- Offer Profile

- Since the last four decades Unitechnik Systems GmbH is considered to be among the leading suppliers of industry automation and informatics. We plan and realize tailored systems for the in-house logistics and production.

We operate on a worldwide scale. Our solutions endow the customers with long term benefits: efficient, durable and operator friendly. In this process, our professional project management lays the foundation for the project success.

We aim at long term business relations based on partnership. This applies to both suppliers and customers. We consider the expert support for the realized systems by our service department as very important.

Automated warehouse & logistics systems

-

Complete turnkey solutions for intralogistics

Unitechnik views intralogistics as a whole. In a leading overall concept, we coordinate high-bay warehousesystems, transport systems, control technology and warehouse management systems. Your decisive advantage: we provide manufacturer-independent advice when selecting individual components. In this way, tailor-made logistics systems are created under the responsibility of an experienced general contractor.

Our technologies - High-bay warehouse

-

Efficient use of space with large load carriers

Do you need large storage capacities? High-bay warehouses enable optimum use of space and offer maximum storage capacity with a height of 12 to 45 meters, as the available floor space can be used optimally and effectively.

Automated pallet warehouses ensure efficient goods storage and distribution - even of heavy and large-volume goods. With the help of complex racking systems, more than one hundred thousand pallet spaces can be realized.

An automated high-bay warehouse is the right solution, especially for enormous volumes of goods. A high-bay warehouse from Unitechnik guarantees optimum use of space, fast and direct access, high process reliability and optimum storage conditions at heights of up to 45 meters.

Advantages of an automated high-bay warehouse:

- Efficient use of space

- Low personnel requirements

- High process reliability

- up to 45m high

HRL with shuttles

-

- Large number of vehicles within the racking system

- Flexibly adaptable to building geometry

- Level and aisle changes possible

- Scalability of performance through additional shuttles

- Multi-deep storage

- Focus: storage and sorting

HBW with storage and retrieval machine(s)

-

- Rail-guided, automatic vehicle for transportation

- Single or double load handling attachment

- Multi-deep storage

- Focus: Storage

Silo construction vs in-house

-

Silo construction:

- Storage system as load-bearing substructure for roof and façade, no separate hall required

- Sequence:

- Floor slab

- Shelving system

- Wall and roof panels

- Installation of the appliances

- Can be used as refrigerated or deep-freeze storage thanks to insulated panels

- Useful from a storage height of approx. 20 meters: We can advise you!

Automated small parts warehouses (AKL) - dynamic and flexible

-

An automated small parts warehouse (AS/RS) enables high handling speeds and fast access to goods. Unitechnik offers dynamic miniload solutions that are optimally integrated into your warehouse technology in order to achieve high storage density and space efficiency. We analyze your processes, design tailor-made small parts warehouses and select the right components. Warehouse management is carried out using our modular "UniWare" software. Our service also includes the electrical and mechanical maintenance of your miniload.

Advantages of an automated small parts warehouse:

- Fast and flexible

- Good price/performance ratio

- Fully automatic

- Various load carriers

AKL with shuttles

-

- Large number of vehicles within the racking system

- Flexibly adaptable to building geometry

- Level and aisle changes possible

- Scalability of performance through additional shuttles

- Multi-deep storage

- Focus: storage and sorting

AKL with storage and retrieval unit(s)

-

- Rail-guided, automatic vehicle for transportation

- Single or double load handling attachment

- Multi-deep storage

- Focus: Storage

Walking beam memory

-

- Consisting of two lift masts with mounted transfer carriages

- Compact, closed design with low approach dimensions

- Multi-deep storage

- Focus: Storage and order consolidation

Skypod system from Exotec

-

- Warehouse robots climb 12 m up the racking and move freely around the area

- Containers or trays are transported autonomously to picking stations

- Multi-deep storage

- Focus: Storage and picking

Skypod system from Exotec

-

Innovative automated intralogistics system with autonomous warehouse robots

The Skypod system from Exotec is a pioneering storage and picking solution for small parts. Several mobile Skypod storage robots move freely around the area and climb up to 14 meters up the shelves. From there, they pick up containers or trays and transport them autonomously to picking stations. The Skypod robots move in an enclosed area and can therefore travel at speeds of up to 4 m/s. They are the only active components in the entire storage area, the rest is steel and plastic. The flexibly designed goods-to-person system offers a wide range of possible applications and can be easily integrated into an overall logistics system from Unitechnik.

Skypod storage robot

- Autonomous mobile storage robots that transport containers or trays between the shelf compartment and the picking station. They travel at speeds of up to 4 m/s, climb up to 14 m on the shelves and have a payload of 30 kg. A loading time of 5 minutes per hour is sufficient.

Shelves

- The modular shelving system from Exotec is up to 14 m high and adapts perfectly to the available space. Single or double-deep storage is possible. The purely passive systems can be extended during operation. Regulations for automatic sprinkler systems are met.

Containers / trays

- Containers and trays have a base area of 650 x 450 mm. The bins are available in heights of 220, 320 and 420 mm. The containers can be divided into 2, 3, 4, 6 or 8 compartments using removable plastic dividers. The payload is up to 30 kg.

Picking stations

- Goods-to-person picking: The Skypod storage robots move onto a height-adjustable ramp for an ergonomic working height. Exotec offers a whole range of solutions: from manual provision to a complete put-to-light system to a fully automated Skypicker.

Conveyer Technology

- The "Exchanger" is used to transfer containers into and out of the Skypod system. It enables the connection of other logistics systems, such as conveyor lines, replenishment from other storage areas, packing stations or AGV systems for production supply.

Deepsky software

- Deepsky is Exotec's warehouse control system. It assigns orders to the Skypod warehouse robots and coordinates all warehouse movements. Thanks to an interface to the Unitechnik UniWare warehouse management system, the Skypod system can be easily integrated into an overall logistics concept from Unitechnik.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs)

-

Flexible conveyor technology

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are increasingly replacing forklift trucks and offer an alternative to continuous conveyor technology. Unitechnik analyzes the requirements, selects suitable systems and integrates them with our UniWare warehouse management system via defined interfaces. We carefully plan transfer points to ensure seamless integration of the automated vehicles into our logistics systems.

Advantages of driverless transport systems / AMR:- Flexible routes

- Scalable performance

- Requires little space

- no forklift drivers

AGV

- What is an automated guided vehicle system (AGV)?

- Equipment: AGVs consist of automated guided vehicles (AGVs) with sensors, cameras or laser navigation systems

- Central control system: Coordinates communication, order placement, route planning and monitoring of the AGVs

- Navigation: AGVs navigate on predefined physical or virtual paths such as magnetic tapes, induction loops or reflector triangulation

- Reaction to obstacles: AGVs stop and wait until obstacles are removed if safety sensors detect them

- Path adherence: vehicles cannot leave the specified path and follow it strictly What is an autonomous mobile robot (AMR)?

- Similarity to AGVs: AMRs look similar to AGVs on the outside, but differ in terms of navigation

- Natural navigation: AMRs can redefine routes and avoid obstacles without the need for fixed paths

- Self-navigation: The robot maps its environment and navigates without fixed hardware by using laser scanners, cameras or lidar systems

- Communication: AMRs communicate either via a central control system or directly with each other

- Swarm intelligence: Several AMRs work together to achieve a common goal through collective intelligence

Areas of application for AMR

-

Areas of application for AGVs and AMRs

AMRs are suitable for applications with multiple and variable destinations, e.g:

- Supply of workstations with material

- Autonomous mobile picking robots

- In hospitals, for example disinfection robots

- Warehouse applications, especially in e-commerce and parcel services

- Autonomous floor cleaners

AGVs have their strengths where defined transport routes need to be operated at high frequency and as predictably as possible.

In summary, it can be said that AGVs are often used in intralogistics environments to perform specific transportation tasks on predefined routes. AMRs, on the other hand, are more versatile and flexible and can navigate and operate autonomously in different industries and environments.

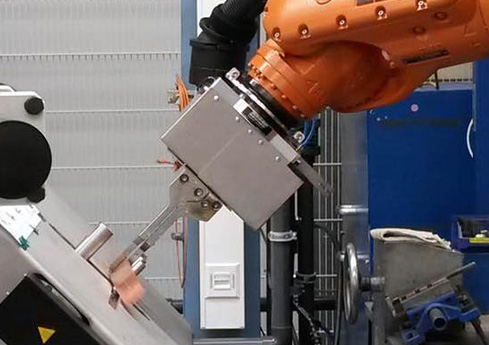

Robotics

-

Robots in logistics: efficiency, precision and innovation

The logistics industry is in the midst of a technological transformation. Innovative robotic solutions such as palletizing and depalletizing robots, picking robots, autonomous mobile robots (AMR), shelf-to-person systems, rackbots and drones are fundamentally changing warehouse and material flow processes.

These technologies are helping companies to work more efficiently and precisely while at the same time responding flexibly to future challenges.

Pick robots

-

Pick robots are specially developed robots that are designed to pick items directly from shelves, containers or conveyor systems and transfer them precisely to target stations such as picking or packaging areas. Equipped with modern sensor technology and AI-based object recognition, they can master even complex tasks such as gripping a wide variety of shapes and sizes of goods:

- Versatility

Pick robots can handle a wide variety of items - from delicate foodstuffs to heavy goods. Their flexible gripping systems automatically adapt to the product characteristics. - Precision

Advanced gripping technologies enable items to be removed safely and quickly, even with complex shapes. AI recognizes the optimum gripping position and prevents damage. - Use in e-commerce logistics

Pick robots are ideal for warehouses with high order volumes. They speed up order picking, increase efficiency and reduce the workload of employees.

- Versatility

Palletizing and depalletizing robots

-

Palletizing robots stack goods efficiently on pallets and make optimum use of space. They are able to create different stacking patterns to increase the stability of the pallets. Depalletizing robots unload pallets and automatically sort the products into storage compartments or onto conveyor belts. They use advanced sensor technology to recognize different packaging and sizes:

- Greater safety

Reduction of physical strain and accident risks for employees. - Consistency

Precise and consistent performance at high throughput rates. - Flexibility

Adaptable for various industries, including beverage, food and pharmaceutical logistics.

- Greater safety

Shelf-to-person systems

-

In shelf-to-person systems, robots pick up complete shelves with the required goods and bring them directly to the picking station:

- Improved ergonomics

Employees no longer have to walk through the warehouse and bend down, as the shelves are brought to their workstation. - Increased speed

The simultaneous processing of several orders reduces picking times. - Flexible adaptation

These systems are ideal for warehouses where stock levels change frequently or demand is subject to seasonal fluctuations.

- Improved ergonomics

Rackbot systems

-

Rackbot systems combine autonomous navigation with intelligent picking technology. These robots move independently through the warehouse, picking items directly from the shelves and consolidating orders:

- Direct picking

Rackbots work like an "autonomous order picker", picking items from within the warehouse aisles and taking them to the packing area. - Wide range of applications

Suitable for different product categories such as food, pharmaceuticals or e-commerce items. - Optimization of material flow

Thanks to AI-supported navigation, rackbots always find the most efficient route, which reduces throughput times.

- Direct picking

Skypod system from Exotec

-

The Exotec system is revolutionizing intralogistics with its innovative Skypod system, which enables three-dimensional mobility:

- Scalability

The modular systems can be expanded as required. - Fast implementation

Simple integration into existing warehouses enables companies to implement the system in the shortest possible time. - Efficiency

The robots move independently of each other, which avoids jams and optimizes throughput.

- Scalability

Autonomous vehicles

-

AGVs are specially designed for transporting goods along predefined routes within warehouses or production environments.

They use various technologies such as optical, magnetic or laser-based guidance systems:- Precision

Ideal for recurring transportation tasks such as supplying production lines. - Robustness

AGVs are designed for continuous use and offer constant performance under high loads. - Areas of application

Available for the transportation of pallets, containers or other heavy loads in production and warehouse environments.

- Precision

Picking systems

-

Many possibilities - We are your expert

Unitechnik offers comprehensive advice on the selection of suitable picking stations and ensures the seamless integration of picking zones into your intralogistics processes.

Whether "goods-to-person" or "person-to-goods" - we offer automated, paperless systems such as "pick-by-voice" and "pick-by-light", which reduce the error rate to a minimum.Our solutions are individually tailored to your logistics processes and represent an important step in our overall projects.

We use state-of-the-art technologies and design customized solutions that are perfectly tailored to your individual processes.

The most important order picking systems at a glance:

- Pick-by-light

- Pick-to-light

- Pick-by-voice

- Pick-by-vision

- Pick by handheld

- Pick & pack

- Multi-stage picking

- Multi-order picking

- Automatic order picking

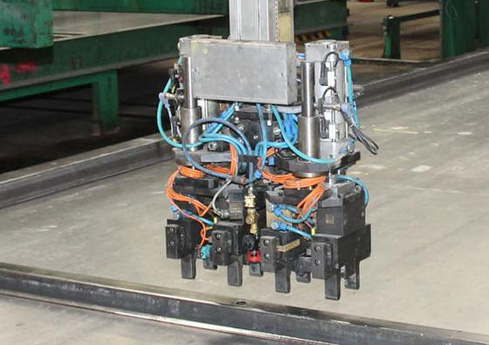

Conveyor technology

-

Intelligent transport systems for optimum material flow

The conveyor technology developed by Unitechnik optimizes the material flow in the logistics center by efficiently connecting incoming goods, storage, picking, packing and loading zones as well as outgoing goods. Our experts determine the best solution for your material flow based on energy consumption, transportation performance and usage costs, regardless of the manufacturer.

Automated guided vehicles offer a replacement for classic conveyor technology in some situations.

Advantages of stationary conveyor technology:

- High performance

- Transport and buffer section

- Even on uneven floors

- Robust technology

Chain conveyor

-

- low maintenance

- Simple technology

- Suitable for higher transport weights

- Suitable for pallets, pallet cages

Roller conveyor

-

- simple installation

- uncomplicated maintenance

- Suitable for longer transport distances

- Suitable for pallets, pallet cages, containers, trays and cartons

Belt conveyor

-

- Versatility

- Low noise level

- Suitable for inclines (up to 18°) and different object surfaces

- Suitable for containers, trays and cartons

Electric monorail/electric floor conveyor

-

- Flexible routing

- Suitable for decoupling systems

- Difference: Suspension rails or floor rails

- Suitable for high transport speeds

- Suitable for pallets and pallet cages

Lifters and lifts

-

- Vertical conveyor systems for lifting and lowering goods

- Optimum use of space by eliminating conveyors with inclines

- Fast vertical movement

- Suitable for pallets, pallet cages, containers, trays and cartons

Services

Systemintegration

- As an experienced general contractor, Unitechnik Systems assumes overall responsibility for your tailor-made logistics center - whether dispatch warehouse or production supply. We are a manufacturer-independent system integrator with a high level of expertise in the areas of process planning, software, control technology and interface management.

At the heart of our logistics systems is our modular UniWare warehouse software. Either as a fully-fledged warehouse management system or as a material flow control system under a third-party warehouse management system.

Logistics Consulting

-

You've come to the right place if...

- you want to expand or optimize your internal logistics

- you see this project as an important step in the development of your company

- you are prepared to work together to develop a solution tailored to your individual processes

- You are open to modern technologies and digitalization

- You are not looking for an off-the-shelf solution

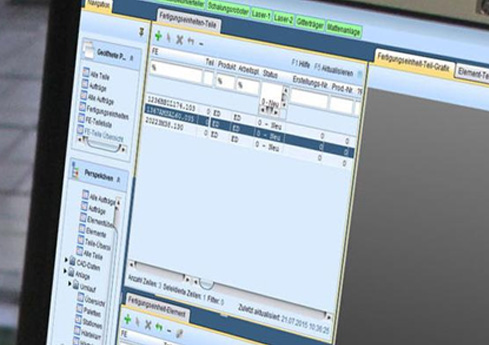

UniWare warehouse management system

- Increase your efficiency with our warehouse management processes

UniWare is an advanced warehouse management system that ensures maximum transparency and efficiency in your logistics center. Our solution optimizes your warehouse resources, guarantees smooth order picking and manages your stock efficiently and reliably. Thanks to the integrated material flow and the standardized PLC interface, you benefit from the use of all standard transport systems on the market.

UniWare offers:

- Warehouse management system (WMS)

- Material flow control system (MFS)

- System visualization (VISU)

Customer Service

-

Our aim is to increase the availability of your automated system - in other words, to minimize faults and rectify them as quickly as possible. More than ten highly qualified specialists are at your disposal around the clock.

Unitechnik's Customer Service offers you customized solutions:- Telephone hotline: Our own experts are on standby around the clock to solve your problems - by telephone and teleservice.

- On-site deployment: Whether it's a malfunction or production support, we support you worldwide.

- Inspection and maintenance: Preventive measures help to avoid breakdowns - it pays off.

- Spare parts service : Sensible warehousing and a strong partner for emergencies will get your system up and running again quickly.

- Customized training: Helping you to help yourself - we train your personnel exactly according to your needs.

- PLC training center: As an official Siemens training partner, we make your staff fit for the future

Retrofit

-

Logistics systems are becoming ever more efficient and economical. You can benefit from this - even without a new building. Unitechnik determines the most effective retrofit for your existing logistics center and develops a comprehensive concept for modernization. In this way, we bring your intralogistics up to date and restructure your material flow.

As a specialist in the automation of logistics centers, we are predestined for an efficient retrofit. With over 40 years of experience, we can provide you with a tailor-made solution as part of the modernization process. Oriented to your ideal process flows.

Energy management

-

Rapidly rising costs for heat, electricity, gas, oil, water and compressed air are making an industrial company's energy consumption more and more of a determining economic factor.

Energy-efficient and environmentally friendly production also shapes a company's image on the market. The sustainable establishment of effective energy management will therefore be a decisive factor for business success in the future.

Unitechnik advises and supports you in the conception and introduction of energy management. We plan and implement the system for you in hardware and software based on the latest methodology and technology. Our comprehensive expertise in industrial automation and information technology enables us to achieve optimum integration into your infrastructure. Unitechnik is a Siemens Solution Partner in the areas of "Automation" and "Power Management".