AMC Europe

- Offer Profile

-

Welcome to AMC Europe Ltd., European headquarters of ADVANCED Motion

Controls, a world leader in servo drive solutions and precision motion controls,

headquartered in California, USA.

ADVANCED Motion Controls was founded in 1987 to provide high quality servo amplifiers and drives for the rapidly expanding automated machinery demands in many industries. AMC’s focus is working with customers to develop and produce motion control amplifiers and drives capable of delivering from 20 W up to 48 kW peak.

ADVANCED Motion Controls has numerous standard products available but also provides custom products for OEMs with specific requirements or special option adaptations that meet their needs. Designs include both analog and digital technology covering a broad range of solutions. The newly introduced Digiflex® family offers multiple configuration capabilities, networking solutions, and provisions for optional software libraries to reduce programming time.

Product Portfolio

Servo Drives

Performance

High performance servo drives start with optimally tuned current loops with fast update rates, then progresses to velocity and position loops that match the machine's dynamics. FlexPro and DigiFlex Performance servo drives are easily tuned through software including the current, velocity and position loops. AxCent servo drives come configured with current loop tuning parameters that are suitable for most applications, but can be further optimized using traditional tuning methods.Power

Our servo drives range from 50W to over 20,000W of continuous power; with peak ratings typically double the continuous rating. We have a wide selection of sub-80V servo drives that are ideal for battery powered systems like mobile robotics and portable devices including IMR, AMR, AGV, medical and laboratory applications. Higher voltage servo drives are available from 120VAC to 480VAC as well as the equivalent DC voltage levels to cover most industrial applications.Network Connectivity

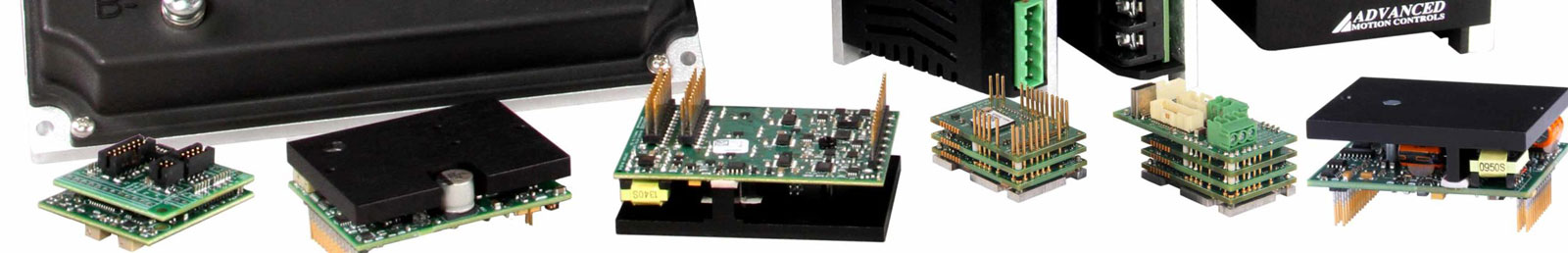

Supported networks include EtherCAT, CANopen, EtherNet/IP, RS485 and more. Machines can be readily adapted for Industry 4.0 and Smart Factories since most servo drive parameters are accessible by the controller over the network bus.Shape and Size

We make it easy for machine designers to find servo drives that physically fit into their applications by offering a variety of form factors. Panel Mount drives are typically found in factories and industrial settings, PCB Mount drives are perfect for tightly integrated systems, while machine embedded designs are a convenient blend of the two. Regardless of the form factor, performance is never sacrificed.Analog Drives

100A40

- Panel Mount: Classic

SPECIFICATIONS- Current Continuous (A) 50

- Current Peak (A) 100

- DC Supply Voltage (VDC) 80 - 400

- Network Communication None

- Size (mm) 235 x 183.2 x 92.4

- Weight (g) 3410

The 100A40 panel mount servo drive is targeted for centralized control and offers high bandwidth and quick response times.- CONTROL/COMMAND

±10 V Analog - PRIMARY FEEDBACK

Tachometer (±60 VDC) - OPERATING MODE

- Current

- IR Compensation

- Velocity

- Voltage

- MOTOR TYPE

Single Phase (Brushed)

120A10

- Panel Mount:

Classic

SPECIFICATIONS- Current Continuous (A) 60

- Current Peak (A) 120 DC

- Supply Voltage (VDC) 20 - 80

- Network Communication None

- Size (mm) 254 x 130.2 x 48.7

- Weight (g) 1140

The 120A10 panel mount servo drive is targeted for centralized control and offers high bandwidth and quick response times.- CONTROL/COMMAND

±10 V Analog - PRIMARY FEEDBACK

Tachometer (±60 VDC) - OPERATING MODE

- Current

- IR Compensation

- Velocity

- Voltage

- MOTOR TYPE

Single Phase (Brushed)

B30A40

- Panel Mount:

AxCent

SPECIFICATIONS- Current Continuous (A) 15

- Current Peak (A) 30

- DC Supply Voltage (VDC) 60 - 400

- Network Communication None

- Size (mm) 203.2 x 142.9 x 40.7

- Weight (g) 990

The B30A40 AxCent™ panel mount servo drive is targeted for centralized control and offers high bandwidth and quick response times.- CONTROL/COMMAND

±10 V Analog - PRIMARY FEEDBACK

- Halls

- Incremental Encoder

- Tachometer (±60 VDC)

- OPERATING MODE

- Current

- Duty Cycle (Open Loop)

- Hall Velocity

- Velocity

- MOTOR TYPE

- Three Phase (Brushless)

- Single Phase (Brushed)

B30A40AC

- Panel Mount:

AxCent

SPECIFICATIONS- Current Continuous (A) 15

- Current Peak (A) 30

- DC Supply Voltage (VDC) 60 - 400

- AC Supply Voltage (VAC) 45 - 265

- Network Communication None

- Size (mm) 203.2 x 165.7 x 103.1

- Weight (g) 2230

The B30A40AC AxCent™ panel mount servo drive is targeted for centralized control and offers high bandwidth and quick response times.- CONTROL/COMMAND

±10 V Analog - PRIMARY FEEDBACK

- Halls

- Incremental Encoder

- Tachometer (±60 VDC)

- OPERATING MODE

- Current

- Duty Cycle (Open Loop)

- Hall Velocity

- Velocity

- MOTOR TYPE

- Three Phase (Brushless)

- Single Phase (Brushed)

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (24V)

- Encoder Following

- Indexing Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

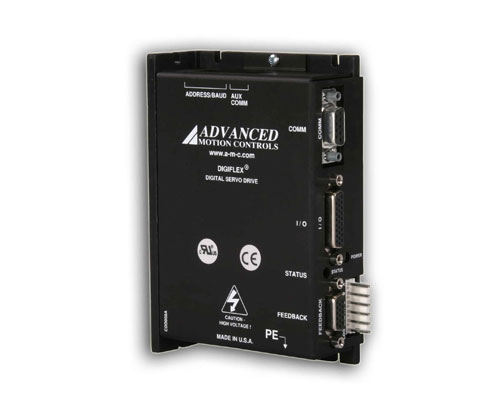

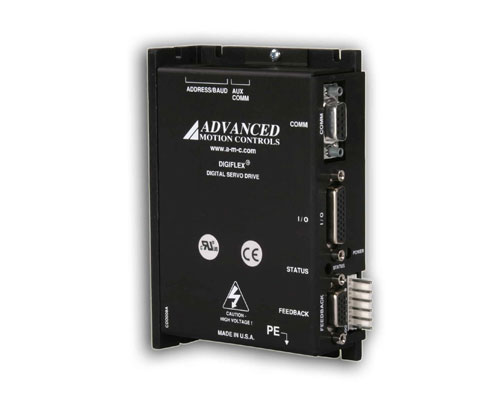

Digital Drives

DPRAHIE-030A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 15

- Current Peak (A) 30

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 91.4

- Weight (g) 5437

The DPRAHIE-030A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (24V)

- Encoder Following

- Indexing Jogging

- Over the Network PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall

- Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRAHIE-060A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 30

- Current Peak (A) 60

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 140.91

- Weight (g) 6165

The DPRAHIE-060A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (24V)

- Encoder Following

- Indexing

- Jogging

- Over the Network PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTE-015B200

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 7.5

- Current Peak (A) 15

- DC Supply Voltage (VDC) 40 - 190 Network Communication Modbus RTU, RS-485/232

- Size (mm) 132.5 x 89.5 x 35.9

- Weight (g) 486

The DPRALTE-015B200 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTE-020B080

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 10

- Current Peak (A) 20

- DC Supply Voltage (VDC) 20 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 132.5 x 89.5 x 35.9

- Weight (g) 486

The DPRALTE-020B080 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTE-025B200

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12.5

- Current Peak (A) 25

- DC Supply Voltage (VDC) 20 - 190

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 190.5 x 111.8 x 35.9

- Weight (g) 872

The DPRALTE-025B200 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTE-040B080

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 20

- Current Peak (A) 40

- DC Supply Voltage (VDC) 20 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm)190.5 x 111.8 x 35.9

- Weight (g) 872

The DPRALTE-040B080 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTR-015B200

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 7.5

- Current Peak (A) 15

- DC Supply Voltage (VDC) 40 - 190

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 132.5 x 89.5 x 35.9

- Weight (g) 486

The DPRALTR-015B200 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTR-015B200

- Panel Mount: DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 7.5

- Current Peak (A) 15

- DC Supply Voltage (VDC) 40 - 190

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 132.5 x 89.5 x 35.9

- Weight (g) 486

The DPRALTR-015B200 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DPRALTR-025B200

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12.5

- Current Peak (A) 25

- DC Supply Voltage (VDC) 20 - 190

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 190.5 x 111.8 x 35.9

- Weight (g) 872

The DPRALTR-025B200 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRALTR-040B080

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 20

- Current Peak (A) 40

- DC Supply Voltage (VDC) 20 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 190.5 x 111.8 x 35.9

- Weight (g) 872

The DPRALTR-040B080 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRANIE-030A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 15

- Current Peak (A) 30

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 91.4

- Weight (g) 5437

The DPRANIE-030A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DPRANIE-060A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 30

- Current Peak (A) 60

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 140.91

- Weight (g) 6165

The DPRANIE-060A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRANIR-030A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 15

- Current Peak (A) 30

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 91.4

- Weight (g) 5437

The DPRANIR-030A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder

- Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DPRANIR-060A800

- Panel Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 30

- Current Peak (A) 60

- DC Supply Voltage (VDC) 255 - 747

- AC Supply Voltage (VAC) 200 - 480

- Network Communication Modbus RTU, RS-485/232

- Functional Safety Safe Torque Off (STO)

- Size (mm) 300.5 x 231.3 x 140.91

- Weight (g) 6165

The DPRANIR-060A800 DigiFlex® Performance™ panel mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Resolver

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DZCANTE-012L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 6

- Current Peak (A) 12

- DC Supply Voltage (VDC) 20 - 80

- Network Communication CANopen

- Size (mm) 63.5 x 50.8 x 18.4

- Weight (g) 99.8

The DZCANTE-012L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls Incremental

- Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DZCANTE-020L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12

- Current Peak (A) 20

- DC Supply Voltage (VDC) 10 - 80

- Network Communication CANopen

- Size (mm) 63.5 x 50.8 x 22.9

- Weight (g) 105

The DZCANTE-020L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DZCANTE-025L200

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12.5

- Current Peak (A) 25

- DC Supply Voltage (VDC) 40 - 175

- Network Communication CANopen

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZCANTE-025L200 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes Current Position Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZCANTE-060L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 30

- Current Peak (A) 60

- DC Supply Voltage (VDC) 10 - 80

- Network Communication CANopen

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZCANTE-060L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZEANTU-020B080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 10

- Current Peak (A) 20

- DC Supply Voltage (VDC) 18 - 80

- Network Communication EtherCAT, DxM Technology

- Functional Safety Safe Torque Off (STO)

- Size (mm) 88.9 x 63.5 x 20.1

- Weight (g) 126

The DZEANTU-020B080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo drive utilizes EtherCAT® communication and is commissioned with DriveWare® via a USB interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- 1Vp-p Sine/Cosine Encoder

- BiSS C-Mode

- EnDat® 2.1

- EnDat® 2.2 Halls

- Hiperface®

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Profile Modes

- Cyclic Synchronous Modes

- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DZRALTE-012L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 6

- Current Peak (A) 12

- DC Supply Voltage (VDC) 20 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 63.5 x 50.8 x 18.4

- Weight (g) 99.8

The DZRALTE-012L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo driver utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZRALTE-020L080

- PCB Mount.

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12

- Current Peak (A) 20

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 63.5 x 50.8 x 22.9

- Weight (g) 105

The DZRALTE-020L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo driver utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental

- Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZRALTE-025L200

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 12.5

- Current Peak (A) 25

- DC Supply Voltage (VDC) 40 - 175

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZRALTE-025L200 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo driver utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction Stepper

DZRALTE-040L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 20

- Current Peak (A) 40

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZRALTE-040L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo driver utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall

- Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZRALTE-060L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 30

- Current Peak (A) 60

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZRALTE-060L080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. This servo driver utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZSANTU-020B080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 10

- Current Peak (A) 20

- DC Supply Voltage (VDC) 18 - 80

- Network Communication DxM Technology

- Functional Safety Safe Torque Off (STO)

- Size (mm) 88.9 x 63.5 x 20.1

- Weight (g) 124

The DZSANTU-020B080 DigiFlex® Performance™ pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems. DZSANTU servo drives are designed for use as sub-nodes on an EtherCAT® network and must be used in conjunction with a DZEANTU node. This drive utilizes DxM™ Technology and is commissioned with DriveWare® via a USB interface.

CONTROL/COMMAND- Over the Network

PRIMARY FEEDBACK- ±10 VDC Position

- 1Vp-p Sine/Cosine Encoder

- BiSS C-Mode

- EnDat® 2.1

- EnDat® 2.2

- Halls

- Hiperface®

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Profile Modes

- Cyclic Synchronous Modes

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXCANTE-008L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 4

- Current Peak (A) 8

- DC Supply Voltage (VDC) 10 - 80

- Network Communication CANopen

- Size (mm) 63.5 x 50.8 x 22.9

- Weight (g) 105

The DZXCANTE-008L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXCANTE-015L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 7.5

- Current Peak (A) 15

- DC Supply Voltage (VDC) 10 - 80

- Network Communication CANopen

- Size (mm) 63.5 x 50.8 x 22.9

- Weight (g) 105

The DZXCANTE-015L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXCANTE-040L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 20

- Current Peak (A) 40

- DC Supply Voltage (VDC) 10 - 80

- Network Communication CANopen

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZXCANTE-040L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes CANopen® communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls Incremental

- Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Interpolated Position Mode (PVT)

- Profile Modes

- Cyclic Synchronous Modes

- Current

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXRALTE-008L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 4

- Current Peak (A) 8

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 63.5 x 50.8 x 22.9

- Weight (g) 105

The DZXRALTE-008L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXRALTE-015L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 7.5

- Current Peak (A) 15

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 63.5 x 50.8 x 22.9 Weight (g) 105

The DZXRALTE-015L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position

- Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

DZXRALTE-040L080

- PCB Mount:

DigiFlex Performance

SPECIFICATIONS- Current Continuous (A) 20

- Current Peak (A) 40

- DC Supply Voltage (VDC) 10 - 80

- Network Communication Modbus RTU, RS-485/232

- Size (mm) 76.2 x 50.8 x 22.9

- Weight (g) 123

The DZXRALTE-040L080 DigiFlex® Performance™ extended environment pcb mount servo drive offers full tuning control of all servo loops and is designed for distributed or centralized servo systems in harsh temperatures or rugged environments. This servo motor drive utilizes RS485 or Modbus RTU communication and is commissioned with DriveWare® via an RS-232 interface.

CONTROL/COMMAND- ±10 V Analog

- Step & Direction (5V)

- Encoder Following

- Indexing

- Jogging

- Over the Network

- PWM and Direction

- Sequencing

PRIMARY FEEDBACK- ±10 VDC Position

- Halls

- Incremental Encoder

- Tachometer (±10 VDC)

OPERATING MODE- Current

- Hall Velocity

- Position Velocity

MOTOR TYPE- Three Phase (Brushless)

- Single Phase (Brushed)

- AC Induction

- Stepper

Motion Control

Performance

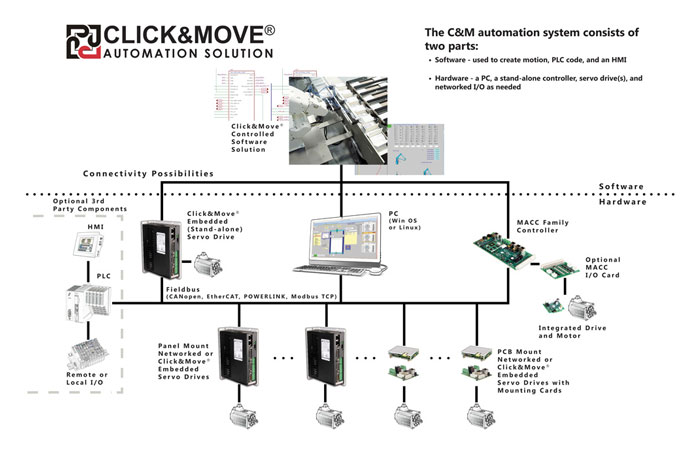

At ADVANCED Motion Controls, our goal was to create a development environment that enables the quick and efficient creation of control programs. We named this system Click&Move® (C&M). This gives you and other system designers the freedom to choose among a wider variety of motion control system. Applications created with Click&Move® can be simple, single-axis, with minimal I/O to complex, multi-axis coordinated movement in real-time.Click&Move Automated Software Solution

- The building blocks of the Click&Move system are the integrated development system desktop, sophisticated function block editor with function block libraries (logic,math,motion,I/O, etc.), C++ compiler, runtime graphical debugger, virtual drive.

Click&Move Quick Facts

- Combines Motion, PLC, and HMI control

- Based on PLCopen, the standard for industrial motion control programming

- Supports CANopen, EtherCAT, and POWERLINK network protocols

- Fully IEC 61131-3 compliant using graphical Function Block Diagrams (FBDs) (pre-configured or user-defined)

- Multiple platforms supported: PC (Win OS, Linux OS or Xenomai real-time framework integrated into Linux environment), stand-alone controller (MACC), and ADVANCED Motion Controls’ drives

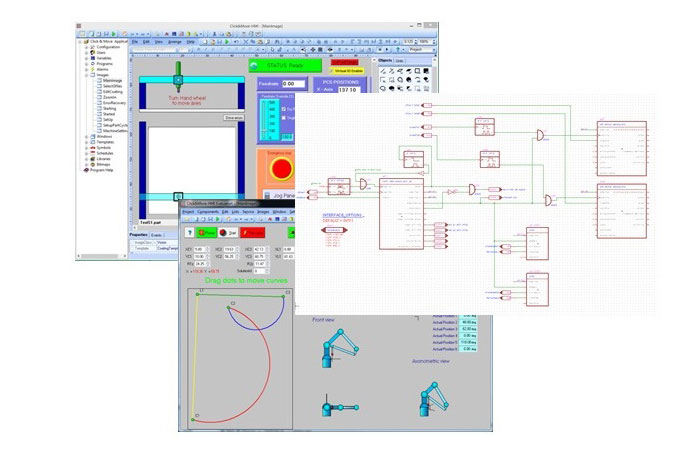

Integrated Design Environment

-

- The C&M Integrated Development Environment (C&M Desktop) provides the user with a programming environment for a range of applications:

- Motion control

- PLC machine control

- G-code file handling for CNC apps

- Process control

- Robotics

The Desktop consists of applications that can be used to create a C&M project, graphically create and edit the function block diagrams (FBDs) of the project, compile the FBDs, debug the code, organize and archive the project files, and test the completed application using the minHMI application, whose GUI automatically adapts to the input/output variables of the CMMain FBD of the project.

- The C&M Integrated Development Environment (C&M Desktop) provides the user with a programming environment for a range of applications:

HMI

- Click&Move® collects several aspects of motion control, real-time computation, and human interface into a single application. On the HMI screen, users can enter commands, enable and disable individual servo drives, display system information, set parameters, and even display a dynamic graphical representation of the motion system (such as a robot wire diagram), which is updated periodically. The system can be configured to automatically generate HMI source code templates that the user can further develop. Multiple source languages can be set, such as C++ code for Qt framework, Python code for Tkinter graphics library, etc.

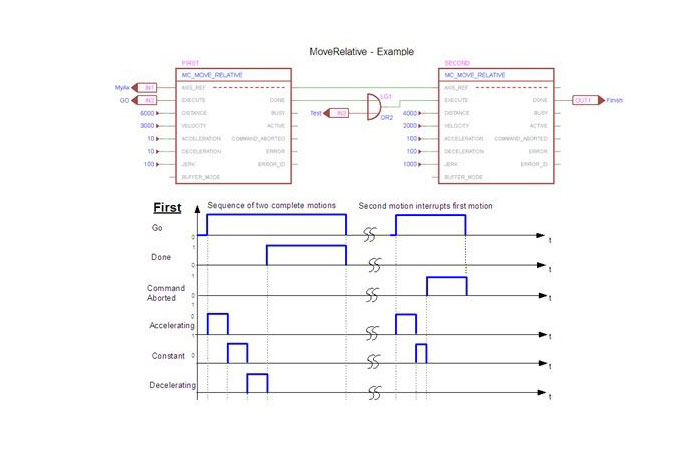

Motion Control Blocks and G-Code

- The motion control of the system is based on the PLCopen standard. The standard provides a wide selection of motion control function blocks for the developer of the control program. With these function blocks, all motions can be programmed, from single-axis to multi-axis coordinated motions. The standard defined only the interface for coordinated motions, not the kinetic relationship of the axes. The standard left this to the implementer. The C&M motion library provides function blocks for many kinetic connections, such as three-axis Cartesian robot, six-axis robot, delta robot, etc.

Conventional machine tools are controlled by G code. The C&M system supports the creation of a controller for G-code controlled machines. The C&M G-code processor supports many G-code dialects and even allows you to control robots with G-code. The system also includes an advanced G-code editor.

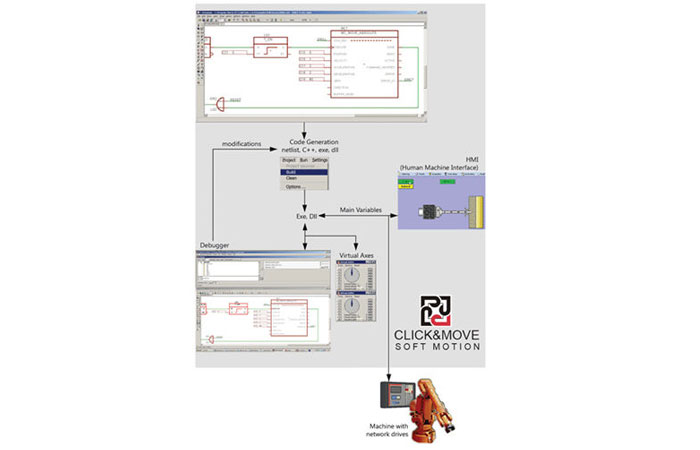

Debugging

-

- Application programming using PLCopen FBD language (IEC 61131-3)

- The development process can take place entirely within the user´s PC

- Virtual axes for motion simulation

- Virtual axis projects can be packaged and exchanged with tech support

- Entirely digital development system helps the support process virtual axes are more portable than real ones

- Debugging tools: graphical and text-based

- Integrated minimal HMI

- Extensive built-in Help - Tutorials, Demos, White Papers, etc.

- Extensive example applications

Solution Architectures

- A Click&Move® system can be put together in thousands of ways, but most architectures follow one of three main structures. The preferred method depends on the application.

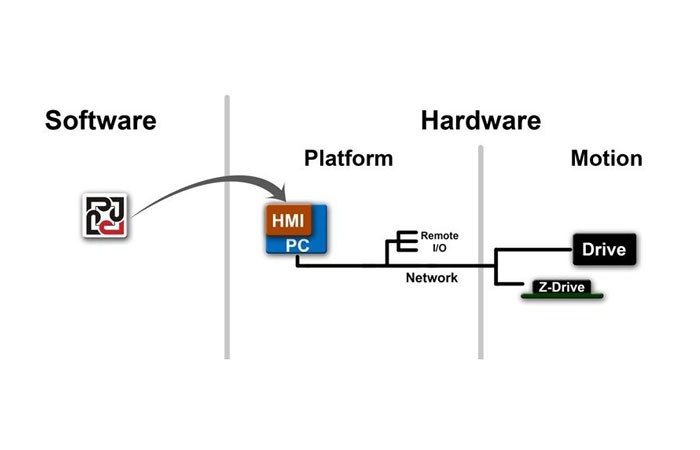

The three structures are:- PC based with non real-time operating system (Windows or Linux)

- PC based with real-time operating system

- Motion Automation Control Card.

PC based with non real-time operating system

In the PC-based solution, the C&M development software is used to create controller code. The code is compiled for the targeted PC platform and then downloaded. Servo drives and I/O are connected to the PC platform via the network. This structure is recommended for CANopen systems.

PC based with real-time operating system

- The POWERLINK and the EtherCAT system can only work on a real-time system. Configuring a well-functioning realtime operating system is not an easy task. Therefore, traditional computers can be purchased from AMC, on which AMC pre-installs a real-time operating system. This operating system is typically the Linux Xenomai system.

The PC-based architecture (real-time Linux environment on a PC) is obviously best-suited for applications where having a PC connected to the system during operation is feasible, such as industrial machines, gantries, and other devices that remain largely stationary. It's also the preferred architecture for any system that has more than 8 motion axes.

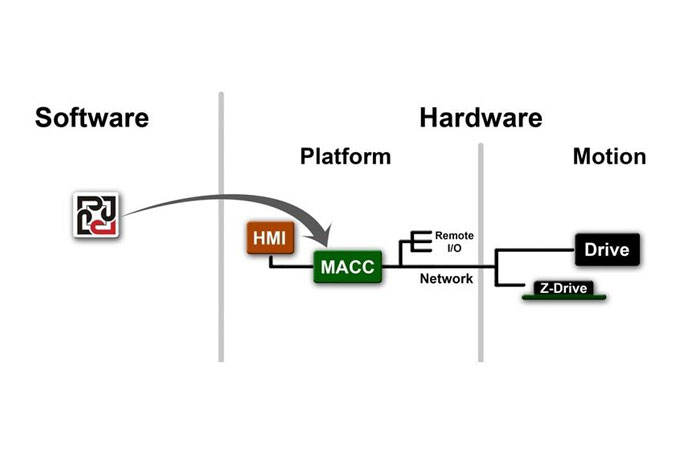

Motion Automation Control Card

- The Motion Automation Control Card (MACC) is a general purpose motion/automation controller with embedded Click&Move® capability. In this scenario, the code is compiled for the MACC platform and then downloaded. The servo drives and I/O are connected to the MACC platform via the network.

The MACC solution is suitable for mobile applications such as AGV's. The MACC is best suited for applications with a combination of both digital and analog servo drives.

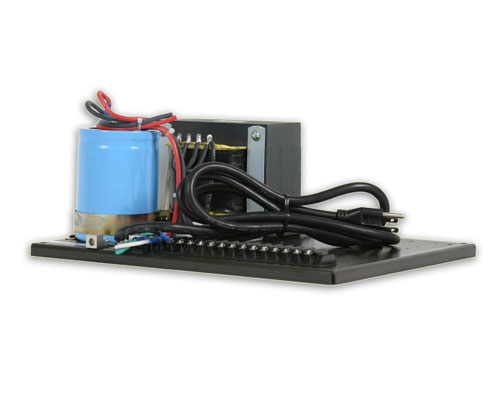

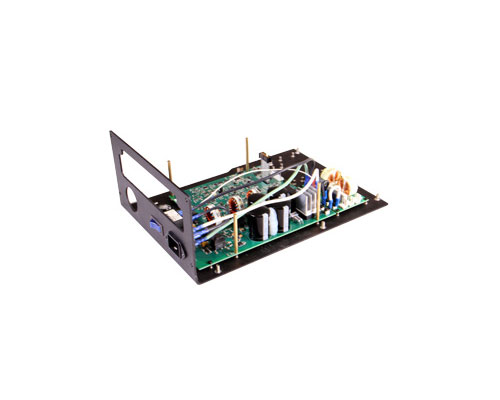

Power Supplies

PFC2400W375

- SPECIFICATIONS

- Output Voltage (DC) 375

- Current Continuous (A) 6.4

- Rated Power Continuous (kw) 2.4

- AC Supply Voltage (VAC) 120, 240

- AC Input Phases 1

- Additional Features Power Factor Correction,Regulated,Built-in Shunt Regulator

PS16H120-L

- SPECIFICATIONS

- Output Voltage (DC) 120

- Current Continuous (A) 7

- Rated Power Continuous (kw) 0.8

- AC Input Phases 1

- Additional Features Isolation

The PS16H120-L is an unregulated power supply with an isolation transformer.

PS16H160

- SPECIFICATIONS

- Output Voltage (DC) 160 Current Continuous (A) 5

- Rated Power Continuous (kw) 0.8

- AC Input Phases 1

- Additional Features Isolation

The PS16H160 is an unregulated power supply with an isolation transformer.

PS16H30-L

- SPECIFICATIONS

- Output Voltage (DC) 30

- Current Continuous (A) 27

- Rated Power Continuous (kw) 0.8

- AC Input Phases 1

- Additional Features Isolation

The PS16H30-L is an unregulated power supply with an isolation transformer.

PS16L120-L

- SPECIFICATIONS

- Output Voltage (DC) 120

- Current Continuous (A) 7

- Rated Power Continuous (kw) 0.8

- AC Input Phases 1

- Additional Features Isolation

The PS16L120-L is an unregulated power supply with an isolation transformer.

PS16L60

- SPECIFICATIONS

- Output Voltage (DC) 60

- Current Continuous (A) 13

- Rated Power Continuous (kw) 0.8

- AC Input Phases 1

- Additional Features Isolation

The PS16L60 is an unregulated power supply with an isolation transformer.

PS300H24

- SPECIFICATIONS

- Output Voltage (DC) 24

- Current Continuous (A) 12

- Rated Power Continuous (kw) 0.3

- AC Input Phases 1

- Additional Features Isolation

The PS300H24 is an unregulated power supply with an isolation transformer.

PS300W170

- SPECIFICATIONS

- Output Voltage (DC) 170

- Current Continuous (A) 15

- Rated Power Continuous (kw) 2.55 AC

- Input Phases 1

The PS300W170 is a non-isolated unregulated power supply.

PS30A

- SPECIFICATIONS

- Output Voltage (DC) 340

- Current Continuous (A) 15

- Rated Power Continuous (kw) 10.1

- AC Input Phases 3

- Additional Features Built-in Shunt Regulator,Built-in Shunt Resistor

The PS30A is a non-isolated unregulated power supply.

Other Accessories

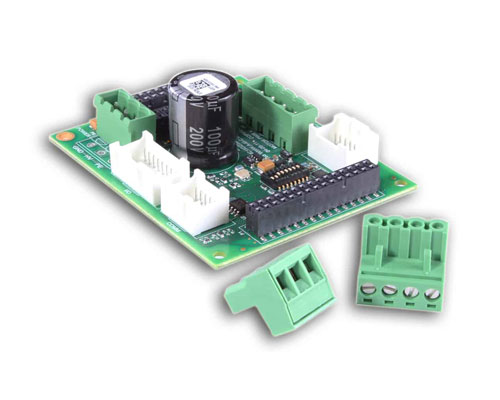

Mounting Card MC1XAZ01

- Family: AxCent

- Size (mm)101.6 x 71.9 x 15.7

- Weight (g) 58.3

- Current Peak (A) 25

The MC1XAZ01 mounting card is designed to hold an AxCent™ family pcb mount servo drive to simplify connection to the controller, motor, and feedback.

Mounting Card MC1XAZ02

- Family: AxCent

- Size (mm) 38.1 x 38.1 x 16.2

- Weight (g) 11.3

- Current Peak (A) 10

The MC1XAZ02 mounting card is designed to hold a micro-size AxCent™ family pcb mount servo drive to simplify connection to the controller, motor, and feedback.

Mounting Card MC1XDZC03-QD

- Family: DigiFlex Performance

- Size (mm) 63.5 x 76.2 x 25.4

- Weight (g) 50.7

- Network Communication CANopen

- Current Peak (A) 25

The MC1XDZC03-QD mounting card is designed to hold a DZCANTE or DZXCANTE DigiFlex® Performance™ family pcb mount servo drive to simplify connection to the controller, motor, and feedback. The motor and power connectors utilize quick-disconnect style connections.

Shunt Regulator SRST175

- SPECIFICATIONS

- Clamping Voltage 175

- Rated Dissipation Capability (W) 95

- Size (mm) 203.2 x 108.0 x 66.70

- Weight (g) 385

The SRST175 shunt regulator clamps the supply voltage to 175 VDC during regeneration or voltage fluctuations.

Shunt Regulator SRST380

- SPECIFICATIONS

- Clamping Voltage 380

- Rated Dissipation Capability (W) 190 Size (mm) 203.2 x 108.0 x 66.70

- Weight (g) 385

The SRST380 shunt regulator clamps the supply voltage to 380 VDC during regeneration or voltage fluctuations.

Shunt Regulator SRST50

- SPECIFICATIONS

- Clamping Voltage 50

- Rated Dissipation Capability (W) 95

- Size (mm) 203.2 x 108.0 x 66.70

- Weight (g) 385

The SRST50 shunt regulator clamps the supply voltage to 50 VDC during regeneration or voltage fluctuations.

Connector Kit KC-23AMPSEAL01

- Family: AxCent

The KC-23AMPSEAL01 mating connector kit provides connector housing, socket contacts and seal plugs. Refer to the mating connector kit datasheet for compatible servo drives.

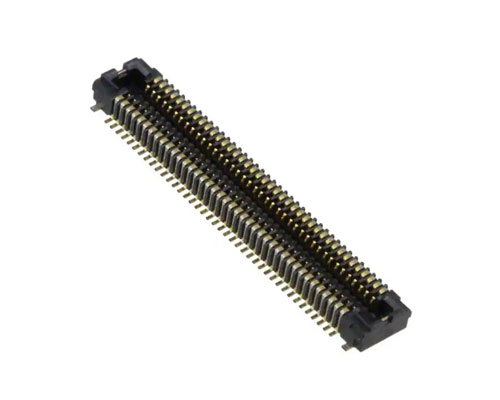

Connector Kit KC-MC1XDZ02

- Family: DigiFlex Performance

The KC-MC1XDZ02 mating connector kit provides mating connector housing and crimp pins. Refer to the mating connector kit datasheet for compatible mounting cards.

Connector Kit KC-MC1XFE01

- Family: FlexPro

The KC-MC1XFE01 mating connector kit provides a surface mount board connector and board spacers. Refer to the mating connector kit datasheet for compatible servo drive models.

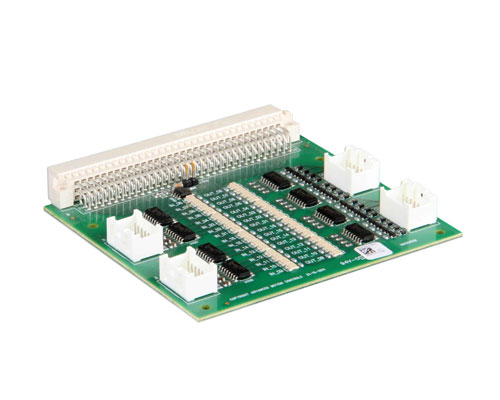

MACC I/O Board MACCIO1

- SPECIFICATIONS

- Size (mm) 219.96 x 99.95 x 13.60

- Weight (g) 153

The MACCIO1 module features the necessary digital and analog I/O’s to support up to four current mode servo drives with ±10V analog command input. A cost-effective and high performance motion control system can be built using the hardware resources of the MACC on-board FPGA and the software resources of the Click&Move® software development environment.- 8 16-bit analog inputs

- 8 16-bit digital inputs

- 16 optocoupled digital inputs

- 16 optocoupled digital outputs

- 2×4 isolated high speed RS422 differential outputs

- 4 isolated high speed RS422 differential inputs

- 4 incremental or EnDat 2.0 encoder inputs (population option)

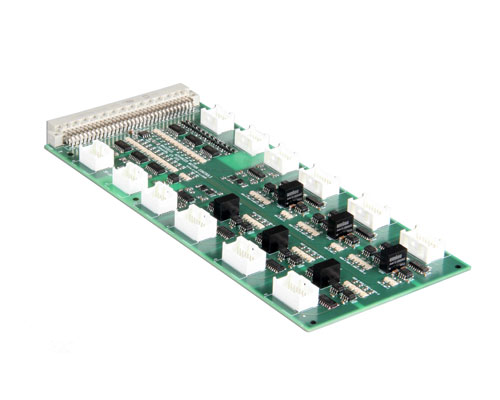

MACC I/O Board MACCIO2

- SPECIFICATIONS

- Size (mm) 99.9 x 80.0 x 11.5

- Weight (g) 53.9

The MACCIO2 module is a minimal solution for simple applications, using switches as input devices and LEDS or small signal relays on the output.- 16 optocoupled digital inputs

- 16 optocoupled digital outputs

MACC I/O Board MACCIO3

- SPECIFICATIONS

- Size (mm) 219.96 x 99.95 x 11.04

- Weight (g) 127

The MACCIO3 module features the necessary digital I/O’s to support up to six position mode servo or stepper drives with Step/Dir command input. A cost-effective and high performance motion control system can be built using the hardware resources of the MACC on-board FPGA and the software resources of the Click&Move® software development environment.- 12 optocoupled digital inputs 2 high speed differential optocoupled digital inputs

- 12 optocoupled digital outputs

- 12 high-speed RS422 differential digital inputs (2 per axis – galvanic isolation population option)

- 24 high-speed RS422 differential digital outputs (4 per axis – galvanic isolation population option)

- 4 independent encoder inputs supporting encoders or handwheels

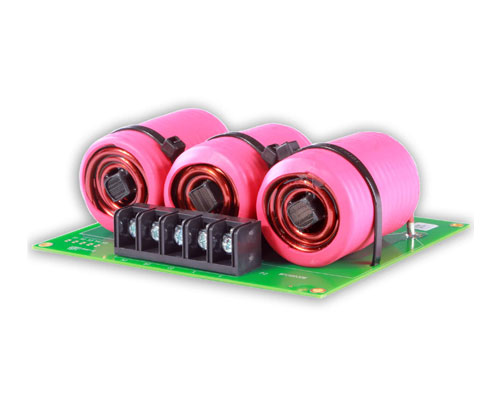

Filter Card BFC10010

- SPECIFICATIONS

- Current Continuous ( A) 10

- Inductance (Line to Line) 200

- Size (mm) 71.0 x 50.6 x 25.0

- Weight (g) 210

The BFC10010 filter card provides additional inductance to meet minimum inductance requirements and reduce PWM switching noise. For use with three phase (brushless) motors.

Filter Card BFC1010

- SPECIFICATIONS

- Current Continuous ( A) 10

- Inductance (Line to Line) 20

- Size (mm) 56.5 x 28.6 x 15.8

- Weight (g) 37

The BFC1010 filter card provides additional inductance to meet minimum inductance requirements and reduce PWM switching noise. For use with three phase (brushless) motors.

Filter Card BFC15030

- SPECIFICATIONS

- Current Continuous ( A) 30

- Inductance (Line to Line) 300

- Size (mm) 134.6 x 113.7 x 43.5

- Weight (g) 1430

Custom Servo Drives & Accessories

- One of the things that sets us apart from our competitors is our willingness to make modified and custom servo drives and other products. We’ve been making custom servo amplifiers nearly since the beginning. Today, make up about one third of our business. Modified products make up another third.

While developing a custom servo drive for a customer, we work closely with them to give them a servo solution that does everything they need. This can include creating drives that have different connectors, shape, number of axes, and other features than our usual product offering.Modified Servo Solution Options

ADVANCED Motion Controls’ offering of off-the-shelf products encompasses a wide range of power, performance, and design considerations. However, sometimes a few minor adjustments to a standard product can be beneficial to make things just right for a specific application without the need to invest in a fully-custom solution. A modified solution can quickly be realized and greatly increase machine performance. Best of all, we’ll do it for you!

For years, ADVANCED Motion Controls has happily produced and sold modified versions of our off-the-shelf servo drive products. In fact, modified servo drives make up approximately a third of our business. Whether it’s a tweak to the drive’s loop tuning or a the customer’s logo silkscreen printed on the cover, small modifications guarantee everyone gets a solution that is specifically tailored to them.

With simple modifications, the cost per unit can be near parity with standard products. As quantities go up, the difference will be less. Also, some options are available that may actually make the modified design cost less than the standard. For example, some customers like their units without the servo drive cover, which reduces the material cost.

Examples of Modified Products and Options

- Tuning to a Specific Machine

- Gain Adjustments

- Current Limits and Voltage Limits

- Temperature, Shock, and IP Considerations

- Conformal Coating

- Silkscreen Branding

- Inverted Inhibit Logic

- Quick disconnect, and many more!

Custom Servo Solution Options

- ADVANCED Motion Controls has a broad servo drive offering and the ability to sell products in a modified form, but some motion control applications need something much different from the off-the-shelf models we offer. Thankfully, ADVANCED Motion Controls has the capability to promptly develop and deliver specified products for OEMs with volume requests.

It can start with a crazy idea, feature creep or near impossible specifications, but sometimes you just have to start over from scratch. Starting with a fresh design affords endless possibilities allowing the designer to expand capabilities beyond servo drive functions including full integration of peripheral components.

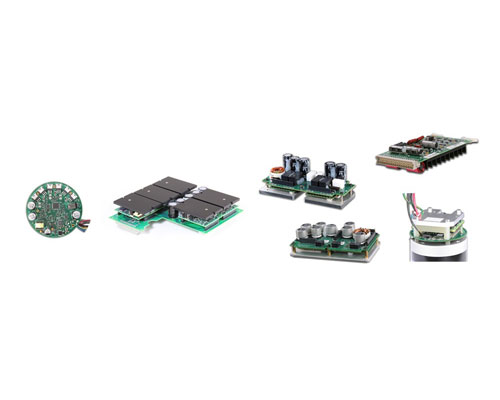

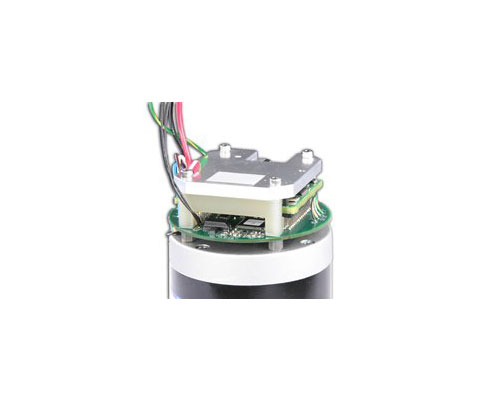

Non-Conventional Shape

- Rather than try to fit a square peg into a round hole, why not find the peg that fits? Some motion control applications can be very limited on space for electronics, which means there might not be room for a standard servo drive. This is where a custom servo drive can be essential. We have delivered all shapes of custom drives including round ones that were integrated onto the backs of motors.

It's not always a matter of changing a rectangle into a circle; Maybe you just need to reduce the width and can sacrifice a little length, or reduce the footprint and sacrifice height.

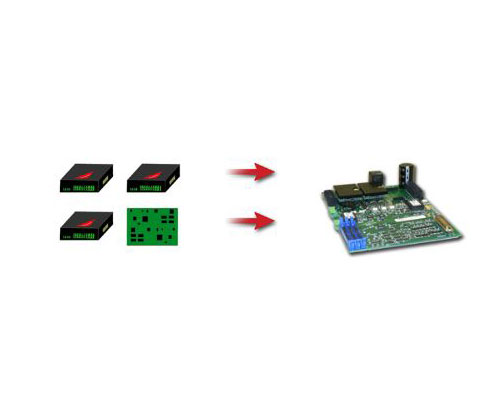

Multiple Axes

- Individual servo drives are typically used to drive one motor and one motor only. However, many applications have multiple motors working together. Rather than using multiple servo drives, you can get a custom multi-axis servo drive that can control more than one motor at once.

Multi-axis designs are smaller than the sum of their parts because they reduce redundant functions and components and take advantage of board layout.

Integrated Drives and Controls

- We pride ourselves on manufacturing servo drives and controls, but how about both at once? Instead of using wires and cables to connect servo drives to a controller, drives and controls can be put together and packaged as a single unit.

Integrated solutions greatly simplify supply management, reduce assembly time, save space, and increase reliability. In addition, like a multi-axis servo drive, this can consolidate control of multiple servo axes to a single unit.

Specialized Network Options

- At present, ADVANCED Motion Controls already has standard products available that support EtherCAT, CANopen, Ethernet/IP, Ethernet TCP, Ethernet POWERLINK, Modbus RTU/TCP, and RS-485/232. Any of these networks can be applied to a custom product. However, we have the technology and experience to create custom drives for more networks such as Profinet RT, Profinet IRT, Profibus, and SERCOS III. These customs can even pave the way for expanding our standard network offering.

Environmental Considerations

- While we have an Extended Environment drive line, sometimes you need something special. All of our extended environment features and modifications can be applied to custom products, sometimes to an even greater extent. For example, we've made custom servo drives that can operate safely in ambient temperatures higher than 100°C and at crushing depths 6000 m below the surface of the ocean. These exceed the capabilities of our standard extended environment products.

Unique Capabilities

- You need a drive with more power than our standard offering? Custom. You need a drive with more I/O ports than usual? Custom. You need a drive with special safety features? Custom. You need a drive that shares it's frame with the device? Custom. Want a magnetic encoder or other contactless feedback? Custom.

Examples

- We don't just talk the talk, we walk the walk. We've manufactured hundreds of custom and modified servo drive models over the years. Here we have just a small handful of them for you to check out.

High Pressure Servo Drive

- This servo drive was used to control an underwater camera traveling 6000m deep in the ocean. It was based on one of our standard solutions, but with a few key modifications that allowed it to work in this application.

- Designed to mount on end of a motor

- Used alternate capacitors and other components that would not be crushed under intense pressure

- Custom baseplate

- Incorporated a rotary magnetic module to replace the traditional Hall sensors and encoder feedback

- Configured the controls for the drive to operate in velocity mode with the host controller closing the position loop

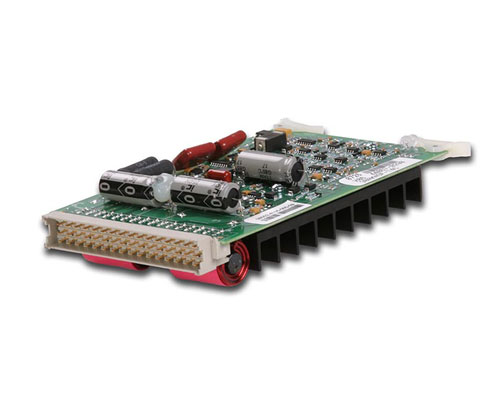

Two-Axis Servo Drive

- Two of these drives were used to simultaneously control treads and elbow joints in a military remotely operated vehicle. Each drive was built to control one elbow joint and one tread, rather than having one two-axis drive for the treads and one two-axis drive for the two elbow joints. This way, the number of unique parts was reduced, making replacements easy.

- No switches or potentiometers

- Duty cycle mode operation

- Axis #1: 30A peak, 24A continuous

- Axis #2: 30A peak, 20A continuous

- Custom operating voltage

- Specified peak current duration

- Specified I/O connectors

- Specified motor and main power connectors

- Conformal coating

- Baseplate integrated as control box cover

Two-Axis Servo Drive

- Baseplate shaped to match custom mount

- Dynamic braking relays hold motors while machine is shut down

- Specified connectors

- Built in inductance for motor compatibility

- Additional bus capacitance per customer spec +/-3V command range

- Special access to tuning values

- Built within size restrictions RTV applied to components for shock/vibration

- Conformal coating

- Custom label

- Delivered less than 2 months after receipt of specification

High Current Output Drive

- 70A peak current (duration 150ms)

- 7A continuous current

- 80kHz switching frequency

- Custom voltage range

- PWM & Direction command

- Duty cycle mode Specified connectors

- Baseplate an integral component in airflow system

Ultra High Performance Drive

- 5kHz Bandwidth

- Maximized phase margin for system stability

- No switches or potentiometers

- 3U rack-mount

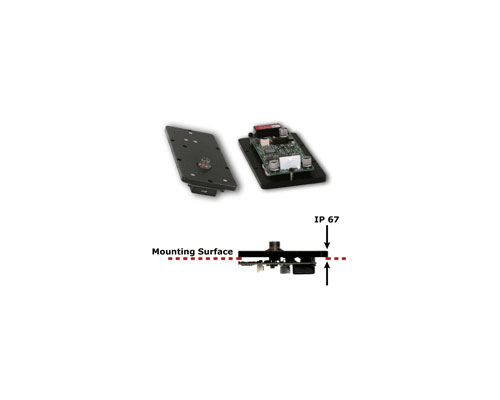

Extreme Environment Drive

- This drive controlled the grasping claw in a military remotely operated vehicle.

- MIL spec connector maintains an IP67 seal between the inside and outside while allowing communication and power to the drive

- Expanded temperature range

- Conformal coating

- USB interface for communication and command over the customer's existing communication hardware

- High powered DC/DC converter specified by the customer

Is a Custom Worth it?

- Is it always worth it to seek out a custom solution, especially if there's a way to make a standard product work? All customs are different, so we have to treat each case individually. However, we can still provide some general guidance.

For customs where there is increased complexity it’s best to add up the cost of the individual components for comparison. A multi-axis solution for example can be a combination of two drives and a mounting card. If you added up the price of the individual components it is very likely that the custom 2-axis drive would cost less (Even including engineering costs and NRE).

custom servo drive collectionEven in cases where there is very low volume, you can still come out ahead if you consider the cost of alternative solutions. For example, how much does it really cost to design your own servo drive? We’ve seen customers struggle for years trying to design their own solution and end up with unsatisfactory results and poor reliability. But when given the chance to step in, we have proven ourselves time and again by delivering excellent solutions in just a few weeks or months making our customers very happy.

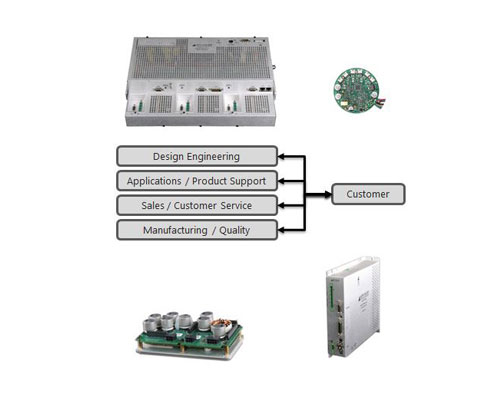

How do We Make it Happen?

So how is it that we can deliver the best solutions so quickly? The simple answer is – it’s just who we are. Our skill-set for designing servo drives is practiced and honed in daily, and it shows in our time-to-delivery, quality, performance and pricing. We truly do believe everything is possible at ADVANCED Motion Controls, and our custom products make that true.

Our Strengths

- On-site engineering and manufacturing

- Close cooperation between our engineering and applications departments and the customer

- Built on the same equipment and by the same people as standard products

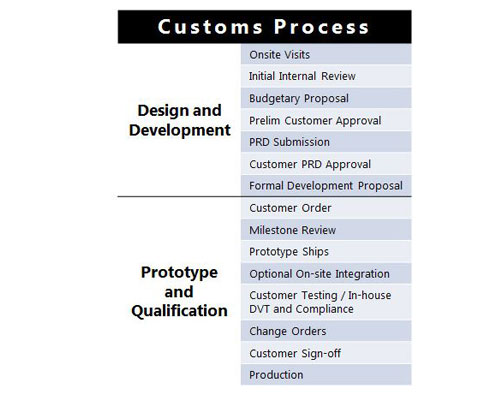

Customs Process

- A custom design has many advantages when it comes to cost and lead times

- Tailored to meet the exact form, fit, and function requirements

- Cost savings due to reduction of components or features not needed for the specific system

- ADVANCED Motion Controls' experience and in-house facilities will produce reliable custom solutions faster than any other suppliers on the market