- Offer Profile

- Machine vision software, 3D metrology software, smart cameras, bar code and identification sensors as well as ready-to-use systems for industries such as food, beverage, electronic as well as areas such as Deep Learning, Thermal Imaging, 2D and also 3D image processing.

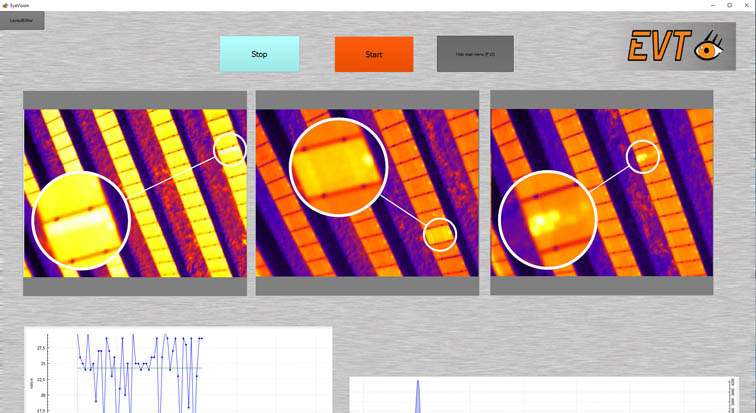

EYEVISION IMAGE PROCESSING SOFTWARE

-

The EyeVision Machine Vision Software and EyeVision 3D Software offers solutions for different applications, such as e.g.:

- 3D capture and evaluation on the point cloud for e.g. pin inspection, bin-picking, etc.

- 3D profile measurement for e.g. weld seam, adhesive bead and sealant inspection, etc.

- 1D and 2D measurement and evaluation (support of numerous line scan and matrix cameras)

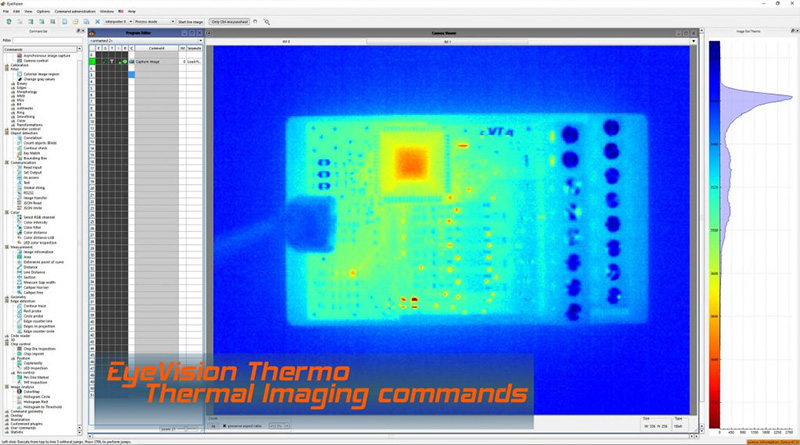

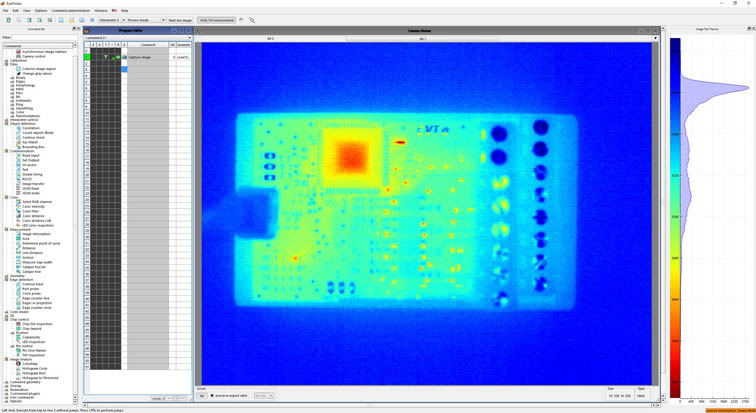

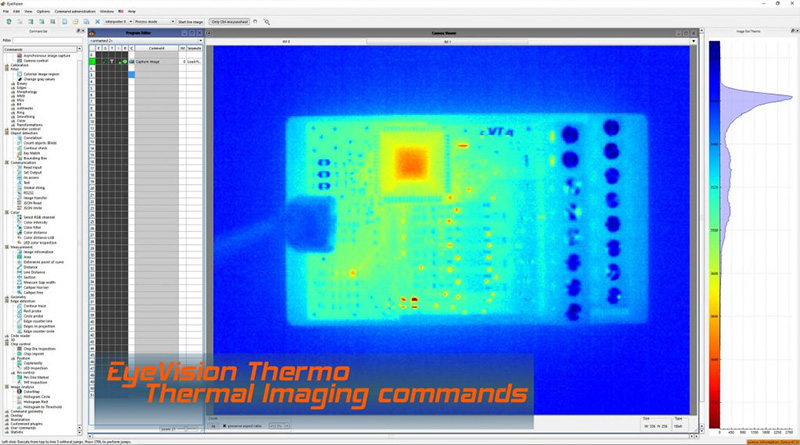

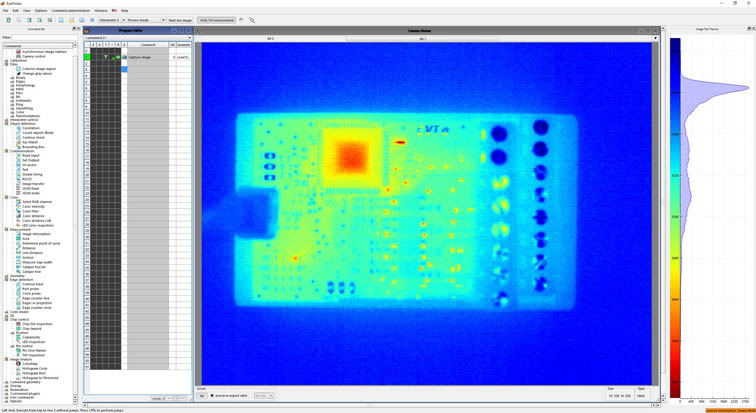

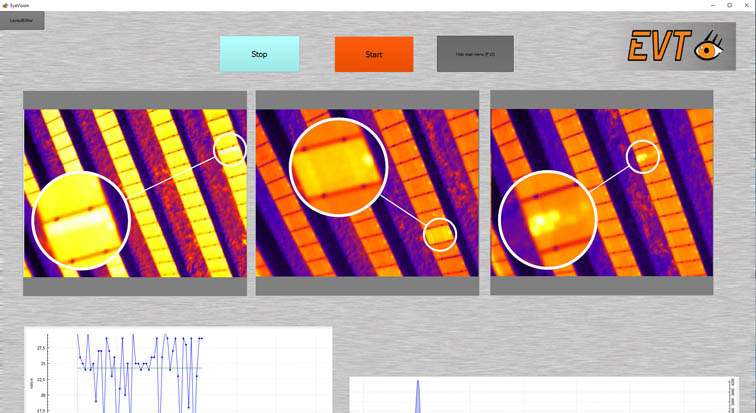

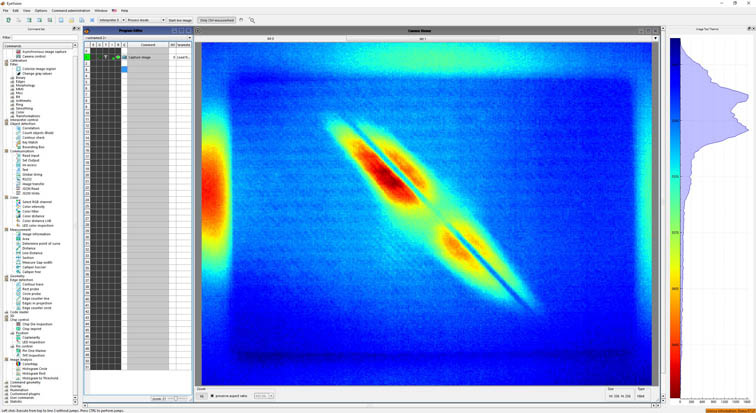

- Thermography capture and evaluation with special commands (for active, passive and lock-in thermal imaging)

- Hyperspectral Imaging capture and evaluation

- Evaluation on color and gray scale images

- Measurement and inspection technology

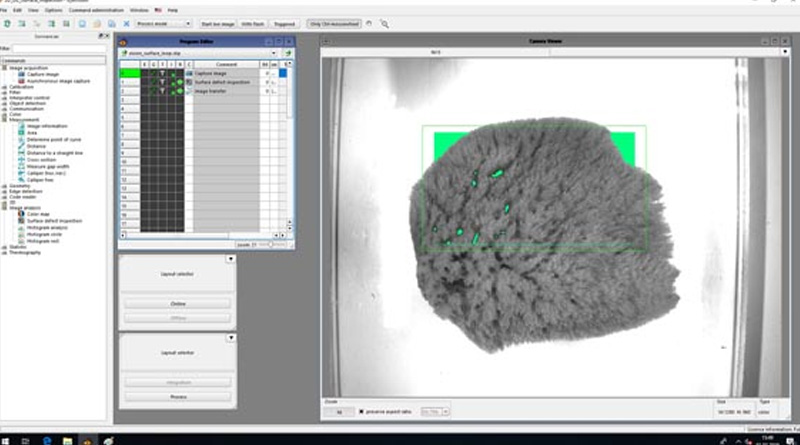

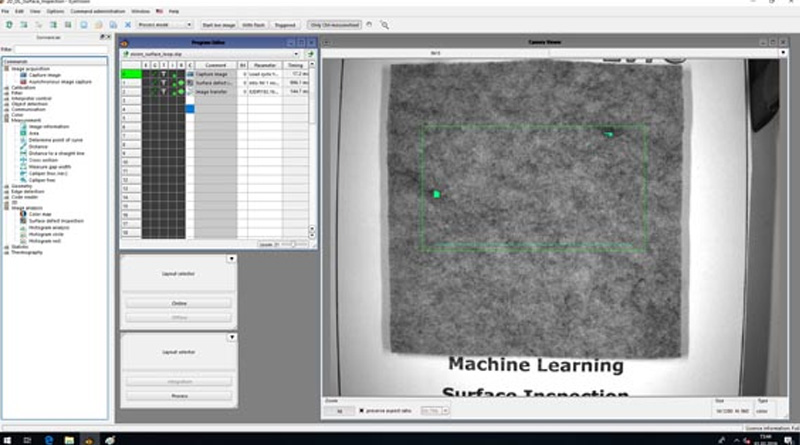

- Surface inspection also with Machine Learning algorithms

- Error detection

- Pattern matching

- Code Reading (DMC, QR, Barcode) as well as OCR/OCV

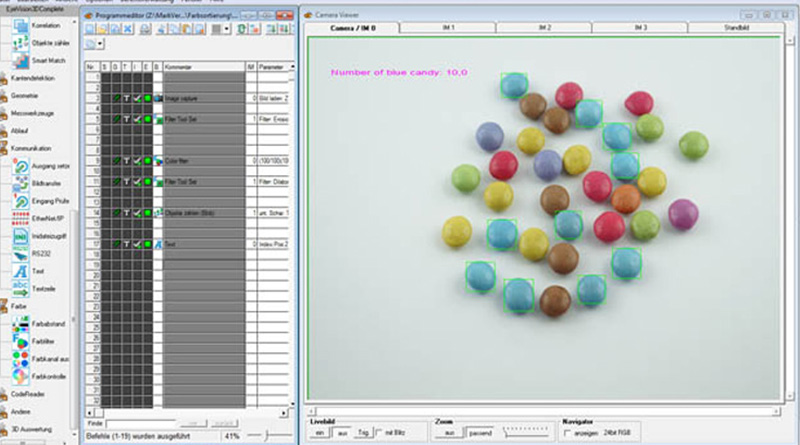

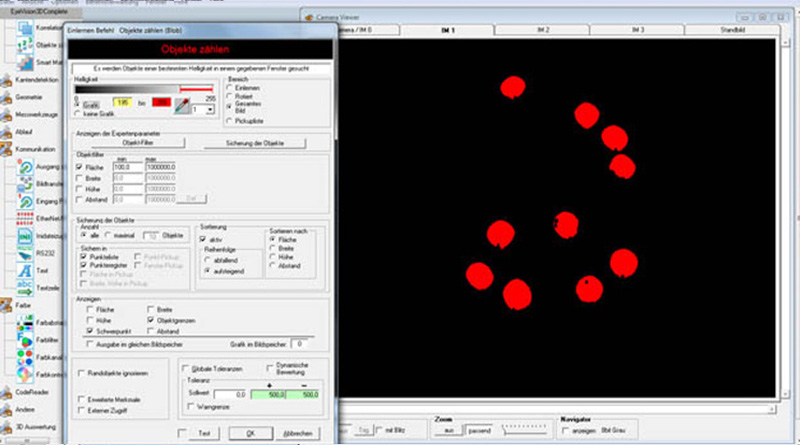

- Object detection and counting

- Position control

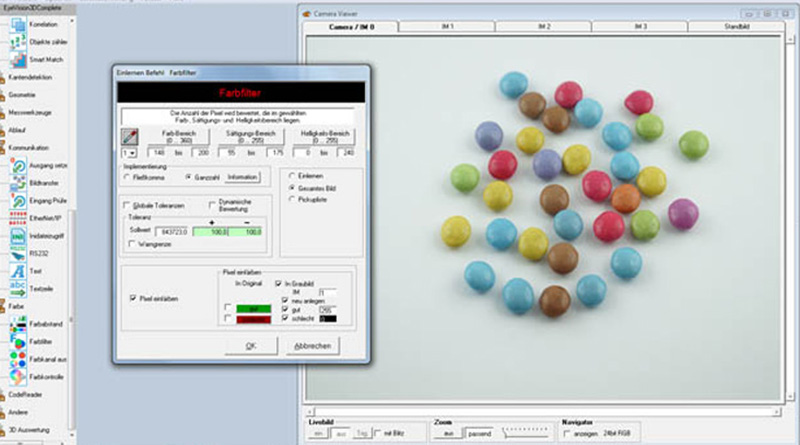

- Color inspection

- contour inspection, etc.

EyeVision is synonymous for “zero-error-production”, a reduction of production time, for quality and production acceleration and therefore als for a higher customer satisfaction.

Thanks to fast installation and univeral usage, the software creates a fast, efficient and cost-effective solution for all applications.

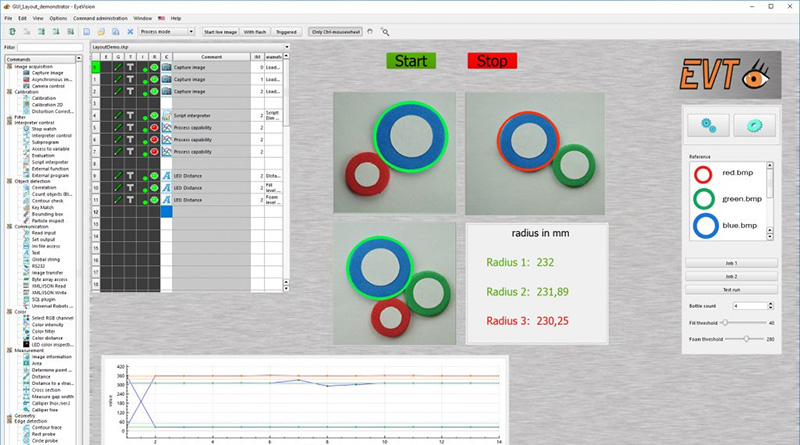

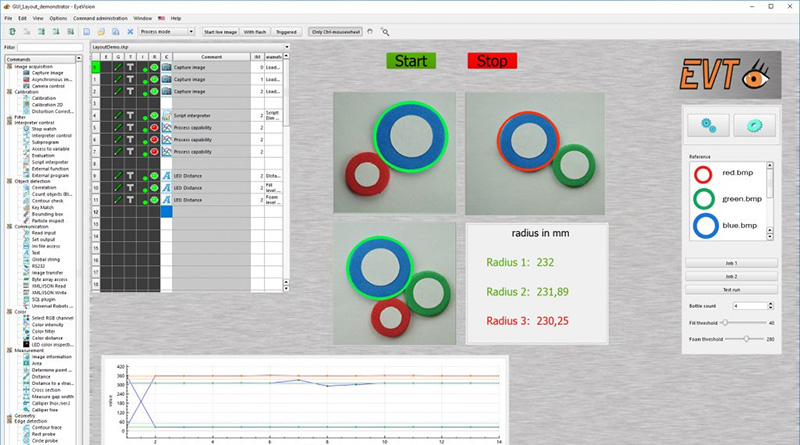

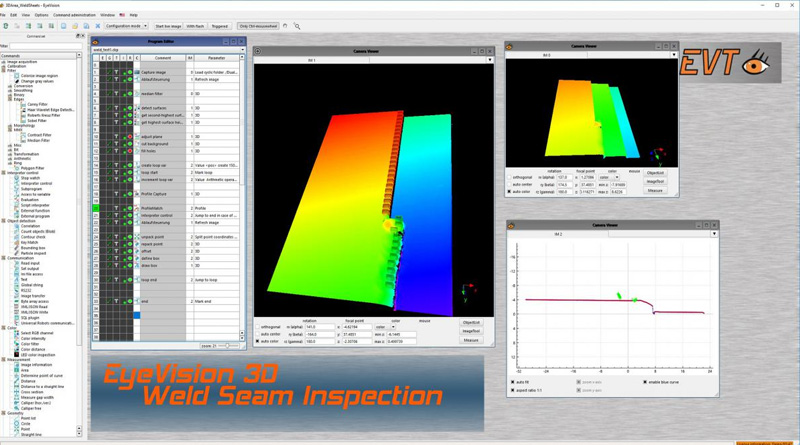

Drag-and-drop programming

- The software is flexible and easy to handle. EyeVision is programmed via the graphical user interface (GUI). The easy programming via drag-and-drop is a well-known feature of the image processing software.

The intuitive user interface allows the creation and configuration of new inspection processes very easy and fast. Thanks to the innovative technique the handling is even for less experienced user very easy.

Flexible hardware choice

-

EyeVision supports line scan, matrix, color, gray scale, thermal imaging and 3D senaors with interfaces:

- USB 2.0, 3.0

- GigE

- GenICam kompatible Kameras

- FireWire

- Camera Link

- RS232

- CoaXPress

The image processing software runs on ARM, x86, x64 and MIPS.

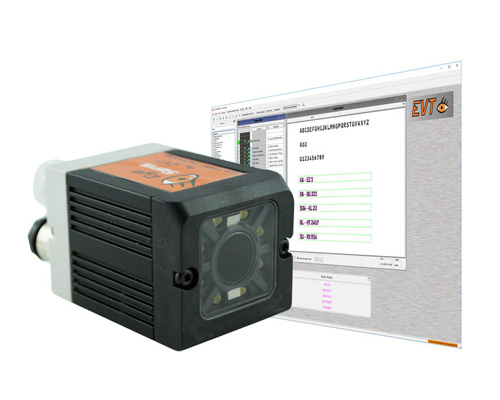

Image processing software for the Smart Camera

- Additionally the EyeVision is available also on the smart camera series EyeCheck and the vision sensor series EyeSens.

TitleMIPI Software EyeVision

-

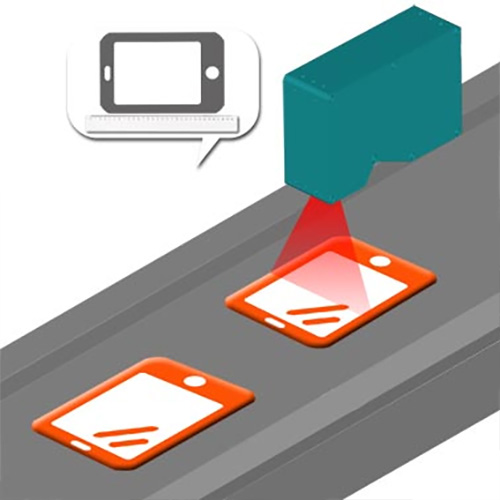

MIPI CSI-2 is already an important interface for mobile devices like smart phones or tablets, but also in image processing and many Embedded Vision applications it plays an important role.

EyeVision supports MIPI sensors by Allied Vision Technology, Basler, Vision Components and Raspberry Pi. This is a list which will grow even longer.

Applications with EyeVision

- Text

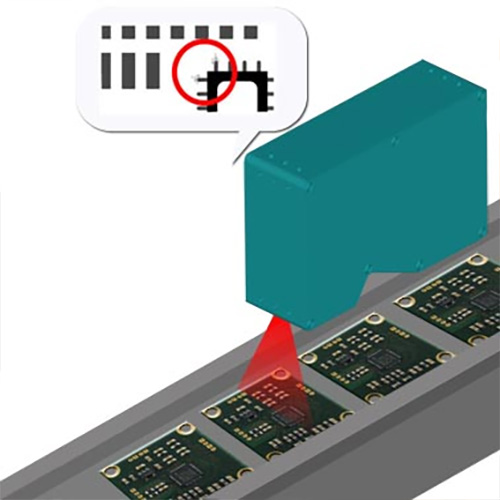

Code Reading, OCR/OCV

-

The EyeVision software has commands for character recognition and verification and code reading for example:

- bar code

- DMC

- QR

Bar code reading

The EyeVision software can read any common bar codes, such as e.g.:

- EAN 13 & 8

- Code 39

- 2/5 Interleaved

- Code 128

- UCP Version A & B

The software can read the code in any position and rotation.

DMC reading

The EyeVision software can also read DMC codes in any position and rotation in the image.

The DMC code can even be read when:

- the code is partially damaged due to dirt or indistinctness

- the surface is reflective

- the DMC code is embossed, needled, etc.

QR code reading

Furthermore the EyeVision software can easily read QR codes. Only one command in the software is necessary and it does not need any complex programming. Its very easy-to-handle.

Codes can also be saved and used for further processes.

Inspection program change via code scan

Code reading can be used manyfold in the quality control process:

- inspection of the code for quality and presence

- using the code for sorting of the goods

- inspection program switch via code scan

OCR/OCV – Optical Character Recognition / Optical Character Verification

The EyeVision software contains commands for OCR/OCV. For that the surface, the quality of the characters, etc. does not matter. EyeVision OCR command can read characters also under contrarious environments.

Also characters on the smallest parts, such as electronic chips can be read.

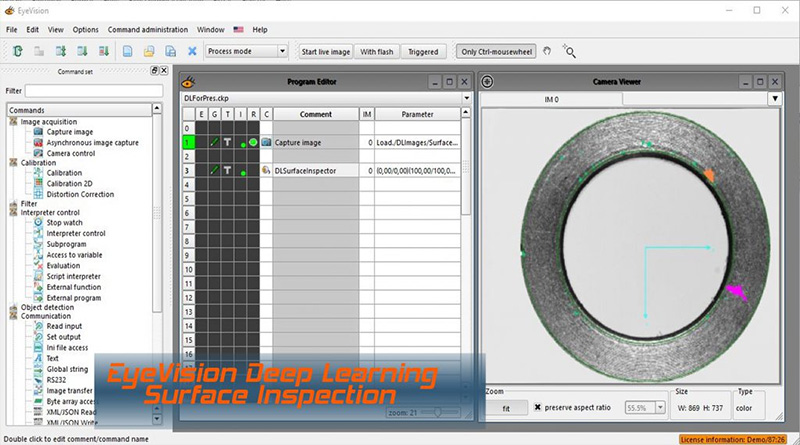

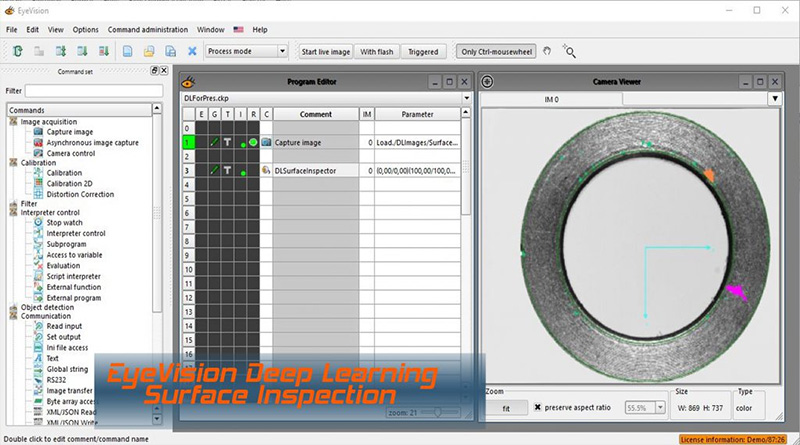

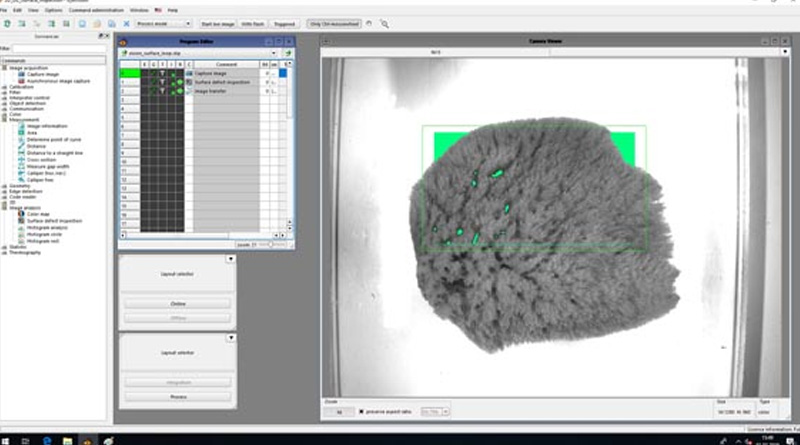

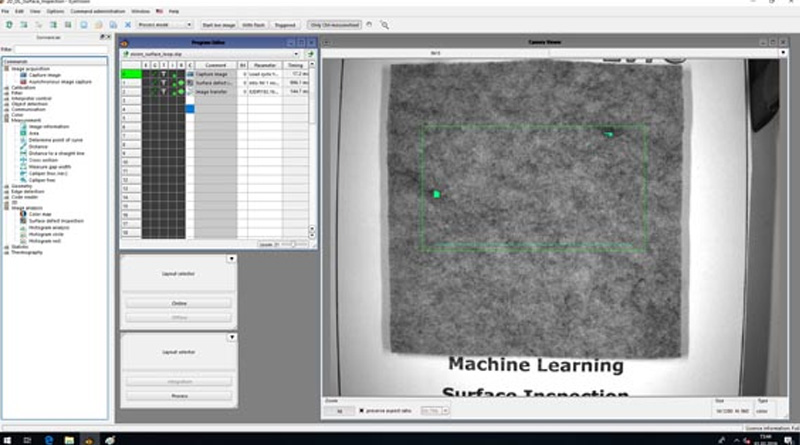

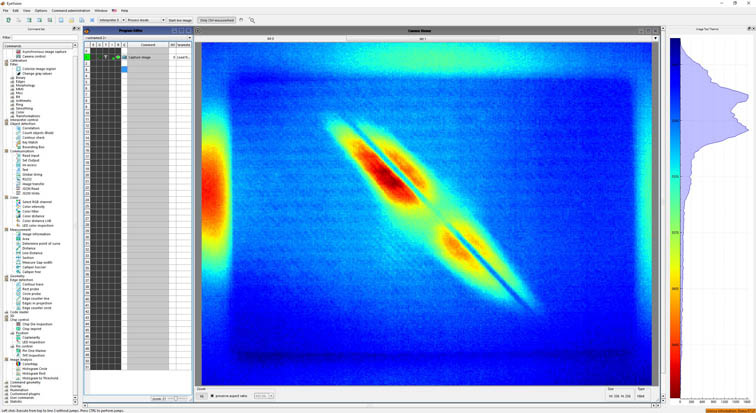

Detection of surface defects with Deep Learning

-

ML Homogeneity Inspector

For the automatic detection of defects on structured surfaces.

The EyeVision software has the ML Homogeneity Inspector for such tasks.With the Deep Learning surface inspection tool the following defects can be detected:

- surface defects

- damages

- contaminations

And that works completely dynamic and automatic.

Challange and solution

The identification of defects on surfaces is a special challange. For example the defects on complex functional and aesthetic technical surfaces. Deep Learning offers a new solution for those difficulties. Because it works without pre-definition of the expected defects. And also without the configuration of an inspection program.

Advantage of the Deep Learning surface detect

- The algorthims can be integrated in any machine vision software.

- The tool can be deployed in a ROI using for example the size of the anomaly surface defect as qualification criterion.

- no teaching in advance

- no setting parameters,

- as the algorithm adapts itself automatically to any random surface

- evaluation of the inspected surface in less than 50 ms on Core i3

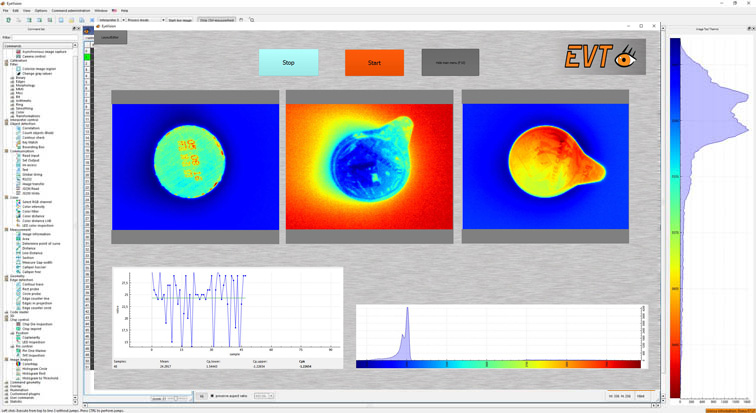

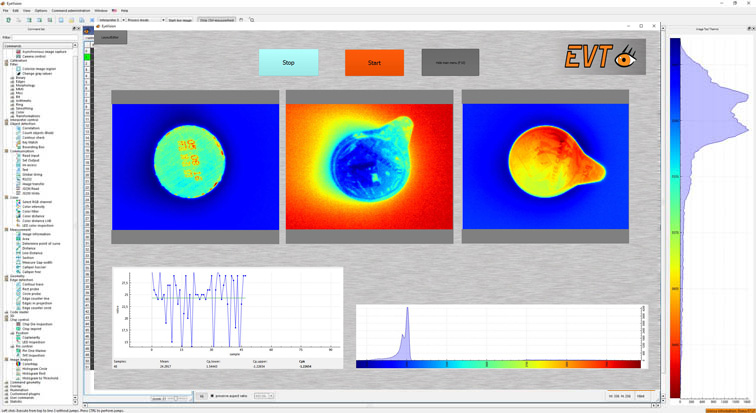

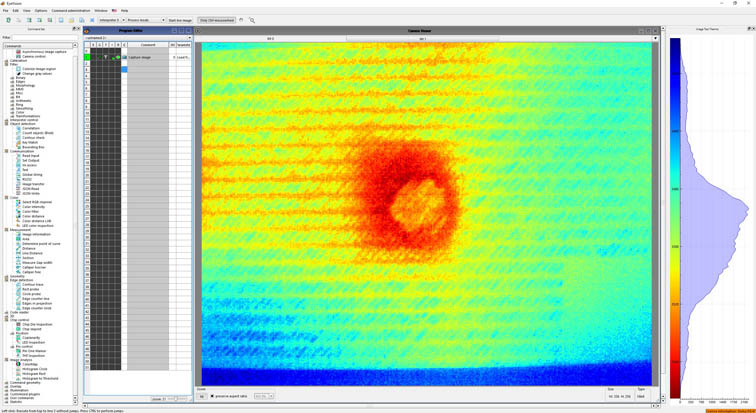

Thermal Imaging with EyeVision Thermo

-

The EyeVision Thermo software offers commands for the thermal measurement and inspection tasks for industrial thermal imaging.

Even demanding evaluations of thermal images can be carried out graphically with the powerful command set. For example in the fields of:

- active

- passive

- Lock-in

EyeVision software thermal imaging applications

- temperature distribution during thermoforming processes

- inspection of fiber reinforced material

- electronic component parts inspection

- inspection of precision resistors

- packaging control and leakage inspection

- inspection of heat-sealed joint, sealing and plastics welding processes

- error search in the fields of high and low tension

- plumbing isolation

- fireproof coating of furnace

- optimizing casting moulds

- fill level detection of containers

EyeVision Thermo …

… offers drag-and-drop programming

… has a intuitive-selfexplanatory user interface

… is programmable without programming skillsEyeVision Thermo camera support

EyeVision Thermo supports thermal imaging cameras by makers such as:

- Automation Technology

- Flir

- Optris

- Dalsa, etc.

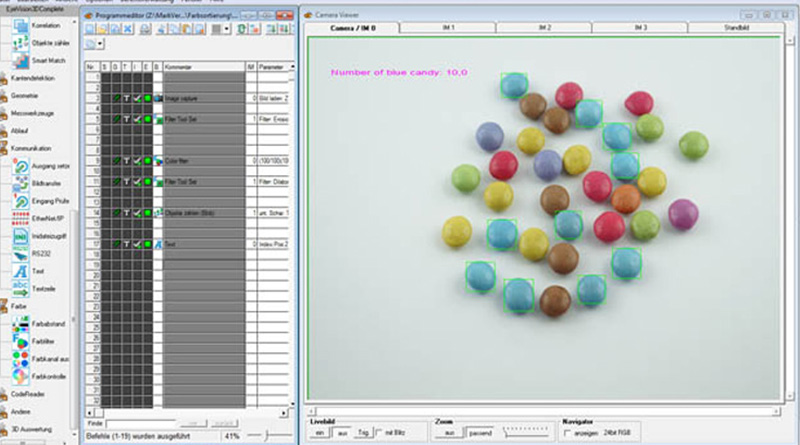

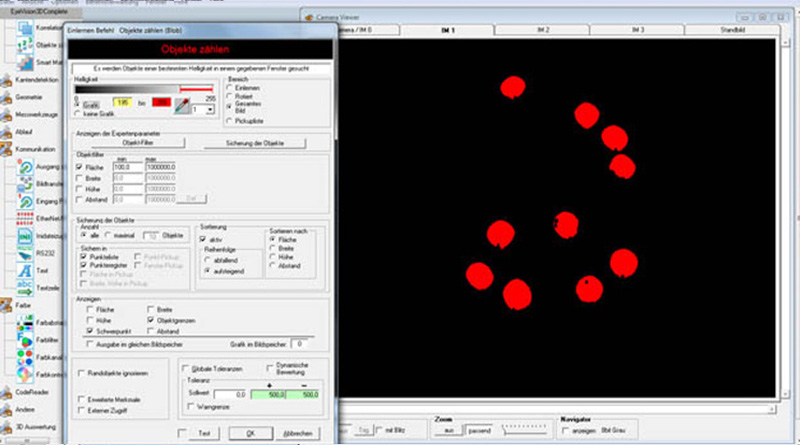

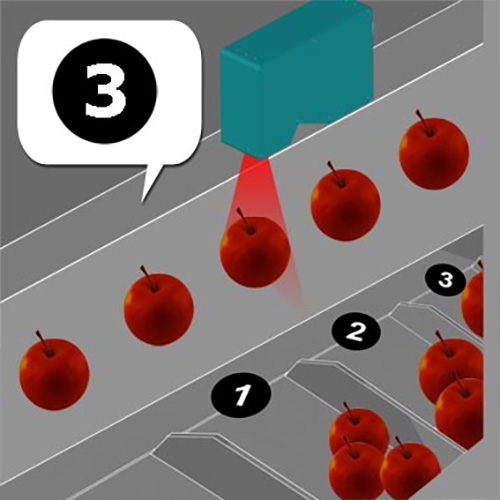

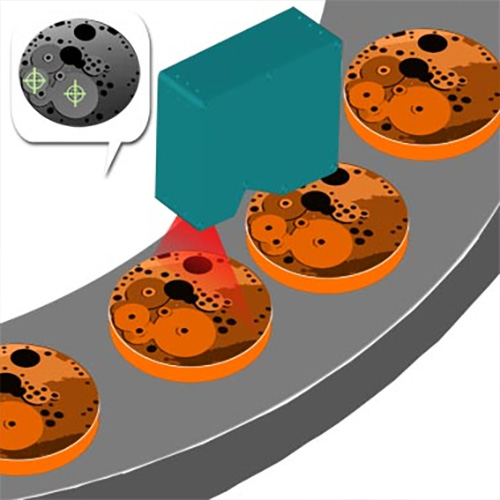

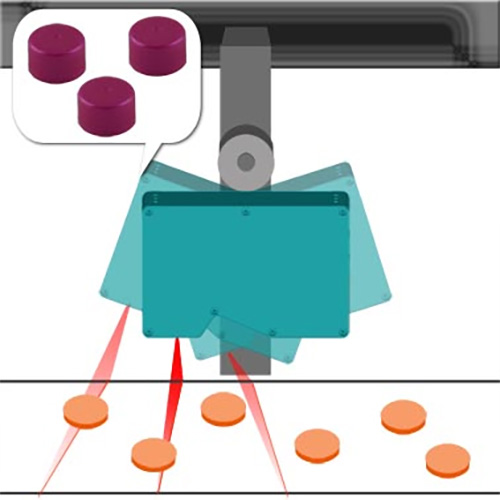

Object detection and counting

-

Object detection via automatic, visual inspection is an important task. It is part of many industrial processes, such as in:

- sorting

- quality control

- packaging

- inventory control

- machine processing, etc.

Applications: object detection with EyeVision

To detect a specific object with visual inspection is task, which is used in different industries.

We would like to give you some examples.

Object detection for the quality control

Quality control is as ever a difficult task in the production process and many processes still rely on the human eye.

The image processing and especially EyeVision can help you here. No matter if electronic-, pharmacheutical- or food and beverage industry.

EyeVision can differentiate between the wrong and the right component part, or detect if a cookie package is not correctly closed. Also EyeVision can detect in a gear wheel has enough spikes or if a blister packaging contains mixed up pills.

Inventory control and object detection

EyeVision can also be applied in inventory control. Objects can be tracked in real time, as there can be objects added and removed any time.

A good inventory control saves the company much time, space and labor costs.

Sorting with EyeVision

With EyeVision the sorting can be handled completely automatically. It saves time, costs and labor and also reduces errors.

For example in agriculture, sorting plays an important role. Especially for example to differentiate the ripe tomatos from the still green tomatos, or the damaged apples from the flawless apples.

But also other industries such as electronic or stamping part industry, count on automated sorting.

And combined with the Deep Learning / Machine Learning, also defects on surfaces can be easily detected.

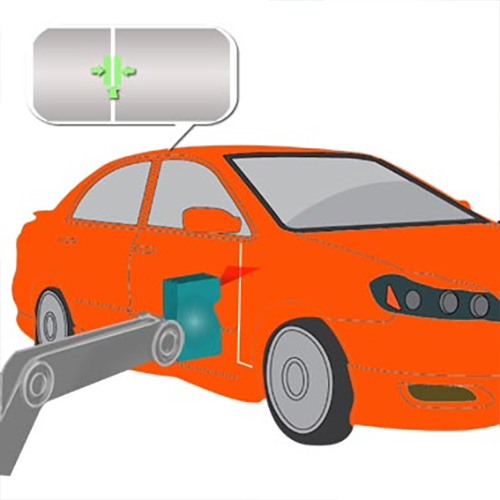

EyeVision for the assembly line

Nowadays we have completely automated conveyor belts and assembly lines, even for complex products as cars.

To offer the modern automated assembly line some more flexibility, it is important to teach the machines to locate objects and place them correctly.

With EyeVision a robot can be controled and the object exactly located.

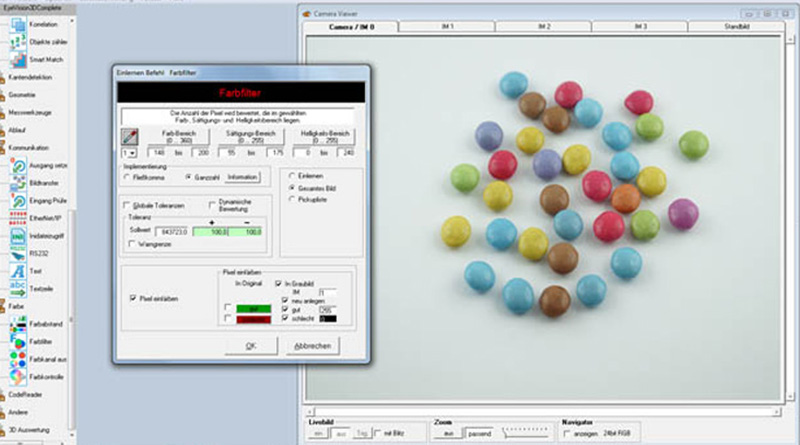

Color recognition and inspection

-

EyeVision can recognize and inspect color. Therefore the software has special color commands for the inspection of color-based quality characteristics. The color recognition is carried out with the highest precision and speed.

Color recognition is important

In many industrial environments color control is an important part of the quality control. Color defects can render products dead stock or lead to customer complaints. The impression of color is but subjectiv. Therefore sometimes an impression of color aberration can occur. The task for EyeVision is to maintain the color aberrations in a tolerable range.

Application fields

The recognition of color is important for many industrial application such as e.g.:

- car finish inspection at the car body pressing

- color inspection of attached parts in automotive engineering

- color sequence and quality in multiple-conduct cables

- color print errors and defects

- etc.

In all industries

Applications for color inspection can be manyfold and can be found in all industries:

- pharmaceutical

- electronic

- food and beverage

- automotive

- etc.

Bottle inspection for the beverage industry

-

With the commands of the EyeVision software bottle inspection for the bottle and beverage production can be carried out.

Application fields of bottle inspection

bottle cap

The EyeVision software inspects if

- the cap is open, askew or correctly closed.

- the correct cap is sitting on the bottle. This can be identified with for example the color or the shape.

- the lockring is in the right position.

Label

The bottle inspection also includes the inspection of the label.

EyeVision inspects:

- position and rotation

- damage and color

Bottle mouth

EyeVision inspects for:

- damage as for example

- cracks and scratches

Preform thread and bottle neck

EyeVision can also be applied to the inspection of the preform during bottle production. The software inspects:

- if the thread is damaged, has cracks or is broken.

- if the bottle neck is undamaged, has cracks or is broken.

Fill level

In bottling plants the EyeVision software can check the fill level. For example to check if the fill level is matched by every bottle, an image of the bottle neck is captured and the fill level measured.

Additionally there are many other inspection applications when it comes to the beverage industry, such as e.g.:

- token for the deposit on refillable and non-refillable containers

- 3D inside pressure of a bottle (beer, lemonade, etc.)

- containers of empties, etc.

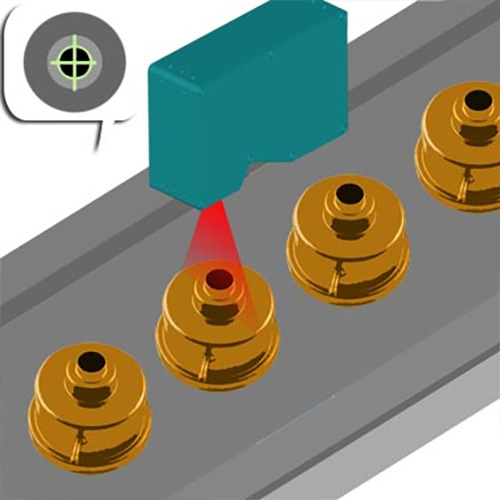

Thread Inspection with EyeVision

-

With the EyeVision Software component parts with a geometry that is difficult to access can be inspected, for example the inside of a drilling hole.

We inspect the internal screw threads for

- completeness

- errors and irregularities (screw thread run)

- contaminations (for example borings)

- etc.

We inspect external threads (metric threads and threads measured in inches) for

- completenes

- size accuracy

- screw thread run (correct direction of rotation and regularity)

- in correspondence with the requirements of the crest and groove of the thread

Advantages of the EyeVision software for thread inspection

With the EyeVision the thread inspection is carried out with only one single command. The drag-and-drop function makes the handling of the software even easier. Therefore it is possible to create an inspection program for the thread inspection without any programming skills.

Additionally the thread inspection with EyeVision offers:

- high measurement and inspection accuracy

- contactless measurement (prevents damages on the component part)

- 100 % inspection quality

- high flexibility when it comes to adaptations to new production requirements

- extremely fast measuringg (only a few millisenconds)

EVT Ready-to-Use System Thread Inspector

The Thread Inspector combines the functions and advantages of the EyeVision software with the emSys hardware.

With the Ready-to-Use Thread Inspector the internal and external screw thread inspection can be integrated into any inspection plant and any robot. In addition existing inspection systems can be extended easily with this screw inspection.

Further advantages of the Thread Inspector:

- Interfaces for intergration into Profinet or Modbus

- Integration in a SCADA system via OPC UA

- Interfaces for control of the camera and the LED-illumination

- Easy configuration for the different thread types

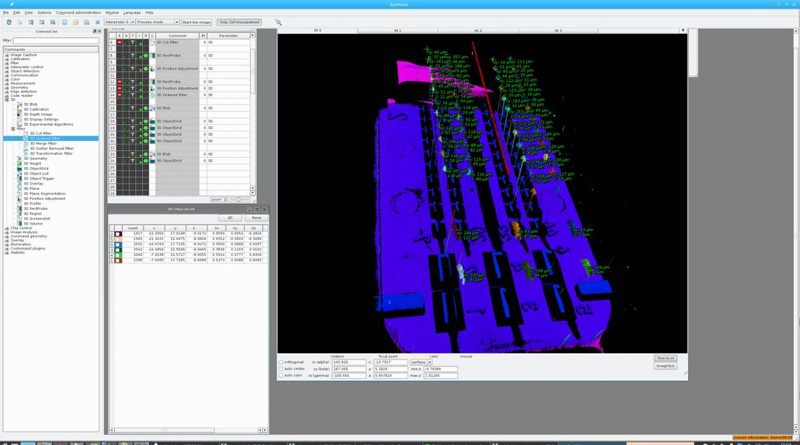

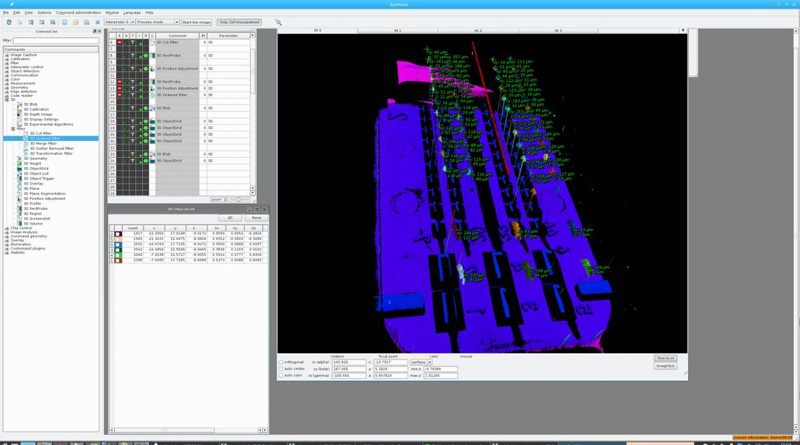

EYEVISION 3D SOFTWARE

-

The key function of the EyeVision 3D software is the capture and evaluation of 3D-images (point clouds).

Based on the point cloud, EyeVision 3D has several commands for:

- detect and count objects

- detect errors

- carry out different metrology operations

EyeScan 3D-sensors for the EyeVision 3D software

With the 3D-camera system EyeScan 3D, EVT offers the EyeVision users an easy access to the third dimension.

3D-Sensors are applicable in all industries, such as for:- quality control

- robot control and guidance

- µ-accurate metrology

- an already calibrated 3D-seanor – based on laser triangulation, shape-by-shade, Time-of-Flight, or stereo vision

- the complete evaluation software EyeVision 3D is supported and can be programmed via drag-and-drop function

Use cases

tire production

- For the tire production a 100%-quality control is indispensable. A 3D inspection also detects the black print on a black tire. At the same time also other surface defects can be detected.

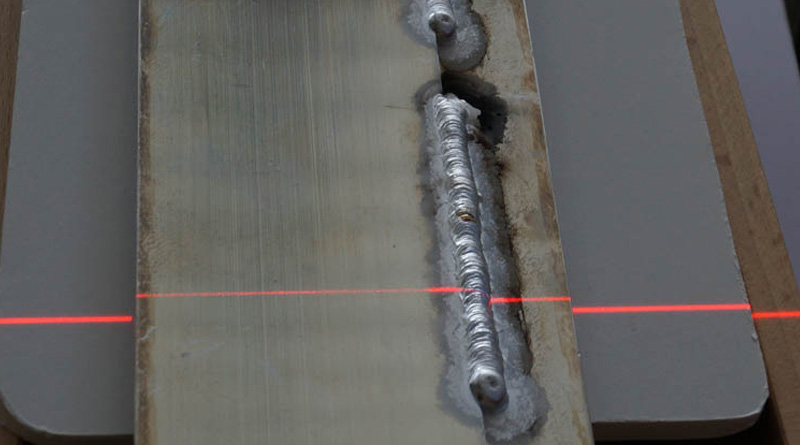

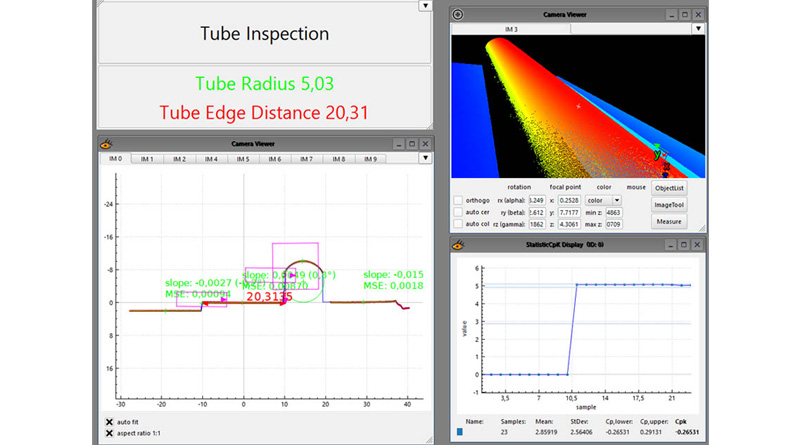

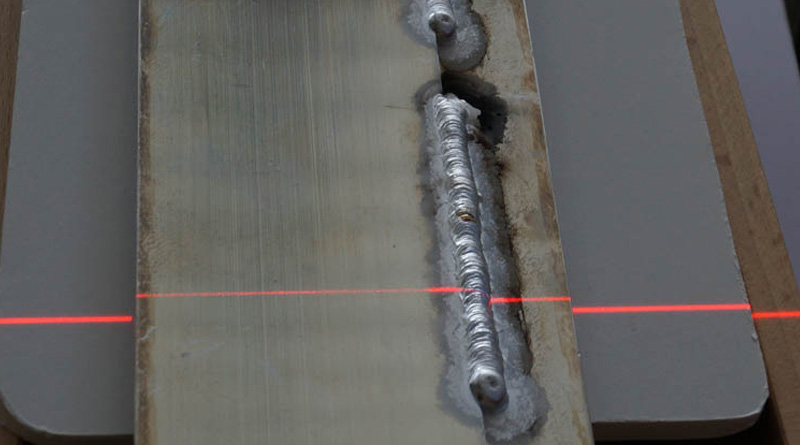

weld seam inspection

- EyeVision 3D checks for weld width and length, countersink free finish, weld seam joint or collapses, unequalsidedness, holes and surface pores.

Inspection of adhesive applications

- Noncontact and nondestructive inspection immediately after the application of the adhesive bead. Suitable for all glues and surfaces. EyeVision 3D recognizes flaws such as e.g.: discontinuity, thickening and position errors of adhesive beads.

Sealing compound inspection

- EyeVision 3D inspects if the sealing compound is applied correctly and checks the positioning of the sealing compound. EyeVision and the EyeScan 3D Sensor guide the robot.

PCB Inspection

- EyeVision 3D inspects at the soldering process and checks the component parts for: alignment, position, presence

Smart Phone Inspection

- EyeVision 3D inspects small-format substrates as e.g. for smart phones. Measures fixed component parts and wavelength-dependent transmissions of filter layers on glass substrates.

groceries inspection

- EyeVision 3D scans size and shape of e.g. fruits and sorts them accordingly afterwards. This process prevents rejection.

inspection of parts of watches

- EyeVision 3D checks on shape-defects fuch as e.g.: cylindrical form, corrugation, circularity. Additionally geometrical dimensions e.g.: diameter, height, width, etc.

cast metal inspection

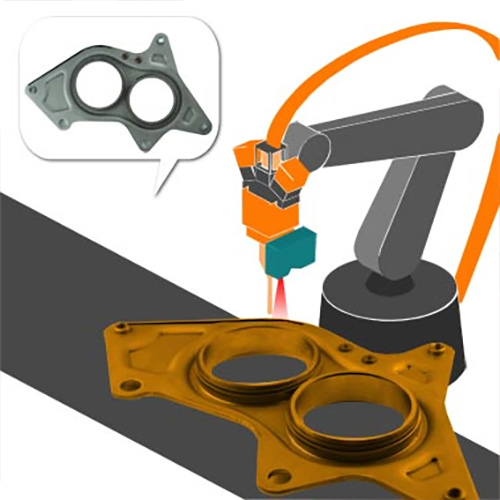

- The 3D sensor scanns cast metal parts and compairs the scanned image with the CAD-data. EyeVision 3D inspects the shape and measurements during the production process.

gap inspection

- EyeVision 3D inspects different gap types e.g.: simple gap, projection-gap, gap with bottom, advanced gap,

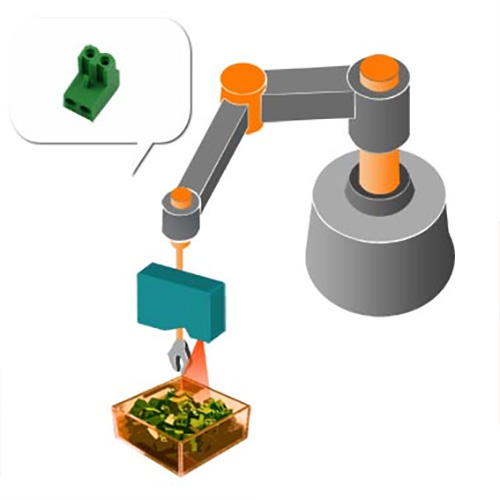

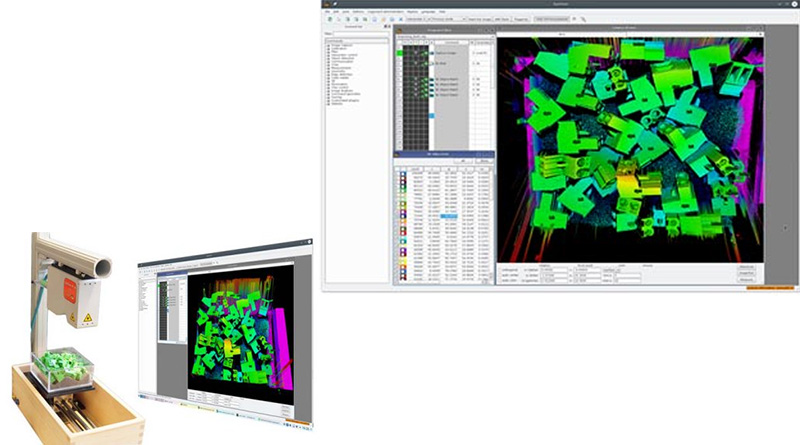

EyeVision 3D für bin-picking

- EyeVision 3D captures component parts in every position and rotation. Reacts on position changes of the objects. EyeVision 3D allows a complete usage of the robot line.

EyeVision 3D to scan large areas and object

- EyeVision 3D can scan large surfaces and can display it undistorted with the 3D Unrolling command, without the need of an axis or robot.

Applications with EyeVision 3D

3D BIN-PICKING

-

How does EyeVision 3D Bin-Picking work?

With the bin-picking command of the EyeVision 3D software it is possible to:

- detect every position and shape of any object

- detect unsorted component parts in a box, pick them up with a robot and feed them to the production machine

- send the position of every detected part in the box to a robot

With the 3D-Matching of the EyeVision 3D it is possible to detect the shape and position of any, previously configured object, with only one 3D sensor. Therefore it is possible to pick even parts in comlicated shapes.

Advantages

With EyeVision 3D a quick image capture of the component part’s surface is carried out and the 3D point clouds are used directly in the EyeVision 3D interface to calculate the respective position of each single part.

EyeVision 3D is the base for numerous systems in the industrial automation, as well as demanding services.

The software offers 3D measurements in the production process, in the field of 3D Robot Vision, as well as packaging and logistics, measurement and comparison in 3D.

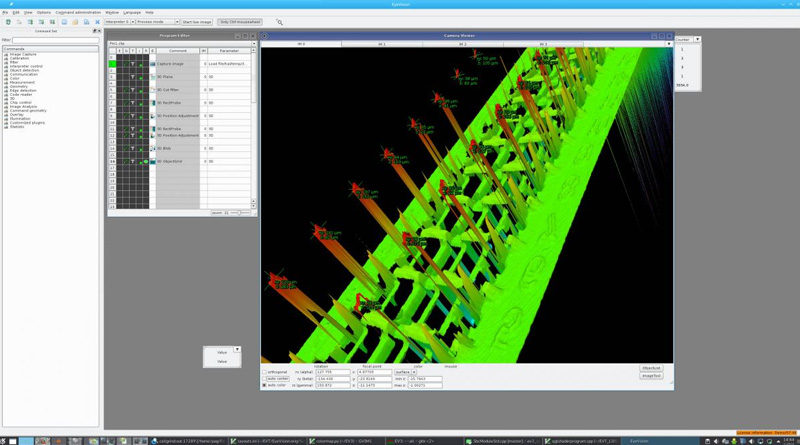

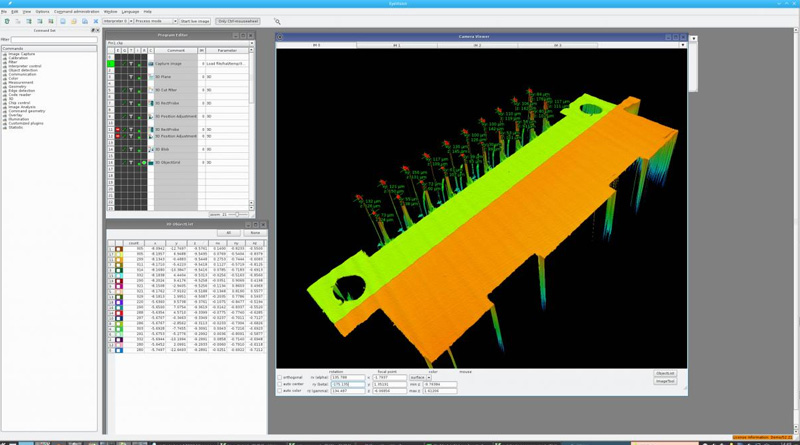

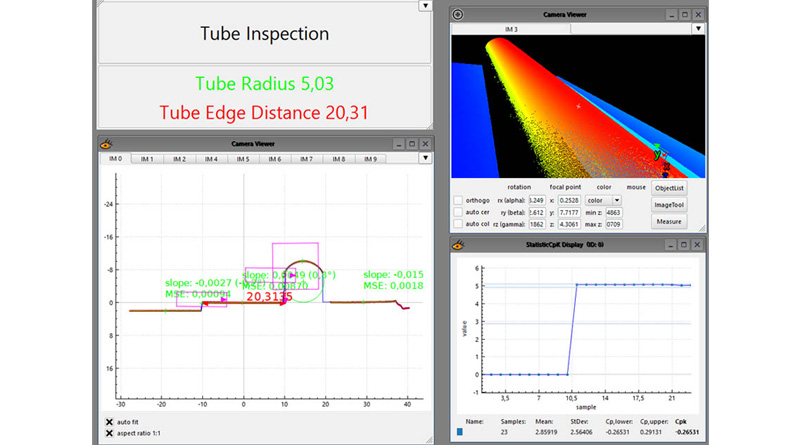

3D PIN INSPECTION

-

With the EyeVision 3D pins of every kind can be measured for their correct position and reeling circle.

Reeling circle and pin embedment depth

- reeling circle or true point

The EyeVision 3D software can carry out a measurement of the so called true point. These are gauges to measure connector tolerances and staggering of the pins.

- measurement of the embedment depth

The software also can measure the embedment depth of the pins. Thanks to the 3D inspection it is possible to measure the height of the pin tips. Those are not only measured in theire x- and y-direction but also the z-direction.

- flaws on the connector

Furthermore the system can detect flaws such as e.g. if the connector pins are bent, if the pins are stuck to deeply into the housing or if the pins stick out too far out of the housing.

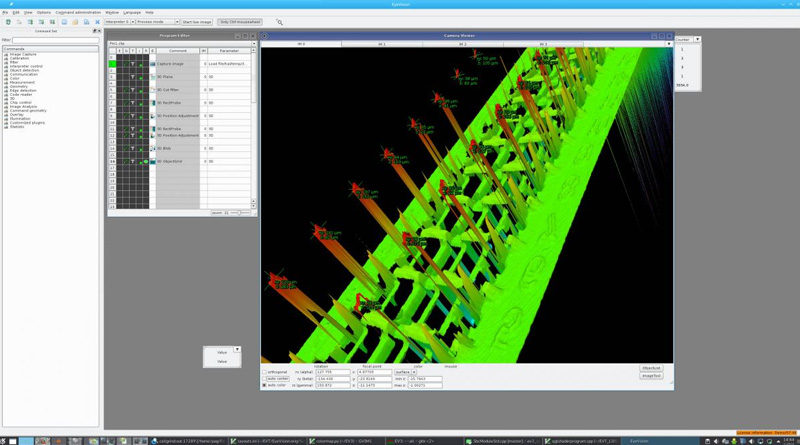

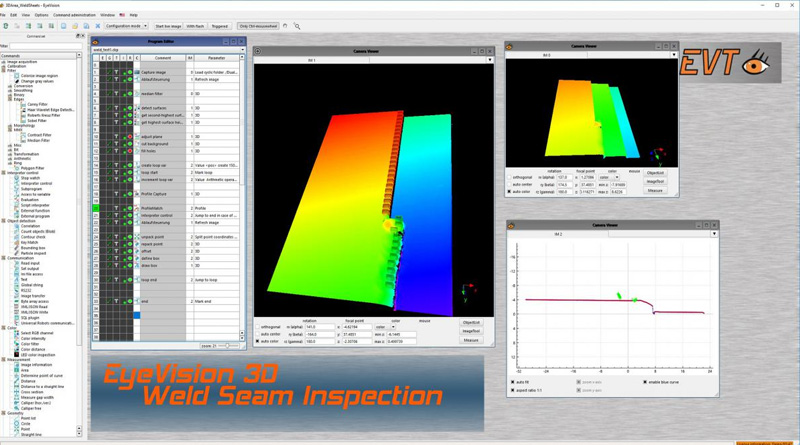

3D WELD SEAM INSPECTION

-

With EyeVision 3D a weld seam can inspected for errors.

The ProfileMatch command is a Matchin Tool for 1D applications, such as e.g. to inspect a weld seam or adhesive bead.

Only a few steps have to be carried out by the user:

- first, a shape is taught-in with the ProfileMatch command and

- the command then detects, if the expected profile matches the actual profile.

- if the weld has an end crater

- width and length of the weld seam

- it the weld seam is missing

- undercuts

- holes and surface pores on the weld seam

- unequal leg length

- In case of an error, the software calculates how big the aberration is.

- Also the command has a height offset.

This means, that the command detects the profile, even when the height is not matching with the height of the taught-in profile. - The profile scanner measures the elevation profile of the weld seam by projecting a laser line onto the object. The laser line profile is then captured by the integrated camera.

- The laser line captured by the camera is transformed into electrical signals, digitized as well as converted into real world coordinates.

The Profile Match Tool raises an alarm in cases of errors such as “plain”. That are so called “warts”, which describe errors, where for example a weld seam is too thick, or shapes too much plain, respectively. There is also an error called “holes”. That describes errors, where for example a weld seam is disrupted or the weld seam is too thin.

Error criterions for weld seams

Errors could be for example:

Calculating the aberration and the height offset

3D laser triangulation sensors as methode for the profile scan

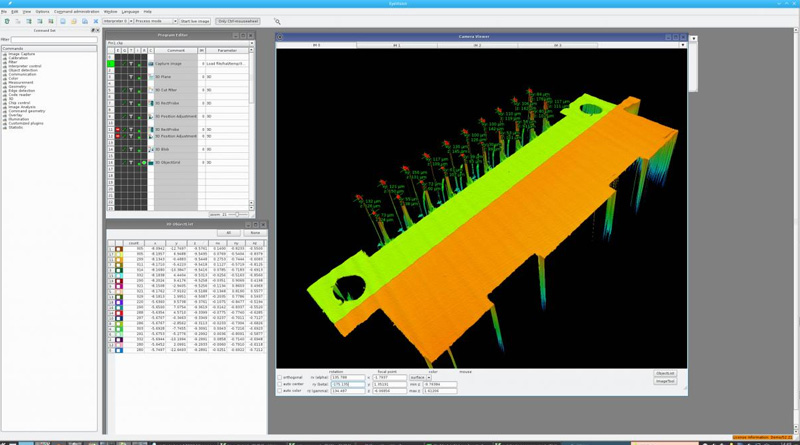

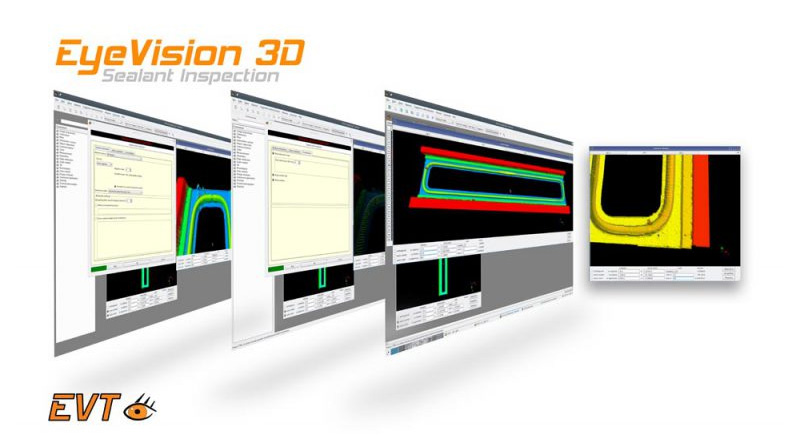

3D GLUE AND SEALING BEAD INSPECTION

-

With the EyeVision 3D software it is easy to inspect adhesive beads and sealing beads.

For this tasks EVT has developed the Sealant Inspector.

Sealant Inspector: command for adhesive bead inspection

The Sealant Inspector of the EyeVision 3D software inspects glue and sealing beads for:

- height & width

- position

- volume & cross section

- open and closed sealing and adhesive beads

- convex and concave sealant

Features of the Sealant Inspector:

- tolerances can be set for all parameters: error warning can be issued

- point cloud is automatically extracted

- evaluation is carried out directly on the point cloud

- detects flaws, helps to prevent reclamations and to reduce test cycle times

- saves costs

WELDSEAM VISION®

-

The WSV (WeldSeam Vision®) is a weld seam inspection system for the inspection of laser and MIG/MAG-weld seams.

Field-of-View, Resolution and Accuracy

For MIG/MAG- and solder seams the WSV offers a field-of-view of 20 – 30 mm and for the laser weld seams a field-of-view of 10 – 15 mm.

The inspection system detects errors with sizes from 0,1 mm and with a resolution smaller than 1 µm depth, even the smallest errors can be detected.

The integrated EyeVision Software and Graphical User Interface (GUI)

The WSV is a “ready-to-use” equipped system and can be delivered for different weld seam sizes. The powerful EyeVision software for weld seam inspection detects all common errors and can be adapted to inspect new weld seams and fulfill new inspection tasks.

The easy-to-handle graphical interface can be used by beginners as well as PLC-programmers in only a few minutes.

Hardware advantage – Only one cable necessary

The sensor head is only connected via a single GigE cable and therefore it is easy to integrate into a robot. The system works with 24 V and in addition has RS232, RS485 and digital I/O.

Features WeldSeam Vision®:

- for sensor EyeScan ST 3D

easy integration into: Tracker system, SCADA, SPS - Interfaces: GigE, USB, RS232, RS485

communication protocol for: Profinet, OPC UA, Modbus, UDP & TCP/IP, Stand-alone system Headless system

- for sensor EyeScan ST 3D

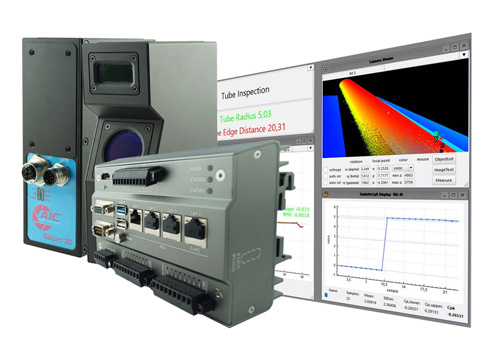

EVT SMARTSENS SATURN 3D PROFILE INSPECTOR

-

The Smart 3D Profile Inspector allows the Single-Button-Training of any profiles. Therefore the profile can be repeatably inspected for flawlessness in the production. Most tasks can be therefore realized in the field of profile production and inspection.

Different Communication Protocols available

The system has a GigE PoE interface, which is connected to the DIN-rail module. There you have also 8 digital inputs and 8 digital outputs in 24 V technology to emit a signal in case of an error or to communicate with a PLC. Alternatively you can communicate with a PLC via the Ethernet interface. There are also TCP/IP, UDP as well as Profinet and Modbus communication available, which makes the integration very easy.

Saturn 3D Triangulationsensor

The Saturn 3D laser triangulation sensor with Linux OS and PoE (Power over Ethernet) can process high data rates supported by the integrated FPGA. The extremely compact and innovative 3D sensor has an encoder interface and with profile rates of up to 6 kHz allows for a high-precision 3D profiling. The Saturn 3D is available with different laser option such as red and blue lasers, depending on customer wishes.

Set up with “Single-Button-Training” function

To simplify the integration and to visualize the latest inspection live, the DIN-rail module has a HDMI and USB interface. With monitor, mouse and keyboard the system can be adjusted intuitively. There is the Single-Button-Training function available for the user to also integrate further inspections. When inspecting the profile, it is compared with the taught-in profile.

In addition other measurements can be carried out to e.g. secure the functional dimensions. For example when inspecting a windscreen wiper, you can inspect the shape and in addition the angle and the width of the wiper lips can be measured also. The number of inspection is not limited. Therefore the user is free to carry out any measurements.

The adaption of the measurement and inspection applications is carried out completely graphically, or in the Single-Button-Mode with a golden part.

Smart Cameras EyeCheck

- The EyeVision image processing software runs on the smart camera series EyeCheck.

EYECHECK 4000 SERIES

-

The EyeCheck 4000 smart camera series is extremely fast thanks to the freely programmable FPGA. It allows to pre-process data in real time. Based on the XILIX Zynq SoC, the cameras are equipped with a DualCore ARM Cortex A9. The user can choose between several matrix sensors and a line scan sensor.

On all smart cameras runs the EyeVision software.

Technical Data

- CPU: 800 MHz / 1GHz DualCore ARM CORTEX A9

- DDR3: 512 MB, 1 GB

- FLASH: 4 GB, 8 GB, 16 GB

- Connector Ethernet: 10/100 MBit – 1 GB

- Digital I/Os: 10 programmable I/Os

- Protection class: IP65

- Power consumption: 4 W

- Power supply: 9~ 30 VDC

- Mount: C-Mount, S-Mount

- Weight: ca. 120 g

- Dimensions: (WxHxL) 64 x 47 x 29 mm

- I/O: CAN / RS485

EYECHECK 5000 SERIES

-

The EyeCheck 5000 series has a QuadCore Intel Atom CPU. The camera is available with Windows or Linux operating system, with CCD or CMOS sensor. The smart camera series offers resolutions of up to 12 MPixel.

On all smart cameras runs the EyeVision image processing software.

Technical Data

- CPU: x86 1 GHz, VIA EdenULV

- Memory: 512 MB DDR2 SDRAM

- Operating System: Windows or Linux

- Connection: Ethernet, 2x USB 2.0, RS-2322C, Sub-D Monitor

- Digital I/Os: Isolated 4 Inputs/8 Outputs

- Power consumption Max.: 17,4 W

- Operating voltage: +12V und +24V

- Mount: C-Mount & CS-Mount

- Temperatur: Operating: -5 bis +45 °C

- Storage: -30 bis +60 °C

- Weight: ca. 760 g

- Dimensions (WxHxL): 94 x 70 x 140 mm

EYECHECK 6000 SERIES

-

With the EyeCheck 6000 smart camera series, EVT offers another camera with Windows operating system. The camera is very robust and with IP67 ideal for rough environments. It also is GenICam, GenTL, Open CV & Open CL compatible and is equipped with an Intel Atom QuadCore CPU.

On all smart cameras runs the EyeVision image processing software.

Technical Data

- Processor: Intel Atom E3845, QuadCore @ 1.91 GHz

- Display: VGA connector, max. 2560×1600

- Memory RAM: 2 GB DDR3L, 16 & 32 GB SSD

- Sensor: Monochrome

- Trigger Input: 1 x Opto-isolated Trigger Input

- Digital I/Os; 4 Inputs / 4 Outputs

- Interfaces: 1x Gigabit Ethernet, 1x RS232, 1x USB 2.0

- Operating System: Windows

- Lens Mount: C-Mount

- Protection class: IP67

- Power consumption: 13 W

- Power supply: 12..24 VDC +/- 10%

- Temperature Operating: 0 bis +50 °C

- Connector: 1x M12 8-pin (female), 1x M12 17-pin (male), 1x 12-pin (male)

- Weight: ca. 195 g

- Dimensions (WxHxL): 68,5 x 110 x 52,7 mm

EYECHECK 7000 SERIES

-

The EyeCheck 7000 smart camera series is a very fast intelligent camera with freely programmable FPGA. Therefore all data can be pre-processed in real time. The FPGA is available for the user. It can solve complexe applications, such as contour matching.

Die EyeCheck 7000 Smart Camera Serie ist eine sehr schnelle intelligente Kamera mit frei programmierbarem FPGA. Somit lassen sich Daten in Echtzeit vorverarbeiten. Der FPGA steht dem Anwender zur Verfügung. Er kann damit komplexe Aufgaben lösen, wie z.B. ein Konturabgleich.

On all smart cameras runs the EyeVision image processing software.

Technical Data

- CPU: Single/ DualCore Cortex-A9 800 MHz

- System: RAM 512 MB

- FLASH: Secure Digital 8 GB (up to 32 GB)

- FPGA: XILINX 28K LEs/ XILINX Artix-7 28K LEs

- FPGA: RAM 1 GB (only for model EC7800)

- Digital I/Os 2 Inputs/ 2 Outputs PNP

- Strobe Outputs: 2 Outputs

- Encoder Input: 3 channels RS422 Line Driver (only for 7800)

- Interfaces: Gigabit Ethernet, RS232, RS485

- Protection class: IP67

- Mount: C-Mount

- Stromversorgung: 24 VDC

- Operating System: Linux

EYECHECK 8000 SERIES

-

You can connect up to 4 sensor heads to the EyeCheck 8000 smart camera.

On all smart cameras runs the EyeVision image processing software.

Technical Data

- Operating System: Linux (Debian)

- CPU: ARM Cortex-A8, 1 GHz

- DSP: 700 MHz C674x

- RAM: 2 GB DDR3-800

- FLASH Memory: 16 GB

- SD card: yes

- Ethernet: 1 Gbit/s

- USB Host/ Device: yes / yes

- GPIOs: up to 44

- RS232 / RS485: yes / yes

- SATA: yes

- CAN Bus: yes

- JTAG: yes

- Real-time Clock (RTC): yes

- Maximum Video Resolution: 1080p

- S-Video: yes

- RGB888: yes

- HDMI: yes

- Audio in /out: yes

- Wake on LAN: yes

EYECHECK 900 & 1000 SERIES

-

The EyeCheck 9xx and 1xxx smart cameras are due to their robust and compact design ideal for rough environments. The cameras are available with lens & illumination or with C-mount.

On all EyeCheck cameras runs the EyeVision image processing software.

EyeSens 1xxx Next Generation

- RAM: 512 MB

- FLASH: 4 GB

- Interfaces: Ethernet (LAN), EtherNet / IP, PROFINET

- Digital I/Os: 2 In- / 2 Outputs, 6 selectable In- / Outputs

- Protection class: IP65 to IP67

- Power consumption: (without illumination & IO) –

- Power consumption: (without IO) < 300 mA

- Power supply: 18 … 30 VDC

- Temperature: Operating: 0 … +50 °C (at 80% Luftfeuchtigkeit)

- Storage: – 20 … +60 °C (at 80% Luftfeuchtigkeit)

- Weight: ca. 200 g

- Dimensions: 70,4 x 45 x 45 mm (without connectors)

EYECHECK ZLS & ZM SERIES

-

The EyeCheck ZLS & ZM smart line scan and matrix camera are of one platform with Zynq and optional Myriad 2 Deep Learning processor. With DualCore ARM Cortex with either 800 MHz or 1.5 GHz.

On all EyeCheck cameras runs the EyeVision image processing sofware. The smart camera is also as RazerCam ZLS & ZM without software available.

Technical Data

- Operating System: Linux

- CPU Dual Core 800 MHz oder 1.5 GHz optional Myriad 2

- Interface: GigE (PoE)

- Interface options: UART, SPI, I²C

- Digital I/Os: 4/4 In-/Outputs galvanically separated, 24V, 3 freely programmable, 24V tolerant

- SDK: C++ for receiving the image data & for parametrization

- Libraries: EVLib, OpenCV, etc.

- Options

as RazerCam without EyeVision Software

as network camera for image transfer

EYECHECK ZQ SERIES

-

EyeCheck ZQ is possibly the smallest smart camera in the world. Only as big as a thumb the camera still contains the full EyeVision software.

Technical Data

Processor: ARM Cortex-A9, 866 MHz DualCore

Memory: 512 MB DDR3 RAM & 4 GB FLASH

Ethernet Port: 10/100M

Communication Port: TCP / UDP

Lighting Control: Embedded Lighting

Power supply: 9 bis 30VDC, 1.5 W

Environmental temperature: -20 bis +55 °C

Dimensions: 20 x 20 x 60 mm

Weight: 50g

SMART CAMERA EYESPECTOR SZ

- The EyeVision Software runs on the EyeSpector SZ smart cameras.

EYESPECTOR SZ SMART CAMERA

-

EyeSpector SZ with Dual-ARM Cortex-A9 with integrated FPGA. Also available as color cameras.

On all smart cameras runs the EyeVision image processing software.

Technical Data

- Integration: Global Shutter

- Processor: Dual-Core ARM Cortex A-9 with 2 x 866 MHz and integrated FPGA

- RAM: 512 MB DDR-SDRAM

- Flash: Eprom 16 GB flash memory

- Dig. I/Os: 2 Inputs, 4 Outputs

- Tigger I/Os: 1 Trigger Input and 1 Flash Tigger Output

- Interfaces: Ethernet 100 Mbit, 8 I/Os

- Supply voltage: 24 V +/-20% DC

- Power Input: < 3 W

- Dimensions ca.: 80 mm x 45 mm x 20 mm, ca. 90g

EYESPECTOR SZ PRO SMART CAMERA

-

EyeSpector SZ pro with Dual-ARM Cortex-A9 with FPGA and integrated LED illumination. Also available as color camera.

On all EyeSpector SZ pro runs the EyeVision image processing software.

Technische Daten

- Integration: Global Shutter

- Processor: Dual-Core ARM Cortex A-9 with 2 x 866 MHz and integrated FPGA

- RAM: 512 MB DDR-SDRAM

- Flash Eprom: 16 GB flash memory

- Dig. I/Os: 4 Inputs, 4 Outputs

- Tigger I/Os: 1 Trigger Input and 1 Flash Trigger Output

- Interfaces: 1 Gbit, Encoder, RS232, 2 x Illumination, 10 I/Os

- Supply voltage: 24 V +/-20% DC

- Power Input: < 3 W

- Dimensions ca.: 88 mm x 58 mm x 36 mm, ca. 300 g

- Protection class: IP67 housing

VISION SENSORS EYESENS

-

The EyeSens vision sensors by EVT are pre-configured for certain application areas and contain commands of the EyeVision software such as e.g. for object- or color detection or for Reading of DMC, bar code, QR code or OCR/OCV.

The compact EyeSens sensors are available with integrated LED illumination and 6, 12 or 25 mm lens.

All EyeSens can be extended with further software modules.

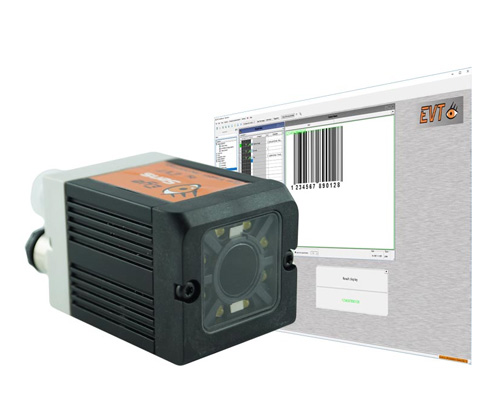

EYESENS ADVANCED BARCODE, DMC, OCR

-

The vision sensor EyeSens Advanced for reading BarCodes, DMC, OCR. This vision sensor can read bar codes in any position and rotation in the image.

DMC Command

The powerful EVO DMC command reads not only flawless codes, but also codes that are for example:

- damaged,

- blurred,

- distorted or

- low contrast

The vision sensor always reports to the user about incorrect codes. Also differences in character thickness are no problem for the sensor.

OCR Command

Additionally the EVO OCR command set offers powerful functions for the optical detection and inspection of characters. The module includes image preprocessing, segmenting, sorting and classifying of characters. The system recognizes even characters that are difficult to read. The OCR command even detects dotted or nailed characters with the OCR-command.

Applications for OCR:

- expiration dates on groceries and pharmaceuticals

- detection of any kind of print and even hand writing

- label and print inspection

- 3D charachters e.g. on car tires

- print quality inspection

EYESENS WIREINSPECTOR SENSOR

-

What does the EyeSens WireInspector?

The vision sensor can inspect a cable and connector for:

- the correct cable assignment

- the correct color and presence of the cable

- and also the bar code on cable trees for a correct assignment and 100% retraceability

EYESENS BAR CODE READER

-

Which codes can the EyeSens BarCode read?

The vision sensor can read many different bar code types such as e.g.:

- Code 39 & Code 128

- 2/5 Interleaved

- EAN13 & EAN 8

- UCP Version A & Version B

EYESENS COLORINSPECT SERIES

- It verifies colored objects with high precision and speed. With the integrated EyeVision software the user can solve applications such as color control and color comparison.

EYESENS DMC READER VISION SENSOR

-

The EyeSens DMC vision sensor has a powerfull DMC Reader command. It reads not only flawless codes, but also codes that are for example:

- damaged,

- blurred,

- distorted or

- low contrast

The vision sensor always reports to the user about incorrect codes. Also differences in character thickness are no problem for the sensor.

EYESENS GTI GEAR TOOTH INSPECTOR

-

The Function of the EyeSens GTI (Gear Tooth Inspector)?

The vision sensor can inspect gear wheels for:

- presence of the gear teeth

- width of the gear teeth

- distance between the gear teeth

For all components to interlock perfectly into each other, the precise measurement of the gearing parameter is very important. Because the aberration would lead to irregular cycle and therefore to increased abrasion.

EYESENS MATCH VISION SENSOR

-

The vision sensor EyeSens Match solves pattern matching applications.

The Function of the EyeSens Match?

The vision sensor can detect previously taught-in patterns in:

- any rotation

- any position

- no matter if complete or incomplete

This means that, when the taught-in pattern in the image moves, rotates or is half invisible, the EyeSens Match can detect the pattern anyway.

EYESENS MEASURE VISION SENSOR

-

What measures the EyeSens Measure?

The vision sensor can measure geometrical shapes and distances:

- circle

- distances & straight lines

- angles & rectangles

Therefore even complex metrology tasks can be solved fast and easily.

EYESENS OBJECTCOUNT VISION SENSORS

-

The vision sensor EyeSens ObjectCount can detect and count objects with the special BLOB command.

What’s the advantage of EyeSens ObjectCount?

The vision sensor can detect and count objects with only one command.

It is suitable for quality control, error detection and the production process on a conveyor belt.

The system counts consequentely for example:

- nuts, apples, oranges, etc.

- salami on frozen pizza

- cog wheels, screws, globes

- borehole, any kind of markings

EYESENS OCR VISION SENSOR

-

The vision senso EyeSens OCR for Optical Character Recognition and Optical Character Verification, with a special EyeVision software.

The system recognizes even characters that are difficult to read. The OCR command even detects dotted or nailed characters with the OCR-command.

The OCR command set offers powerful functions for the optical detection and inspection of characters. The module includes image preprocessing, segmenting, sorting and classifying of characters.

Applications for EyeSens OCR:

- expiration dates on groceries and pharmaceuticals

- detection of any kind of print and even hand writing

- label and print inspection

- 3D charachters e.g. on car tires

- print quality inspection

EYESCAN 3D SENSORS

-

EyeScan 3D sensors are supported by the EyeVision 3D image processing software.

The sensors can solve different applications:

3D Pin-Inspection

bin-picking

weld seam inspection

glue and sealing bead inspection

inspection of food and beverage, electronic, car parts, etc.

EyeVision 3D also supports 3D sensors from other companies such as for example: Wenglor MEL, QuellTech, Photonfocus, LMI, Basler, Intel RealSense, BlueTechnix, Chromasens, etc.

EYESCAN AT 3D SENSOR

- The EyeScan AT 3D sensor is a high-speed and high-resolution laser triangulation sensor. It supports the EyeVision 3D software.

EYESCAN LT 3D SENSOR

- The EyeScan AT 3D sensor is a high-speed and high-resolution laser triangulation sensor. It supports the EyeVision 3D software.

EYESCAN LTZ 3D SENSOR

- The EyeScan LTZ 3D sensor is a compact and fast laser triangulation sensor with Dual-Core ARM processor and FPGA for fast preprocessing of the data. It supports the EyeVision 3D software.

EYESCAN ST 3D SENSOR

-

3D laser triangulationssensor

- 3D sensor with profile speed of 3 kHz up to 6 kHz*

- Integrated FPGA and high-precision 3D profiling

- Power over Ethernet (PoE)

- Encoder Interface

- Innovative 3D sensor: small and compact

- cost-effective and easy to handle

INTEL REALSENSE SUPPORT

-

Intel RealSense support by the EyeVision 3D Software

The Intel® RealSense™ Depth Cameras are supported by the EyeVision 3D Software.

Therefore it is possible:

- to detect a 3D object,

- to determine the color of an object with the color camera or

- to carry out 2D measurements or code reading with the gray and color camera

BASLER TIME-OF-FLIGHT 3D SENSOR SUPPORT

-

The EyeVision 3D software supports the Basler Time-of-Flight sensor.

Therefore volume measurements, work space surveillance, 3D-object detection and other applications can be carried out. An important application is also the automatic loading and unloading of boxes from palettes with a robot.

BLUETECHNIX TIME-OF-FLIGHT 3D SENSOR SUPPORT

-

The EyeVision 3D Software supports the Time-of-Flight 3D sensor by BlueTechnix (Become).

Therefore volume measurements, work space surveillance, 3D-object detection and other applications can be carried out. An important application is also the automatic loading and unloading of boxes from palettes with a robot.

CHROMASENS 3DPIXA SENSOR SUPPORT

-

The EyeVision 3D software supports the Chromasens 3DPIXA.

The 3DPIXA stereo camera is a combination of line scan technology with fast stereo algorithms running on GPU. Providing 3D data and 2D color images simultaneously opens up combined 2D and 3D inspection.

Typical Applications for Chromasens 3DPIXA

- Fast inline height measurement

- Completeness check in 2D and 3D

- Verification of 2D and 3D dimensions

- Identifying micron defects

- Combined 3D and 2D color inspection

- 3D web inspection

How does 3D stereo vision work?

The stereo image processing uses the same principal as the human eye, the stereoscopic offset. As only two cameras are necessary, the stereo image processing relies on the capture of identical characteristics from both cameras. But because an object does not always have special characteristics, often a random pattern projection is used.

LMI GOCATOR 3D SENSOR SUPPORT

-

The EyeVision 3D software supports the Gocator 3D sensors by LMI.

The LMI Gocator is available in differen technologies. EyeVision supports the lasertriangulation and shape-by-shade sensors.

WENGLOR MEL 3D SENSOR SUPPORT

-

The EyeVision 3D software supports the wenglor MEL 3D sensors weCat3D.

With the lasertriangulation sensors many applications are possible z.B.:

- Bin-Picking

- Pin-Inspection

- Weld seam inspection

- Glue and adhesive bead inspection

- etc.

SHAPEDRIVE 3D SENSORS

-

The ShapeDrive 3D sensors project several patterns onto the object to be measured and then record them by means of a camera. As a result, the object is digitalized as a 3D point cloud. Neither the object nor the 3D sensor is in motion during the scan.

MLAS ShapeDrive – for small measuring volumes

The 3D-sensors of the MLAS series are distinguished by high precision for small measuring volumes. The 10 models are available in two performance classes with camera resolutions of 5 and 12 megapixels.

QUELLTECH 3D SENSORS

-

QuellTech laser-scanners make use of the triangulation principle to detect the two-dimensional profile of surfaces. The scanners perfectly meet all requirements for a large range of measuring applications, allowing flexible integration even into difficult environments.

PHOTONEO PHOXI 3D SCANNER

-

The EyeVision 3D software supports the PhoXi 3D scanner by Photoneo. With the Shape-by-Shade sensor applications such as bin-picking and many more can be solved.

The scanner features large depth of scan, high accuracy and easy integration.

How does Shape-by-Shade work?

The basic principle is triangulation. Although the whole surface of the workpart is captured at once by projecting a striped pattern onto the surface and capture it by a measurement camera, which looks vertically onto the surface. From the striped pattern with sinusoidal intensity progress, which is projected in quick succession, the exact lateral stripe position (phases) for all points on the surface are detected.

EMSENS SYSTEMS

-

EmSens Systems consist of software, computing hardware and camera and are preconfigured for a specific application field. They include commands of the EyeVision software for e.g. object detection, color recognition or code reading of DMC, Barcode or OCR/OCV.

The computing hardware consists either of an EmSys machine vision computer, a Raspberry Pi or an Odroid. As for the cameras, GigE as well as USB cameras can be selected. As a standard we use cameras from Basler but, optionally all cameras of the makers that are supported by the EyeVision software can be used.

EMSENS BARCODE READER

-

The Machine Vision System EmSens Barcode Reader, for reading bar codes. This system can read codes in any rotation and position in the image.

Which codes can the EmSens BarCode read?

The machine vision system can read many different bar code types such as e.g.:

- Code 39 & Code 128

- 2/5 Interleaved

- EAN13 & EAN 8

- UCP Version A & Version B

EMSENS COLOR INSPECT SYSTEM

-

The EmSens Color Inspect for the inspection of colored quality characteristics. For example for the inspection when assembling cables, sorting bottles, inspecting label and print material.

The Machine Vision System Hardware

The hardware consists of a GigE or USB camera of one of the camera makers, which are supported by the EyeVision software such as e.g. Basler, Allied Vision, Baumer, Teledyne Dalsa, usw.

As computing hardware are three options available:

- Machine Vision Computer EmSys

- Raspberry Pi

- Odroid

EMSENS DMC SYSTEM

-

The EmSens DMC machine vision system has a powerfull DMC Reader command. It reads not only flawless codes, but also codes that are for example:

- damaged,

- blurred,

- distorted or

- low contrast

The vision sensor always reports to the user about incorrect codes. Also differences in character thickness are no problem for the sensor.

The Machine Vision System Hardware

The hardware consists of a GigE or USB camera of one of the camera makers, which are supported by the EyeVision software such as e.g. Basler, Allied Vision, Baumer, Teledyne Dalsa, usw.

As computing hardware are three options available:

- Machine Vision Computer EmSys

- Raspberry Pi

- Odroid

EMSENS MATCH SYSTEM

-

The EmSens MatchMachine Vision Sytem solves pattern matching applications. For the detection of errors, quality control, label and print inspection, etc.

The Function of the EmSens Match?

The vision sensor can detect previously taught-in patterns in:

- any rotation

- any position

- no matter if complete or incomplete

This means that, when the taught-in pattern in the image moves, rotates or is half invisible, the EmSens Match can detect the pattern anyway.

EMSENS MEASURE SYSTEM

-

The EmSens Measure Machine Vision System to solve metrology applications.

What measures the EmSens Measure?

The Machine Vision System can measure geometrical shapes and distances:

- circle

- distances & straight lines

- angles & rectangles

Therefore even complex metrology tasks can be solved fast and easily.

EMSENS OBJECT COUNT SYSTEM

-

The EmSens Object Count Machine Vision System can detect and count objects with the special BLOB command.

What’s the advantage of EmSens Object Count?

The Machine Vision System can detect and count objects with only one command.

It is suitable for quality control, error detection and the production process on a conveyor belt.

The system counts consequentely for example:

- nuts, apples, oranges, etc.

- salami on frozen pizza

- cog wheels, screws, globes

- borehole, any kind of markings

EMSENS OCR/OCV SYSTEM

-

EmSens OCR/OCV Machine Vision System for Optical Character Recognition and Optical Character Verification, with a special EyeVision software.

The system recognizes even characters that are difficult to read. The OCR command even detects dotted or nailed characters with the OCR-command.

The OCR command set offers powerful functions for the optical detection and inspection of characters. The module includes image preprocessing, segmenting, sorting and classifying of characters.

Applications for EmSens OCR:

- expiration dates on groceries and pharmaceuticals

- detection of any kind of print and even hand writing

- label and print inspection

- 3D charachters e.g. on car tires

- print quality inspection

READY-TO-USE SYSTEMS

- The Ready-to-use systems offer versatile solutions with only a small amount of adjustment and at the push of a few buttons in industries such as food, beverage, electronic as well as areas such as Deep Learning, Thermal Imaging, 2D and also 3D image processing.

The system includes an already preconfigured EyeVision Software solution for free adaption, as well as an EmSys computing hardware and an industrial camera of one of the supported makers such as Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, or also thermal imaging cameras by Optris or Flir. There are GigE and USB cameras available.

EVT BOTTLE CORK INSPECTOR

-

With the Cork Inspector we have a new member in our Beverage Inspection series. It can inspect corks from e.g. wine bottles, if they are in the correct position, or stick out too much (convex) or are seated too deep in the bottle neck (concave).

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and an industrial camera of the supported makers such as e.g. Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, Flir, etc.

WELDSEAM VISION®

-

The WSV (WeldSeam Vision®) is a weld seam inspection system for the inspection of laser and MIG/MAG-weld seams.

Field-of-View, Resolution and Accuracy

For MIG/MAG- and solder seams the WSV offers a field-of-view of 20 – 30 mm and for the laser weld seams a field-of-view of 10 – 15 mm.

The inspection system detects errors with sizes from 0,1 mm and with a resolution smaller than 1 µm depth, even the smallest errors can be detected.

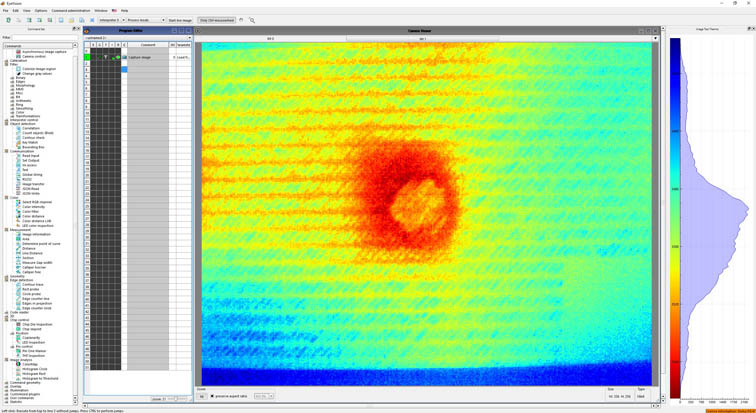

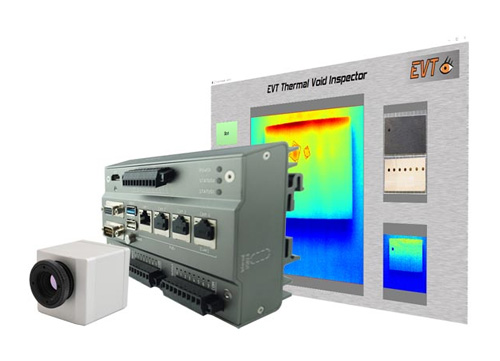

EVT HOLE & VOID INSPECTOR

-

The Hole & Void Inspector (HVI) is based on active Thermal Imaging. The HVI can detect concealed holes and voids in diverse material such as e.g. wood, caoutchouc, plastic, foamed material or fiber-reinforced plastic material, etc.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and a thermal imaging camera of the supported makers such as e.g. Optris, Flir, etc.

EVT HOTGLUE INSPECTOR

-

The HotGlue Inspector checks, if the adhesive points between cardboard surfaces of boxes are present and hot enough to glue the cardboard box together. With up to 60 boxes per second (which amounts to 3600 boxes per minute). Available camera resolutions are 291 x 120 and 640 x 480 Pixel.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and a thermal imaging camera of the supported makers such as e.g. Optris, Flir, etc.

EVT LABEL ALIGNMENT INSPECTOR

-

The Label Alignment Inspector (LAI) checks the position and the alignment of a previously defined label. The parameters are defined by the user. Afterwards the inspection can be applied immediately to the production process.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and an industrial camera of the supported makers such as e.g. Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, Flir, etc.

EVT MULTI-THERMAL INSPECTOR

-

The EVT Smart Multi-Thermal Inspector (MTI) can monitor an arbitrary number of areas for their correct temperature. Additionally a warning can be issued, when the temperature is too high or too low.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and a thermal imaging camera of the supported makers such as e.g. Optris, Flir, etc.

EVT SMART SCRATCH INSPECTOR

-

With the intelligent, on Machine Learning based EVT Scratch Inspector, the detection of defects on surfaces is very easy. Based on a Deep Learning method, the Inspector detects any distrubances on the surface, similar to the human eye.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and an industrial camera of the supported makers such as e.g. Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, Flir, etc.

EVT WIRE INSPECTOR

-

The EVT Wire Inspector can inspect cables and connectors for their correct contact assignment and can be either used for a hand-work place or for the automatic cable assembly directly online, where it is integrated in the machine.

The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and an industrial camera of the supported makers such as e.g. Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, Flir, etc.