- Offer Profile

-

KAPP NILES is a globally operating group of companies with high-quality and economical solutions for finishing gears and profiles. About 1,000 employees represent the innovative strength and expertise of the sustainably managed family company which has grown for over 125 years. With production sites in Germany as well as worldwide sales and service branches, we are responsive and reliable in all major markets. KAPP NILES is partner for companies from numerous industrial sectors in the mobility, automation and energy segments. The perfect interaction between machine, tool and technology enables the precise machining to a thousandth millimetre and up to a diameter of eight metres. Each system solution is individually optimised for customer requirements and serviced by us throughout its life cycle. Highly accurate measuring equipment complements the comprehensive product range to ensure the required quality. KAPP NILES supports efficient and stable processes with innovative services and digital solutions.

DIGITAL SOLUTIONS

- Digital solutions from KAPP NILES are displayed in the software platform KN assist. Our digital products aim to generate the greatest possible added value for you. Quality, availability, efficiency, resources, user-friendliness and service play a major role here. We focus on the core areas of connectivity, production, machine and support in order to master all current and future challenges together with you. The digital solutions thus stand for a perfect interaction of efficient processes around our machines.

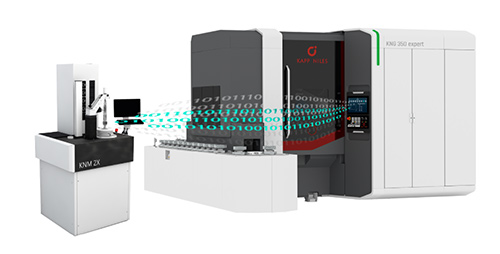

KN CONNECT

-

What does KN connect include?

- Standardised connection to your network via a separate IPC

- IPC with firewall and OPC UA server

- Provision of data (umati data scope) via OPC UA

What are the advantages of KN connect?

- Standardised interface across machine manufacturers through OPC UA and umati → Also for existing machines

- Machine becomes I4.0 ready → Basis of digital solutions and requirement for further products

- Secured TÜV-certified interface

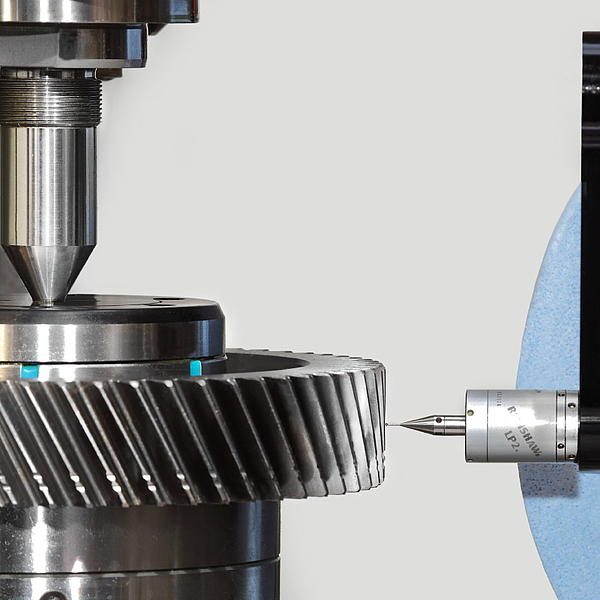

CLOSED LOOP

-

What does Closed Loop by KAPP NILES include?

- Standardised transmission (GDE format) of correction values via network or USB

- Automatic or manual execution of corrections

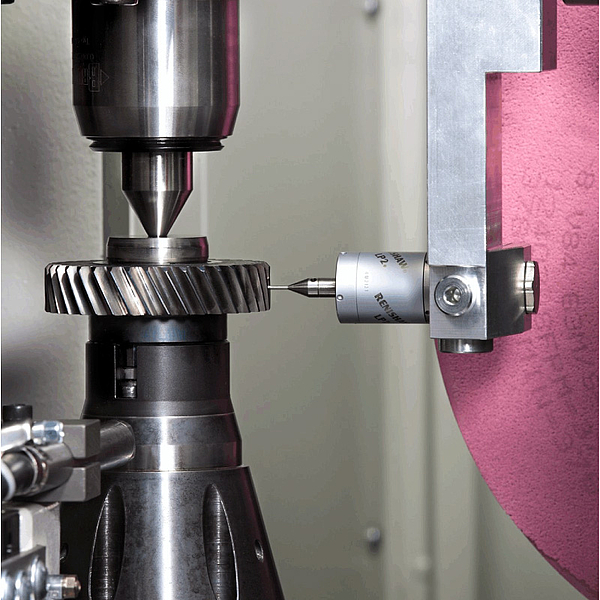

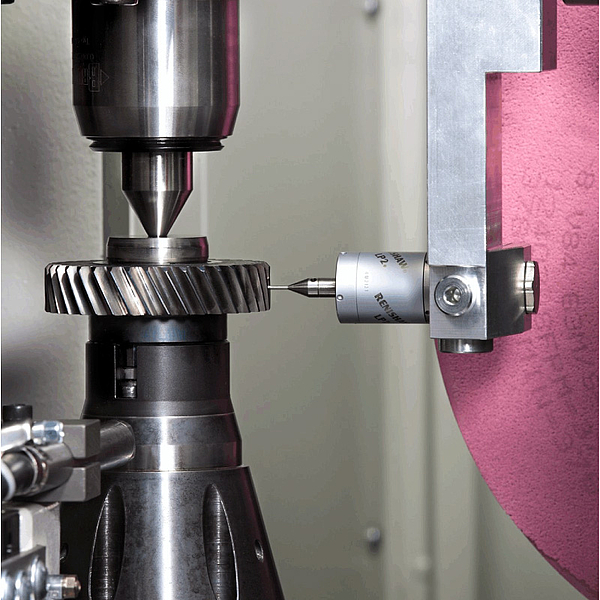

- Correction values for profile angle deviation fhα, flank line angle deviation fhβ and tooth width, sphere dimension, two-ball dimension Wk

What are the advantages of Closed Loop by KAPP NILES?

- Automatic correction of series parts during production according to defined rules, if necessary with spindle reference

- Reduction of the rejection rate

- Compatibility with machines from other manufacturers (both machining and measuring machine)

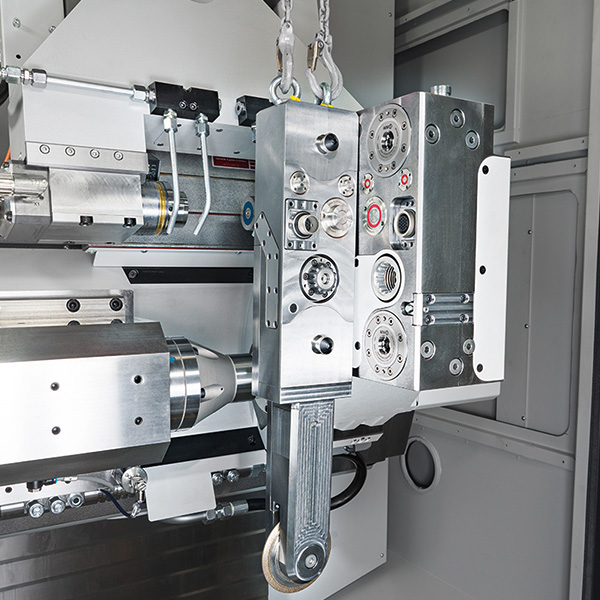

TOOL MANAGEMENT

-

What does Tool Management include?

- Guided change sequences (step by step)

- Avoidance of incorrect installation of a component with simultaneous flexibility

- Display of all relevant component information (ID, geometry data, process data, ...)

What are the advantages of Tool Management?

- Reduction of the risk of crashes due to the set-up of an incorrect component

- Reduction of preparation times for grinding project

- Support in planning and analysing the condition of a component

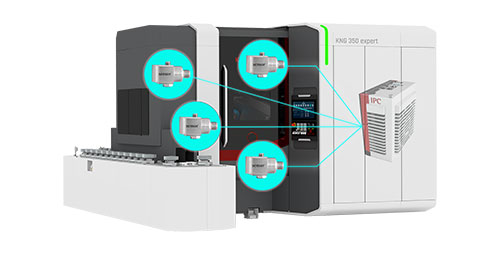

CONDITION MONITORING

-

What does Condition Monitoring include?

- Monitoring of the linear and rotatory axes by reference runs

- Evaluation of the wear condition through indices from 0-100 and prognosis regarding durability

- Interface to other (digital) products in your production system, e.g. parts tracing

What are the advantages of Condition Monitoring?

- Reduction of unplanned machine downtime

- No unnecessary or premature replacement of components → Reduction of inventory costs

- Maintenance of production quality through monitoring of quality-relevant components

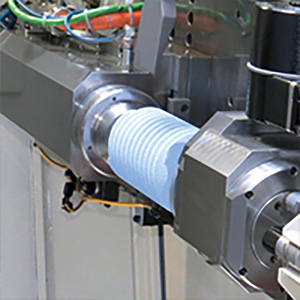

PROCESS MONITORING

-

What does Process Monitoring include?

- Monitoring of the worm condition and analysis of ripples / orders

- Evaluation of the condition and indications based on the adjustable limits

- Interface to other products (such as parts tracing) and export function for analysis outside the machine

What are the advantages of Process Monitoring?

- Reduction of rejection rates through 100 % inspection of all components

- Early detection of defects ? Timely rejection of conspicuous components

- Process monitoring can be adapted to your individual requirements

PART TRACING

-

What does Part tracing include?

- Recording of defined data during the grinding process for each workpiece

- Creation of a data record for each workpiece with a defined identification (ID)

- Interface to your systems for transmitting the data records

What are the advantages of Part tracing?

- Complete traceability and documentation of all manufactured components

- Evaluation of data for process optimisation

- Reduction of the rejection rate through rapid identification of anomalies and potential sources of error together with connected analytical systems

DIGITAL SERVICE

-

What does Digital Service include?

- Processing your service requests via a ticket system

- Support through live video, voice over IP, chat and whiteboard functions

- Documentation of your service activities for each system can be viewed in the system archive

- Faster and easier support and solution finding through targeted communication via a ticket system (no e-mail traffic)

- Documentation, operating manuals and e-plans for each machine are digital and up-to-date available

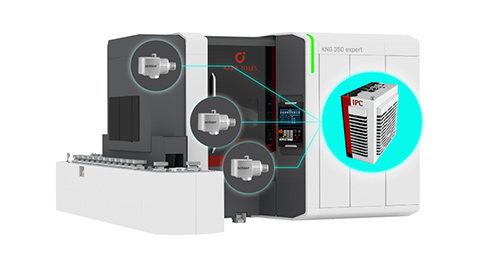

SENSOR PACKAGE

-

What does Sensor Package include?

- Standardised hardware

- Additional sensors in the machine

- Input modules for sensor detection

- Recording of additional signals, including high-frequency signals

- Relevant for monitoring the condition of the axes (condition monitoring)

- Relevant for analysing the machining process (process monitoring)

Innovative Technology for Gears and Profiles

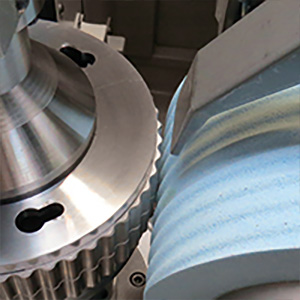

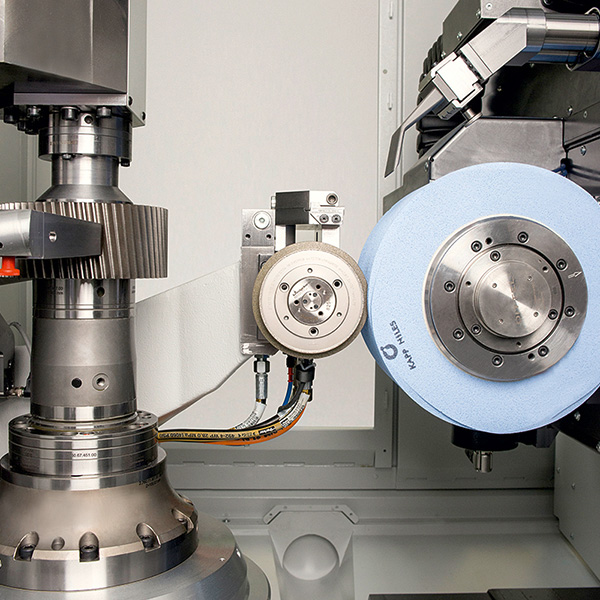

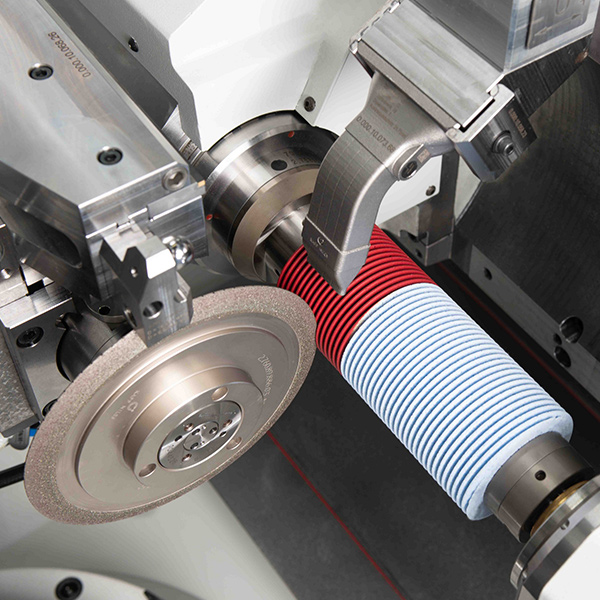

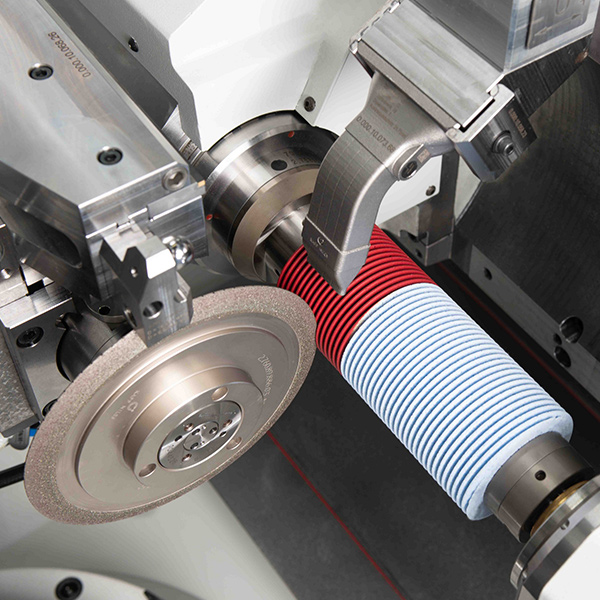

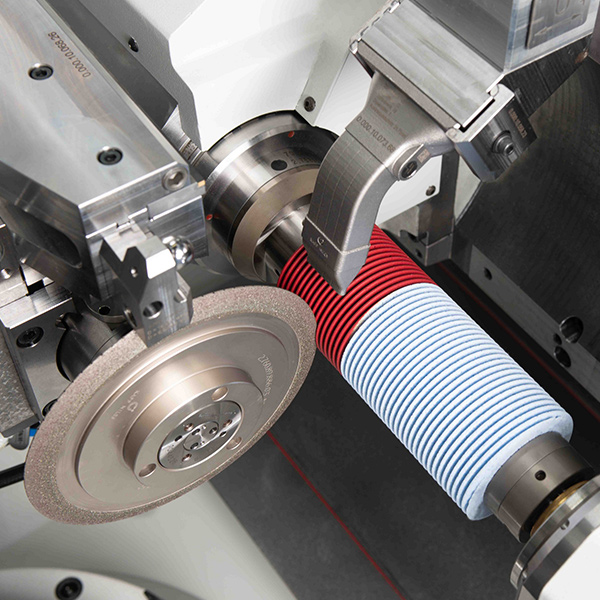

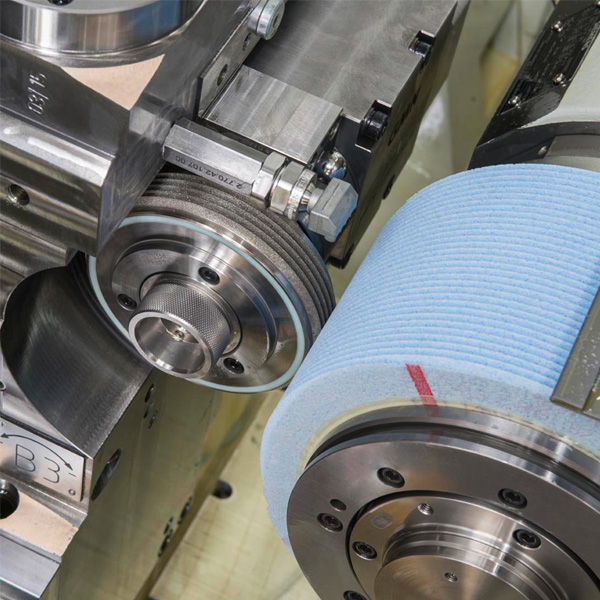

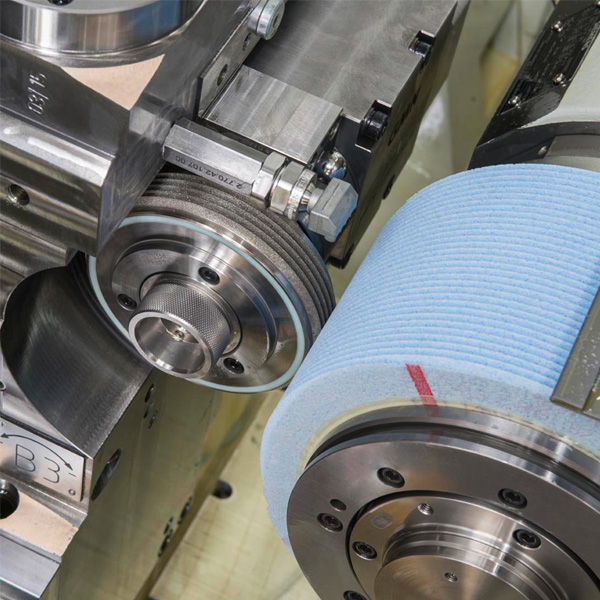

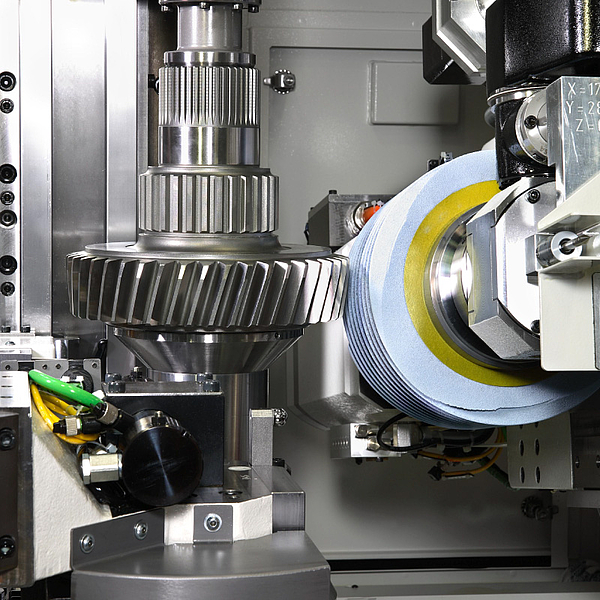

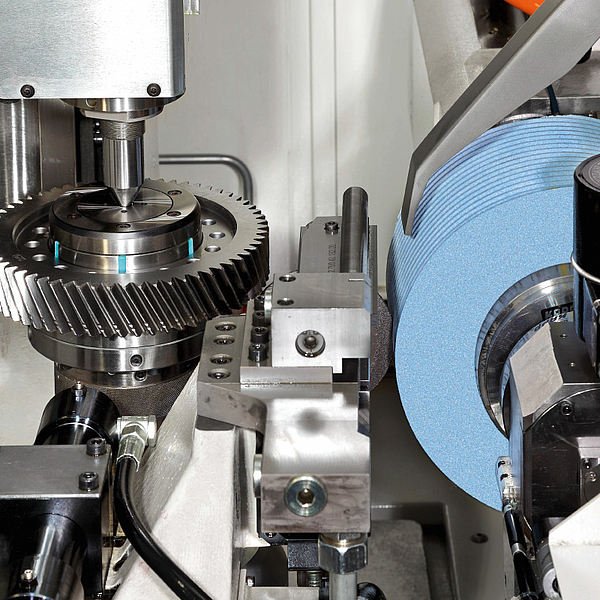

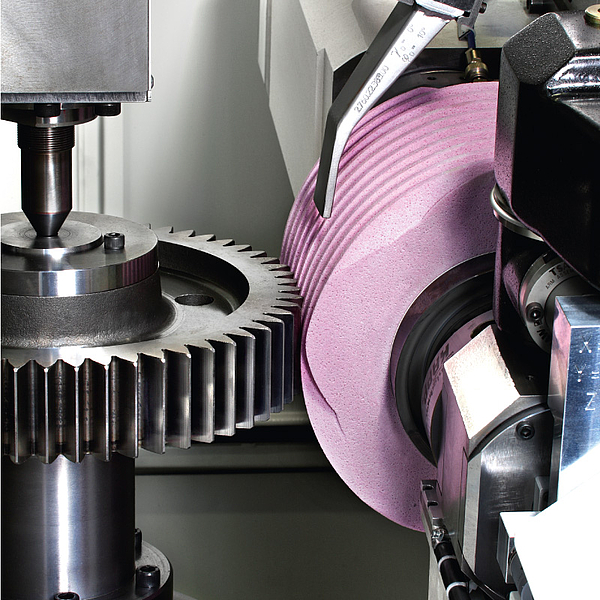

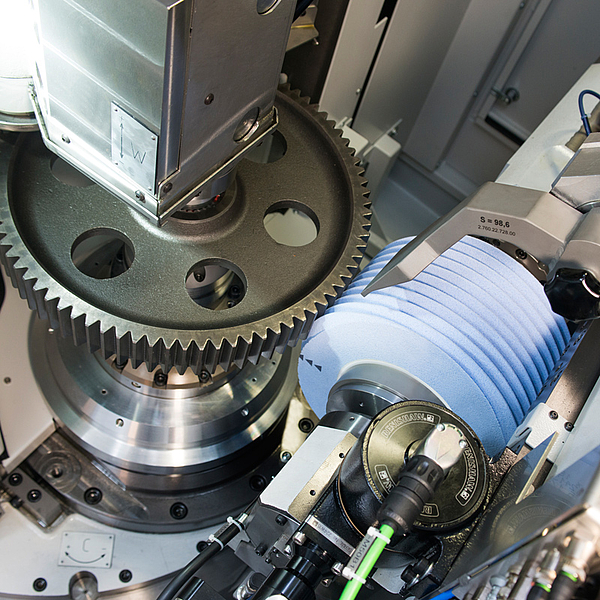

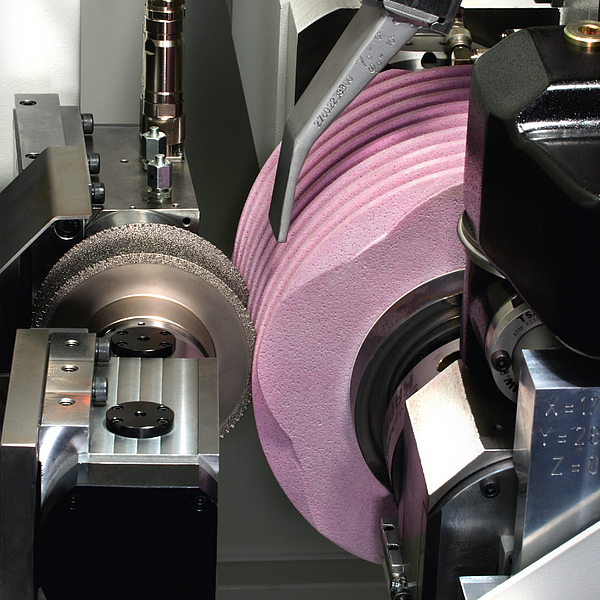

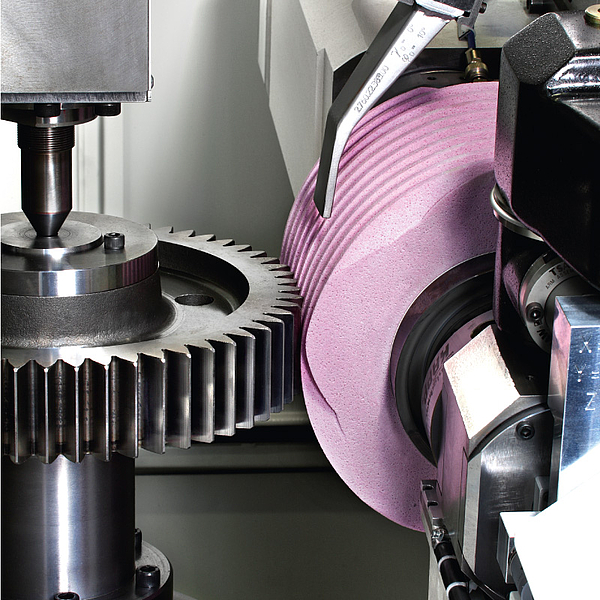

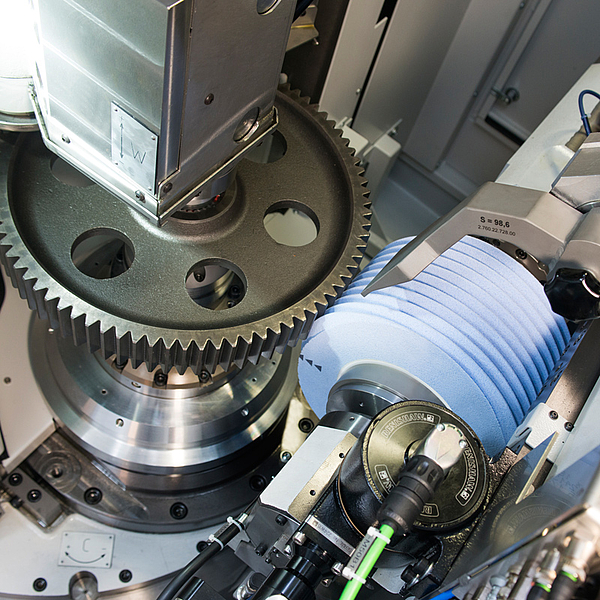

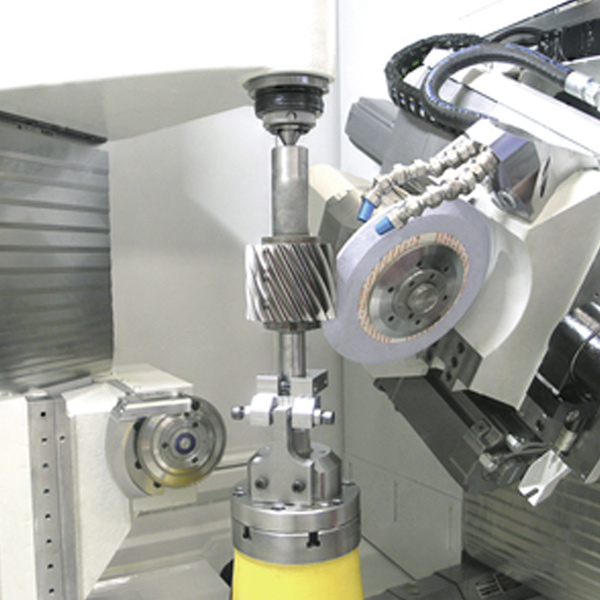

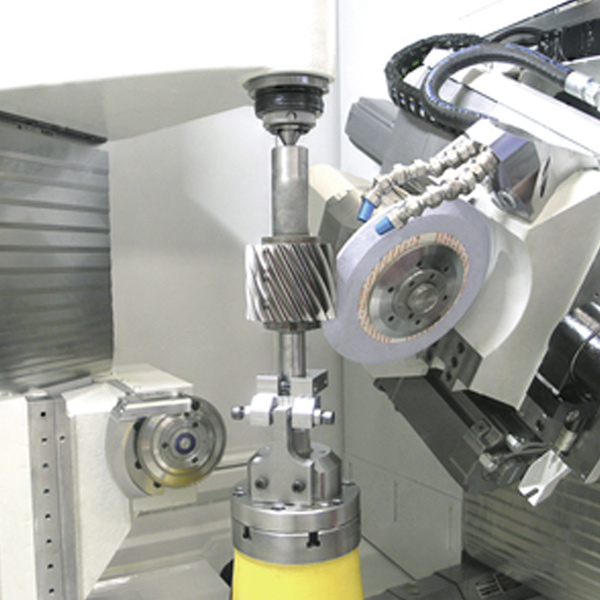

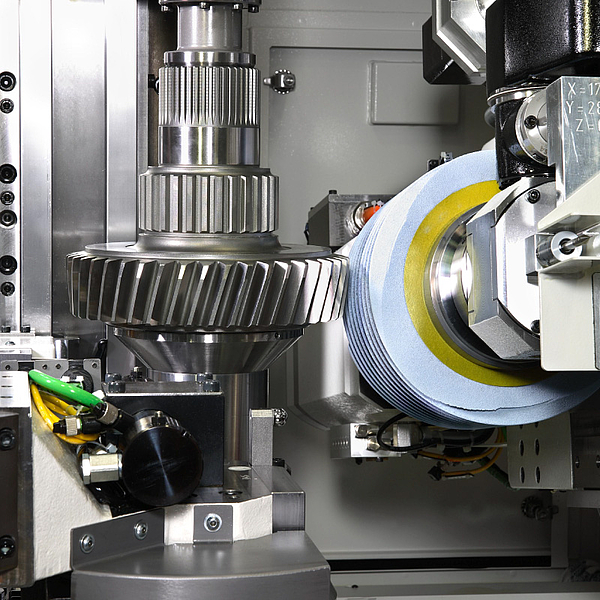

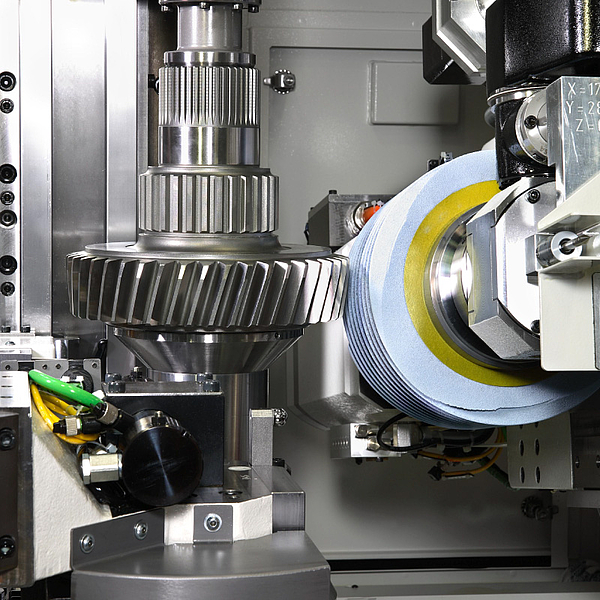

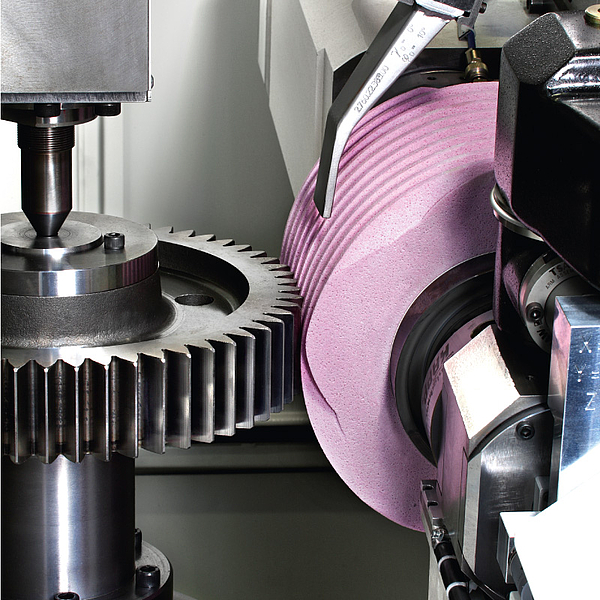

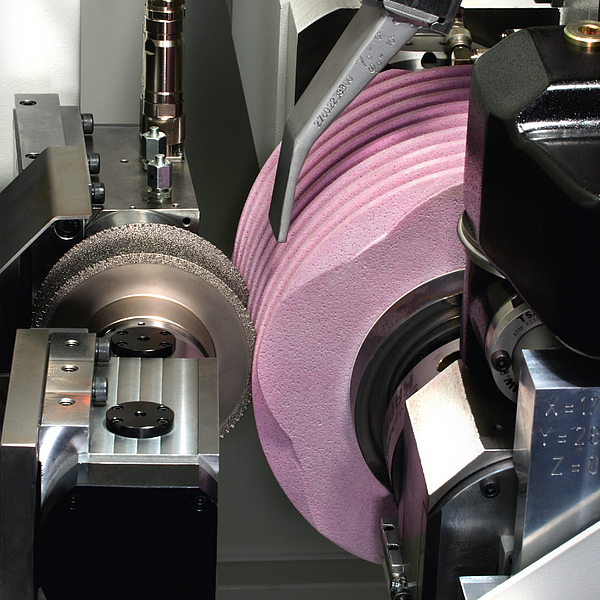

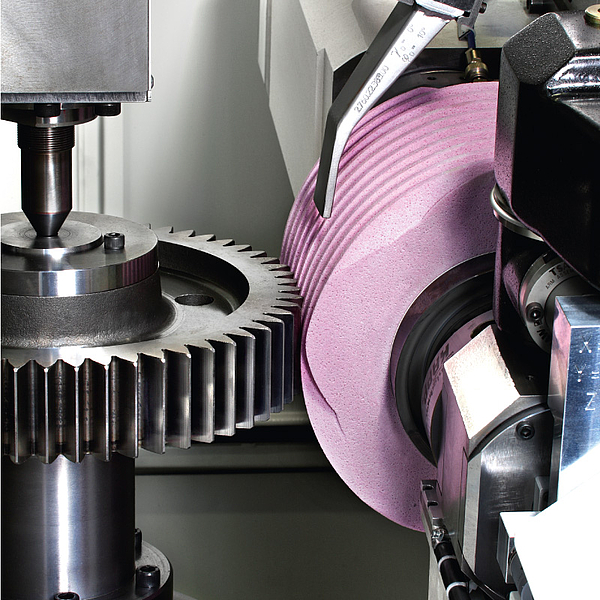

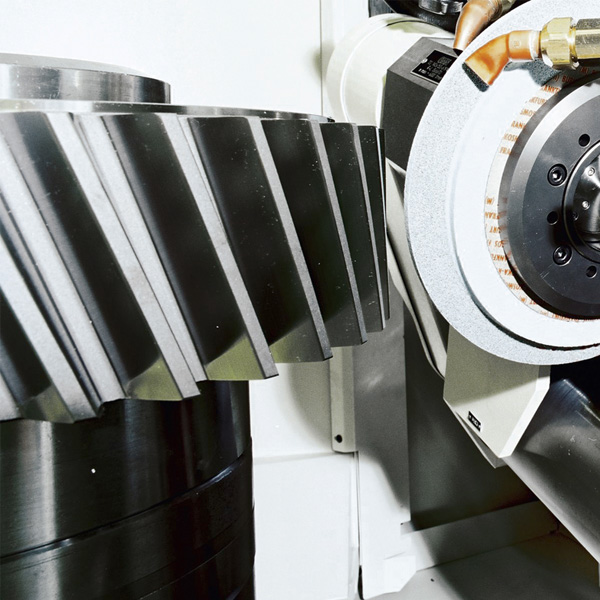

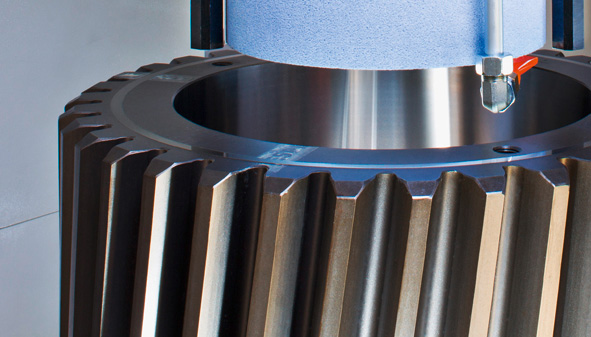

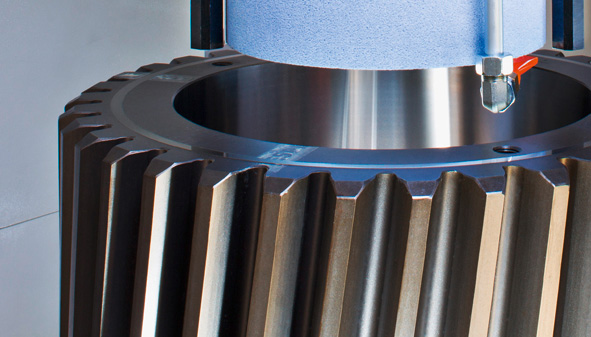

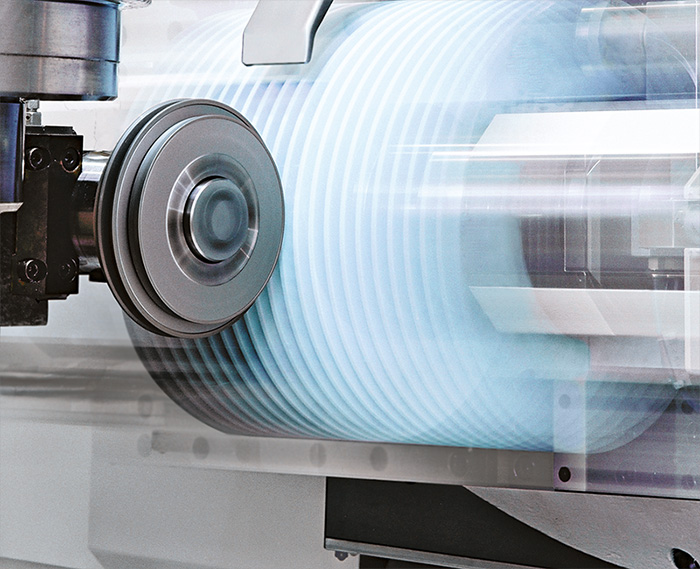

- Continuous generating grinding

For continuous generating grinding all tooth flanks of the workpiece are machined simultaneously during one stroke of the helical tool. This is realized with a synchronized constant rotation of the workpiece relative to the grinding tool. Due to the kinematics of this process indexing and positioning times are greatly reduced resulting in low cycle times. Therefore it is a highly productive and cost-effective process well suited for small and medium-sized gears. Both dressable ceramic tools and non-dressable CBN tools can be used (in cylindrical or globoid design).

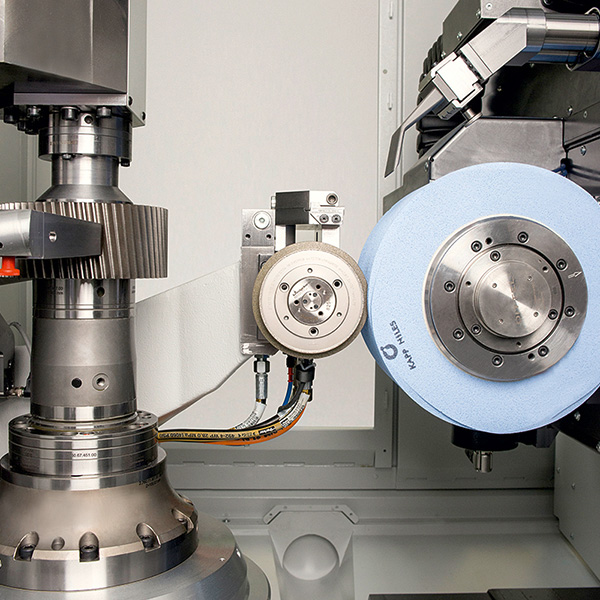

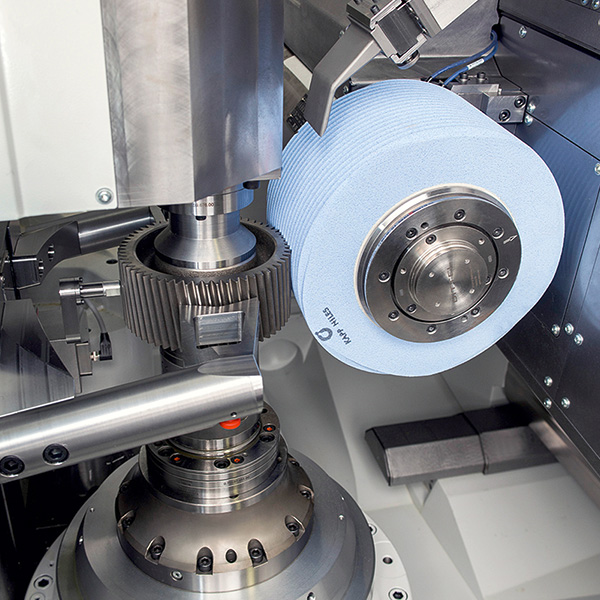

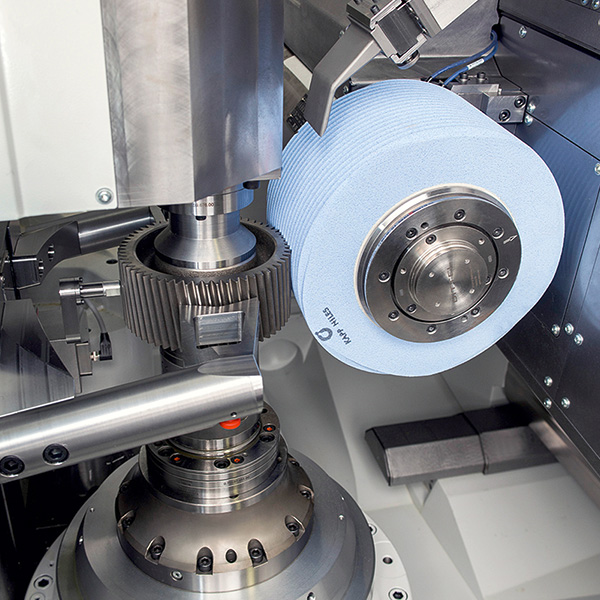

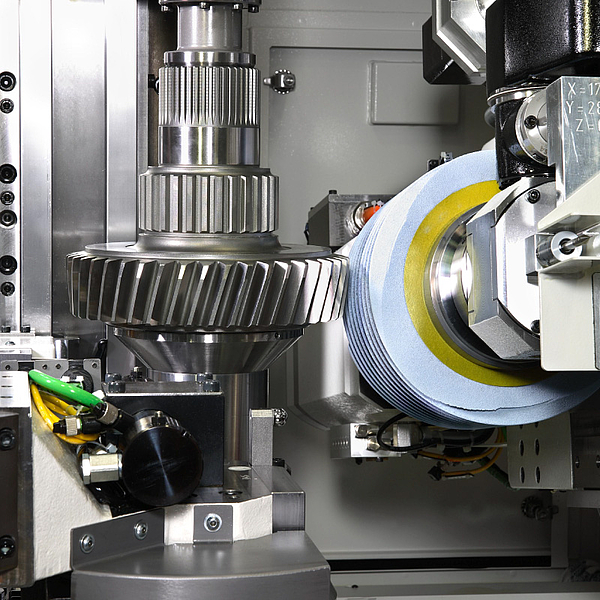

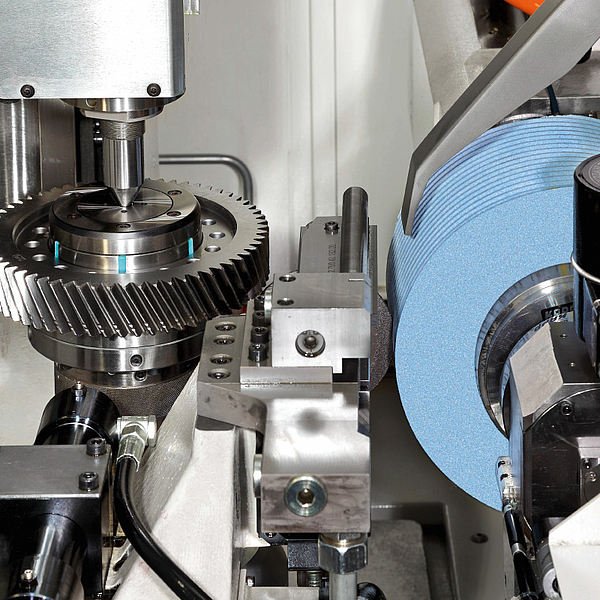

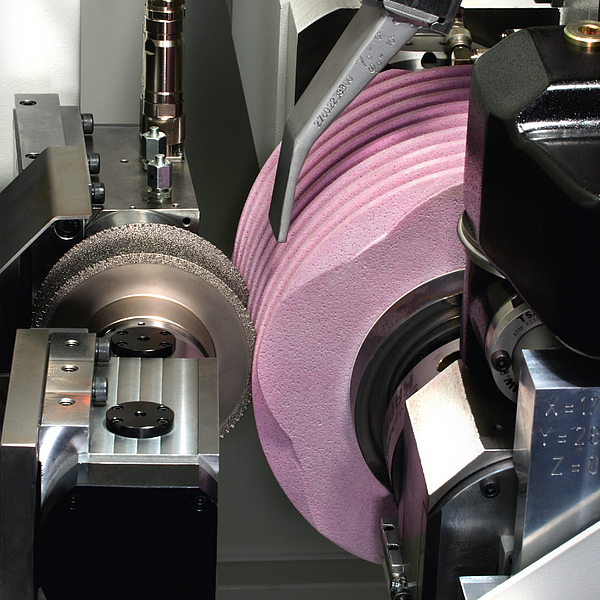

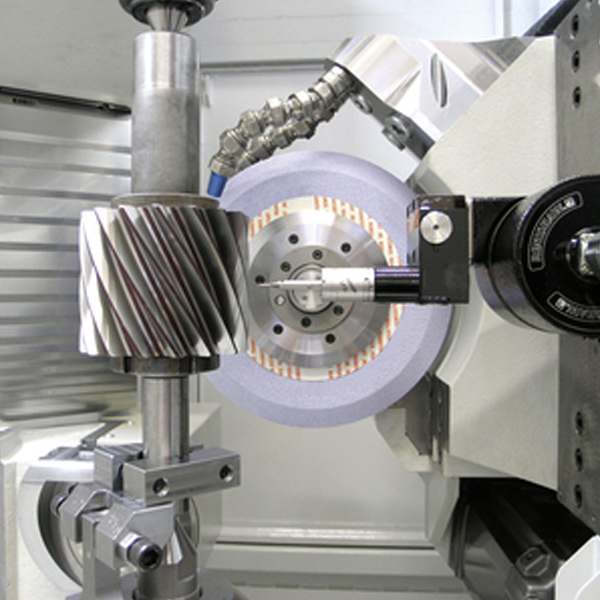

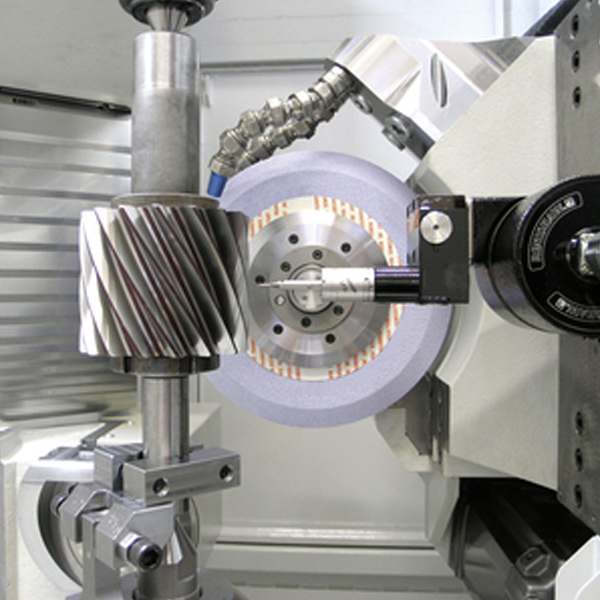

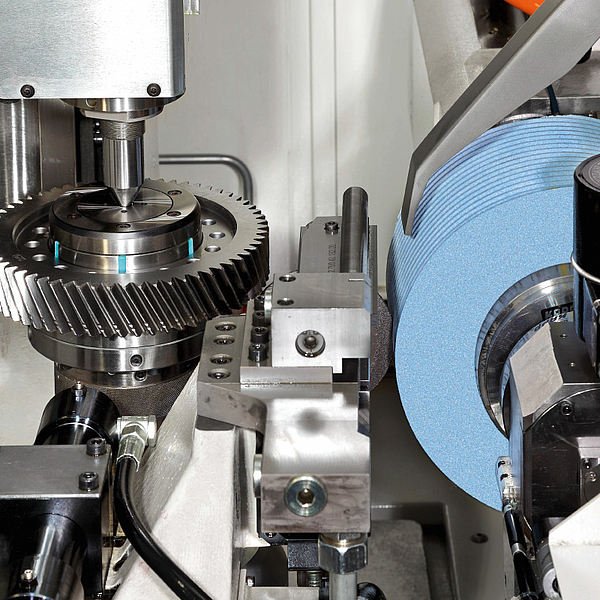

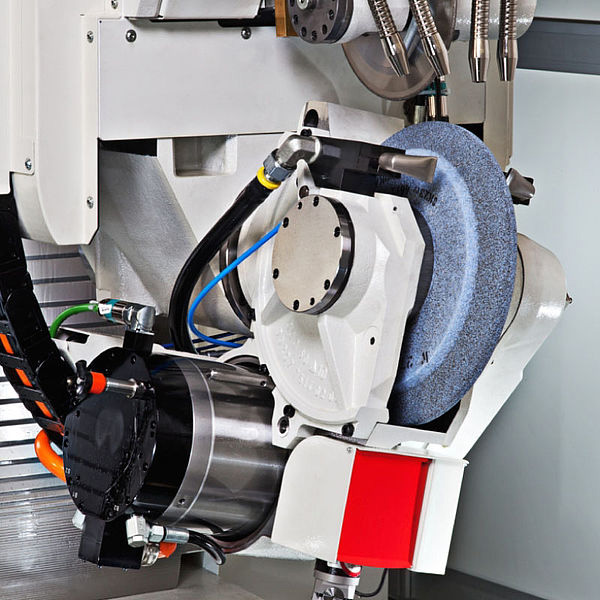

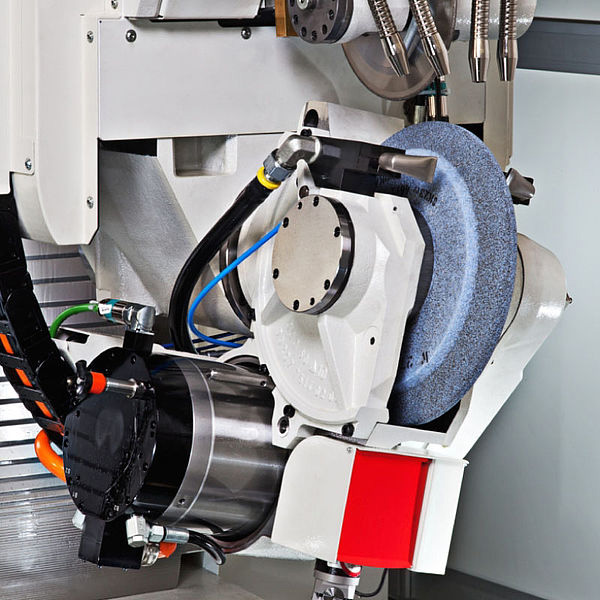

Discontinous profile grinding

Profile grinding of gears describes a process for which the tooth flanks are machined gap after gap with single or multi-ribbed profiled tools. Regarding the possible work piece geometries this process offers highest flexibility while achieving highest quality. Profile grinding is mostly utilized for small batch series and prototype manufacturing. Dressable ceramic wheels as well as non-dressable CBN-tools can be used for this grinding process.

topological generating and profile grinding

- the prevention or targeted manipulation of process-related bias presents a challenging requirement for a production process. Due to the user-friendly guidance and machine-internal calculation of dressing and grinding paths, this method has found its way into the field of serial production.

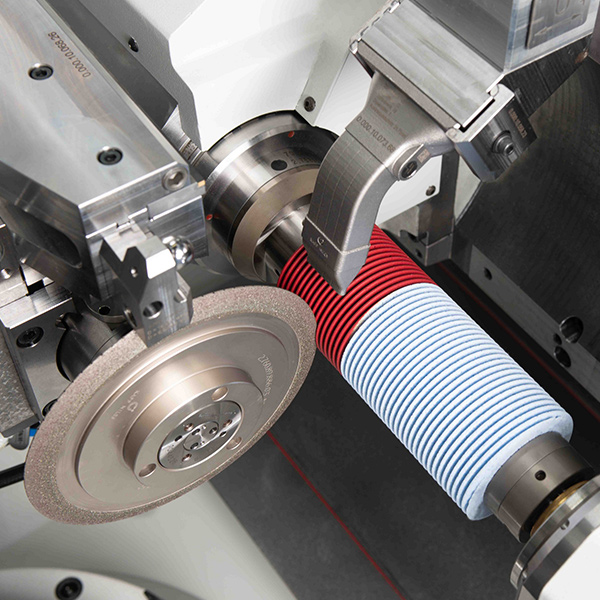

superfinishing

- KAPP NILES machines provide the option to integrate precision grinding technology into both the profile and generating grinding process. The additional effort required for this is generally less than 50 % of the machining time of a conventional grinding process.

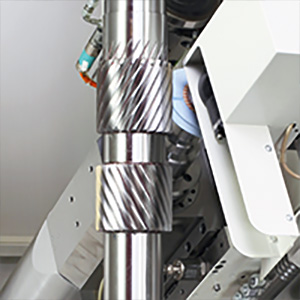

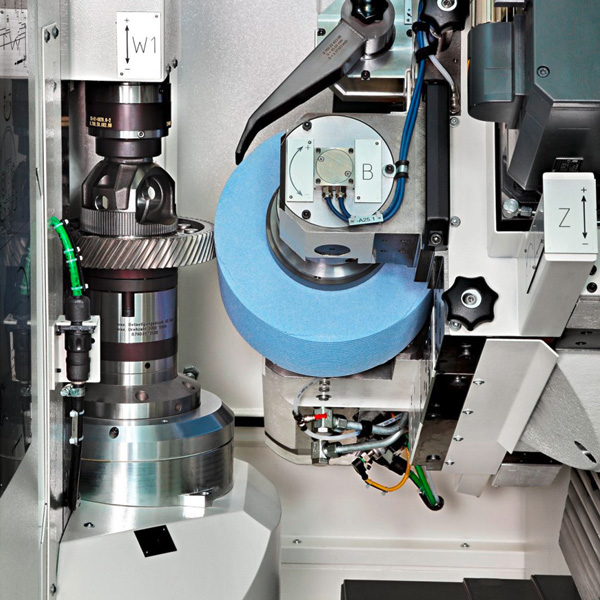

generating grinding with small tools

- using high-speed grinding spindles on the KX 160 / 260 TWIN machines, gears with interfering edges which could previously only be machined with the profile grinding or honing process can now be machined with the generating grinding process. This new development offers high potential for optimisation.

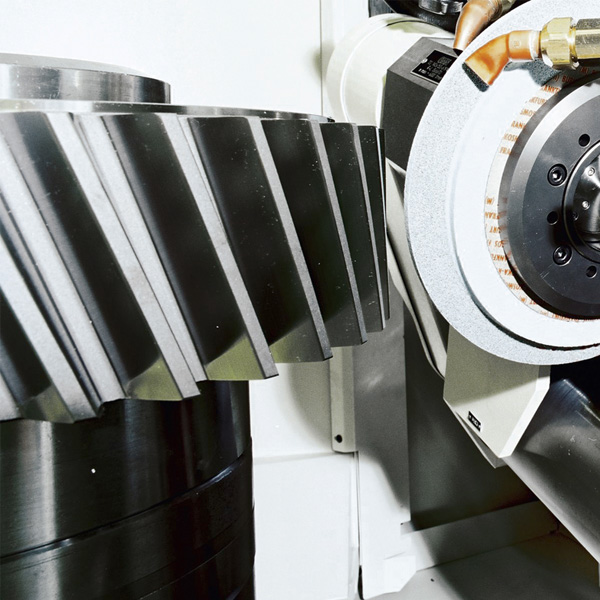

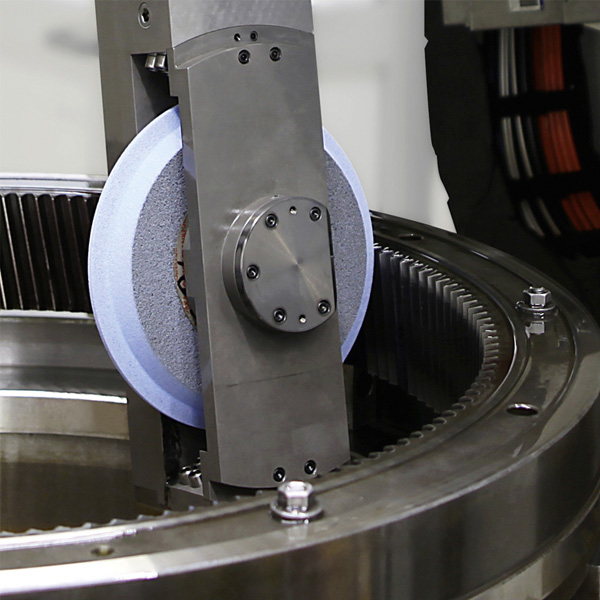

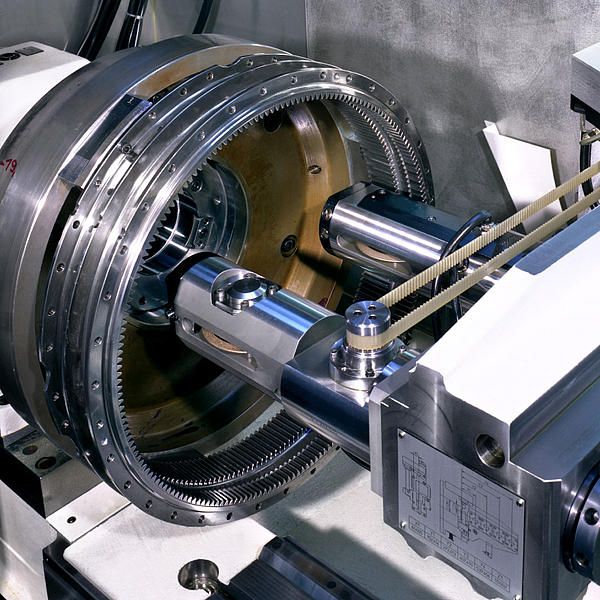

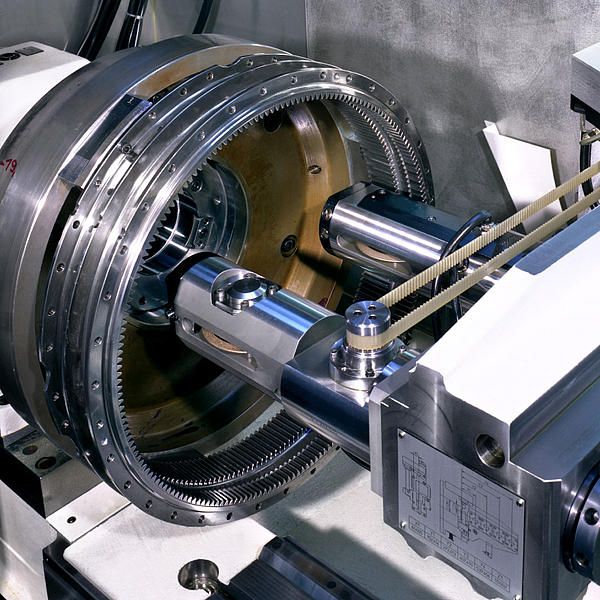

cycloidal gearbox

- cycloidal gearboxes distinguish themselves by high transmissible torques, better rigidity and low wear. For high precision profile machining of the two main components of a cycloidal gearbox - cam disk and needle ring gear - high performance technologies from KAPP NILES are available.

double helical gears

- KAPP NILES offers a wide range of machine concepts for grinding double helical gears in all different sizes. Whether equipped with a horizontal or vertical workpiece axis, the hardware / software of all machines can be upgraded with innovative solutions for grinding helical gears.

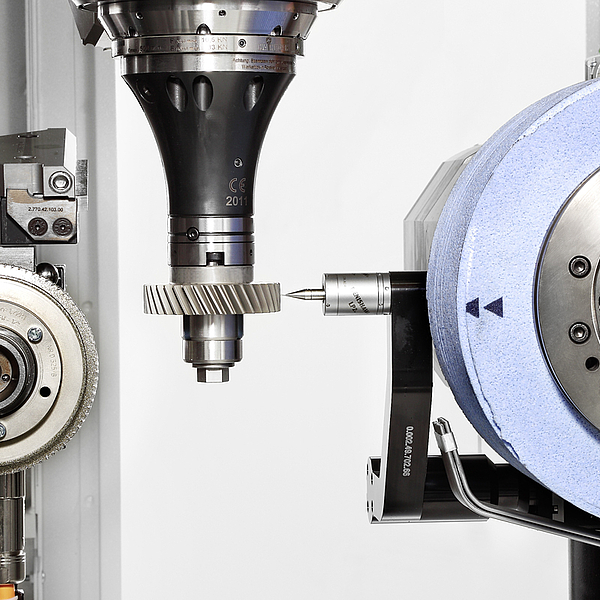

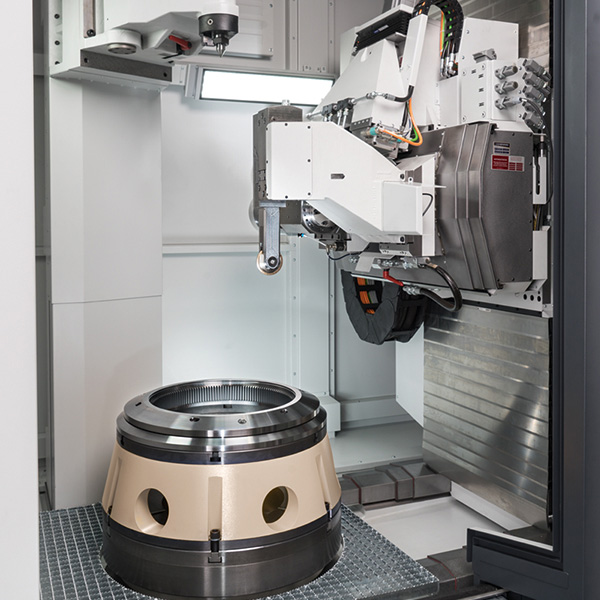

tool management

- KAPP NILES offers intelligent clamping equipment and tools providing all information relevant to the process via an integrated RFID data storage carrier of the machine control unit. The new components allow for time savings by forgoing manual data input and thus eliminating input errors.

Fine grinding / Polish grinding

- With the demands for higher flank load capacity of gears and efficiency increases of gear boxes, fine and polish grinding has become more and more established. By integrating these downstream processes, surface qualities of Rz

Generating(Profile)-Grinding Machines

-

machines customised for your requirements

Most of the following solutions combine continuous generating grinding and discontinuous profile grinding in one machine. For the grinding of your gears, shafts, rotors and special profiles KAPP NILES offers best suitable profile grinding machine and generating gear grinding machine. KAPP NILES generating gear grinding machines are best suitable for the medium and large batch production of gears with very high precision in conjunction with high productivity.

KNG 5P expert

-

- max. tip diameter [mm]: 350

- max. workpiece length [mm]: 700

- module range [mm]: 0.5 - 6.0

- max. face width [mm]: 400

- max. helix angle [deg]: ± 45

Machine concept

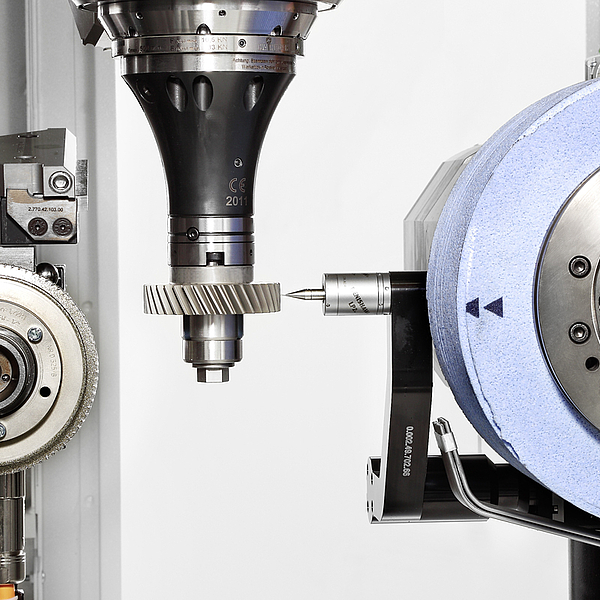

The KNG 350 expert is based on a compact, set-up-optimised machine concept and is intended for use in medium and largescale series production of external geared components. The integrated workpiece handling ensures short non-productive times and can handle both bored parts and shafts. The new functional and ergonomic machine design paired with the innovative user-friendly interface KN grind supports the user during set-up and optimisation of grinding projects.

High-performance technology options combined with application-specific aligning and measuring functions enable maximum precision and surface qualities on the workpiece. The NC-controlled aligning device adapts automatically to different workpieces

KNG FLEX

-

- max. tip diameter [mm]: 350

- max. workpiece length [mm]: 700

- module range [mm]: 0.5 - 6 / 0.5 - 8

- max. face width [mm]: 400

- max. helix angle [deg]: ± 45

Machine concept:

The KNG 350 flex is based on a compact, set-up-optimised machine concept for use in the prototype sector up to large series production. Both externally and internally toothed workpieces can be machined. The performance-optimised grinding spindle with counter bearing is designed also for the use of large grind-ing worms with widths of up to 200 mm. This allows an efficient realisation, especially when machining of components with large modules and using 2-sector worms for fine grinding or polishing applications. From manual loading to a comprehensive automation solution, the concept offers full flexibility. The functional and ergonomic machine design paired with the innovative user-friendly interface KN grind supports the user during set-up and optimisation of grinding projects.

Due to the use of auxiliary spindles small grinding wheels can be applied. Both involute internal gears and special profiles can be machined with the internal grinding device.

KNG FLEX HS

-

- max. tip diameter [mm]: 350

- max. workpiece length [mm]: 700

- module range [mm]: 0.5 - 6 / 0.5 - 8

- max. face width [mm]: 400

- max. helix angle [deg]: ± 45

Machine concept:

The KNG 350 flex HS is based on a compact, set-up-optimised machine concept and is intended for use in small, medium and large series production of externally toothed components up to 350 mm diameter. The machine is characterised in particular by the highest grinding quality and productivity, even when machining with small tools. Using a high-speed grinding spindle (HS) with a speed of 25,000 rpm, even gear teeth with interfering contours can be ground, requiring tool diameters of min. 55 mm (generating grinding) or 20 mm (profile grinding). The concept also offers full flexibility in the selection of loading and automation solutions. From manual loading to downsize automation to robotic loading. The optionally integrated ring loader ensures the shortest non-productive times and can handle both bore parts and shaft-shaped workpieces. The new functional and ergonomic machine design paired with the innovative user-friendly interface KN grind supports the user during set-up and optimisation of grinding projects.

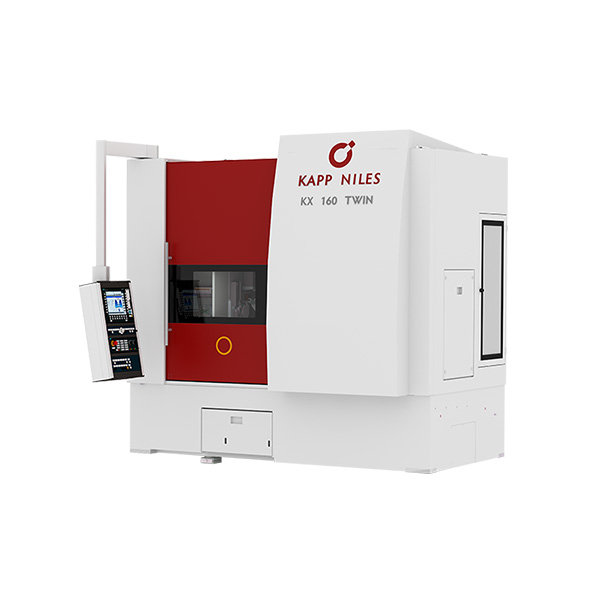

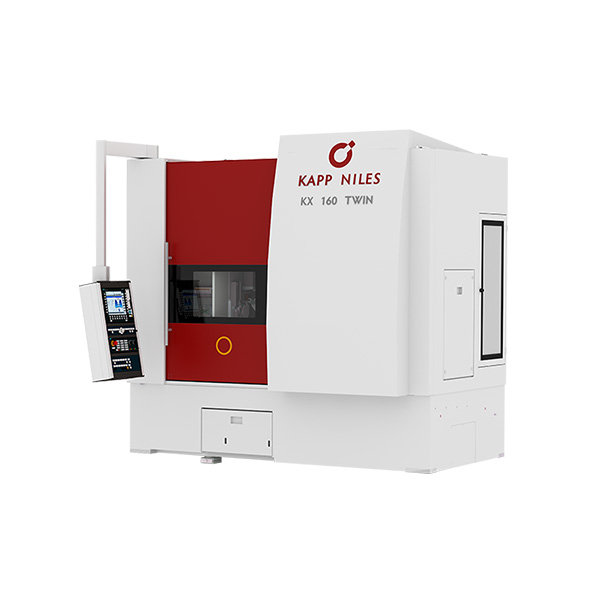

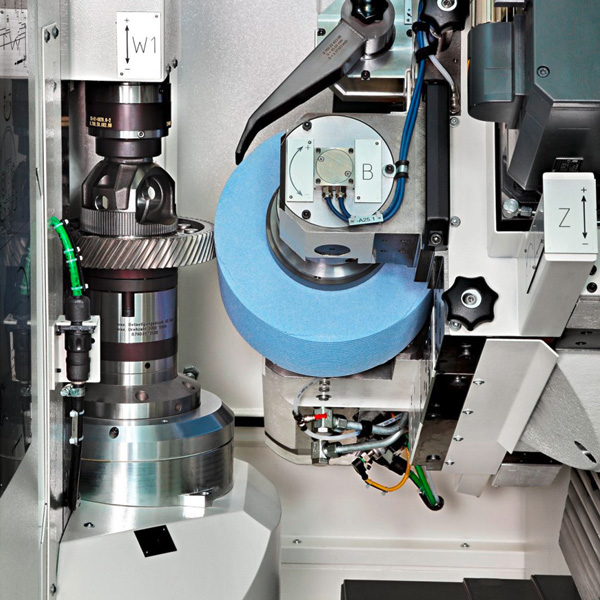

KX TWIN SERIES

-

- max. workpiece length [mm]: 770

- Module range [mm]: 0.5 – 4.5 | 0.5 – 6

- max. face width [mm]: 320 (520)

- max. helix angle [deg]: ±45

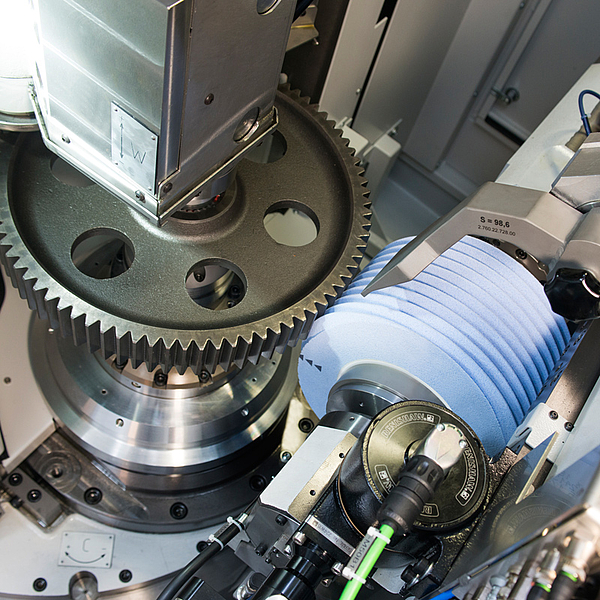

Machine concept

Machines of the KX TWIN series have been designed for continuous generating grinding with dressable and non-dressable tools. They are particularly suitable for the high production volumes in the medium and large batch production of gears and shafts.

The concept includes two identical workpiece spindles arranged at opposing sides of an rotary indexing table. While machining one part, the second workpiece spindle simultaneously loads / unloads and aligns another part.

The machines are optimised for automatic loading with a standardised, cost-effective combination of pallet conveyor and gantry loader. By using an optional high-speed grinding spindle (HS), it is even possible to grind gears with interfering edges which require a tool diameter of 55 mm (generating grinding) or 20 mm (profile grinding).

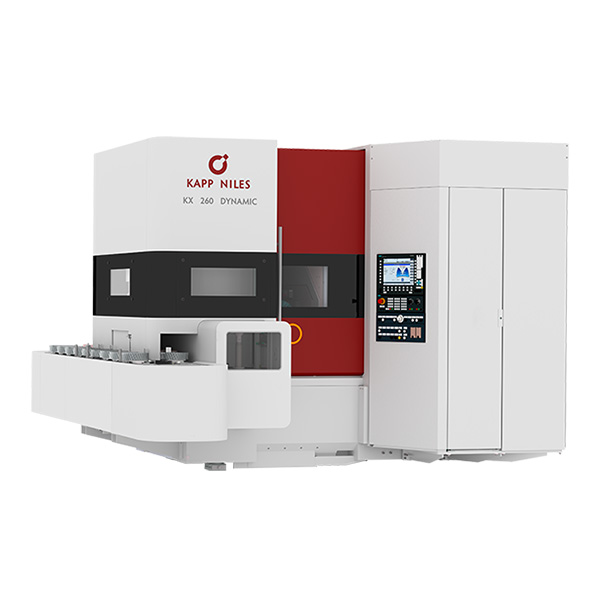

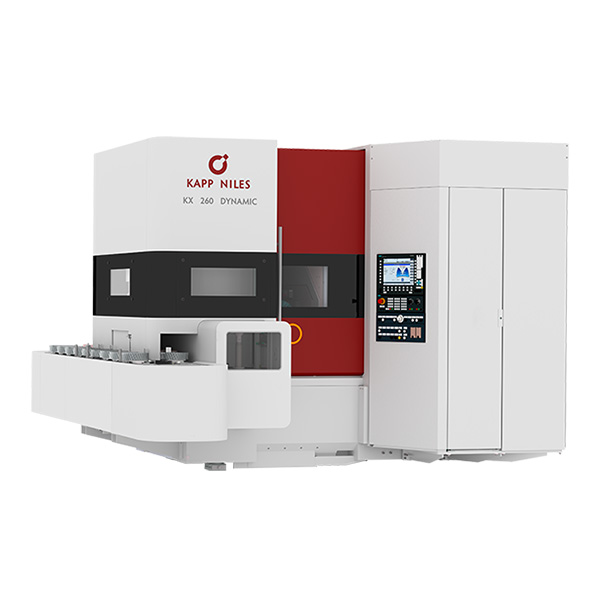

KX DYNAMIC SERIES

-

- max. workpiece length [mm]: 150

- Module range [mm]: 0.5 – 4.5 | 0.5 – 6

- max. face width [mm]: 80 | 100

- max. helix angle [deg]: ±35 | ±45

Machine concept

Intended to be used within the automotive industry, the DYNAMIC series convinces with minimal set-up and non-operational times. The concept is based on the integrated loading function and the optionally available automatic changeover of the workpiece fixtures.

Parallel to grinding operation, the second pick-up axis can unload the finished workpiece and pick up an unmachined part. The workpiece is aligned outside the working area. To reduce non-productive times, the workpiece spindle can be swivelled into the working area in an already accelerated state.

Continuous generating grinding with dressable grinding tools is used as machining process. For application-specific purposes, dressing tools with integrated tip dresser as well as flexible tools with separate tip dressers can be used on the dressing unit. The integrated automation reduces the space requirement to a minimum. Topological generating grinding is available as an option..

KX 300 P

-

- max. tip diameter [mm]: 350

- max. workpiece length [mm]: 800

- module range generating / profile [mm]: 0.5 - 8 / 0.5 - 10

- max. face width [mm]: 320

- max. helix angle [deg]: ±45

Machine concept

Based on different tool and process technologies, user-specific, optimal production solutions can be configured.

The tool spindle with counterbearing can hold dressable and non-dressable grinding worms or profile grinding wheels. Due to the use of auxiliary spindles small grinding wheels up to a minimum diameter of 25 mm can be used.

Machines can be loaded either manually or automatically. The use of an integrated ring loader allows short loading times for both bore and shaft parts.

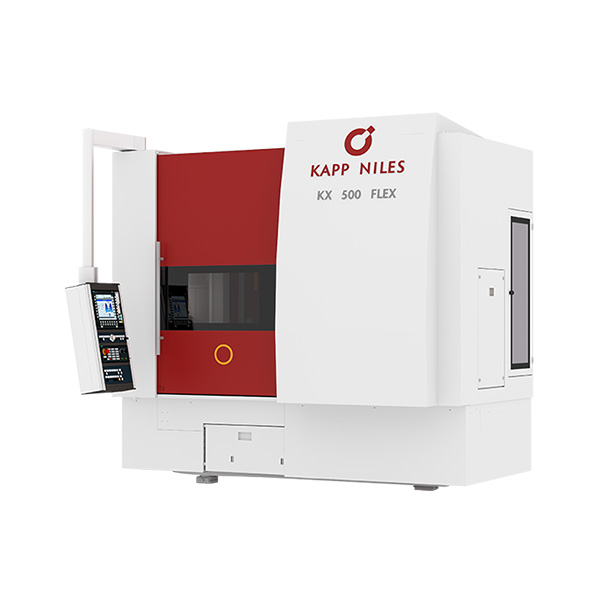

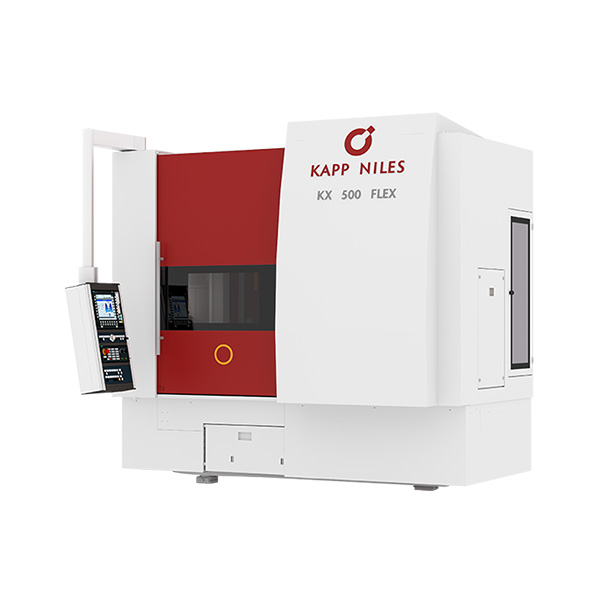

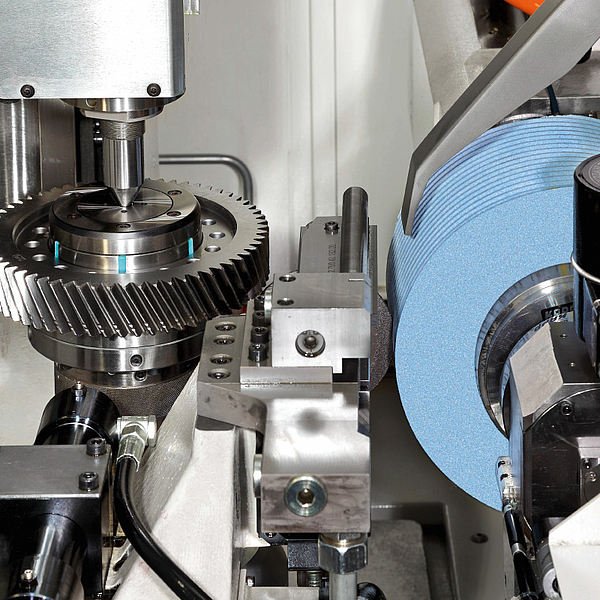

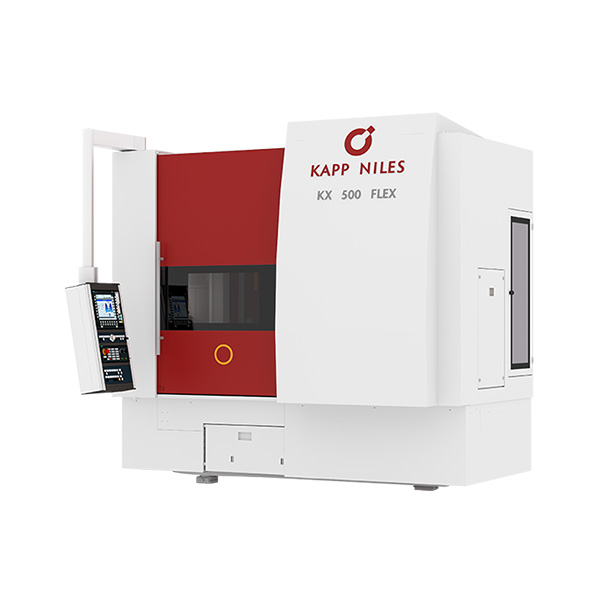

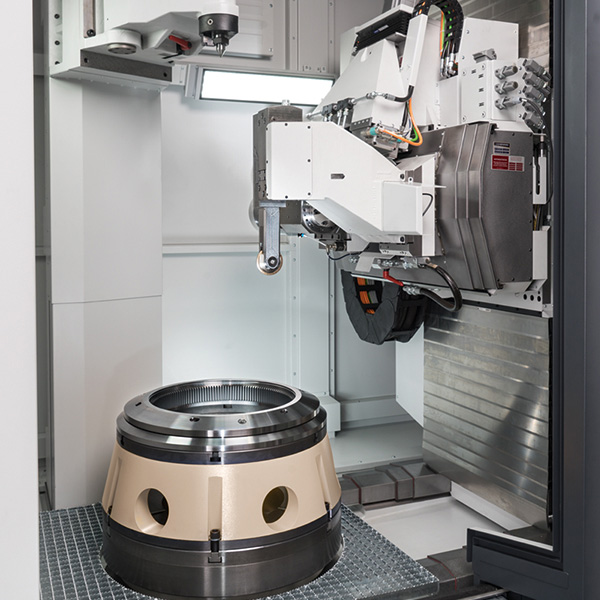

KX 500 FLEX

-

- max. workpiece length [mm]: 1,000

- module range generating / profile [mm]: 0.5 - 8 / 0.5 - 12

- max. face width [mm]: 520

- max. helix angle [deg]: ±45

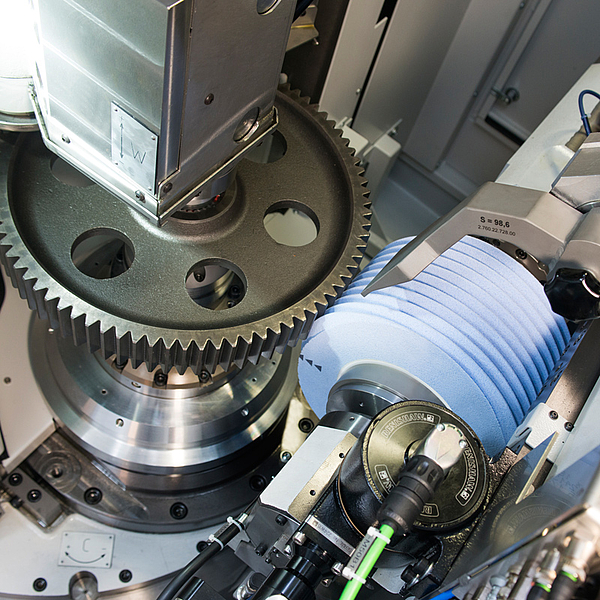

Machine concept

The patented KX 500 FLEX is designed for the flexible use of a wide range of tooling and machining technologies. Thus, application-specific production solutions can be configured to perform diverse processing jobs and a wide range of batch sizes efficiently and economically.

Dressable tools for versatile machining processes and non-dressable CBN tools can be used for highly productive manufacturing as well as grinding of gear geometry with interfering edges.The machine concept is based on a rotary indexing table which incorporates the tailstock and dresser offset against the workpiece spindle. The dressing unit can accommodate a single or twin spindle dresser.

Due to the use of auxiliary spindles small grinding wheels can be applied. Both involute internal gears and special profiles can be machined with the internal grinding device.

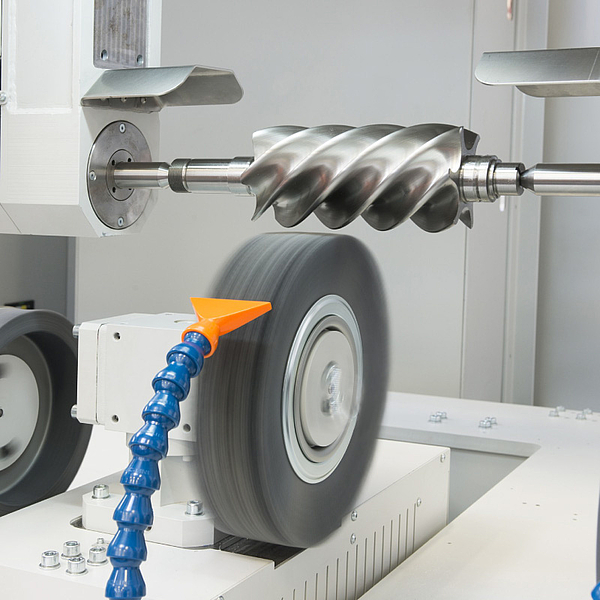

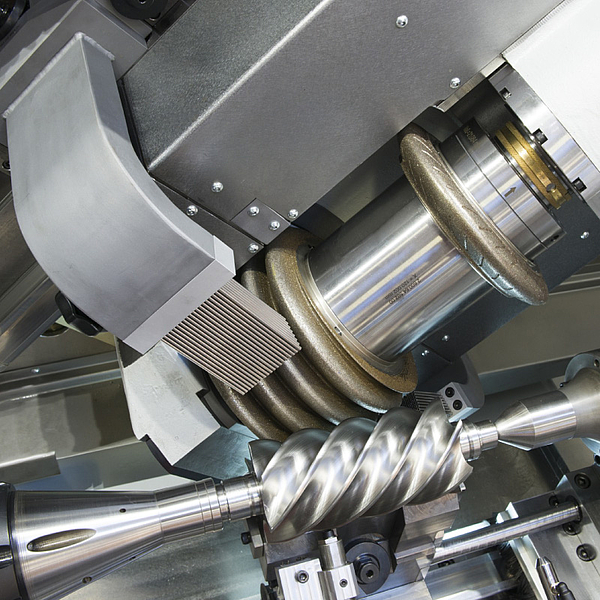

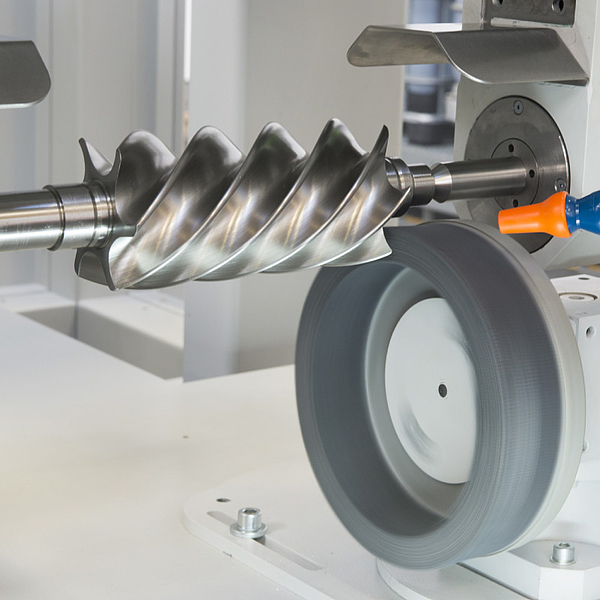

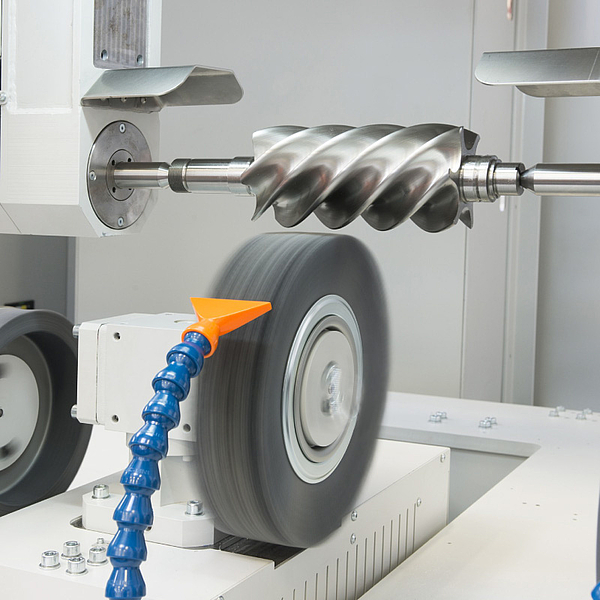

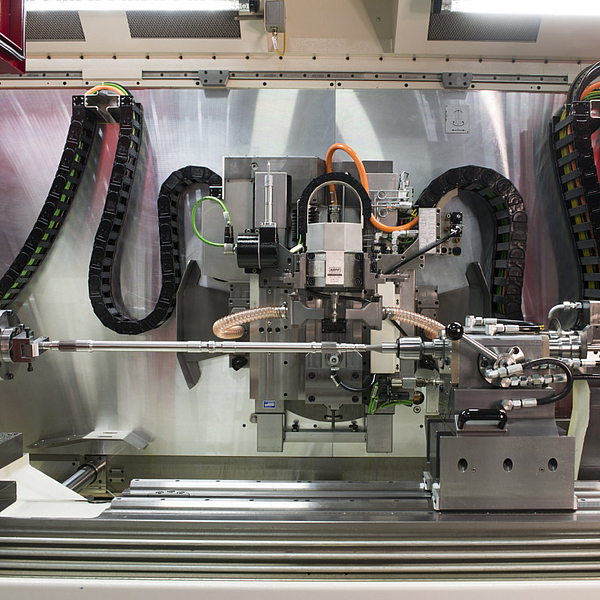

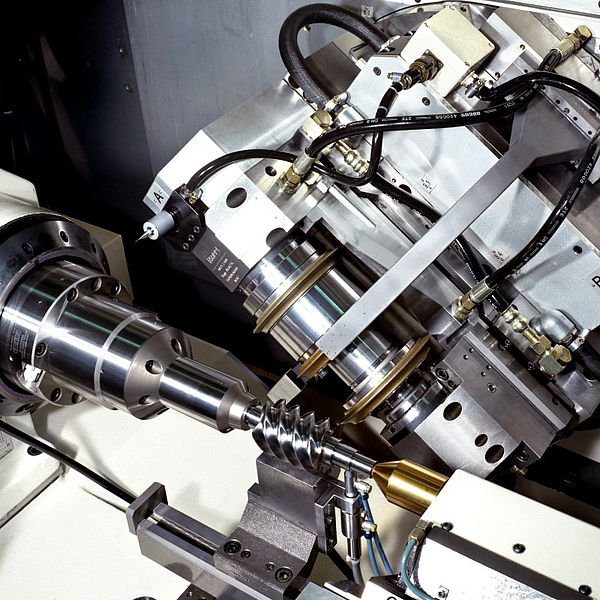

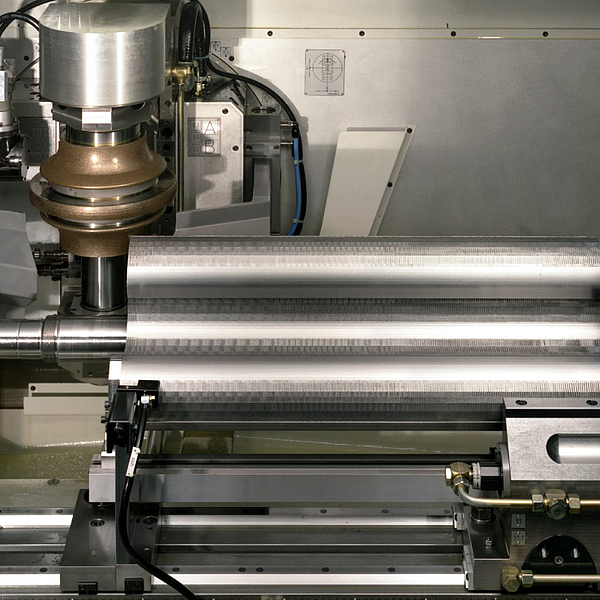

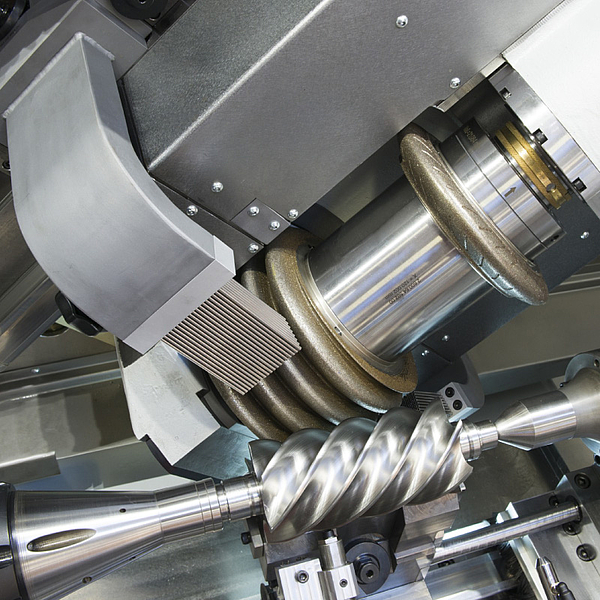

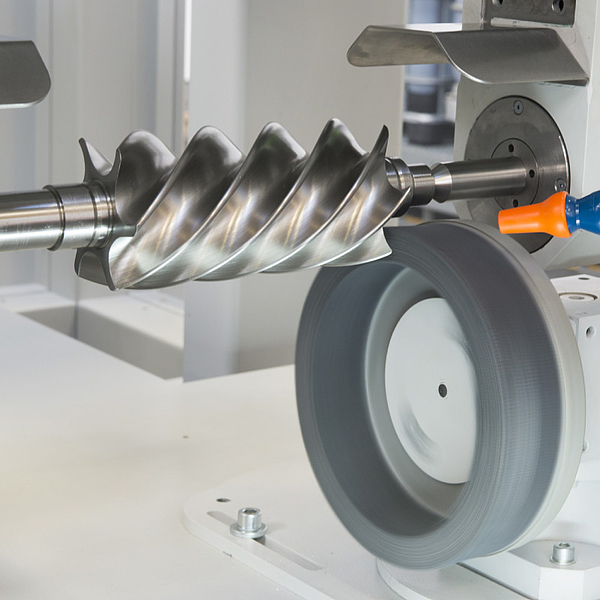

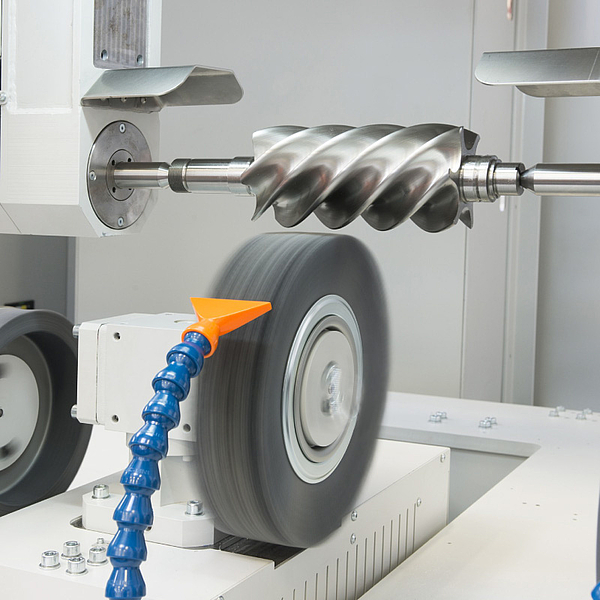

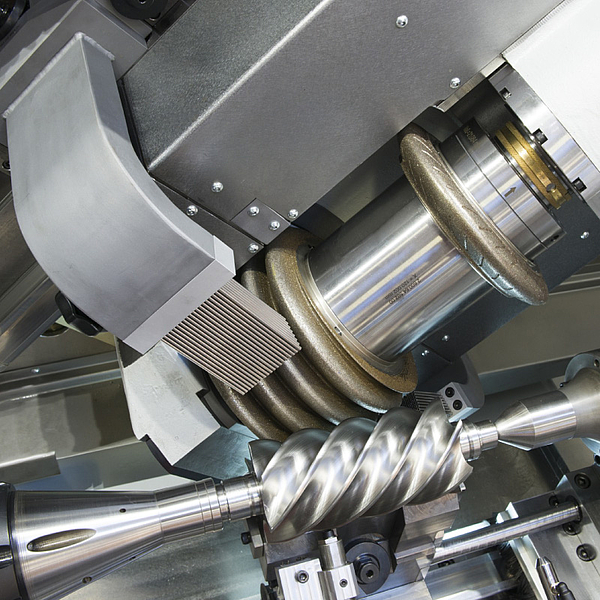

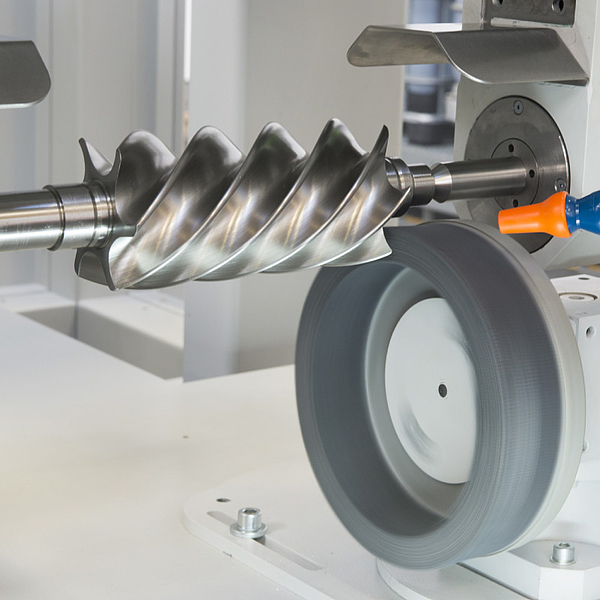

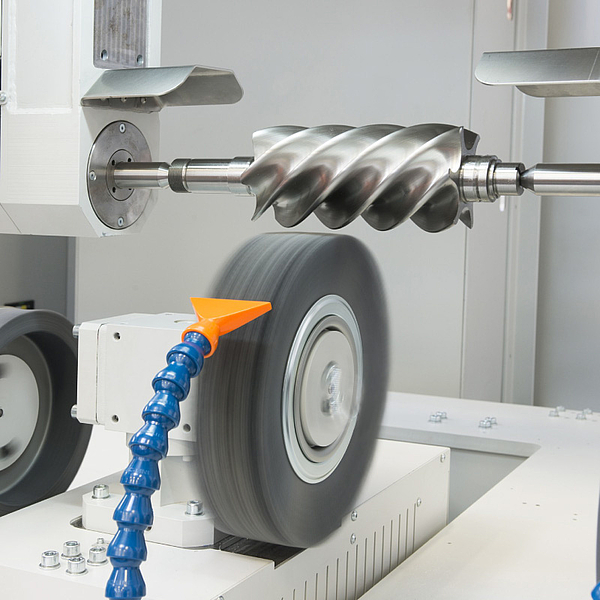

RX 120

-

- max. outer diameter [mm]: 120

- max. workpiece length [mm]: 425

- max. profile length [mm]: 220

- max. profile width [mm]: 80

- max. profile depth [mm]: 30

machine concept

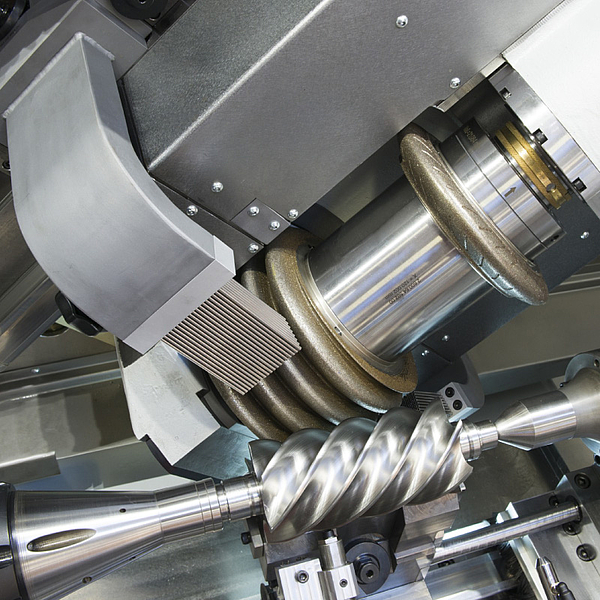

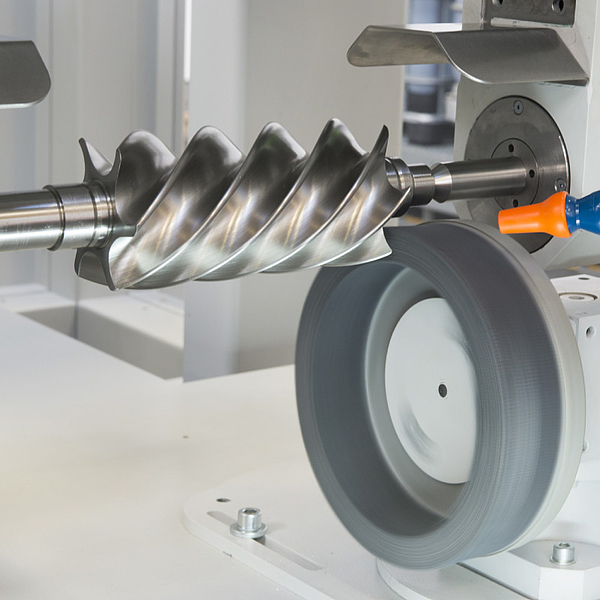

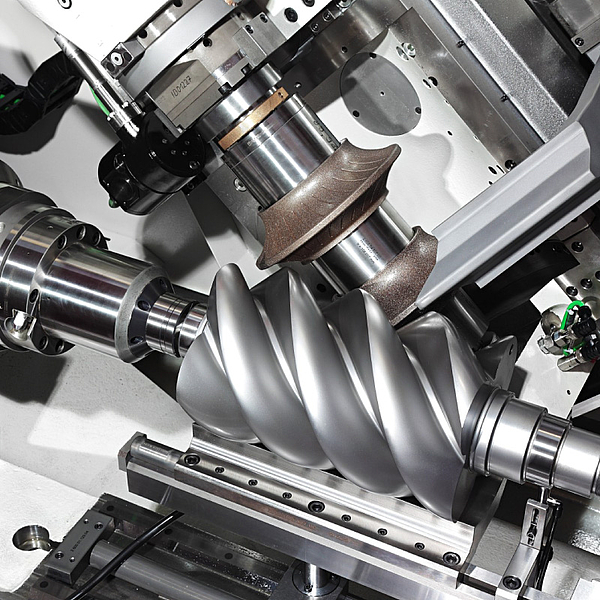

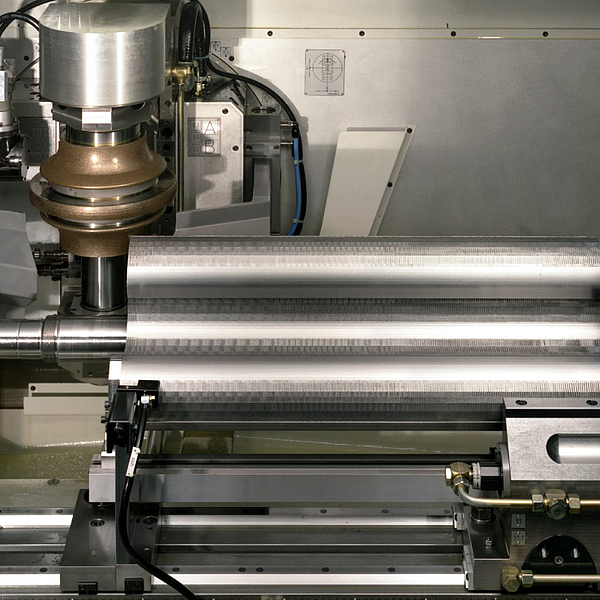

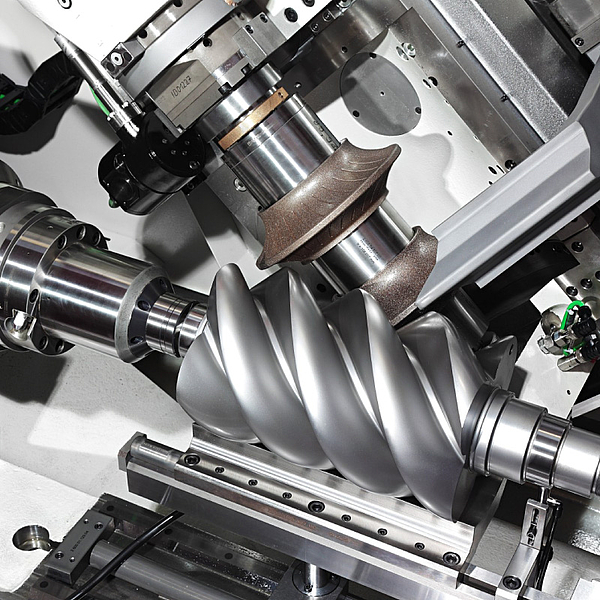

The machines of the RX series are used for pre-finish and finish grinding of pre-profiled steel and cast iron screw rotors.

Due to the innovative drive concept on the tool side, a maximum drive power of 46 kW is reached. Especially for roughing, this high performance results in extremely high stock removal rates and shortens machining times considerably. In combination with an optimally adapted tool technology, a highly productive and efficient working process will be guaranteed.

With regard to pre-grinding, the patented rotor grinding machine RX 120 provides the option to use the advantages of continuous generating grinding instead of profile grinding in manufacturing rotor profiles. For the finishing operation, only profile grinding is used. By applying the generating grinding process as the pre-grinding process, a reduction of up to 40 % in grinding times can be realised compared to conventional machines and processes.

Profile Grinding Machine

-

machines customised for your requirements

KAPP NILES is one of the market leading manufacturers of profile grinding machines. We offer worldwide service and sales of machines for high-precision profile grinding of gears and profiles. Using KAPP NILES profile grinding machines, you are able to grind such workpieces as gears, shafts and profiles with the highest accuracy.

KNG 3P ready

-

- max. workpiece length [mm]: 825

- max. face width [mm]: 400

- max. helix angle [deg]: -45 /+135

machine concept

The profile grinding machine KNG 3P ready offers an inexpensive entry into precision machining. It has been designed as a solution for flexible production of small and medium lot sizes. The machine is characterised by a grinding spindle with high drive power for components up to module 10 mm. The directly driven rotary table is generously dimensioned for a table load of up to 350 kg. The dresser sits stationary against the tool axis and even allows the use of small dressing wheels with a minimum diameter of 65 mm. The working area can be used without any restrictions at large helix angles. Thanks to the low height of the machine bed and the short distance to the machine elements all operations can be carried out without requiring means.

The innovative, operator-friendly user interface KN grind allows a machine-oriented and an intuitive input of all relevant project data.

KX 300 P

-

- max. tip diameter [mm]: 350

- max. workpiece length [mm]: 800

- module range generating / profile [mm]: 0.5 - 8 / 0.5 - 10

- max. face width [mm]: 320

- max. helix angle [deg]: ±45

machine concept

Based on different tool and process technologies, user-specific, optimal production solutions can be configured.

The tool spindle with counterbearing can hold dressable and non-dressable grinding worms or profile grinding wheels. Due to the use of auxiliary spindles small grinding wheels up to a minimum diameter of 25 mm can be used.

Machines can be loaded either manually or automatically. The use of an integrated ring loader allows short loading times for both bore and shaft parts.

KX 500 FLEX

-

- max. workpiece length [mm]: 1,000

- module range generating / profile [mm]: 0.5 - 8 / 0.5 - 12

- max. face width [mm]: 520

- max. helix angle [deg]: ±45

Machine concept

The patented KX 500 FLEX is designed for the flexible use of a wide range of tooling and machining technologies. Thus, application-specific production solutions can be configured to perform diverse processing jobs and a wide range of batch sizes efficiently and economically.

Dressable tools for versatile machining processes and non-dressable CBN tools can be used for highly productive manufacturing as well as grinding of gear geometry with interfering edges.The machine concept is based on a rotary indexing table which incorporates the tailstock and dresser offset against the workpiece spindle. The dressing unit can accommodate a single or twin spindle dresser.

Due to the use of auxiliary spindles small grinding wheels can be applied. Both involute internal gears and special profiles can be machined with the internal grinding device.

ZE Series: ZE 400 | 650 | 800 | 1200

-

- max. tip diameter [mm]: 400 (500) | 650/800 | 1,000/1,200

- max. workpiece length [mm]: 1,100

- module range [mm]: 0.5 - 20 (25)

- max. face width [mm]: 400 | 600 | 600

- max. helix angle [deg]: -45/+120

Machine concept

The gear profile grinding machines in the ZE series are used for high-precision machining of external and internal gears. The machine concept stands for maximum quality, very straight forward handling and compact design. The machines are equipped with a dresser, counter support, integrated measuring device, balancing unit and comprehensive software for grinding and measuring of involute profiles, which enables machining of a wide range of applications.

Easy accessibility provided by doors that open wide, and oper-ation from the hall floor allow easy set-up for machining individual parts and small-scale serial production. The machines feature generously dimensioned rotary tables with electrical direct drive and deep rotary table bores. All machines of the ZE series can be equipped with internal grinding units.

KNG 10P master | KNG 12P master

-

- max. tip diameter [mm]: 1000 / 1250

- max. workpiece length [mm]: 1,545

- module [mm]: 0.5 - 35.0

- max. stroke lengh [mm]: 1000

- max. helix angle [deg]: + 45 / - 120

Machine concept

The machines in the master series are perfect for high-precision machining of external and internal gears as well as special profiles. The machine concept stands for maximum workpiece quality.

High thermal stability and rigidity are achieved through an optimised design and matching components. The inherently rigid machine base enables easy installation without anchoring in the hall floor.

The dressing and grinding spindles are equipped with state-of-the-art direct drives. The new functional and ergonomic machine design paired with an innovative user-friendly interface supports the user during set-up and optimisation of grinding projects. High-performance technology options and application-specific alignment and measuring devices mean that maximum quality can be achieved even with batch size 1.

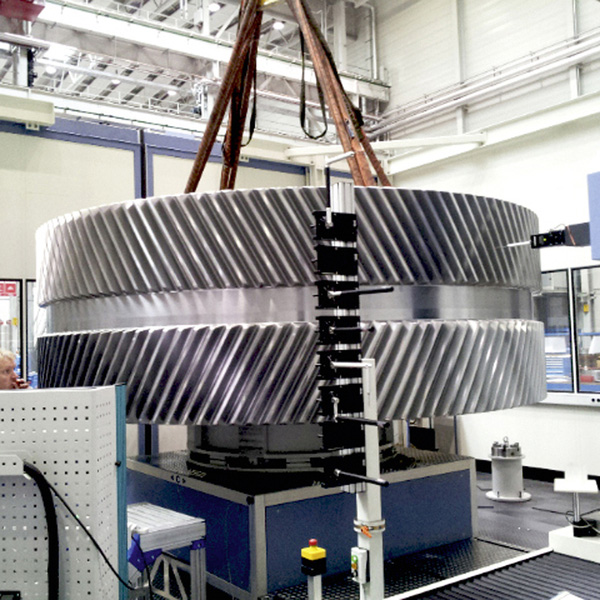

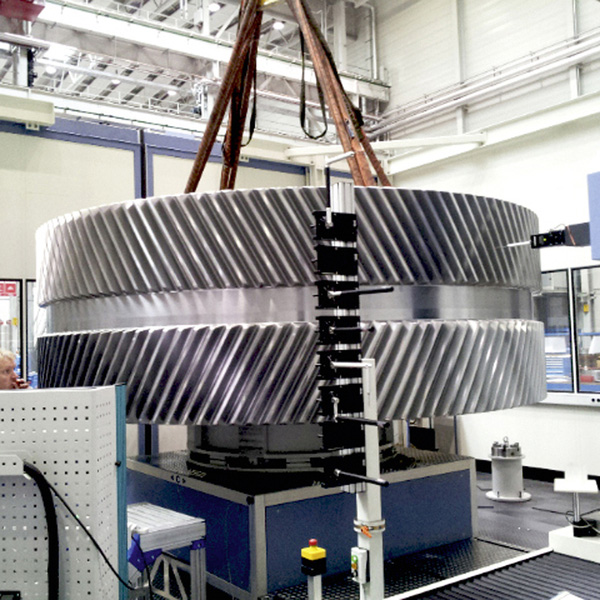

ZP 110/12/16 | 20/24 | 30-80

-

- max. tip diameter [mm]: 1,600 / 2,000 / 2,400 / 2,800 | 3,200 / 4,000 / 5,000 / 6,000 / 8,000

- max. workpiece length [mm]: 1,700 (2,050) | 1,700 (2,050) | on request

- module range [mm]: 40 | 40 | 50

- max. face width [mm]: 1,000 (1,500 / 1,800)

- max. helix angle [deg]: - 45 / + 120

Machine concept

The machine concept stands for maximum workpiece quality, flexibility and a long service life. The basic machines are equipped with a dresser, integrated measuring device, balancing unit and comprehensive software. The machines feature generously dimensioned rotary tables with electrical direct drive and large rotary table bores. Hydrostatic bearings and guides allow for pre-cise positioning, excellent load capacity and a virtually unlimited service life. Due to state-of-the-art drive and control technology, even the most challenging applications can still be machined using 5-axis interpolation. All machines of the ZP series can be equipped with internal grinding attachments. Different spindle variants are available for grinding external gears.

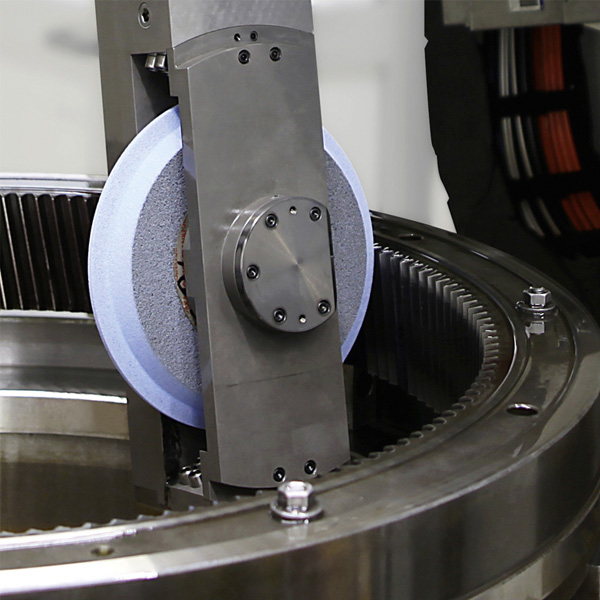

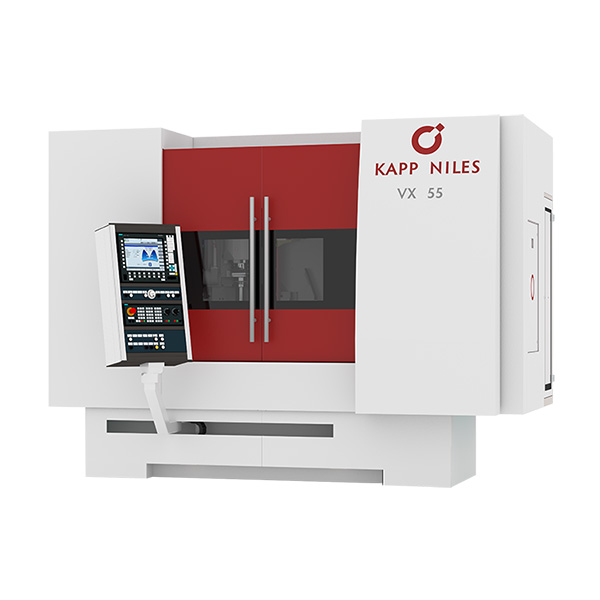

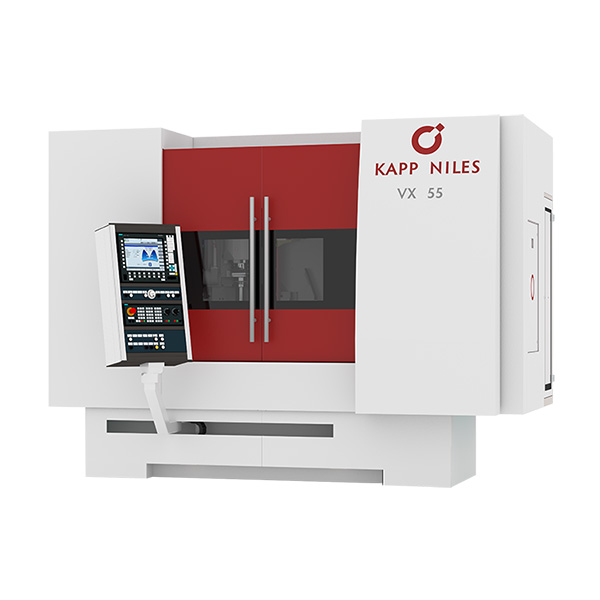

VX Series: VX 55 | VX 59

-

- max. tip diameter [mm]: 1,000 / 1,250 / 1,600 | 2,000/ 2,400 (2,800) | 3,200 / 4,000 / 5,000 / 6,000 / 8,000

- max. workpiece length [mm]: 1,700 (2,050) | 1,700 (2,050) | on request

- module range [mm]: 40 | 40 | 50

- max. face width [mm]: 1,000 (1,500 / 1,800)

- max. helix angle [deg]: - 45 / + 120

Machine concept

The profile grinding machines of the VX series are extremely suitable for meeting the highest requirements concerning the final quality of the produced gears. Both dressable tools and non-dressable CBN tools may be used in the process. As the grinding adapter can be fitted with two exchangeable grinding spindles, the cutting passes can be realised with the sequential use of roughing and finishing tools in one workpiece set-up. As an alternative, multiple gears can be machined in one set-up.

VX machines configured for the use of dressable tools feature integrated dressing equipment producing any type of grinding wheel profile. The dressing and grinding programme is generated automatically based on the gear data. The combination of measuring system and profile dressing equipment also allows for automated machining according to the so-called GMG-strategy (grinding - measuring - grinding).

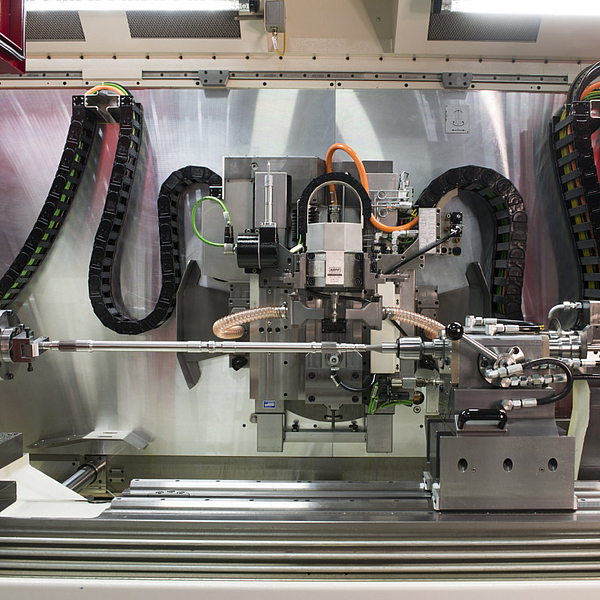

Rotor Grinding Machines RX 55 / 59

-

- max. outer diameter [mm]: 320 | 320 (400)

- max. workpiece length [mm]: 1,200 | 1,650

- max. profile length [mm]: 550 | 850

- max. profile width [mm]: 180 | 180

- max. profile depth [mm]: 80 | 80

Machine concept

The profile grinding machines of the VX series are extremely suitable for meeting the highest requirements concerning the final quality of the produced gears. Both dressable tools and non-dressable CBN tools may be used in the process. As the grinding adapter can be fitted with two exchangeable grinding spindles, the cutting passes can be realised with the sequential use of roughing and finishing tools in one workpiece set-up. As an alternative, multiple gears can be machined in one set-up.

VX machines configured for the use of dressable tools feature integrated dressing equipment producing any type of grinding wheel profile. The dressing and grinding programme is generated automatically based on the gear data. The combination of measuring system and profile dressing equipment also allows for automated machining according to the so-called GMG-strategy (grinding - measuring - grinding).

Rotor Grinding Machine RX 120

-

- max. outer diameter [mm]: 120

- max. workpiece length [mm]: 425

- max. profile length [mm]: 220

- max. profile width [mm]: 80

- max. profile depth [mm]: 30

machine concept

The machines of the RX series are used for pre-finish and finish grinding of pre-profiled steel and cast iron screw rotors.

Due to the innovative drive concept on the tool side, a maximum drive power of 46 kW is reached. Especially for roughing, this high performance results in extremely high stock removal rates and shortens machining times considerably. In combination with an optimally adapted tool technology, a highly productive and efficient working process will be guaranteed.

With regard to pre-grinding, the patented rotor grinding machine RX 120 provides the option to use the advantages of continuous generating grinding instead of profile grinding in manufacturing rotor profiles. For the finishing operation, only profile grinding is used. By applying the generating grinding process as the pre-grinding process, a reduction of up to 40 % in grinding times can be realised compared to conventional machines and processes.

Special Solutions

GAS / GIS / HGS

- GAS

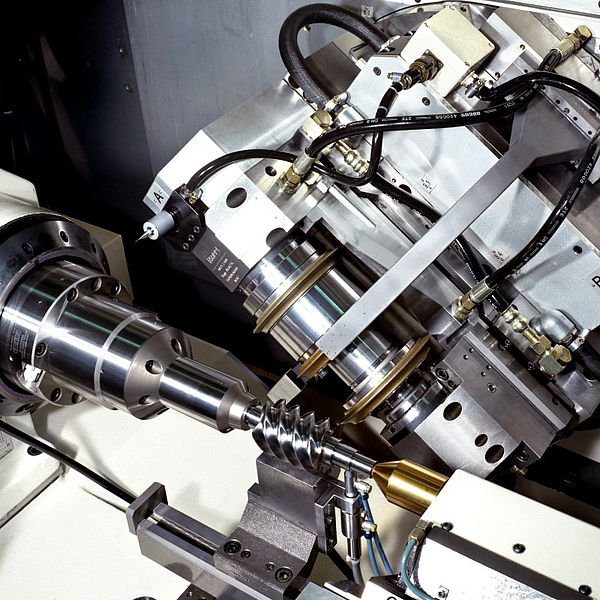

Machines from the GAS series are used for processing external threads and similar profiles. Typical components for these machines are external ball screws for automotive steering systems, as well as drive worms and small pumps and metering components. Parts are only machined by discontinuous profile grinding with non-dressable CBN profile grinding wheels or dressable ceramic grinding wheels.

GISMachines of this type are used for the hard and soft finishing of internal threads in ball screw tracks or similar profiles. Typical applications besides vehicle steering are recirculating ball screws in the field of automotive.

Parts are machined by discontinuous profile grinding.

Non-dressable CBN profile grinding wheels are exclusively used, typically in a combination of roughing and finishing tools.

HGSThe high-speed grinding machine HGS is mainly used for grinding slots in pump rotors into the solid, through-hardened material. Slot widths of 0.5 to 2.0 mm can be produced with high efficiency due to package clamping and automatic unloading and loading. The in process measuring control ensures maintaining slot width tolerances.

The HGS uses non-dressable CBN profile grinding wheels only.

Gear Grinding Centres ZP B

-

- max. tip diameter [mm]: on request

- max. module [mm]: on request

- batch size: prototype to medium series

- processing method: gear profile, bore and face grinding

Machine concept

Based on the well-known ZP series, application-specific solutions have been developed.The machines of the ZP B model have been designed for complete hard finishing (gearing and reference surfaces) of external planetary and bull gears with a tip diameter of up to 3,000 mm. The combination of machining processes ensures a high potential for optimising workpiece quality while at the same time reducing set-up and machining times.

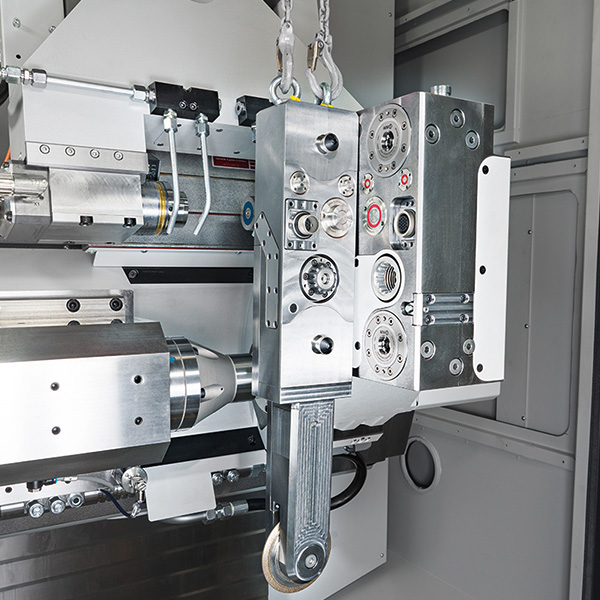

ZPI

-

- max. tip diameter [mm]: on request

- max. module [mm]: on request

- batch size: prototype to medium series

- processing method: profile grinding

The machines of the ZPI model are developed for profile grind-ing of highly precise internal gears with large modules. Especially the series production in the wind energy sector requires higher stiffness and stronger grinding power. A heavy internal grinding device was developed especially for this purpose, with the greatest emphasis on the rigidity of the grinding spindle bearing.

The measuring device is permanently integrated in the grinding head which leads to a reduction of set-up times to a minimum.

ZP I/E

-

- max. tip diameter [mm]: on request

- max. module [mm]: on request

- batch size: prototype to medium series

- processing method: profile grinding

Machine concept

The machines of the ZP I/E model are used for high precision profile grinding of internal gears with large modules with a root diameter of up to 2,900 mm. The grinding arm is designed to allow it to rotate by 180°, thus the machine can be refitted for grinding external gears and special profiles within 30 minutes. The basic machines are equipped with a dresser, integrated measuring device, a balancing unit and comprehensive software.

ZP E/I

-

- max. tip diameter [mm]: on request

- max. module [mm]: on request

- batch size: prototype to medium series

- processing method: profile grinding

Machine concept

The concept of the ZP E/I model is based on the use of two independent grinding columns. Thus, these machines will be used by job shops primarily. The use of a common rotary table and the peripheral units such as cooling lubricant system significantly reduces the investment cost and floor space compared with two individual machines. Different rotary tables and col-umn bases of the ZP series are available.

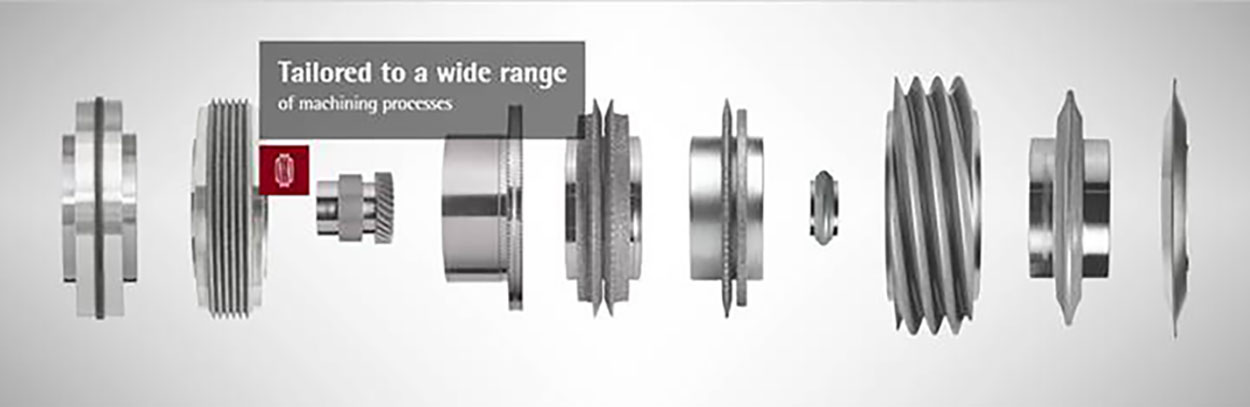

Tools

- As a manufacturer of gear and profile grinding machines KAPP NILES offers sophisticated/highly developed technologies with different, the particular task customised tooling concepts.

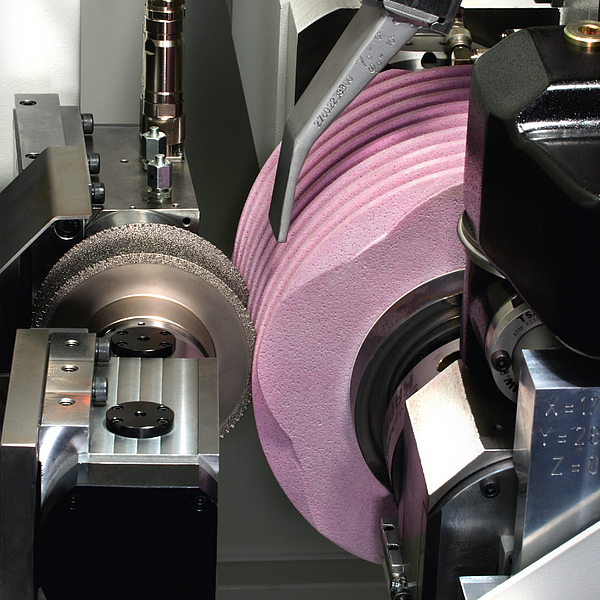

Dressing tools

- For profile dressing of vitrified bonded grinding tools. In addition to CBN and diamond tools for hard and soft finishing of gears and profiles there are dressing tools for profiling of vitrified bonded grinding tools in the product line.

Grinding tools

- Discontinuous profile grinding is usually used for

smaller lot size production and also for bigger gears. Therefore KAPP

delivers sintered diamond form rolls which can be in an economic version

with natural diamond or in a long life version with handset CVD diamond

sticks.

These rolls can be reground several times and exhibit a high tool life.

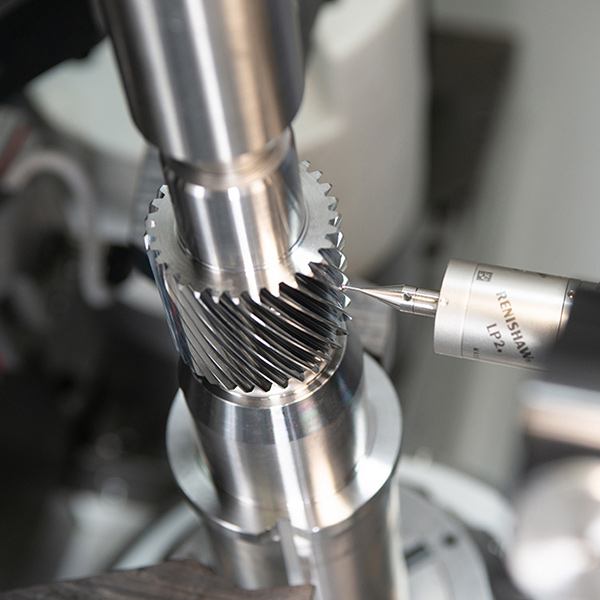

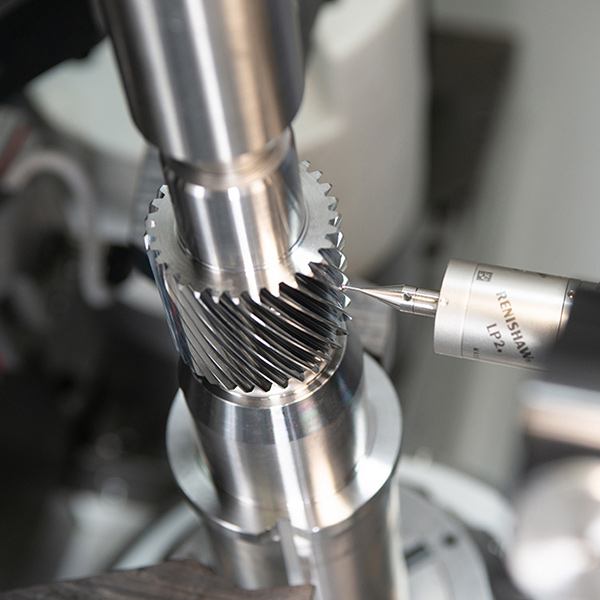

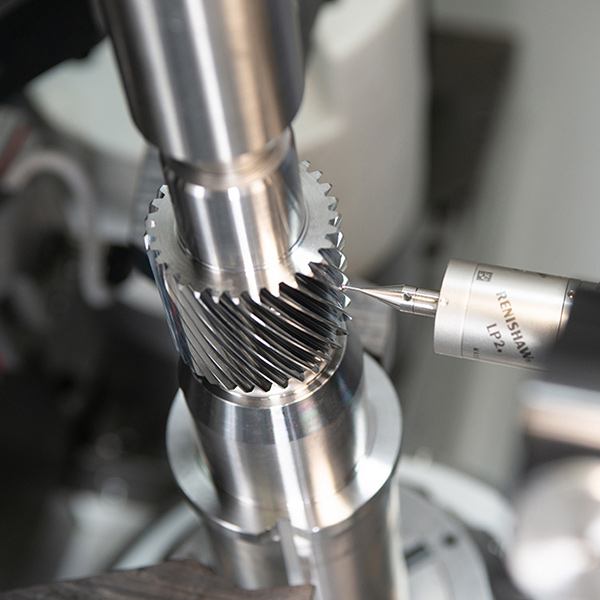

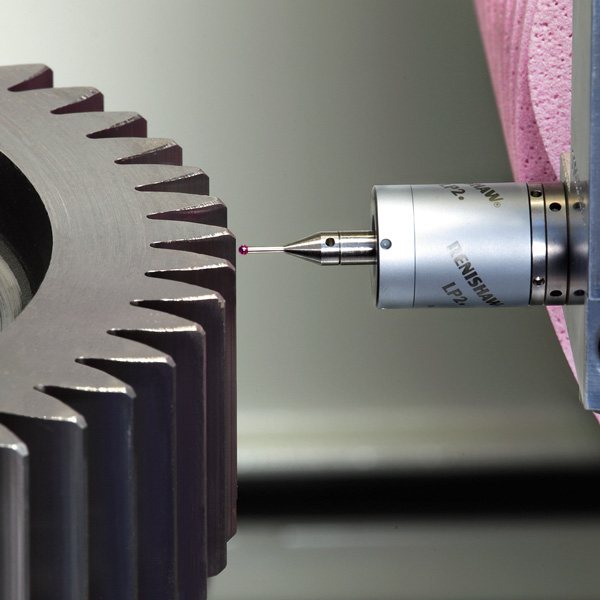

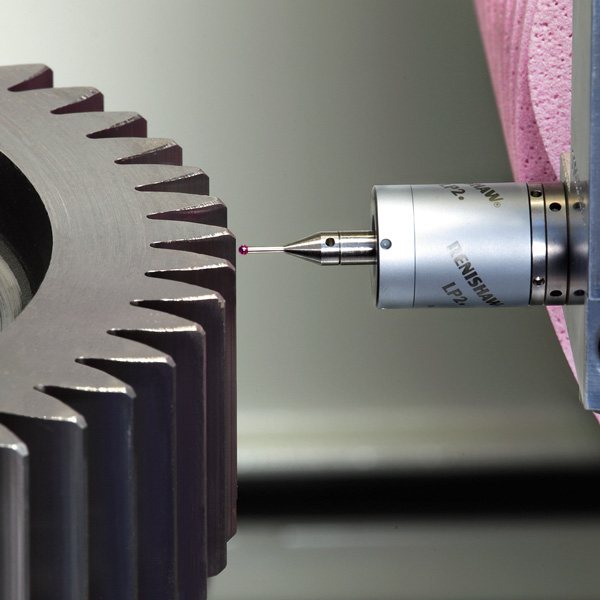

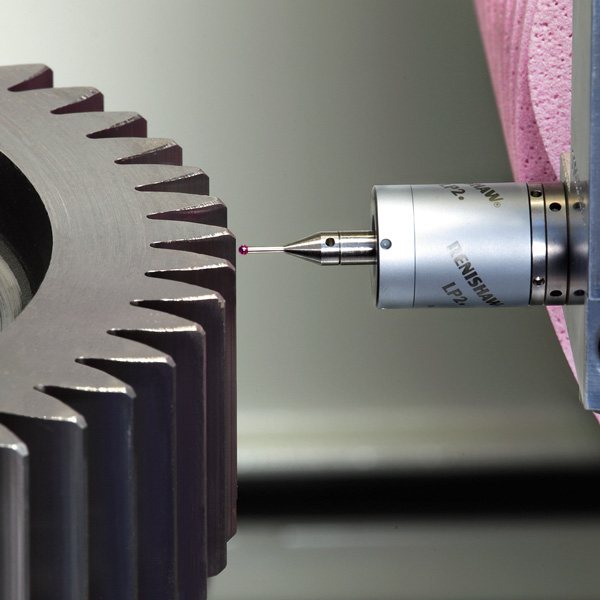

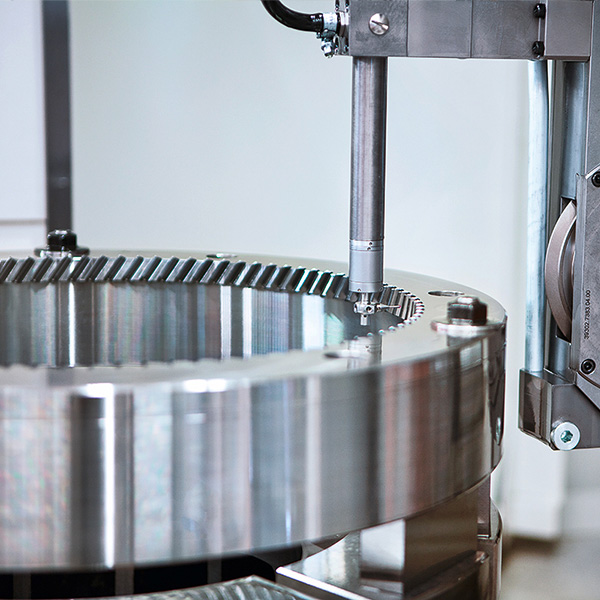

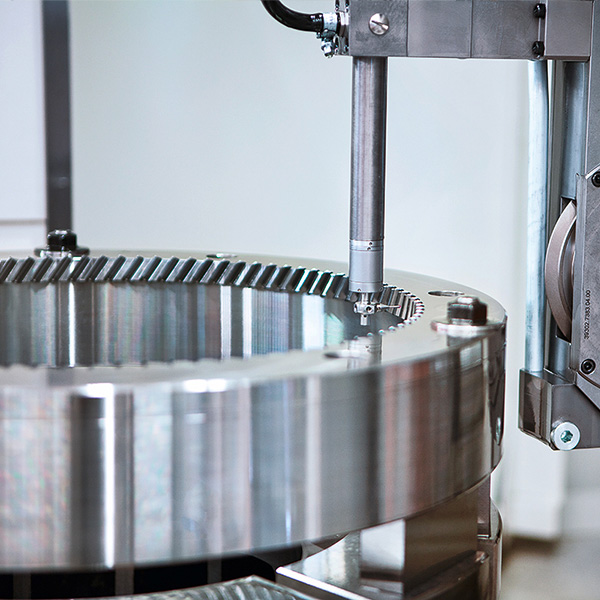

Metrology

-

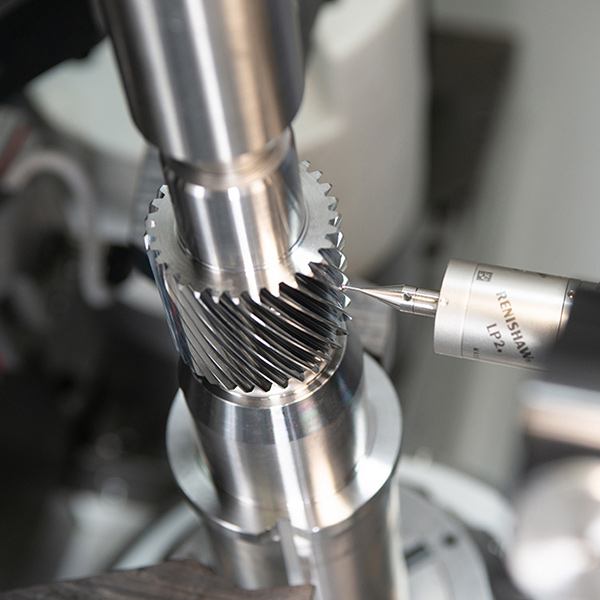

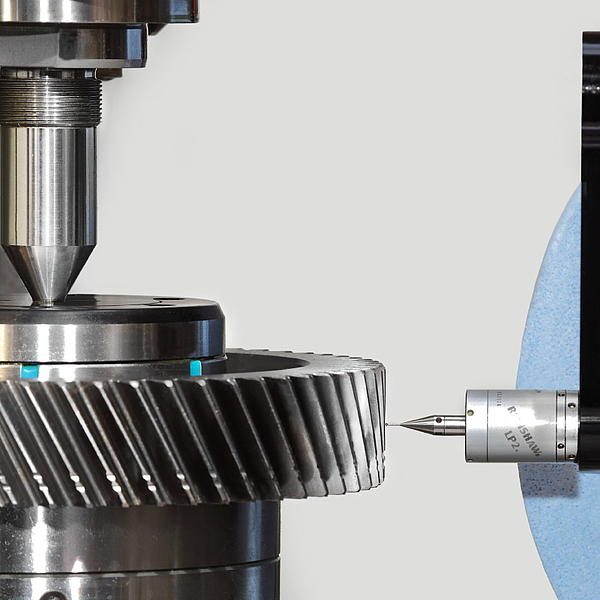

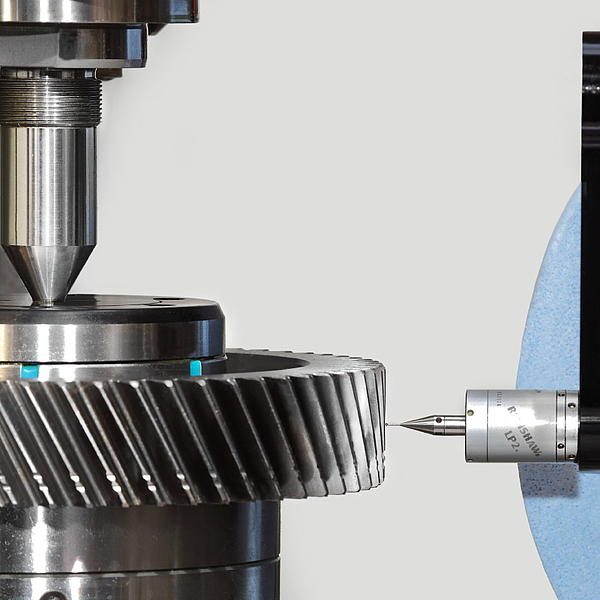

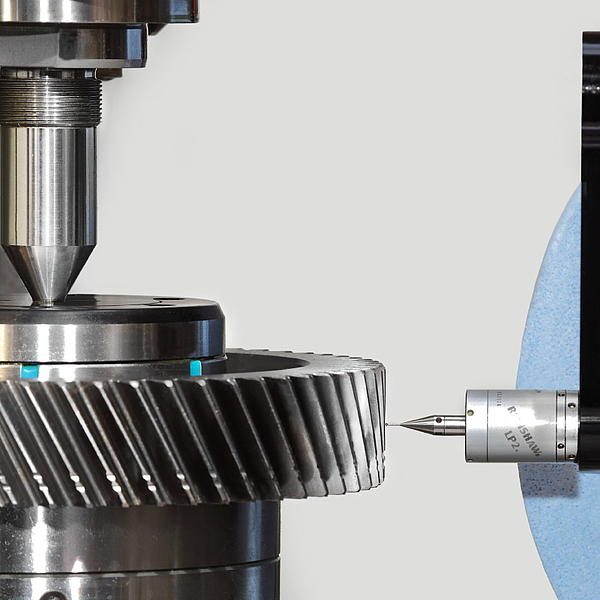

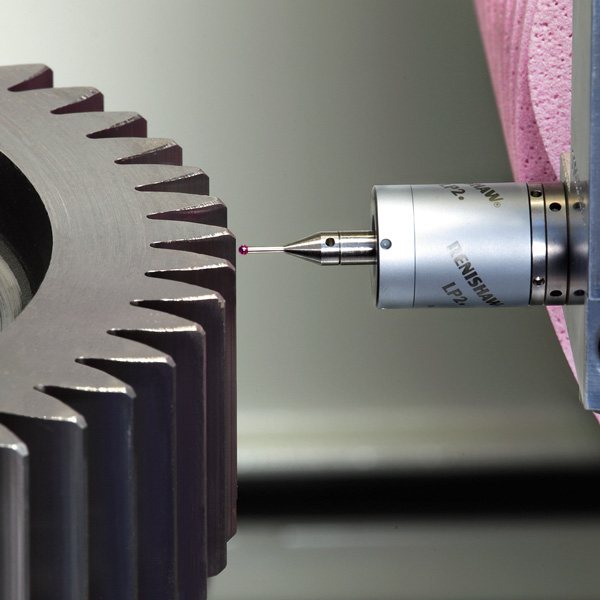

The precise surface quality of components is the decisive factor in grinding. The measuring technology of KAPP NILES Metrology complements the comprehensive product portfolio of the KAPP NILES Group to ensure your required quality.

The range of stationary and mobile measuring machines, measuring devices and special measuring equipment ensures an especially comprehensive competence in the field of gear cutting technology. With our measuring machines, you can achieve the desired surface quality faster by immediately checking the grinding results.

All measuring machines convince with the high-performance operating and evaluation software KN inspect for measuring and evaluating of toothed and rotationally symmetrical components as well as gear cutting tools. With numerous modules, the software covers all measuring tasks customary in the industry. The scope of services is tailored to your individual measuring tasks. All international norms and standards as well as specific requirements can be taken into account in the evaluation.

KN inspect guides and supports you intuitively when entering workpiece and process data. A convenient help function is available for all input steps. The measurement results are already displayed on the screen during the fully automatic measurement process. After completion of the measuring process, the measuring protocol is available in paper form and electronically for further use. By scanning of component identifier (DMC), the data will be read automatically. Data export happens via GDE file.

In addition to our range of measuring machines and measuring devices, we support you with bottlenecks in quality inspection and quality assurance in the area of contract measurements.

Measuring machines

- machines customised for your requirements

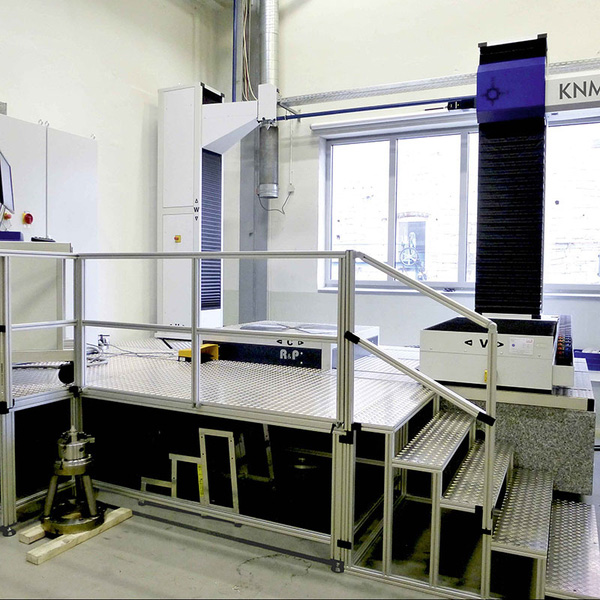

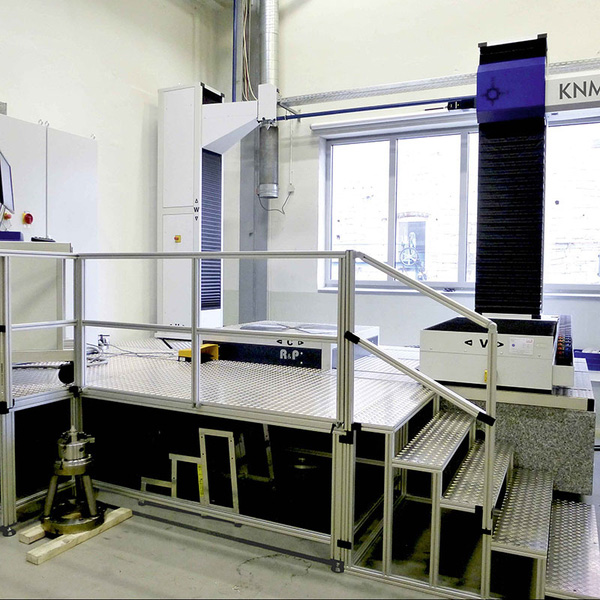

KNM 2X / 4X / 6X | 9X series

-

Analytical measuring machines for small and medium-sized workpieces

- max. workpiece diameter [mm]: 300 | 450 | 750 | 1,250

- max. measurable workpiece length internal / external [mm]: 450 | 400 / 650 | 400 / 800 | 400/1000

- counter support L / D [mm]: 480 / 300 | 850 / 450 | 1,000 / 700 | 1,200 / 1,000

- max. workpiece weight [daN]: 80 | 500 | 500 | 2,000

The KNM 2X / 4X / 6X / 9X analytical measuring machines are designed for high-precision measurements of gears, gear tools and rotationally symmetric workpieces.

All guides and base plates made of granite are extremely stable in the long-term and have identically low expansion coefficients. Air bearings with emergency operation properties ensure perfect and wear-free guides without short-term errors. Air spring elements underneath the base plates safely shield from jolts and vibrations. Separate bases are not required.

Non-ferrous linear and torque motors of the rotary tables ensure ultimate position precisions and path accuracy. Despite the compact design, spacious travel ranges ensure a tangential generating motion towards the base circle for any profile. Based on the requirements, different scanning touch probe systems can be used. The control cabinet can be arranged freely.

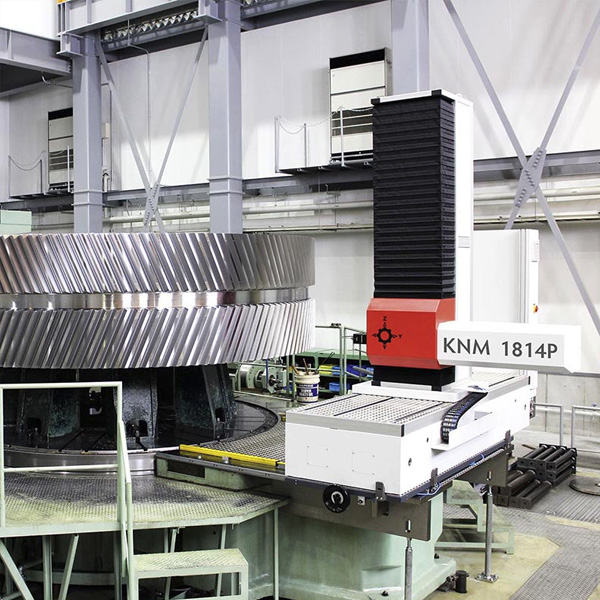

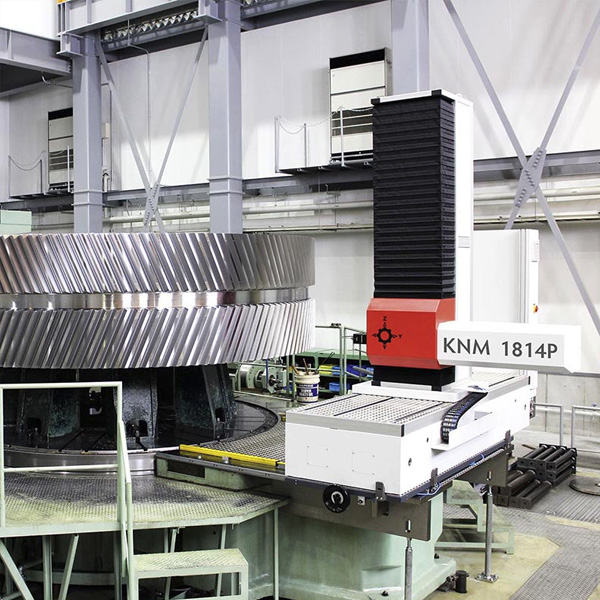

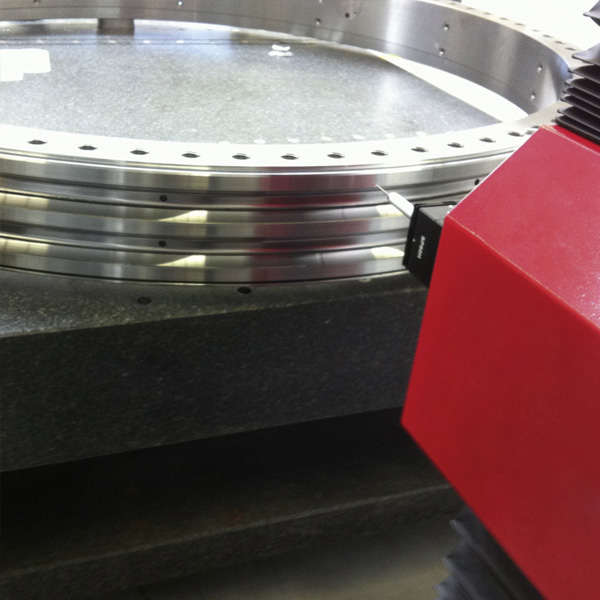

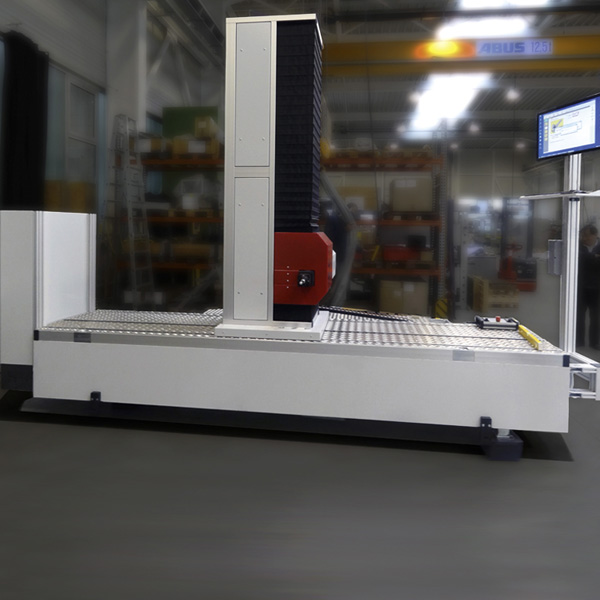

KNM X series

-

Measuring machines for large workpieces up to 6,000 mm

- max. workpiece diameter [mm]: 6,000

- measurable workpiece length [mm]: 1,000 - 2,100

- number of machine axes: 3+1 / 4+1

- max. workpiece weight [daN]: 1,500 - 40,000

According to customer-specific requirements, the KNM X series can be either designed as a stationary machine for medium and larger sized gears, or as a docking station. For this purpose, any size of the machine base can be combined with a rotary table and a transportable 3-axes measuring device. The KNM X machines boast high-precision mechanics with optimal accessibility, laser-based safety equipment, large bearing clearances and generously dimensioned guiding cross-sections.

Linear motors are used in all linear axes. High-precision rotary tables with air or hydrostatic bearing (diameter of 500 to 1,800 mm) feature direct drives / through-holes. Controlled air spring elements underneath the base plates safely shield from jolts and vibrations. No separate foundations are required. The use of drives close to the centre of gravity ensures a low level of dynamic distortions.

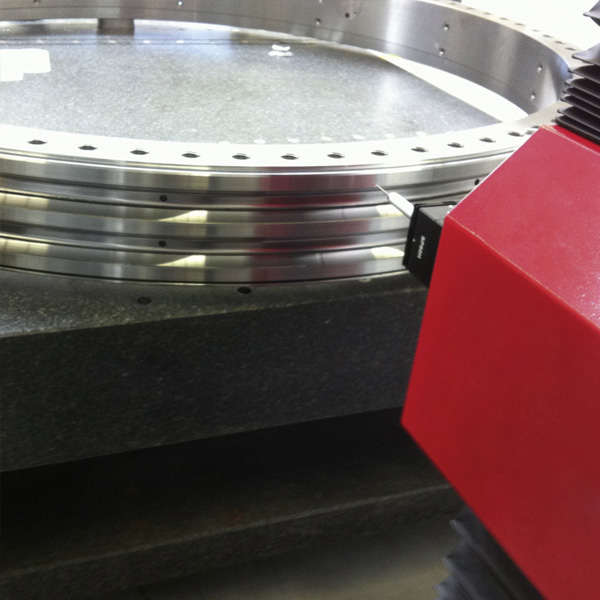

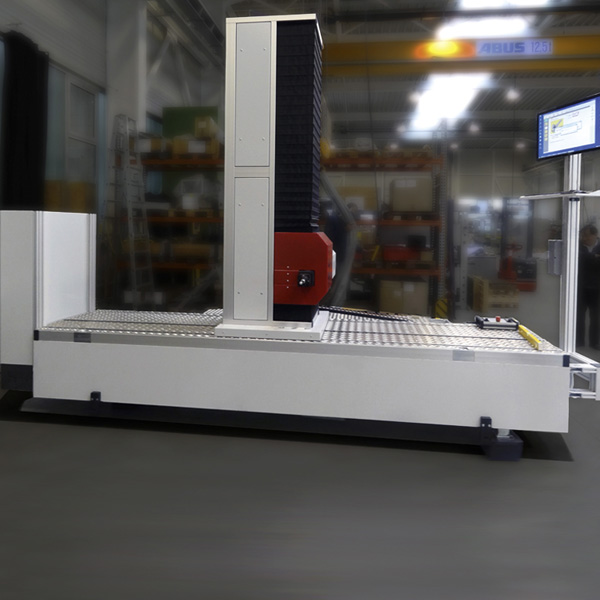

KNM P series

-

Portable measuring machines for gears and diverse components

The equipment of the KNM P series has been optimally adapted directly to the production machine according to the specific customer requirements regarding the autonomous measurement of gears, ring-shaped workpieces such as bearing rings, housings etc. The combination of base plate and rotary table in a customised design (docking station) forms a full-featured 4-axis measuring device. Measurements can even be carried out without rotary table directly in the workshop area. In the KNM P machines, specially designed high-precision mechanics add to optimal accessibility with state-of-the-art drive technology (linear motors). The CNC-controlled 3-axis structure allows for checking all gear parameters or general workpiece profiles. Arbitrary workpiece diameters and easy transport are especially worth emphasising. The measuring equipment is placed on a sturdy base connected directly to the production machine or foundation.

KNM 67P- max. workpiece diameter [mm]: variable

- max. measurable workpiece length [mm]: 700 mm

- number of axes: 3

- travelling paths [mm]: X-axis 400 mm, Y-axis 600 mm, Z-axis 750 mm

- max. workpiece diameter [mm]: variable

- max. measurable workpiece length [mm]: 1200 mm

- number of axes: 3

- travelling paths [mm]: X-axis 700mm, Y-axis 1600mm, Z-axis 1200mm

- max. workpiece diameter [mm]: variable

- max. measurable workpiece length [mm]: 1400 mm

- number of axes: 3

- travelling paths [mm]: X-axis 700mm, Y-axis 2800mm, Z-axis 1400mm

- max. workpiece diameter [mm]: variable

- max. measurable workpiece length [mm]: customised designs available

- number of axes: customised designs available

- travelling paths [mm]: X/Y/Z-axes customised designs available

Measuring equipment

- features for your inspection needs

spline gauges

-

functional hand held gauges for in-process measuring

We offer a wide range of spur and helical gears as well as worms for the rolling test and as machine calibration patterns. More-over, we produce functional Go and No-Go composite and variable indicating spline gauges to support your inspection needs. To verify our inspection system accuracy, we maintain gear prototypes which have direct traceability with the NIST–Y1 US standards laboratory.features

- Plug Gauges (Involute, Parallel & Serration)

- Ring Gauges (Involute, Parallel & Serration)

- Taper Master Plug Gauges

- Spur Master Gears

- Helical Master Gear

- Helical Master Component Replica

- Variable Spline Indicator Ring Type

- Variable Spline Indicator Plug Type

- Indicating Ring Type Gauges

- Taper Spline Mandrels

- Rotalock Mandrels

- Lead and Involute Artefacts