- Offer Profile

- From project planning to

installation, we support our customers with advice and assistance. As a

system supplier of complete crane systems, we can respond to specific

customer demands. Our customers particularly value the variety of

accessories and options. Our high product quality and readiness to deliver

make us a reliable and competent partner worldwide.

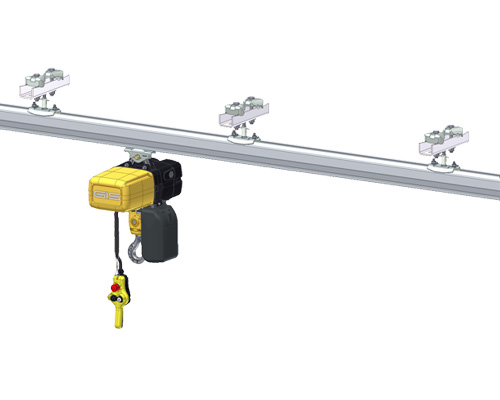

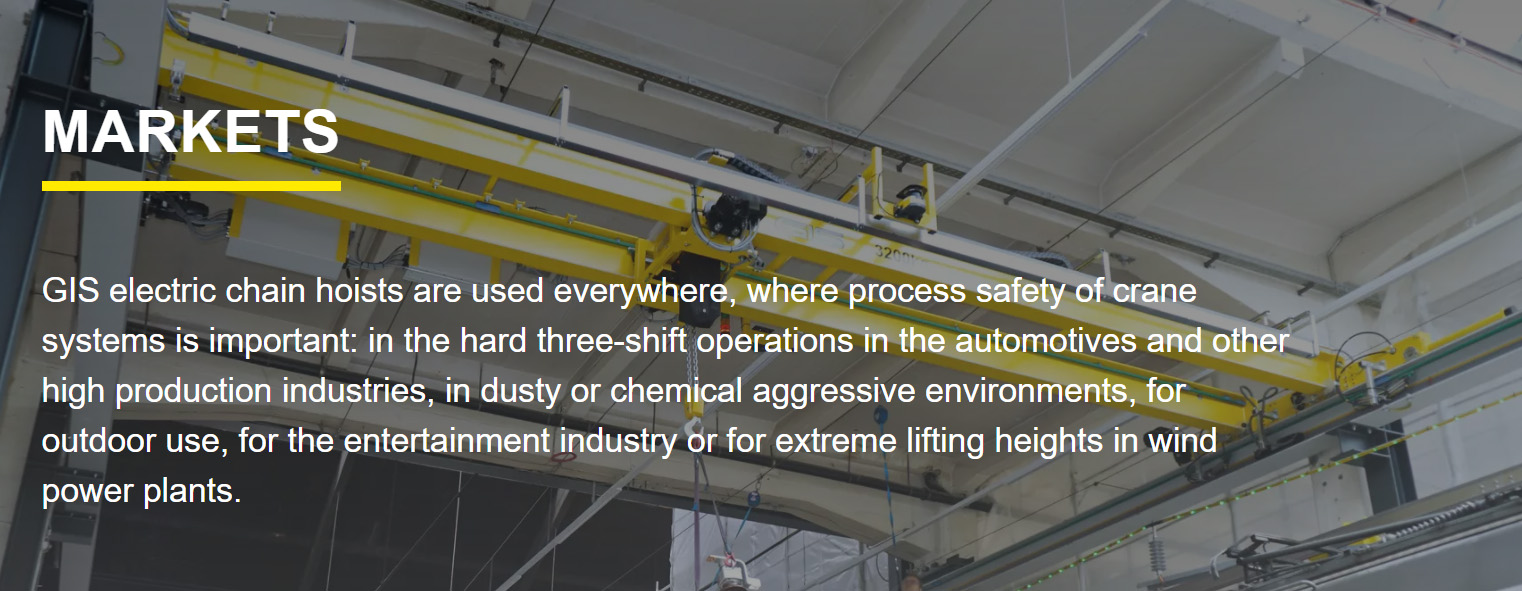

Hoist

Electric chain hoists industry

- Simple and easy to use – reliable and safe in operation – long-lasting and easy to maintain. GIS electric chain hoists have been developed and manufactured in Switzerland for more than 50 years. Hundreds of thousands of them are in operation worldwide – stationary or mobile.

Electric chain hoist GP

-

GPM250, GP250 - 2500, up to 6300 kg

The GP is simple in its structure and does not contain any sensitive electronics, which minimizes the risk of operational interruptions. It is characterised by quiet running and is made for longevity whilst working hard. The ergonomic control switch with 42 V low voltage allows convenient and safe working. Maintenance is easy, quick and needs no special tools.

Profile steel chain

The case hardened and manganese phosphated profile steel chain provides about 15% more capacity at an identical nominal diameter compared to the traditional round steel chain. The larger cross-sectional area reduces wear and increases the lifetime of the chain. The load hook with stable, guided hook latch and safety rubber buffer provides maximum safety.Polygonal connections

The inner part of the modularly designed chain hoist embodies real innovation. All shaft-hub connections are built to a polygonal design. This allows significantly faster disassembly and assembly during maintenance.Protection class IP65

A feature of the hoist and the control switch is the protection class IP65. It is dust proof and protected against water jets. As it is compact and robust designed, the GP is best suited for dusty environments as well as for outdoor operation.Control switch

The control switch fits comfortably in your hand and is ergonomically designed. It is robust, impact resistant, safe to operate and controlled by 42 V low voltage. Push buttons placed in parallel increase the ease of operation. The external strain relief protects the control cable.Reliable and long-lasting

- 3 year warranty

- Chain safety factor minimum 8-times (DIN EN 14492 A3, ISO M5)

- Protection class IP65 as standard

Easy to operate

- 60 % higher lifting capacity

- Quiet running with 3-step drive and helical gearing

- Polygonal connections

Customer specific

- Three- or single-phase version

- Direct control, special control, radio remote control, frequency inverter

- Special versions such as synchronized electric chain hoist, low headroom version, corrosion resistant version, ATEX

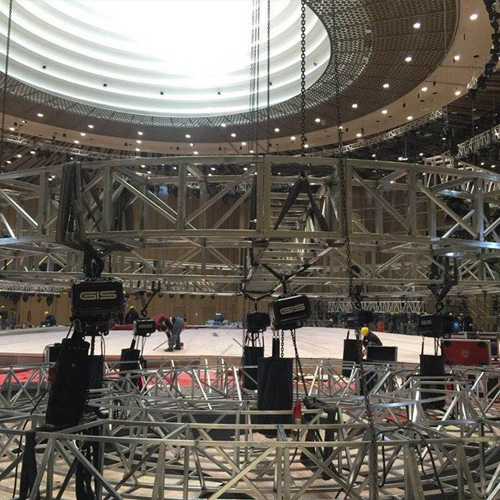

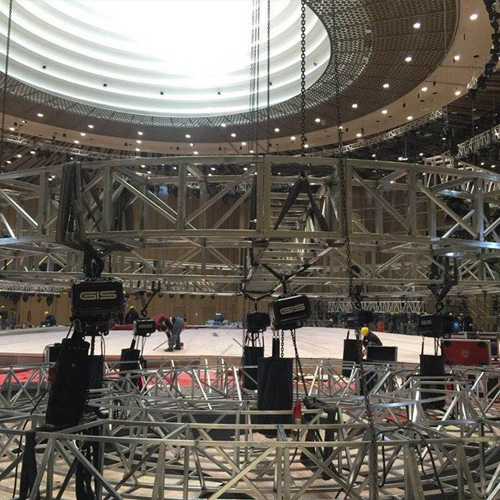

Electric chain hoists entertainment

- Simple and easy to use – reliable and safe in operation – longlasting and easy to maintain. In theatres, schools, sports centres, multifunction event venues, arenas, congress centres, TV studios or on concert tours, GIS chain hoists are in use worldwide. Developed and manufactured in Switzerland – for the world market.

Electric chain hoist LPL with motor D8

-

Electric chain motors D8

LPML250 for 500 kg, LPL500 for 1000 kg

Light

The LPML250 and LPL500 Series chain motor maximum lifting capacity compares favourably to the self-weight, making it the lightest entertainment chain motor in its class worldwide.

LPML250, weighing only 12 kg, lifts 500 kg. The self-weight of the LPL500 is just 23 kg, offering a lifting capacity of 1000 kg. The ideal motors for mobile use, the lower self-weight and compact size also has a positive impact on transport costs.Light and powerful

- The lightest entertainment chain motors in its class

- LPML250: Self-weight 12 kg, lifting capacity 500 kg

- LPL500: Self-weight 23 kg, lifting capacity 1000 kg

Reliable and long-lasting

- 3 year warranty

- Protection class IP65 as standard

- Housing and cover made of aluminum

Comfortable

- Quiet running: With 3-step drive and helical gearing

- Easy assembly of a second brake

- Polygonal design for an easy maintenance

- Available as a kit with flight case and controller

Electric chain hoist LP with motor D8

-

Electric chain motors D8

LPM250, LP500 - 2500, up to 6300 kg

Powerful

The case hardened and manganese phosphated profile steel chain provides about 15 % more capacity at an identical nominal diameter when compared to the traditional round steel chain. The larger cross-sectional area reduces wear and increases the lifetime of the chain. The load hook with stable, guided hook latch and safety rubber buffer provides maximum safety.Reliable and long-lasting

- 3 year warranty

- Aluminium casing and cover

- Weatherproof: Protection class IP65 as standard

Easy to operate

- Quiet running: with 3-step drive and helical gearing

- Simple: Polygonal design for an easy maintenance

- Usable as stationary or climbing hoist without modification

Customer specific

- Different operating and control voltages

- Easy assembly of a second brake

- Wide range of accessories and options

Electric chain hoist LP with motor D8+

-

Electric chain motors D8+

LPM250, LP500 - 2500, up to 2500 kg

Powerful

The case hardened and manganese phosphated profile steel chain provides about 15 % more capacity at an identical nominal diameter when compared to the traditional round steel chain. The larger cross-sectional area reduces wear and increases the lifetime of the chain. The load hook with stable, guided hook latch and safety rubber buffer provides maximum safety.Reliable and long-lasting

- 3 year warranty

- Safe: Chain safety factor minimum 8-times

- Weatherproof: Protection class IP65 as standard

Easy to operate

- Usable as stationary or climbing hoist without modification

- Quiet running: with 3-step drive and helical gearing

- Simple: Polygonal design for an easy maintenance

- Different operating and control voltages

- Second brake without housing extension

- Wide range of accessories and options

Electric chain hoist LP with motor C1

-

Electric chain motors C1

LP500 - 2500, up to 2000 kg

For both path and load measurement, additional components and electrical parts can be easily integrated in the chain hoist. On the drive shaft and/or the chain wheel, the installation of incremental or absolute encoders is prepared for path measurement. Special eyebolt and hook suspensions allow easy installation of a load measuring pin for load measurement. Our partners who develop and supply the control for multiple hoists value this highly.

All LP motors are equipped with a 3-stage self-contained gear. The helical gearing with geometric optimisation and the chain wheel with minimum 5 pockets ensure extremely quiet running. This allows the quiet handling of loads during events. Thanks to the sound absorption of the transmission the sound pressure level of the LP500 is only 60 dB.

Reliable and long-lasting

- Robust: 3 year warranty

- Proven DC spring brake, with or without monitoring

- Highest safety with brake positioned after the slipping clutch

Easy to operate

- Quiet running: with 3-step drive and helical gearing

- Weatherproof: Protection class IP65 as standard

- Simple: Polygonal design for an easy maintenance

Customer specific

- Preparation for load and path measurement

- Suitable for frequency inverted operation

- Wide range of accessories and options

Special products

- For a lot of lifting tasks GIS electric chain hoists offer the perfect solution. Depending on the complexity of the demand special products come to use. If synchronous lifting of 2 load hooks, a corrosion resistant or explosion proof execution - we offer a custom-designed solution for every requirement.

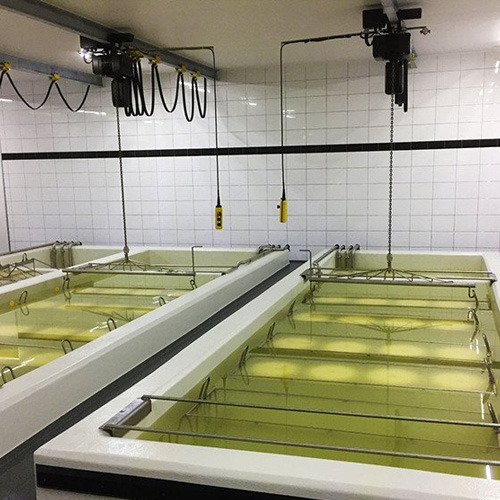

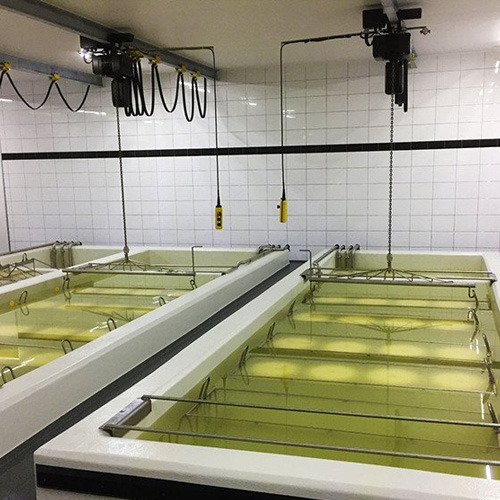

Corrosion resistant

-

GPR, up to 1250 kg

Demands in the food industry (e.g. cheesemaking or meat processing) are particularly stringent. Corrosion-resistant electric chain hoists are ideal for such applications.

Likewise in sewage plants and some sectors of the chemical industry, they offer valuable advantages.- Corrosion resistant electric chain hoist

- For use in food, pharmaceutical or chemical industry, wastewater treatment plants, outdoor use

- Housing cataphorese coated

- Round, stainless steel chain

- Suspension corrosion resistant

- All parts in contact with the chain (wearing parts such as chain wheel, load hooks, screws) in corrosion resistant version

- Protection class IP65

- Special grease for food industry

- Option: overpressure release valve

- Option: manual or motorised trolley in corrosion resistant version

Explosion proof

-

GP ATEX, up to 6300 kg

This gasproof execution guarantees maximum safety:

The entry of gas is avoided through an overpressure in the housing. At a lost of pressure in the housing the power will be cut immediately.- Electric chain hoist explosion proof ATEX version

- Available in a dust- and gasproof execution

- For zones 22 (D) and 2 (G)

- Protection class IP65

- Option: motorised trolley in ATEX version

Frequency-controlled

-

GPFU, up to 2500 kg

The programmable frequency inverter confirms to the highest standards.

The soft start guarantees for a precise positioning of the load.

The lifting speeds and accelerations can be adjusted according to the requirement.- Electric chain hoist with frequency inverter

- For applications with high switching frequency and shift operation

- Lifting speed up to 9.6 m/min.

- With soft start for precise and gentle positioning of the load

- Transportation without overshooting and exact positioning of the load in combination with frequency-controlled motorised trolley

- Speeds and ramps for lifting and travelling programmable adjusted to the application

- Protection class IP65

- Option: motorised trolley with frequency inverter

- Option: equipped with radio remote control

- Option: load-dependent lifting

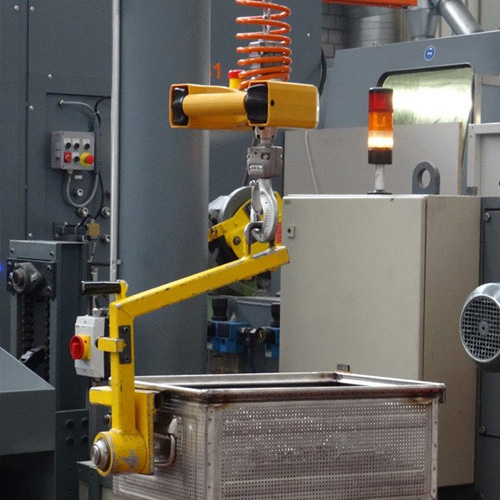

Handy chain model

-

GPH, up to 500 kg

The Handy chain model is ideal for cost-effective transport of small loads such as crates or containers.

Higher hoisting speed and creep speed as standard allow precise load positioning.

Since the control unit is fixed to the load suspension device, loads can easily be transported with one hand only. Various suspension attachments can be fitted.- Handy chain model for quick and easy positioning of loads

- Control of electric chain hoist and guidance of the load with one hand

- Control unit with rocker switch for left- and right-handed operation

- Hook end positions adjustable by geared limit switch

- Perfect to combine with GISKB slewing or suspended crane

- Option: handy kit for retrofitting of GIS standard electric chain hoist

- Option: with frequency inverter

- Option: customised devices for load handling

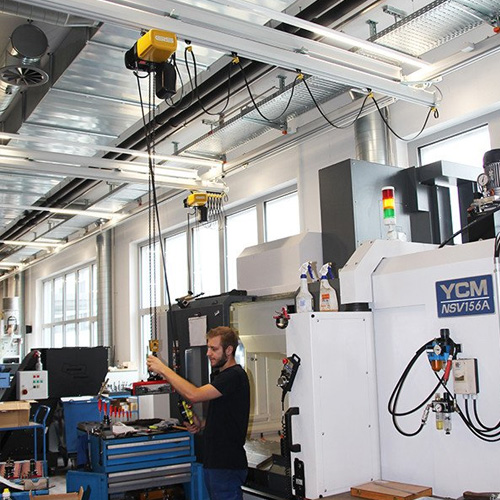

Handy telescope model

-

GPHT, up to 250 kg

The Handy telescope model has an additional extending guide tube to stabilize hoisting and lowering for extremely precise load positioning.

A common application of this model is for placing workpieces on machine-tools. A special attachment is available for eccentric lifting.- Handy telescope model for fast and accurate positioning of loads

- Operation of electric chain hoist and simultaneous precise guidance of the load with one hand

- Ideally suited for eccentric loads

- Control unit with rocker switch for left- and right-handed operation

- Hook end positions adjustable by geared limit switch

- Perfect to combine with articulated slewing crane or GISKB suspended crane

- Option: with frequency inverter

- Option: customised devices for load handling

- Option: with slack chain shutdown

Synchronised hoist

-

GPS, up to 2 x 2500 kg

The GIS Synchron is ideal for transporting long bulky loads.

The appropriate synchronous lifting of the hoist and the accurate levelling of the two load hooks assure precise positioning of the load without undesirable rotation.

This kind of hoist is used in the automobile and printing industries among other applications.- Synchronised electric chain hoist for transportation of large and bulky loads

- Precise parallel run of two hooks without twisting the load

- 2 electric chain hoists connected electrically and mechanically

- With temperature monitoring

- Hook position individually adjustable by geared limit switch

- Distance between load hooks 0.7-5.0 m

- Perfect to combine with GISKB suspended crane or travelling crane

- Option: with trolleys

- Option: with frequency inverter

- Option: customised devices for load handling

Low headroom version

-

GPK, up to 2000 kg

These electric chain hoists are designed for low ceilings. The chain is diverted through an additional block to increase lifting height.

For large bulky loads the block spacing can be extended.- Solution for especially low rooms

- Obtaining room height using a sophisticated chain guide

- Hook position adjustable by means of a geared limit switch

- Available with a lengthened frame for transporting large and bulky loads

- 1 or 2 lifting speeds

- Optionally with trolleys

- Optionally with frequency inverter

Wind power plants

-

GP, up to 1000 kg

Electric chain hoists for wind power plants are used for the transportation of spare parts and tools from the ground to the nacelle.

Because of the large lifting height these hoists are equipped with some special features:

For example there is an automatic switch from normal to creep speed before the end postion is reached.

This function avoids that load hook runs against the hoist's housing with high speed as this could possibily cause unsecured parts of the load to fall down (i.e. items from the tool box).

The protection cap over the load hook is another gadget. It elminates the risk that load hook sticks to something unintentionally during the long way to the top.- Electric chain hoist for wind turbines

- Lifting speed up to 16 m/min.

- Lifting height up to 200 m

- Temperature monitoring with shutdown function of the motor in case of overheating

- Automatic switching from high to low lifting speed shortly before the stroke end by geared limit switch

- External limit switches for hook end positions

- Tempered special chain

- Load hook with protective cover

- Option: with manual or motorised trolley

- Option: chain container

Manual chain hoist

-

GISHKZ, up to 3000 kg

The manual chain hoist is a perfect fit if you want to lift small loads or if there is no power available.

- Lifting heights freely selectable

- Safety brake holds the load in any position safely

- Overload protection as a standard

- Swiveling top and bottow hook

Push Trolleys

- No matter if push travel or electric movement - GIS trolleys provide horizontal travel solutions tailored to meet specific requirements. Our trolleys are designed for the use in combination with electric chain hoists of the series EM, GCH and GP but are a perfect fit for roller boxes and endcarriages of travelling cranes as well.

Push trolley GHF500 K

-

GHF500, up to 500 kg

Push trolley for steel beams

Side plates made of die-cast aluminium with fall and climbing protection

Pefect smooth running thanks to glass fibre reinforced plastic wheels

Very low tare weight of only 2.5 kg

Flange width 50 - 149 mm

Push trolley GHF

-

GHF1250 - 6300, up to 6300 kg

Manual trolley for steel beams

Manual or electric chain hoist moved manually

Load wheels made of cast iron, with ball bearings

Side plates made of cast iron with fall and climbing protection

Flange width infinitely variable

Push trolley corrosion resistant

-

GHFR1250 - 2500, up to 1250 kg

Corrosion resistant manual trolley for steel beams

Manual or electric chain hoist moved manually

Load wheels made of stainless steel

Spindle corrosion resistant

Side plates cataphoresis coated with fall and climbing protection

Flange width infinitely variable

Motorised trolleys

- GIS motorised trolleys allow loads up to 6300 kg to be moved smoothly. The travel movement is matched to the load and the local conditions, with fixed travel speeds or infinitely variable by means of a frequency inverter. GIS trolleys are frequently used by our customers as components for endcarriages of overhead travelling cranes due to their good travel characteristics and durability.

Motorised trolley GMF

-

GMF1250 - 6300, up to 6300 kg

- Motorised trolley for steel beams

- Side plates made of cast iron with fall and climbing protection

- Load wheels made of cast iron, with ball bearings

- 1 or 2 travelling speeds

- Flange width infinitely variable

- Control box with easily accessible connections

- Option: travel limit switch

- Option: radio remote control

Motorised trolley corrosion resistant

-

GMFR1250 - 2500, up to 1250 kg

- Corrosion resistant motorised trolley for steel beams

- Side plates cataphoresis coated with fall and climbing protection

- Load wheels made of stainless steel

- 1 or 2 travelling speeds

- Spindle corrosion resistant

- Flange width infinitely variable

- Control box cataphoresis coated with easily accessible connections

- Option: radio remote control

Motorised trolley frequency controlled

-

GMF FU 1250 - 4000, up to 4000 kg

- Motorised trolley with frequency inverter

- Basic specification like GMF 1250 - 4000

- Transport without oscillation and precise positioning of loads

- Soft start for high demands

- 2 speeds are programmable: for starting / positioning and travel

- Speed 3.6 - 30 m / min.

- Optionally with remote control

Motorised trolley explosion proof

-

GMF ATEX 1250 - 6300, up to 6300 kg

- Explosion proof electric trolley in ATEX execution

- Available in a dust- and gasproof execution

- Flange width infinitely variable

- 1 or 2 travelling speeds

- Protection class IP65

- Available for zones 22 (D) and 2 (G)

Crane Systems

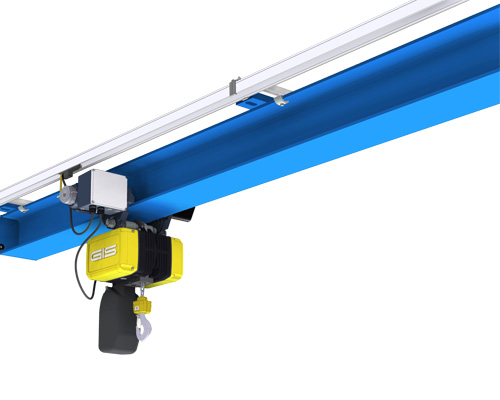

Light crane systems

- The GISKB light crane system is the perfect solution for the fast and safe overhead transport of your goods. Due to its flexible and modular design the crane system can be tailored to the needs of your workplace. Supported by hollow profiles made of steel or aluminium, materials can be moved in a linear direction or to cover an area – additionally, GISKB wall-mounted slewing jib cranes or pillar slewing jib cranes are available. The GISKB II profile is also approved as a horizontal security system according to DIN EN 795: 2012.

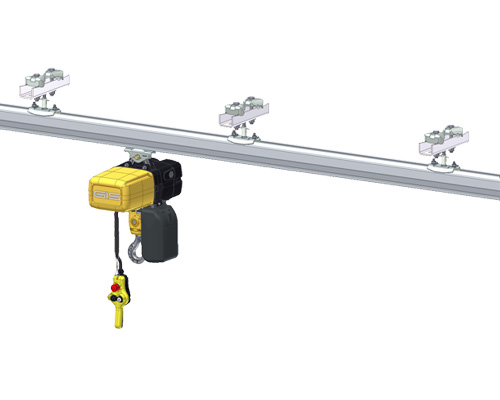

Monorail GISKB steel

-

up to 1600 kg

Due to the combination of bends and track switches, offset working stations can be approached very precisely in the workflow.

The electric tug with frequency inverter ensures a soft start and nonswinging transport of loads.

In order to increase flexibility the crane system is operated via radio remote cont- For the connection of several working stations

- Suspension monrail rigid or pendulating

- Manual or steplessly electrical travel

- Combinable with track switches, bends, interlocking devices and turntables

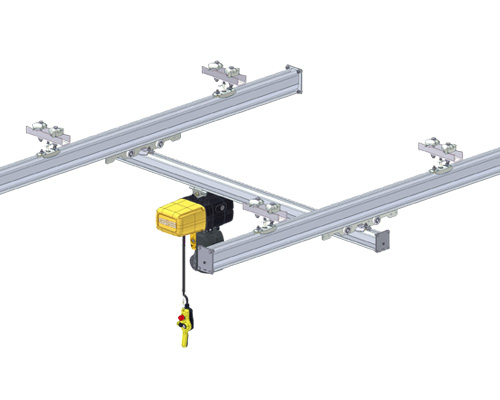

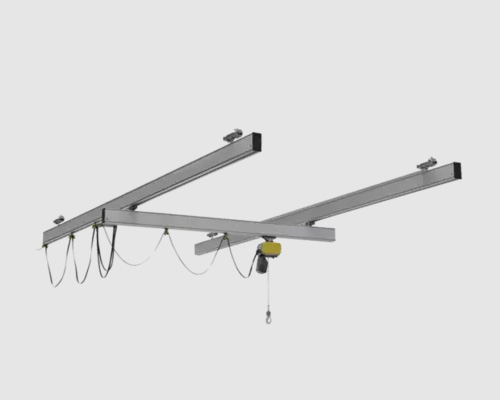

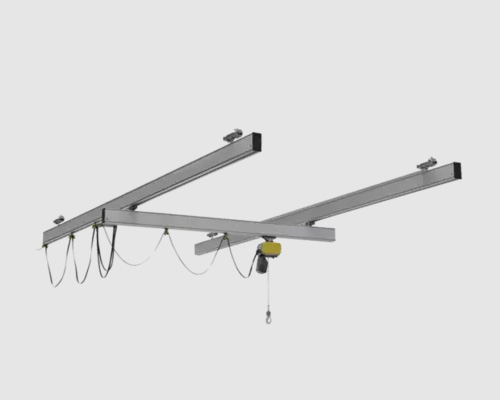

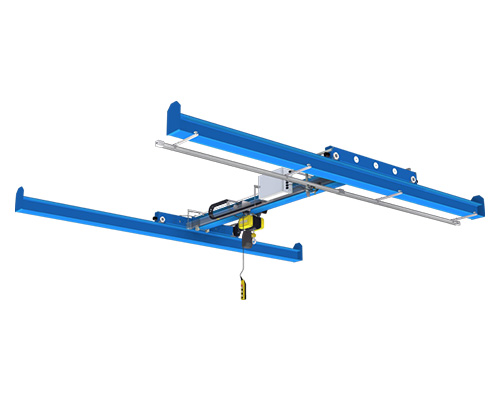

Single bridge suspended crane GISKB steel

-

up to 1600 kg

Due to the modular design GIS KB crane systems are easy to plan and install.

All components are screwable. This allows subsequent retrofitting and extension of existing systems without problems.

The pendulating or rigid suspension is adjusted to the existing ceiling construction.

For power supply a trailing cable, a C-rail or a conductor line can be chosen.- For regular or optimised construction height

- Suspension crane track rigid or pendulating

- Manual or steplessly electrical crane and cross travel

- Profile reinforcement to increase span width

- Option: for multiple crane bridges

- Option: telescopic jib

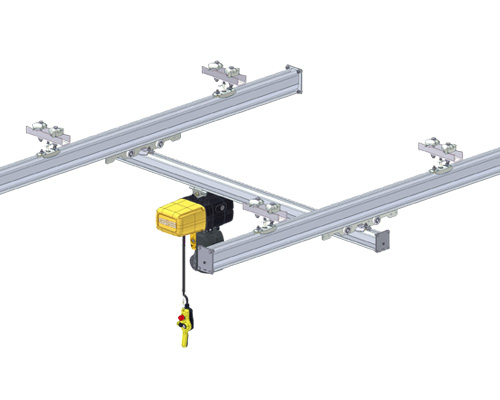

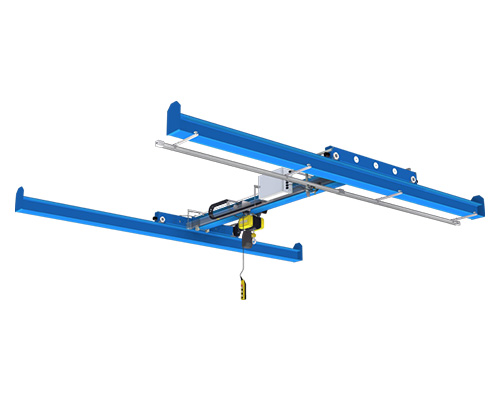

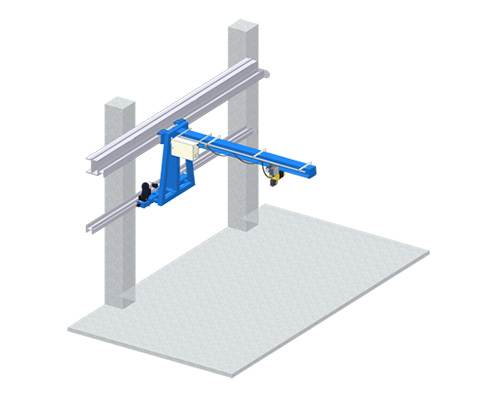

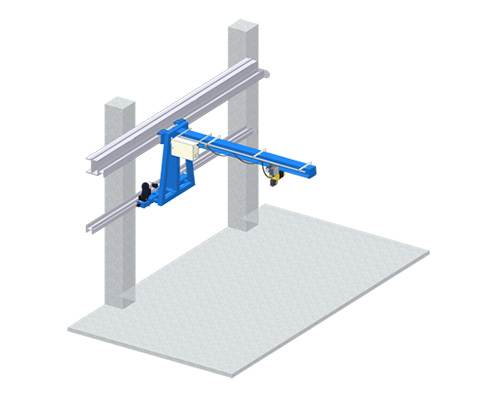

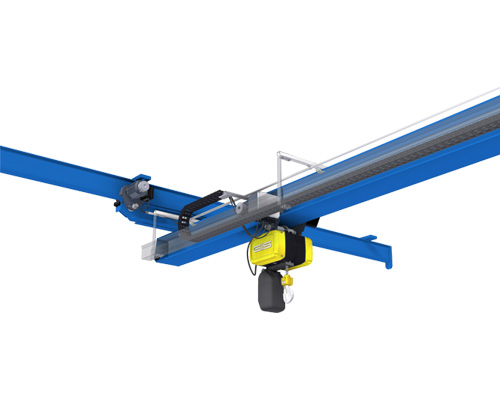

Double bridge suspended crane GISKB steel

-

up to 2000 kg

Compared to traditional structural steel beams the GISKB crane system with hollow profiles has the major advantage that the treads of the profiles are significantly better protected from dust.

In thisway the plastic rollers of the trolleys maintain their quiet running properties and are durable. In a long run, manual moving of the electric chain hoist and crane bridge can be carried out effortlessly

and precisely.

Due to their numerous advantages such as modularity, lightweight construction, flexibility, dust protection and simple installation GISKB crane systems are used in various industries.- For larger span widths or transport distances

- For regular or optimised construction height

- Suspension crane track rigid or pendulating

- Manual or steplessly electrical crane and cross travel

- Profile reinforcement to increase span width

- Option: for multiple crane bridges

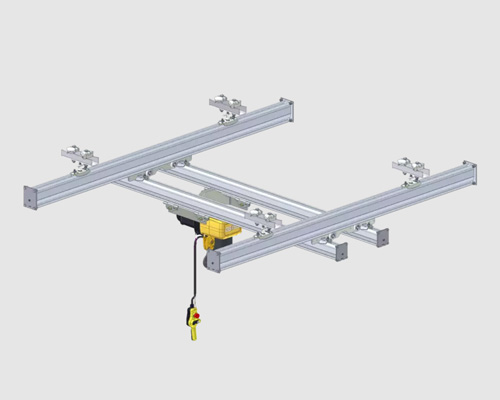

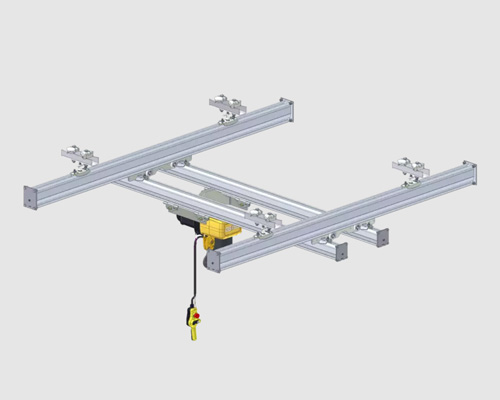

Crane system GISKB Alu

-

up to 630 kg

Simple installation

Thanks to the low weight of the aluminium profiles and the flexible connection options equipment installation is carried out quickly and easily.

The modular construction-kit system allows smooth retrofitting or extension of an existing system at any time.- Aluminium profile GISKB Alu

- As single or double bridge suspended crane or monorail

- For regular or optimised construction height

- Suspension crane track and monorail pendulating

- Manual crane and cross travel

- Perfect smooth running of the trolleys

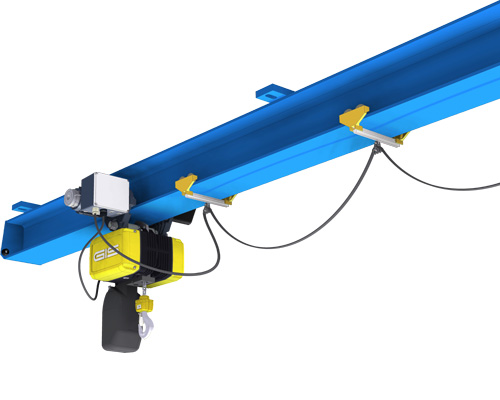

Travelling cranes

- GIS travelling cranes define the overhead material transport up to 5000 kg lifting capacity in terms of efficiency. Our objective is rational and area covering goods handling. Based on structural and customer's requirements, we offer and realise the appropriate, robust and durable solution in design, ergonomics and safety.

Overhead travelling crane

-

up to 6300 kg

Robust and durable crane systems for long-term, safe use. All of our electric drives and electric chain hoists are state of the art. The calculation basis and calculations meet national and international standards.

Our way to construct convinces through its simplicity, combined with durability and reliability. We rely on decades of experience as a manufacturer of travelling cranes and on our know how to respond to customer-specific requirements.

All from a single source.- As single- or double-bridge travelling crane

- Construction with standardised beams

- The welded crane rail serves as guidance and keeps the crane bridge in the track

- Large hook dimension through crane bridge placed on crane track

- Control switch on trolley or control switch independent of trolley (roving pendent) or radio remote control

- Crane track fixation on supports (free standing system) or on wall / pillar

- Drives stepless or pole-changeable

- Very quiet running

- Longitudinal power supply with conductor line or C-rail

- Central crane control 42 V

- Option: multiple crane bridges (tandem operation)

Underslung travelling crane

-

up to 6300 kg

The underslung travelling crane is a popular variation of GIS travelling cranes.

The crane tracks are usually mounted directly to the ceiling. For this reason, the longitudinal trolleys are mounted below.

This solution allows us to incorporate the standard trolleys. Various construction solutions according to our customer’s requirement demand special versions such as higher hook dimension, overhang load, with or without telescopic version, bypass control or large span widths.

- As single- or double-bridge travelling crane

- Construction with standardised beams

- Control switch on trolley or control switch independent of trolley (roving pendent) or radio remote control

- Crane track fixation to ceiling, pillars or steel beams, mounted directly or distanced (free standing system)

- Standard drives EMFE stepless or pole-changeable

- Lateral overhang of hook possible

- Longitudinal power supply with conductor line or trailing cable

- Cross beam power supply via conductor line, cable or energy chain

- Option: multiple crane bridges (Tandem operation)

- Option: low headroom construction for transverse bridge

- Option: branch terminal line possible

Monorail steel beam

-

up to 6300 kg

In many cases, the monorail is the most conventional solution for material transport from A to B. A prerequisite for this that the points can be connected with a line.

Variations in the lines are corrected by bends or track switches.

The commercial I or H steel profiles are low cost and designed for heavy lifting capacities. GIS manual or motorised trolleys are ideally suited as a complementary system and can be adapted to the flange width of the steel beam by adjustable bolts.

- Construction with standardised beam

- With manual or motorised trolley

- Crane track fixation to ceiling, pillars or steel beams, mounted directly or distanced (free standing system)

- Overhang of hook possible

- Control switch on trolley or control switch independent of trolley (roving pendent) or radio remote control

- Standard drives EMFE stepless or pole-changeable

- Power supply with conductor line, parallel running C-rail with trailing cable or cable carriage

- Several chain hoists on a monorail possible (tandem operation)

- Option: Monorail with bends or track switches

- Option: Telescopic execution

Crane kit components

-

up to 6300 kg

Depending on the customer’s requirements, we offer the kit components with GIS trolleys, electric chain hoist, control unit box and control.

Crane bridge and crane track can be procured and installed on site.

With this simple and ecological offer you have the advantage that all major crane components originate from a single partner.

Of course we support you on request in your projects with calculations, project drawings and wiring diagrams.- For underslung- or overhead travelling crane

- Connection points for trolley and crane bridge are standardised

- Very simple way to mount a standard travelling cran

- All components such as crane kit, trolleys, electric chain hoist and radio remote control from a single source

- Assembly with steel beams provided on site

Gantry crane

-

up to 6300 kg

Gantry cranes do not need auxiliary constructions like pillars or crane tracks. This is a big advantage especially for outdoor installations.

The mobile gantry crane allows the handling of loads at different locations. This mobility in case of temporary workplaces or workplaces to be set up, but also in case of machine reconstructions and repairs is appreciated.- Guided on rails or mobile

- Floor-bound individual solution

- Steel or aluminum construction

- Power supply via cable, cable drum

- Rail-guided solution for higher span width and load capacity

- Electrically or manually moved

- Control switch on trolley or control switch independent of trolley (roving pendent) or radio remote control

- Individual solution

Console crane

-

up to 1000 kg

Console cranes are a perfect fit for areas where no bridge or gantry cranes can be mounted. Aside from that they are also used as workstation or complementary cranes for big overhead cranes.

- On wall rails

- Mobile cantilever for maximum ground clearance

- Norm-steel beam

- Electrically moved

- Control switch on trolley or control switch independent of trolley (roving pendent) or radioremote control

- Several cantilevers possible

- Power supply with conductor line or C-rail and trailing cable

Slewing jib cranes

- GIS pillar- and wall-mounted slewing jib cranes offer a simple and functional solution for ergonomic goods handling. Depending on the desired load capacity, the jib working radius and the running properties, aluminium or steel profiles are used. In combination with a GIS electric chain hoist and a trolley (manual or electric), a GIS vacuum-handling system or another load-handling device, you get a complete crane system from one source – directly from the Swiss manufacturer.

Slewing pillar crane GISKB steel

-

up to 1000 kg

Treads inside the profile protected from dirt

Trolley with smoothly running plastic rollers

Cost-efficient alternative to suspendend crane- Steel jib profile GISKB

- Treads inside the profile protected from dirt

- Trolley with smoothly running plastic rollers

- Slewing range up to 270°

- Jib length up to 6 m, longer jibs on request

- Option: equipped with an electric tug

- Option: equipped with a telescope

Slewing pillar crane GISKB Alu

-

up to 500 kg

Due to the excellent running properties of the low moving mass the working speed is increased while positioning is precise.

This leads to significantly shorter cycle times, which has a positive effect on the production costs.- Aluminum jib profile GISKB Alu

- Treads inside the profile protected from dirt

- Perfect smooth running during turning and longitudinal travel

- Slewing range up to 270°

- Jib length up to 6 m, longer jibs on request

- Option: equipped with a telescope

Slewing pillar crane IPE steel beam

-

up to 5000 kg

Maximum use of room height by overhead jib arm.

Higher load capacities and jib lengths compared to jib cranes made of hollow profiles.

Use of manual or electric GIS trolleys.- Steel jib beam IPE

- Slewing range up to 360°

- Jib length up to 12 m, longer jibs on request

- Option: equipped with a telescope

- Option: equipped with trolley and slewing system electric

- Option: equipped with radio control

- Option: equipped with weather-protection package

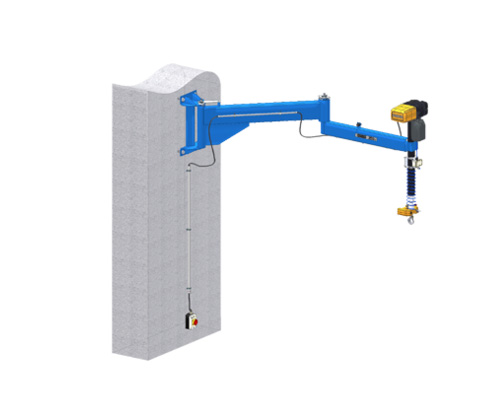

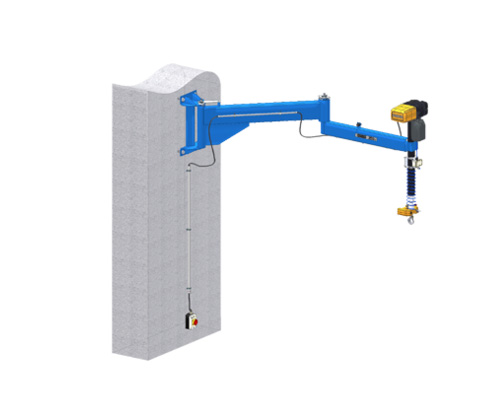

Articulated wall slewing crane GWD-TR steel pipe profile

-

up to 250 kg

The articulated slewing pillar crane GSD-TR allows a maximum slewing range.

To further increase positioning accuracy the jib arms can optionally be equipped with a regulator for the adjustment of the slewing resistance.

The articulated slewing crane comes to use whenever easy and fast handling of work pieces, tools and small parts is required.- Articulated jib crane with maximum slewing range

- Suitable for eccentric load suspension with GIS handy telescope

- Slewing range up to 270° (inside), or up to 330° (outside)

- Jib length up to 2.6 m, longer jibs on request

- Option: equipped with a brake at the inner and outer joint

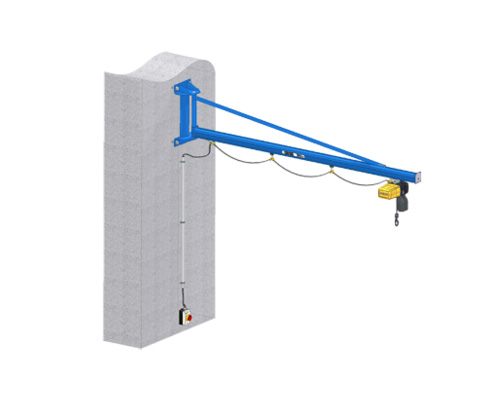

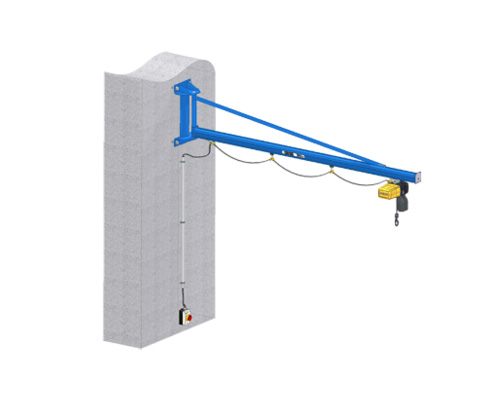

Slewing wall crane GISKB steel

-

up to 1000 kg

GIS wall-mounted slewing jib cranes are a cost-efficient alternative to pillar-mounted slewing jib cranes or complete crane systems.

The key benefit of wall-mounted slewing jib cranes is that they do not require any floor space, since they are mounted to stable concrete walls or existing

pillars. Our wall-mounted slewing jib cranes are sturdy, easy to install and designed in accordance with the latest EU-Norm 13001.- Steel jib profile GISKB

- Treads inside the profile protected from dirt

- Trolley with smoothly running plastic rollers

- Slewing range up to 180°

- Jib length up to 6 m, longer jibs on request

- Option: equipped with pillar clasp

- Option: equipped with an electric tug

- Option: equipped with a telescope

Slewing wall crane GISKB Alu

-

up to 500 kg

Due to the excellent running properties of the low moving mass the working speed is increased while positioning is precise.

This leads to significantly shorter cycle times, which has a positive effect on the production costs.

GIS wall-mounted slewing jib cranes are a cost-efficient alternative to pillar-mounted slewing jib cranes or complete crane systems.

The key benefit of wall-mounted slewing jib cranes is that they do not require any floor space, since they are mounted to stable concrete walls or existing pillars.- Aluminum jib profile GISKB Alu

- Treads inside the profile protected from dirt

- Perfect smooth running during turning and longitudinal travel

- Slewing range up to 180°

- Jib length up to 6 m, longer jibs on request

- Option: equipped with a telescope

- Option: equipped with pillar clasp

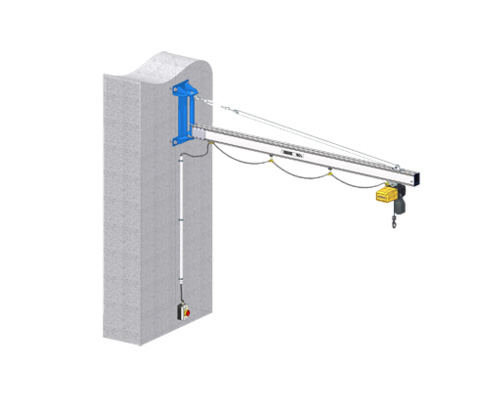

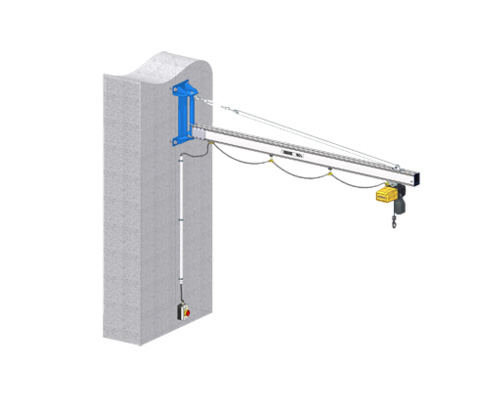

Slewing wall crane IPE steel beam

-

up to 5000 kg

Maximum use of room height by overhead jib arm.

Higher load capacities and jib lengths compared to jib cranes made of hollow profiles.

Use of manual or electric GIS trolleys.- Steel jib beam IPE

- Overhead jib

- Slewing range up to 180°

- Jib length up to 12 m, longer jibs on request

- Option: equipped with a telescope

- Option: equipped with trolley and slewing system electric

- Option: equipped with radio control

- Option: equipped with weather-protection package

- Option: equipped with pillar clasp

Articulated wall slewing crane GWD-TR

-

up to 250 kg

The articulated slewing wall crane GWD-TR allows a maximum slewing range.

To further increase positioning accuracy the jib arms can optionally be equipped with a regulator for the adjustment of the slewing resistance.

The articulated slewing crane comes to use whenever easy and fast handling of work pieces, tools and small parts is required.- Articulated jib crane with maximum slewing range

- Suitable for eccentric load suspension with GIS handy

- telescope

- Slewing range up to 180° (inside), or up to 330° (outside)

- Jib length up to 2.6 m, longer jibs on request

- Option: equipped with a brake at the inner and outer joint

- Option: equipped with pillar clasp

Mobile slewing jib crane

-

up to 250 kg

The mobile slewing jib crane allows the handling of loads at different locations.

This mobility in case of temporary workplaces or workplaces to be set up, but also in case of machine reconstructions and repairs is appreciated.- Easy to transport

- Use at different locations

- Pillar of slewing jib crane with a concrete base

- No anchorage on the floor

- Slewing range up to 270°

- Jib length on request

- Jib made of GISKB steel or aluminum hollow profile or IPE steel beam

Ceiling crane

-

up to 1000 kg

GIS ceiling cranes have the key benefit that they do not require any floor space, since they are mounted to stable ceilings.

The console of the jib crane can be combined with GISKB steel or aluminium hollow profiles or IPE steel beams. This helps to reach the required load capacity and jib arm length without limitation of the handling.- Installation on existing ceilings

- Slewing range up to 360°

- Jib length on request

- Jib made of GISKB steel or aluminum hollow profile or IPE steel beam

- No floor space required

Vacuum Handling Systems

Vacuum lifters

-

GIS vacuum lifters guarantee the gentle handling of goods of different materials like wood, glass, stone, metal or plastic.

Flat, convex and concave shapes with smooth or porous surfaces can be safely, effortlessly and gently transported with the appropriate vacuum lifter.

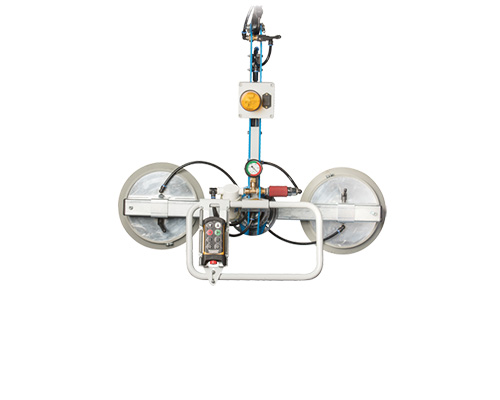

Ejector device GHGE

-

up to 320 kg

Vacuum lifters of the type GHGE are used for airtight goods such as glass, metal and plastic.

These units are designed for glazing glass panels and thus are mainly sold to the glass industry.

The vacuum is generated by compressed air, whereby the equipment is much smaller and lighter.

As a result, the investment is much lower, however the operating costs are slightly higher.- Developed for handling glass panels and other airtight transported goods

- Vacuum production with compressed air (no electrical cables necessary)

- With holder for control switch/radio control

- Complete solution including electric chain hoist, crane system or slewing crane

- Sturdy and durable devices

- Small and light device with low purchase costs

- Suction surfaces, traverses and operating panels can be tailored to customer needs

- Fully complies with the European Norm EN 13155 (warning system, two-handed operation, vacuum tank, non-return valve)

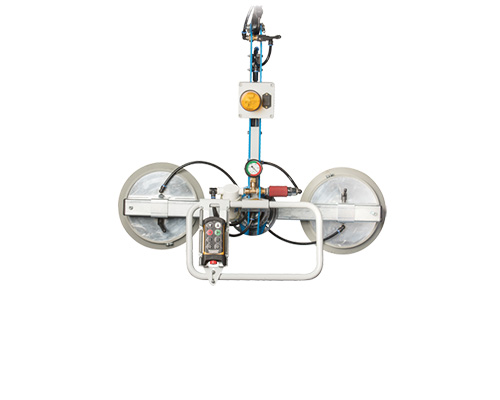

Vacuum lifter GH/K

-

up to 1000 kg, with tilting up to 500 kg

Vacuum lifters of the type GH/K are used for airtight goods such as glass, metal and plastic.

From standard products for sacks, cardboard boxes or panels, to customer-specific versions, we offer a wide range of vacuum lifting solutions.

Small transport loads with frequent handling or heavy, unwieldy transport goods with unusual handling – every vacuum system is tailored to its use and assures gentle material handling.- For airtight goods: metal, plastic, glass, stone...

- Central operating unit for complete crane system. With mounting for customer’s existing control switch/remote controller on request

- Complete solution including electric chain hoist, crane system or slewing crane

- Sturdy and durable devices

- Weight-saving construction with low installation height

- Suction surfaces, traverses and operating panels can be tailored to customer needs

- Available as glass lifting unit, turning unit or shelf storage operation unit

- Fully complies with the European Norm EN 13155 (Warning system, two-handed operation, vacuum tank, non-return valve)

Vacuum lifter GN/K

-

up to 500 kg, with tilting up to 500 kg

Vacuum lifters of the type GN/K are used for slightly air-permeable goods such as wooden boards, fibreboards, concrete slabs, cardboards, porous plastics and cheese loafs.

From standard products for sacks, cardboard boxes or panels, to customer-specific versions, we offer a wide range of vacuum lifting solutions.

Small transport loads with frequent handling or heavy, unwieldy transport goods with unusual handling – every vacuum system is tailored to its use and assures gentle material handling.- For slightly permeable goods: wooden panels and boards, concrete slabs, cardboard, textiles, cheeses

- Central operating unit for complete crane system. With mounting for customer’s existing control switch/remote controller on request

- Complete solution including electric chain hoist, crane system or slewing crane

- Sturdy and durable devices

- Weight-saving construction with low installation height

- Suction surfaces, traverses and operating panels can be tailored to customer needs

- Available as turning unit or shelf storage operation unit

- Fully complies with the European Norm EN 13155 (Warning system, two-handed operation, vacuum tank, non-return valve)

System and Components

Systems

-

A variety of special versions and a large range of accessories ensure practical solutions for every application.

Whether the transport goods have to be tilted or turned, we support you with the customer-specific vacuum handling system.

Storage and retrieval unit

-

up to 500 kg

- For efficient storage and retrieval of boards and pallets

- Lifting by vacuum lifter or lifting fork

- Optimum use of room height

- Lifting guide up to 360° slewable

- Tilting device available

- Electrically/manually movable

Free standing system

-

up to 320 kg

- In the case of high ceilings or insufficient support

- In combination with a GISKB crane system as a monorail or suspended crane

- Use at different locations

- Installation by fixing supports to the floor

Power supply

- Great attention is paid to the electrical equipment. Not only the energy supply of all motor-driven components, but also the control calls for clear and orderly planning. So we are using single or combined systems such as trailing cable, C-rail, conductor line or an energy chain. The conditions are determined by the customer’s requirements and local conditions.

Trailing cable

-

- Cable trolley inside profile or on steel beam

- For contaminated or humid environment

- Cost effective solution for monorail

- Suitable for outdoor use

- Option: equipped with compressed-air supply

C-rail

-

with trailing cable

- For contaminated or humid environment

- Suitable for outdoor use

- Use of the entire travel rangeSimple installation

- Option: for roving pendent

- Option: equipped with compressed-air supply

Conductor line

-

external

- Space-saving (no hanging cable) for crane and monorail system

- Use of the entire travel range

- Aesthetic solution

- Suitable for use with multiple crane bridges

- Option: IP 54 (dust protected for the wood industry)

Energy chain

-

several energy supplies

- Space-saving (no hanging cables)

- Use of the entire travel range

- Aesthetic solution

- Simple carrying of various cables (wiring harness) on crane bridge

- For power and compressed-air supply

- Perfectly suitable for vacuum lifters or pneumatic tools

Applications

Sewage Treatment Plant

- Whether a slewing jib crane or a gantry crane outdoors or a travelling crane indoors - GIS crane systems are adapted to the local conditions, such as an aggressive environment. Special paints, corrosion resistant components or increased IP protection class are part of our daily business. Early, conscientious clarification during the planning phase by our field service is therefore extremely important.

Agriculture and Farming

- The technical equipment in agriculture is usually subject to very tough conditions. Therefore, the quality of the equipment used is a crucial factor. As a Swiss manufacturer we guarantee our products for their robustness, reliability, durability and the same high quality. For outdoor use GIS electric chain hoists in the higher protection class IP65 can be supplied.

Automotive Industry / Trucks

- For process optimisation the automotive and commercial vehicle industries are dependent on smoothly functioning lifting devices. GIS electric chain hoists and cranes are used in areas where a business interruption cannot be afforded because it causes very high downtime costs generally. Our product portfolio offers a variety of solutions to increase efficiency and improve ergonomics.

Building sector

- In the provision of materials, in the material transport and on the construction site GIS electric chain hoists and cranes are important helpers for all lifting technical applications. The fully aluminium housing of the chain hoist is extremely robust and holds up to the not always careful handling on the construction site.

Chemistry and Pharmacy

- World-renowned companies such as Nestle, Novartis and Syngenta trust in the equipment of their production facilities on the decades of experience of GIS. Individual and tailored to the production processes in detail the crane systems help to increase productivity and ensure operational safety in the manufacturing process.

Glass processing industry

- GIS vacuum handling systems perfectly suitable are for the careful transportation of glass panels and glass panes. The largest version of the GIS vacuum lifter can lift glass from the central control unit and it can be flipped, rotated and transported horizontally. For the exclusive vertical transport of glass, the simpler version with of vacuum generation through compressed air, combined with a GIS electric chain hoist is sufficient.

Woodworking

- In sawmills, carpentries or furniture factories GIS cranes are often equipped with a vacuum lifter; very popular and widely deployed. They are ideal for transporting bulky and heavy loads. From the provision of the tree trunk through charging the mechanical processing to storage and retrieval, we offer complete handling solutions.

Plastics technology

- The demands placed on our products in this segment are very extensive. Whether an overhead crane, a small crane system, or a crane with chain hoist and suspension, we can usually offer an economic solution from our product portfolio. For load carrying the load hook of the chain hoist, the vacuum device used for sucking in the load or for custom load handling devices.

Machinery and plant engineering

- From our own experience we know the needs of the machine industry. With many of our customers GIS products are in intensive use on a daily basis. Be it as electric chain hoist which is installed in a machine or a crane system for load transport. World-renowned companies like Victorinox trust our products and services. Edwin Schuler, head of maintenance at Victorinox says: "GIS electric chain hoists and cranes have been used in our production plant for years, because we rely on Swiss quality and we appreciate proximity to the manufacturer with the appropriate expertise."

Metall and steel prosessing

- GIS travelling cranes, light crane systems or slewing jib cranes with electric chain hoist and trolley are used in this industry primarily for internal transport of goods. For particularly difficult local or spatial conditions we also design special constructions as telescopic cranes, cranes in low profile design for optimum utilisation of the room height or free-standing crane systems with unshielded or insufficiently resilient building structure.

Food industries

- Whether a crane system with big-bag cross or spreader beam for transporting feed sacks or galvanised and radio-controlled systems for the immersion of cheese wheels in a salt bath: the locations and applications for GIS crane systems and vacuum system solutions in the food industry are manifold. The requirements range from corrosion resistant components, via acid-resistant paint to the use of special food grade grease for the gearbox and the load chain of the electric chain hoist.

Public transport

- GIS electric chain hoists and cranes are used by countless suppliers and manufacturers of public transport such as rail, metro, tram, bus, post bus, boat, plane, funicular and cable car. On the one hand they are used for machine loading in producing components for public transport and on the other hand GIS cranes are also useful helpers in the maintenance and servicing of public transport.

Transport and logistic

- GIS crane systems and vacuum handling systems offer excellent support when assembling and palletising packaged finished products before delivery to the shipping department. With our lifting aids the handling of goods is carried out efficiently and ergonomically. Also in external logistics, such as in the aerial cable way Titlis, GIS electric chain hoists are used for the transport of goods or transport of the snow groomer from the valley station Engelberg.

Entertainment industry

- In theatres, schools, sports centres, multi-purpose halls, arenas, convention centres, TV studios or concert tours GIS electric chain hoists are in use worldwide. They are quiet in operation, light and compact, which is why they are ideally suited for the special requirements of the entertainment industry. Whether as a permanent installation in opera houses such as Zurich, Helsinki and Sydney, in O2 arenas like Berlin or Prague or as a climbing hoist in mobile events: our customers appreciate the reliability and operational safety of GIS electric chain hoists and the corresponding durability.

Wind- and waterpower

- Mainly used for maintenance work on the generators our travelling cranes, bridge cranes and electric chain hoists used in hydroelectric power plants. Up to 150 m in height above ground the GIS electric chain hoists come up in the nacelle (gondola) for repair and maintenance work in wind turbines. The fitter appreciates especially that the fast rising speed of the electric chain hoist automatically reduces before reaching the gondola. He does not need to monitor continuously for up to 15 minutes the lifting operation and can concentrate in the meantime on other work.