- Offer Profile

- BLOHM - Productivity and high-performance

BLOHM grinding machines have been used worldwide for decades, wherever productivity, performance and precision are required. They are developed in Hamburg and produced in a modern manufacturing facility to high quality standards. More than 15,000 delivered machines reflect the international recognition of the BLOHM brand. This accumulated experience forms the basis for the company's special grinding expertise in the area of surface and profile grinding.

BLOHM Grinding Machines

- The product range includes standard machines for individual and small batch production, as well as customized production machines.

Special highlights are:- Modular design of the machines offers sophisticated solutions for almost any workpiece size

- Varied machine applications can be integrated according to customer requirement

- Automated grinding machines (including tool change, measuring and clamping systems)

- Worldwide presence in the market segments of general mechanical engineering, bearing, automotive, hydraulic, tool making and turbine industry

- Technology and demonstration centers (Hamburg and Göppingen) make extensive know-how available to customers

- Technological leadership in the aviation turbine industry

- Worldwide sales and service network for consultation and customer service directly on the spot

- HelpLine, remote service and field service for maintenance with system

- Traditionally proven approach based on a strict quality code, combined with the use of cutting-edge methods (ISO 9001)

Surface and Profile Grinding Machines

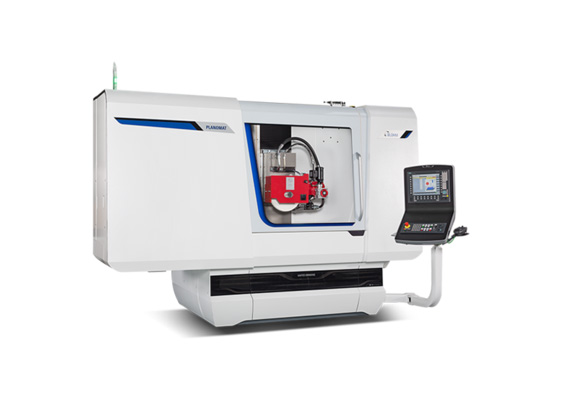

- Clear and simple no matter how complex the task is. This is the operating concept of the PLANOMAT HP machine series.

PLANOMAT HP

-

The universal machine

The PLANOMAT HP combines reproducible precision and powerful speed with high flexibility – the ideal combination for efficient profile grinding. The robust, inherently stiff design with 3-point installation ensures the exactness of the modular PLANOMAT HP machines. A driving power of up to 24 kW combined with high-precision, digitised ball-type drives guarantees high infeed speeds and accelerations. Table speeds of up to 40 metres per minute reduce grinding times and increase productivity. Almost maintenance-free linear guideways and the highly efficient, lifetime-lubricated grinding spindles reduce the maintenance requirement to a minimum. Depending on the task, the PLANOMAT HP series offers six different working ranges: from 400 mm x 800 mm to 600 mm x 2000 mm. In addition, two different control concepts enable optimal adaptation to the respective grinding task. The EasyProfile control unit, an innovative BLOHM user interface on a Siemens platform with touch screen, optimally handles all routine workshop requirements, thanks to its intuitive operation. If the PLANOMAT HP is equipped with the professional Sinumerik 840D CNC control unit, complicated applications in toolmaking and series production are possible- Grinding range: 800 x 400 mm to 2000 x 600

- Distance between table and spindle centre: 150...700 (opt. 950)

- Travel/infeed speed:

- X-axis: 900 - 2100 mm, 30...40.000 mm/min

- Y-axis: 550 (opt. 800) mm, 4...6000 mm/min

- Z-axis: 360 mm, 4...6.000 mm/min

- Grinding spindle drive power: 15 kW at 1000 1/min (opt. up to 24 kW)

- Max. grinding wheel diameter: 400 mm

- Max. grinding wheel width: 80 mm

Production Grinding Machines

- Maximum stock removal guaranteed! The production grinding machines in the PROFIMAT and PROKOS series have been specially designed for batch production.

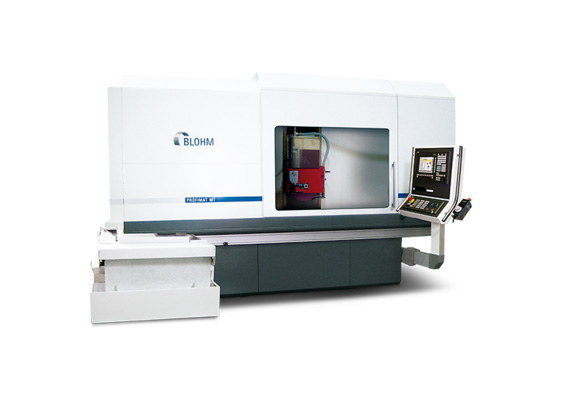

PROFIMAT MT

-

The powerful machine

In applications where the production process requires high stock removal rates, the flexible and powerful PROFIMAT MT is the right choice. A driving power of up to 60 kW and cutting speeds of 170 m/s guarantee maximum productivity – for both conventional and CD/IPD grinding processes, as well as for all high-speed grinding processes with CBN. Pretensioned anti-friction guideways in all machine axes guarantee the necessary system rigidity and reduce maintenance requirements. The extremely efficient BLOHM software ensures exact interpolation of the axes and thus high workpiece quality. The scope of supply of the PROFIMAT MT comprises a Siemens Sinumerik 840 D control system with comprehensive operator prompting.- Grinding range: 800 x 400 mm to 2000 x 600

- Distance between table and spindle centre: 150...700 (opt. 950)

- Travel/infeed speed:

- X-axis: 900 - 2100 mm, 15...25.000 mm/min

- Y-axis: 550 (opt. 800) mm, 4...3.750 mm/min

- Z-axis: 360 mm, 4...4,000 mm/min

- Grinding spindle drive power: 27.5 kW at 1500 1/min (opt. up to 60 kW)

- Max. grinding wheel diameter: 500 mm

- Max. grinding wheel width: 200 mm

PROFIMAT MC

-

The compact machine

Whether precision, profile, internal or external cylindrical grinding – the PROFIMAT MC is a highly efficient grinding centre for any application. This extremely compact travelling-column machine offers everything that modern production solutions require, with a machine width of just 2000 mm. Different spindle variants enable diverse applications: The five-axis CNC profile grinding machines in the series can optionally be equipped with a horizontal spindle for drive capacities up to 60 kW as well as a stationary or an NC-swivelling vertical spindle with grinding spindle speeds of up to 60,000 revolutions per minute. With a maximum cutting speed of 170 m/s, travelling-column machines are suitable for both conventional grinding tasks and for CD, IPD and all CBN methods. Equipped with the relevant accessories - such as automatic tooling change, for example – the PROFIMAT MC is even suitable for combination machining. With the aid of the professional Sinumerik 840D CNC control system from Siemens, virtually any grinding task is possible.- Grinding range: 700 x 600 mm and 1.000 x 600

- Travel:

- X-axis: 700 mm and 1000 mm

- Y-axis: max. 550 mm

- Z-axis: max. 520 mm

- Grinding spindle drive power: 27.5 kW at 1500 1/min (opt. up to 60 kW)

- Max. grinding wheel diameter: 500 mm

- Max. grinding wheel width: 220 mm

PROFIMAT RT

-

Are you looking for a grinding solution for the production of large lot sizes or batch production? Then the PROFIMAT RT could be the right machine for you. This highly efficient production machine with a travelling column design is equipped with a rotary indexing table. This enables workpiece handling in parallel with the primary processing time, i.e. continuous, simultaneous loading and unloading during the grinding process. Low setup costs combined with high efficiency and the possibility of simple adaptation of automatic workpiece change systems set benchmarks in modern and cost-effective production. With a maximum spindle power of 60 kW and a cutting speed of up to 170 m/s, the RT is ideally suited for both conventional grinding and for CD, IPD and all CBN grinding processes.

- Indexing table, diameter: 1000 (opt. 1200) mm

- Travel:

- X-axis: 700 mm

- Y-axis: 550 mm

- Z-axis: 320 mm

- Grinding spindle drive power: 27.5 kW at 1500 1/min (opt. up to 60 kW)

- Max. grinding wheel diameter: 500 mm

- Max. grinding wheel width: 200 mm

PROKOS XT

-

Grinding the Change

The PROKOS XT is the ideal grinding machine for the automated machining of complex workpieces. From the machine design through to the production process, the PROKOS XT is designed for productivity, efficiency and quality.

Your Benefits:- Machine for grinding, drilling and milling

- Speed stroke grinding

- 24 positions for tools up to a diameter of 300 mm

- SmartCAM for a complete CAD consistency

- Workpiece dimensions: 300 x 300 x 300 mm

- Travel:

- X-axis: 450 mm

- Y-axis: 450 mm

- Z-axis: 900 mm

- Grinding spindle drive power: 35 kW at 4,300 1/min

- Max. grinding wheel diameter: 300 mm

- Max. grinding wheel width: 50 mm