumulation Belts

- Accumulation belts are used when collecting conveyed

goods behind a barrier or when sliding onto or off a belt. The particularly

stiff design of the belts ensures level conveying in larger belt widths. So

pushing unit goods on or off from the side is no problem at all.

Minimum friction coefficients between slider bed and underside and accumulation goods and top face must be maintained so that required power and wear and tear is kept low.

Siegling Transilon accumulation belts with duroplastic urethane coating (UH or U2H) are particularly abrasion resistant and have low friction coefficients. These properties guarantee long durability and reduce maintenance costs.

Accumulation belts

- Accumulation belts are used when collecting conveyed goods behind a barrier or when sliding onto or off a belt. The particularly stiff design of the belts ensures level conveying in larger belt widths. So pushing unit goods on or off from the side is no problem at all.

Minimum friction coefficients between slider bed and underside and accumulation goods and top face must be maintained so that required power and wear and tear is kept low.

Siegling Transilon accumulation belts with duroplastic urethane coating (UH or U2H) are particularly abrasion resistant and have low friction coefficients. These properties guarantee long durability and reduce maintenance costs.

SE/FR (flame retardant)

- Flame retardant Siegling Transilon belts (SE/FR) prevent the fire from

spreading. In keeping with EN 20340/ISO 340 (SE) and MSHA Std 2G

(30CFR18.65) measured according to ASTM D-378 (FR) these belt extinguish

after being subjected to an open flame and do not re-ignite should they come

into contact with a stream of air.

ATEX-compliant Processing Belts

- Since 1 July, 2003 guideline 94/9EG for avoiding ignition

risks in explosive atmospheres, known in the trade as “ATEX guideline 95”,

has come into force. When used in conveyors, processing belts are also at

risk of ignition from static electricity or friction heat, if they are not

used properly. Two partners are responsible for seeing this is done: the

belt supplier and conveyor manufacturer.

As a belt supplier Forbo Siegling faces up to this responsibility and if required, will supply processing belts that may be used in an explosive atmosphere.

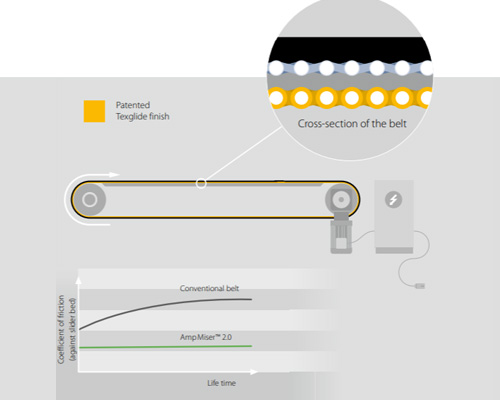

AMP MISER 2.0 - The new generation of energy saving conveyor belts

-

One of Forbo’s key corporate objectives is to maximise environmental friendliness and to enhance product value at the same time. On this basis, we successfully conduct research and development by closely liaising with OEMs and end users. The new generation of energy-saving conveyor belts is another prime example of our approach. The Amp Miser™ 2.0 belts now allow you to save up to 50 % of the energy required for power transmission. And they don’t cost any more than conventional belts.

- Lower power consumption

- Substantially reduced energy costs

- Fewer CO2 emissions

BioBelt™

-

In Bio Belt products, petroleum-based feedstock and synthetic materials have been extensively replaced by renewable plantbased materials. Because they are bio-degradable at the end of their product life, these play a major role in complying with the “cradle-to-cradle” principle. With an additional, already patented, special coating on the underside (Amp Miser™) they achieve energy savings of up to 40 %.

The properties

- made of renewable materials: resource-efficient production

- bio-degradable: environmentally friendly disposal

- patented, low-friction underside coating: up to 40% energy savings during operation, low noise pollution

- helps reduce carbon footprints: supports your sustainability concept

- physical properties equal conventional belts: easy to substitute without modifying the conveyor

TRANSTEX CONVEYOR BELTS

-

Transtex conveyor belts are characterized by ruggedness, lateral stiffness, wear and puncture resistance

Horiyontal conveying

-

Logistics and parcel service companies operating worldwide have been relying upon Transtex quality for years. On an exclusive basis, Forbo Movement Systems have added Transtex conveyor belting to their product range with worldwide stocks, sales and service. Thanks to ready availability, we are expanding your possibilities wherever conveyor belts are placed under heavy mechanical stress.

An extensive product range with two product lines is available. The maximum production widths - depending on the type - range from 1,800 mm to 2,100 mm. Larger widths are available on request.

Solutions: As individual as our customers

- Nowadays innovative concepts in production, material

flow and logistics are vital competitive factors. High efficiency flat

belts, conveyor belts and processing belts often play a pivotal role here.

So leading manufacturing companies all over the world count on Forbo Siegling specialists as competent partners in developing groundbreaking solutions in power transmission, conveying and manufacturing.

The result:

comprehensive, industry specific product ranges for our customers.

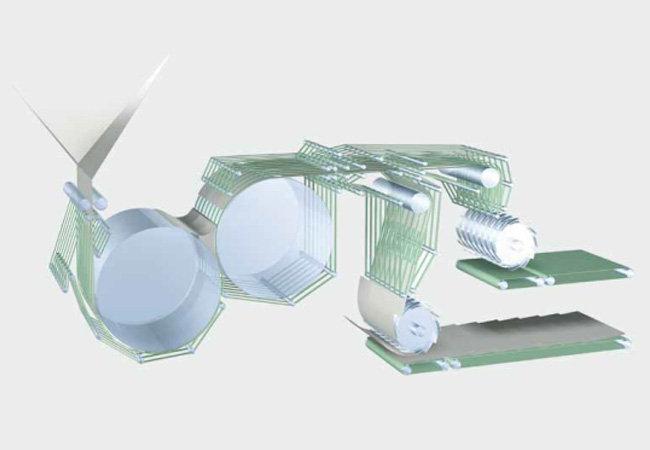

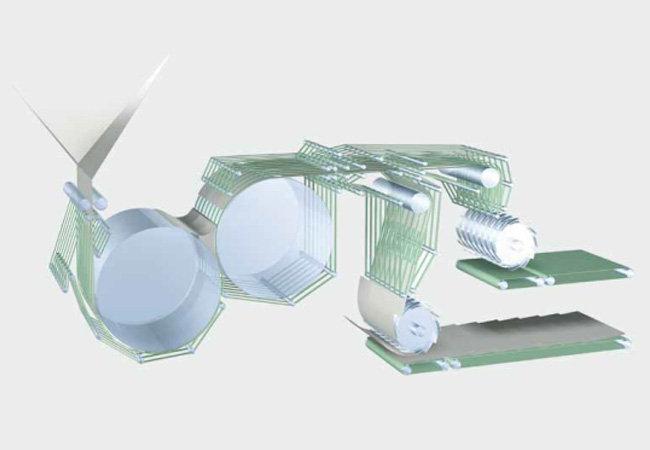

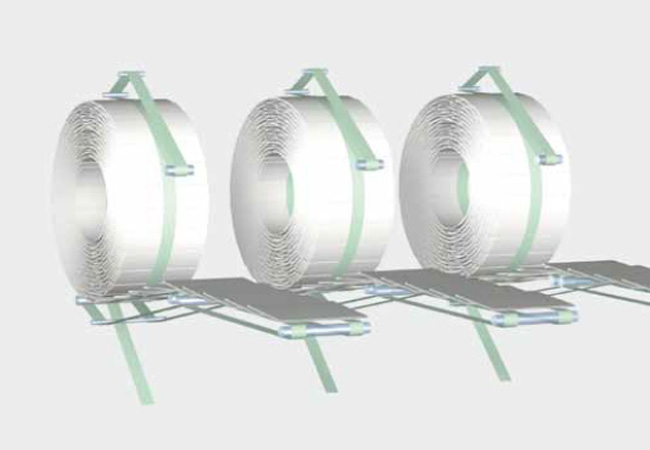

Plastic Modular Belting – Siegling Prolink

- Because of their construction conventional conveyor belts

are not suitable for many applications. Siegling Prolink plastic modular

belts are an excellent solution in these cases: The material is

rot-resistant, durable and physiologically safe (all standard materials used

are FDA compliant). As a rule cleaning the belts is simple.

Every belt's a specialist

The Siegling Prolink system consists of seven series functionally designed for diverse conveying and processing tasks. Inserted connecting rods join the individual modules together making them flexible and endless.

This means:- variable widths and length

- simple repair

- low stocks

High quality materials

By using different materials the characteristics of the various modular types are more specialised. With this variability Siegling Prolink fulfils all practical requirements: In conveying, positioning, washing, drying, freezing...

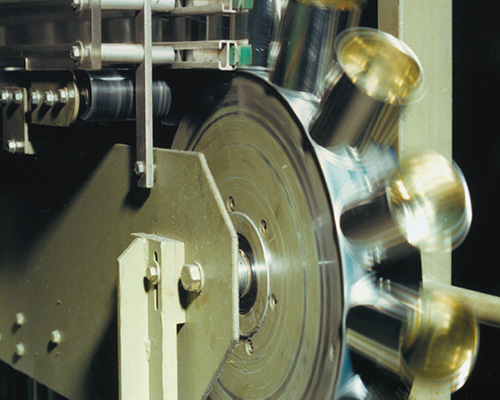

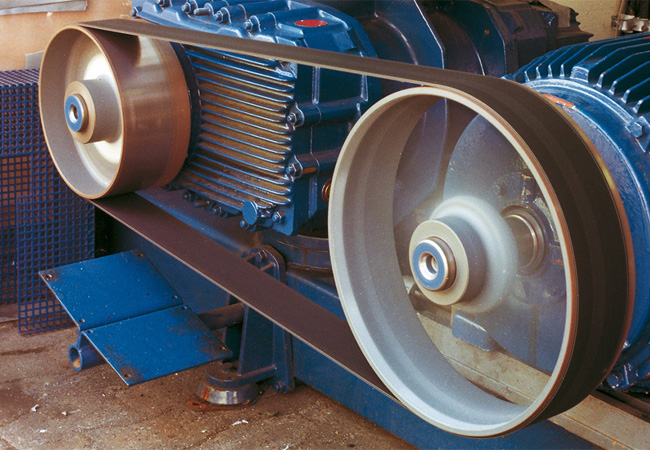

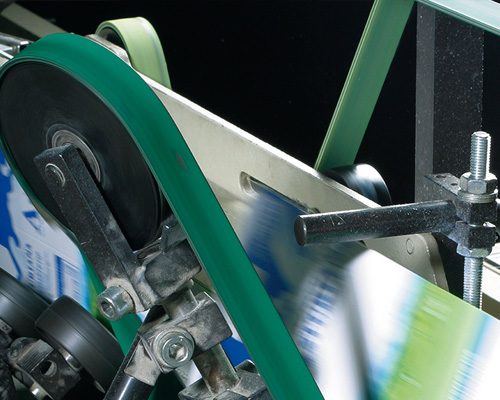

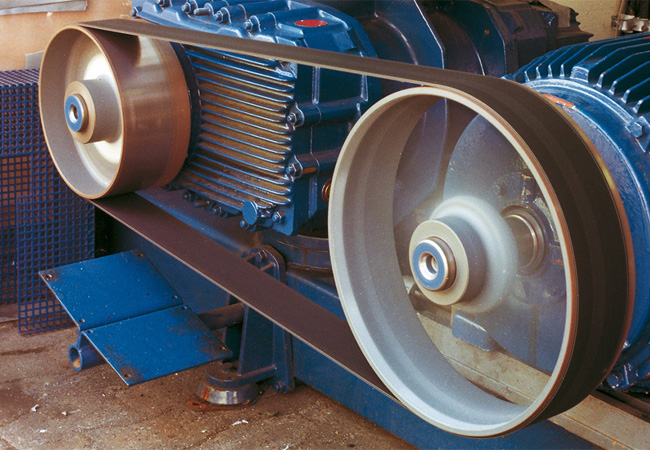

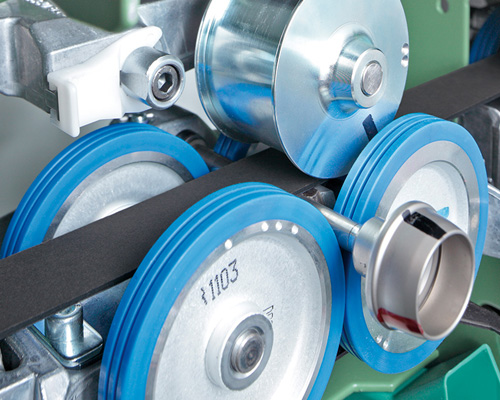

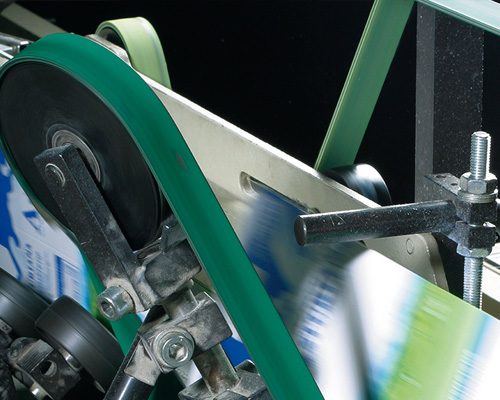

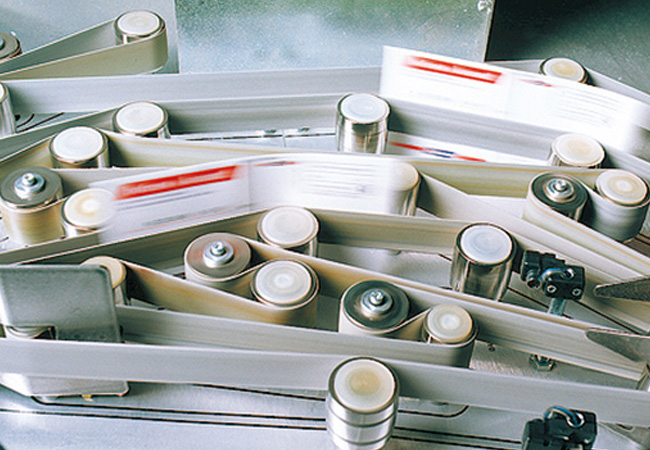

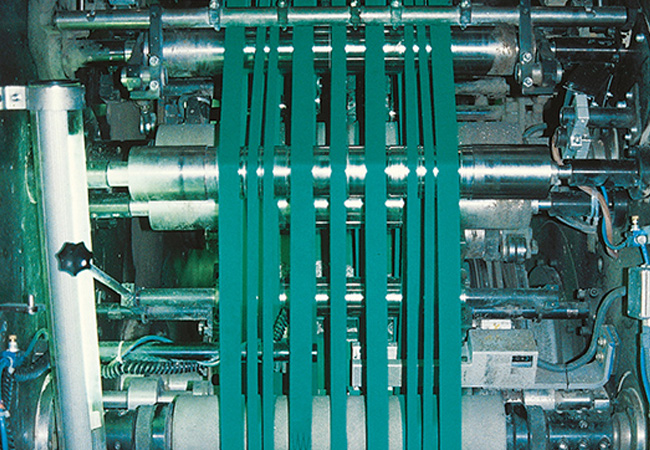

Flat Belts – Siegling Extremultus

- High-efficiency flat belts

for traction drive power transmission in all branches of industry

High-efficiency tangential belts and spindle tapes

for modern, high-efficiency machines in the textile industry

Folder and carrier belts, machine tapes

for precise machine performance in letter sorting systems and in the paper, printing and packaging industries

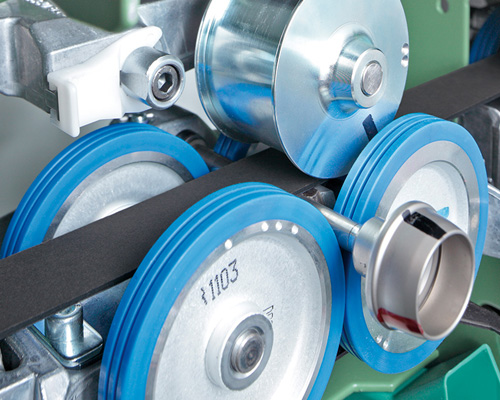

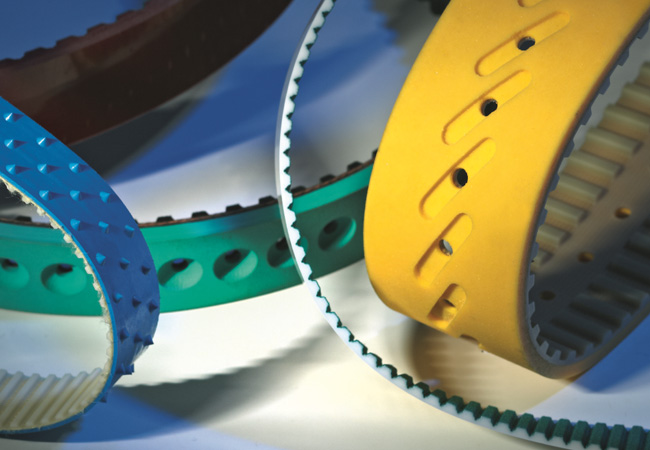

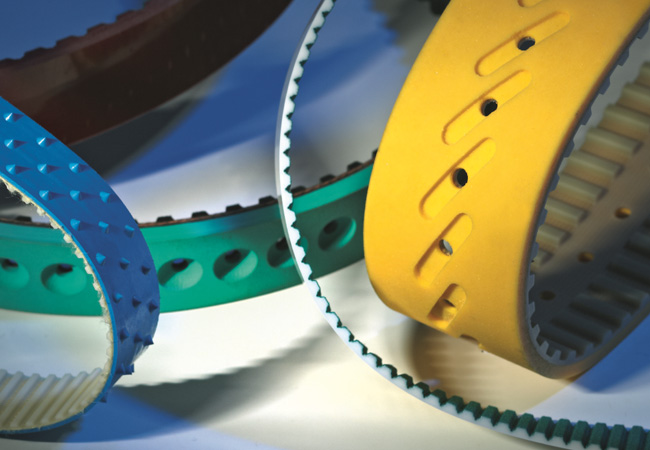

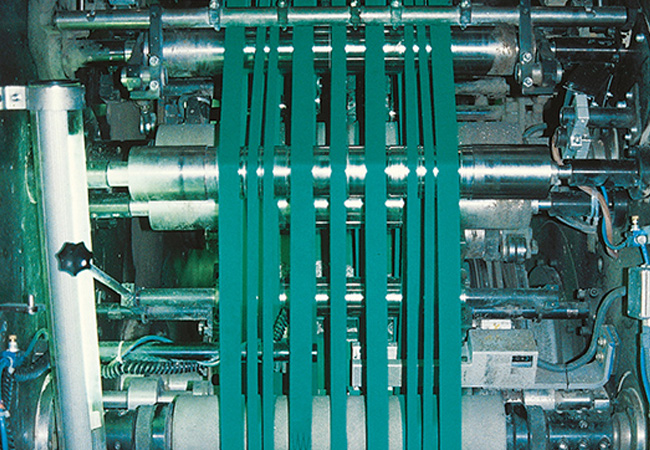

High-Efficiency Timing Belts – Siegling Proposition

- As form-fit power transmission and conveying elements

Siegling Proposition timing belts round off the family of tried and tested

Siegling Transilon conveyor and processing belts.

Our extensive experience in the field of light materials handling is our guarantee for excellent product quality and practice-oriented service.

The "pros" of Siegling Proposition:

- Delivery times

All standard types can be supplied at short notice ex stock - Service

We don't just provide the timing belt. We also offer sound expert advice at the design stage and can supply standard equipment at short notice on request. - Quality and price

Forbo Siegling quality at sensible prices means maximum price effectiveness for you. Have us draw up an offer! - Finishing: Siegling Proposition timing belts are available open or welded endless. The belt widths available have been selected to match standard toothed pulley widths.

- Delivery times

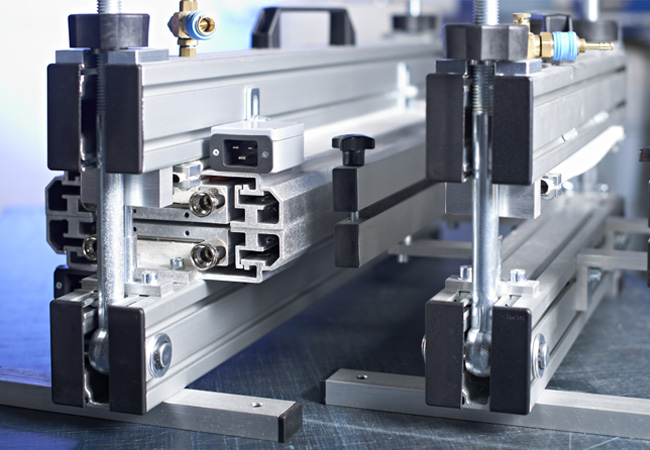

Tools, Accessories and Training

- The Forbo Siegling Range for Efficient and Reliable

Splices

As a leading manufacturer of conveyor and power transmission belts, Forbo Siegling has in-depth theoretical and applicational expertise in splicing technology. We keep procedures and equipment technology in tune with current belting developments by closely co-operating with users and equipment manufacturers. We provide innovative and functional solutions.

All components are compatible with each other and from one source – for effective and reliable endless splicing:- High Quality Tools with all the Accessories

- Comprehensive Service

- Detailed Procedural Instructions

Supplementary Products

-

- Siegling Transvent Ventilation Belts

- Siegling Linpack Folder and Carrier Belts with Linatex Top Face

- Siegling Round Belts

- Siegling Propipe Feeder and Haul-off Belts

- Belt Scrapers

- Mesh Belts

Industries and Applications

- In the production, trade and service industries, Forbo Siegling's high

efficiency flat belts and conveyor belts are often irreplaceable system

components.

We provide comprehensive product ranges for the various requirements of the most different of sectors and at the same time the guarantee of maximum service life and economical operation.

The following links will show you what Forbo Siegling has to offer for your industry:

Food Belts

Logistics / Airports

Textile Industry

Industrial Production

Raw Materials / Wood / Fibre Boards

Paper Industry and Letter Sorting

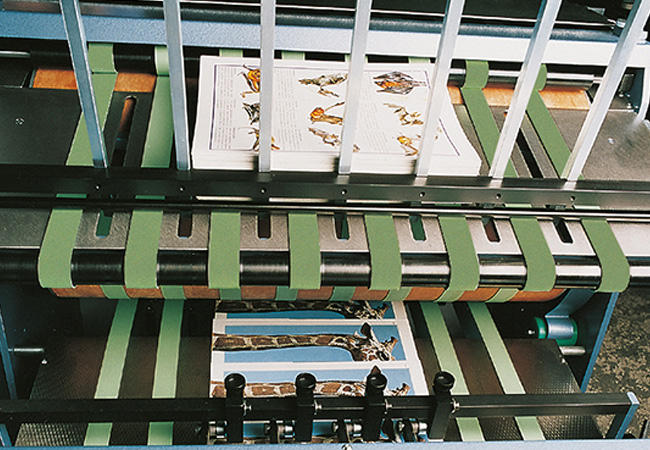

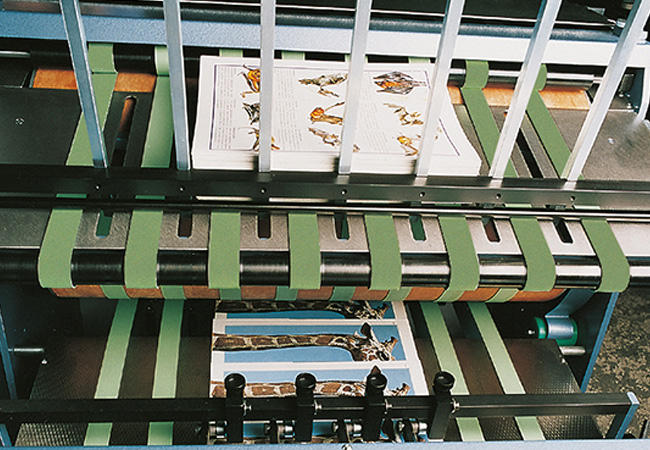

Printing Industry

Sports and Leisure

Tobacco Industry