- Offer Profile

-

Unparalleled expertise and experience in vision technology for automated quality control.

Our machine vision systems are some of the most innovative and advanced on the market today. They are used all over the world in automated production processes for quality control, inspection, guidance, identification, measurement, tracking and counting – in many diverse industries.

Industrial Vision Systems Ltd (IVS®) is a global provider of vision systems, machine vision and automated inspection machinery. Our non-contact vision systems and machines are used in all areas of production across a diverse range of industry sectors. Our mission is to make companies more efficient, highly flexible and quicker with our machine vision solutions.

Applications - Advanced inspection and machine vision applications, utilising the very latest vision system technology.

-

Industrial Vision Systems Applications.

Our vision system solutions cover a wide range of application areas. Everything from checking the presence of a screw or nut on an automotive sub-assembly, through to metrology checks on an orthopaedic joint, up to precision surface inspection of a continuous material web.

Our machine vision systems combine leading-edge technology and high-performance image processing to solve a wide variety of automated inspection, identification and quality control problems. Take a look at each of the areas we cover below – the chances are we have a solution for your inspection requirement.

Our vision system application areas

Explore some of the key features and benefits of using an IVS vision system for inspection, guidance, quality and verification

Deep Learning/Artificial Intelligence

- Deep learning in the context of industrial machine vision teaches vision systems, robots and machines to do what comes naturally to humans, i.e. to learn by example. New multi-layered “bio-inspired” deep neural networks allow the latest IVS® machine vision solutions to mimic the human brain activity in learning a task, thus allowing vision systems to recognise images, perceive trends and understand subtle changes in images which represent defects.

Measuring and Metrology

-

Measuring in machine vision is used to confirm the dimensional accuracy of components, parts and sub-assemblies automatically, without the need for manual intervention.

IVS® provides sub-pixel precision vision systems for reliable metrology, measurement and dimensionally accurate inspection. From checking simple geometrical tolerances to micron-level detection, customers can be confident that our metrology and measuring vision solutions provide robust and repeatable results. Powerful gauging wizards are incorporated into our vision systems, enabling customers to make sophisticated measurements to sub-pixel accuracy at very high speeds.

Pattern Recognition and Pattern Matching

-

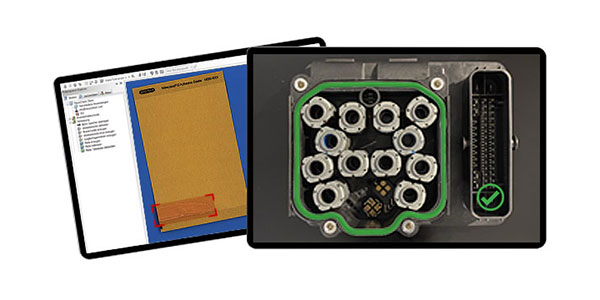

Pattern recognition and pattern matching is used in machine vision for automated quality checks to confirm that a pattern is presence and in the correct position, it is also used to enable automation through robot position and training.

Our pattern matching algorithms use a “gold master” training image as a “digital signature” pattern for the part, component, label, text or object that the vision system has to deal with. Powerful, precision geometrical algorithms then match at speed providing real-time inspection.

Code Reading

- Powerful vision systems for the identification, decoding and grading of 1D and 2D codes as well as character strings for full production line traceability. All of the most common barcodes and data matrix codes can be read in any orientation at high speeds. Our code reading tools are designed to deliver accurate results in some of the toughest and most-demanding manufacturing environments.

Optical Character Recognition (OCR)

-

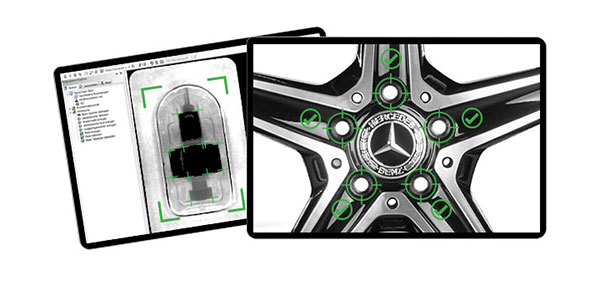

Powerful OCR (Optical Character Recognition) and OCV (Optical Character Verification) solutions for robust inspection and verification of complex numbers, character and language types. Train, classify and verify any character set – enabling the high-speed checking of scribed, stamped, printed or pre-printed text in all languages, fonts, sizes and styles.

From packaging label inspection through to laser etched identification of numbers, all character sets can be read robustly and repeatedly regardless of variations in ambient factory conditions and environments. Check scribed, stamped, printed or pre-printed text in all languages, fonts, sizes and styles.

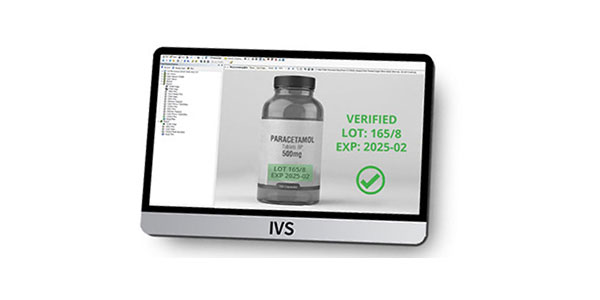

Robot Control

-

Precise 2D and 3D robot positioning and part guidance. IVS robot guidance and alignment solutions provide high precision feedback to all major robots. Using industry-leading machine vision tools to quickly and precisely locate and align components, patterns and fiducials, even under adverse conditions.

Reduce expensive tooling allowing products to arrive in any orientation and be guided accurately and robustly. Non-linear calibration corrects for lens and perspective distortions, providing exact co-ordinates and ultraprecision.

Colour Matching and Verification

-

Our powerful vision systems provide 24-bit colour processing to offer enhanced image processing and precision for quality control applications – everything from pill inspection and blister pack checks through to verifying food stuffs and electronic components. Check labels, features, conformal coats, beads, glue, food products, organic products and parts for detailed colour analysis.

Overall quality verification of parts, components and sub-assemblies is achieved through colour searching, pattern checks and template matching. Colour matching can be used for segmentation and analysis of products operating in RGB and HSI.

Surface Inspection and Flaw Detection

- Advanced surface and flaw detection provides inspection for anomalies, contamination, scratches, cracks, discolouration or inclusions at high speeds. Check for stains, flaws, noise and pattern changes within your product surface. From single component inspection on one surface to multi-camera web inspection of materials, all areas of automated surface inspection are covered.

Image Archiving

-

Automated traceability through photo capture, save and recall. Storing an image record of every product manufactured is now a critical tool in the modern production process, providing front line brand and warranty protection based on time-stamped photos in case of later warranty claims.

Automatic image archiving enables all the scanned images to be stored onto the system hard drive automatically without operator intervention. Easily recall your full production photos or view images of individual products before they left your facility.

Our Products

-

Immensely powerful, state-of-the-art automated quality control machine vision inspection systems and machines.

Our family of solutions covers everything from vision system component supply up to fully customised systems designed, built and installed by our expert engineers. Protect your brand, increase quality and lower costs.

Whichever way you look at it, we’ve got you covered.

- Machine Vision Applications

- Presence verification/completeness checks

- Gauging/dimensional inspection

- Character recognition (OCR, OCV)

- Robot guidance

- Pattern recognition

- Colour processing/colour recognition

- Surface inspection

- Position verification

- Print inspection

- Bar code and data matrix code reading

Industrial Vision Systems Ltd provide fully integrated machine vision solutions, including stand alone special purpose machines, retro-fits to already established lines and cells, as well as work on new machines and projects. We work with end users, systems integrators and OEM machine builders alike providing a one-stop solution for the full range of engineering services required in today's modern industrial automation market where vision can be applied. Our company's services comprise consulting, engineering, on-site integration, support, maintenance and training.

Typical Applications:

Medical and Pharma Solutions

- Class-leading medical device and pharmaceutical inspection machines, from standalone benches to fully automated systems.

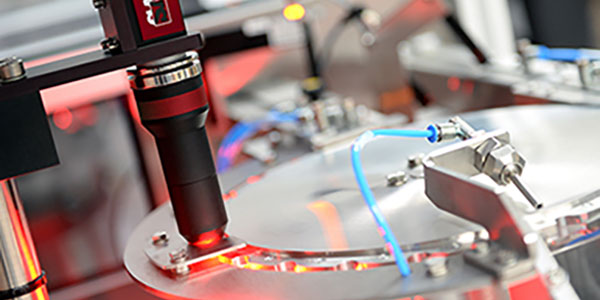

Contact Lens Inspection

- A full range of high-speed quality control vision inspection products for contact lens and optical lens production.

Special Purpose Machines

- Custom vision inspection systems, cells and lines tailored to your exact needs.

Vision Systems and Sensors

- General purpose, powerful vision systems, sensors, cameras and components for machine vision inspection.

Integrated Vision Systems

- Our expert vision engineers will get you automated quicker and faster, deploying a right-first-time vision system within your project timelines.

Packaging and Label Inspection

- Fully automated 100% inspection and rejection machines for the quality control inspection and quality assurance of packaged items after final packing.

Optical Sorting Machines

- Inspect, sort, grade and classify your manufactured components with ease. 360 degree comprehensive analysis of your parts at up to 600ppm.

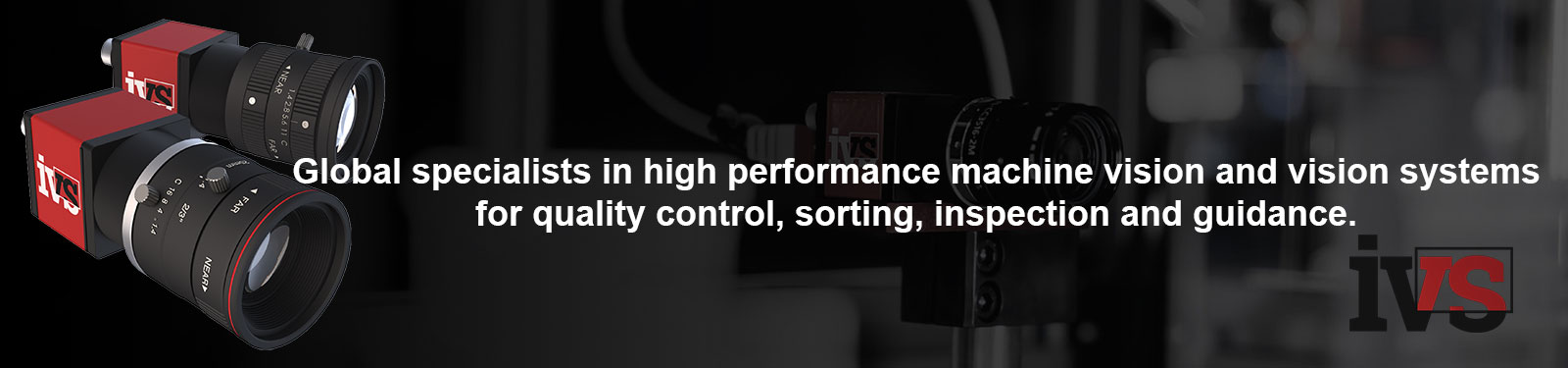

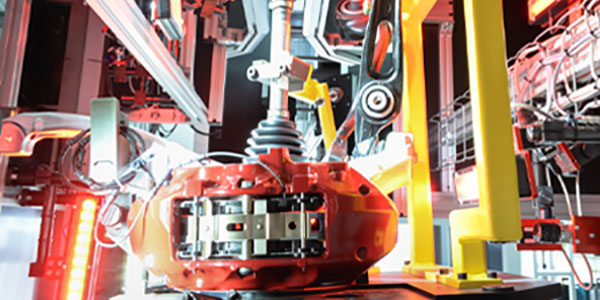

Automotive Vision Inspection

- Precision quality control vision inspection machines and systems for the automotive, engineering and associated industries.

Robot vision

- A complete family of robot vision products and integrated robot vision solutions for flexible machine vision inspection and precision guidance.

Automated Image Archiving

- Automatically save Ultra HD photos of all your products, before they leave the factory. Save photos against part, serial and lot numbers for recall and warranty protection.

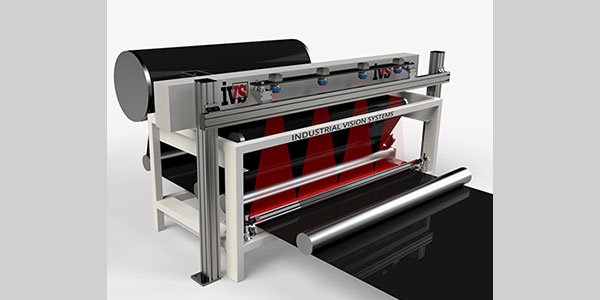

Web Inspection

- Flexible web and linescan inspection solutions utilising multi-camera linescan cameras for quality checks on continuous webs, large products and cylindrical items.

Food Quality Inspection Machines

- Ideal for automated quality control checking for the food processing industry – reliable inspection and rejection machines prior to and after packaging.