- Offer Profile

OUTSTANDING FOR GREATER PRODUCTIVITY IN YOUR BUSINESS.

Do you have challenging machining tasks? We have outstanding solutions. For three generations, we have been developing tool systems based on outstanding quality, long tool life and process reliability. As an ARNO customer, you benefit from a combination of experience and pioneering spirit that has been a cornerstone of our family-owned company's tradition since day one. Besides these values we are also influenced by the typical Swabian talent for inventiveness. We are proud to help our customers secure an extra competitive edge through clever new products and advancements, and we will continue along this path in the future.

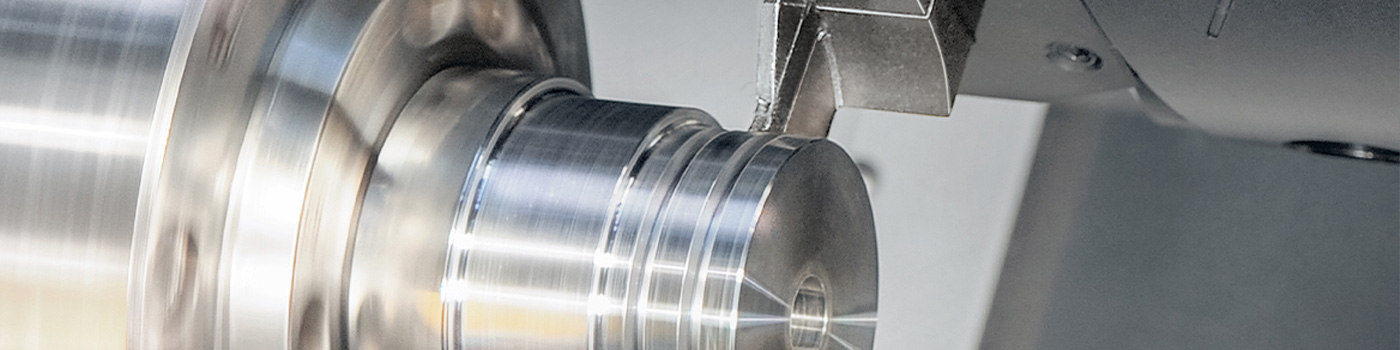

TURNING

-

By using ARNO insert and tooling technologies you benefit from improved tool life, enhanced chip control and high quality surface finishes leading to reduced downtime, increased uptime and reduced costs across your turned parts requirements.

If you have a turned parts requirement make ARNO your tooling partner of choice; a partner with the greatest experience and knowledge covering your application requirements. In particular the depth and breadth of our ground hi-positive insert solutions program is Globally unique in its’ range of standard solutions. A standard solutions portfolio that has the greatest range of grades and geometries with an excess of 10 standard corner radii ranging from 0.03mm to 3mm. A standard offer that is also allied to a full special tooling solution capability. With ARNO turned parts solutions watch your quality and capability increase and your production and part costs decrease.

SYSTEM-HIGHLIGHTS

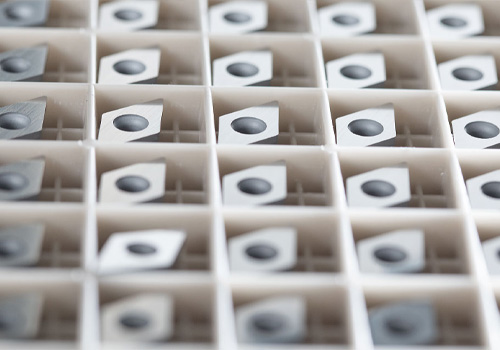

INDEXABLE INSERT

-

MEGA SELECTION AND EVERY INSERT IS A CHAMP.

From precision machining of thin-walled workpieces to roughing of large components, ARNO has the optimum indexable insert for every application.

HIGH-POSITIVE INDEXABLE INSERTS

-

SOFT MATERIALS – SHARP EDGES.

Ideal for long-chipping materials, thin-walled components and optimal surface qualities – high-positive indexable inserts with sharp edge executions from ARNO.

INDEXABLE INSERTS FOR HARD TURNING

-

THIS IS WHERE HARD MEETS HARD.

For highest quality surfaces and maximum productivity with hardened materials: CBS indexable inserts from ARNO.

INDEXABLE INSERTS FOR WHEEL MACHINING

-

GLEAMING PROSPECTS.

The optimum solution for greater speed when processing non-ferrous metals – PKD indexable inserts from ARNO.

INDEXABLE INSERTS FOR EXOTIC MATERIALS

-

EXOTIC MATERIALS – SHARP SOLUTIONS.

Ideal for fine machining of high-temperature materials and stainless steels: high-positive indexable inserts with edge-honed executions from ARNO.

CUTTING INSERTS AND CARRIER TOOLS WITH THROUGH-TOOL COOLANT

-

COOL, WHERE IT REALLY MATTERS.

Optimal cooling, even when space is tight – thanks to cutting inserts with coolant channel for the ARNO AMS Mini-System.

KMH TOOL HOLDERS

-

FLEXIBLE SEAT FOR EVERY SITUATION.

Well thought-out for a wide variety of applications: KMH tool holders with VDI shank from ARNO.

TOOL SYSTEMS

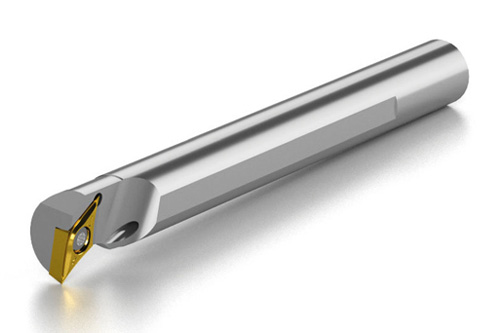

BORING BARS | INTERNAL MACHINING

-

DIVERSE INNER QUALITIES.

Whether small or large diameter, the ARNO system for internal grooving guarantees smooth processes and high quality.

For internal grooving you can always depend on ARNO quality. Whether you need boring bars made of steel or solid carbide, with or without through-tool coolant, ARNO has you covered. With a wide variety of clamping holders and work angles, we have the optimum solution for every requirement. And of course, for every diameter – our ISO boring bars are available with shank diameters from 8 mm to 40 mm. In combination with the matching mini indexable inserts from ARNO, you can effortlessly machine down to Dmin 4.8 mm.

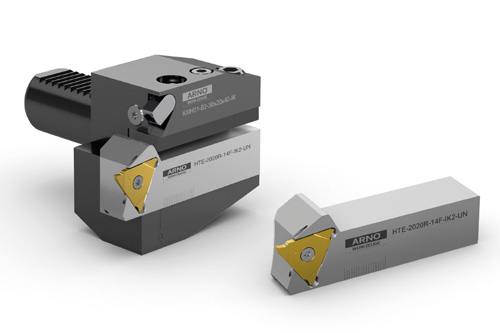

THREAD CUTTING

-

THE BEST TOOLS FOR HIGH-ACHIEVERS.

Reliable and versatile – the ARNO thread-cutting system for all types of threads, pitches and dimensions from a core diameter of 3.2 mm.

Unsurpassed quality, process reliability and versatility – this is the promise behind the ARNO thread-cutting system. With typical ARNO quality right down to the last detail, you benefit from a long tool life and maximum precision. Whether an internal or external thread, trapezoidal or round thread, Whitworth or conical pipe thread – with the appropriate clamp holders, boring bars, indexable inserts and support plates, success is possible at the first attempt.

PRECISE BENEFITS of the ARNO thread-cutting system

- Versatile – one system that lets you create all types of threads, gradients and dimensions

- High quality – all system components in the usual ARNO quality

- Economical – long tool life and precise results from the first attempt

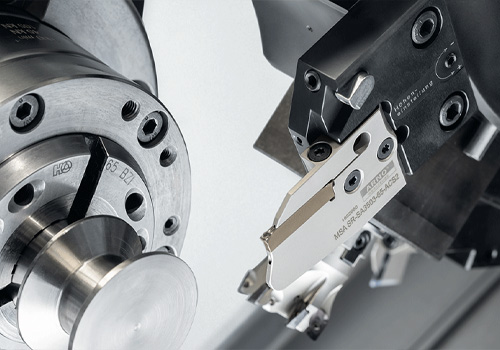

TURNING HOLDERS | EXTERNAL MACHINING

-

VAST SELECTION, OUTSTANDING DURABILITY.

Wide variety and high quality with a precise fit – tool holders from 8x8 to 32x32 mm.

Look no further for the right KMH holders and tool holders for your requirements – with or without through-tool coolant, for almost every machine type, with different clamping systems and angles, in many sizes and with variably positionable coolant connections for all products in the ARNO SpecialDesign range. Special holders are also available.

Despite all these options one thing always remains the same: the quality. All ARNO holders are fully nickel plated and made from high quality, extremely tensile, carefully processed material. This means they are particularly robust and durable. At the same time, the tool life of these indexable inserts is significantly increased thanks to the associated precise and stable insert seat. Special markings make it easier to install the holders with through-tool coolant, thus ensuring reproducible processes and an optimal chip flow.

MULTIPLE BENEFITS with ARNO tool holders- Large selection – suitable for almost every machine and requirement

- Nickel plated, high tensile strength, precisely machined – top quality guarantees longevity

- Process reliability through simple mounting of holders with through-tool coolant

GROOVING

-

When you work with ARNO tools, you benefit from reliable processes when it comes to complex grooving operations, and long tool life and higher productivity in your production.

If you're looking for innovative solutions for grooving operations, you've come to the right place. At ARNO you'll find versatile innovative tool systems for an enormous range of applications. Whether you work with external or internal machining, aluminium or steel, narrow parting off and grooving or complex shapes, we offer you customised systems to achieve very high process reliability and productivity in your production, from holders through to inserts.

SYSTEM-HIGHLIGHTS

ACS – ARNO COOLING-SYSTEM

-

THE UNRIVALLED ORIGINAL.

The ACS – ARNO Cooling System: the patented cooling system for efficient parting off, grooving and groove turning with the SA and SE grooving systems.

FLANGE MOUNTED HOLDERS

-

THE CONNECTION TO MAXIMUM RIGIDITY.

One interface less for more process reliability: with flange mounted holders for monoblock holders, grooving modules and grooving blades.

3D-PRINTED GROOVING MODULES

-

INNOVATION: A COOLANT HOLE WITH EDGES AND CORNERS.

The first series-produced additive manufactured tool in the world: the ACS module with triangular coolant hole ensures maximum cooling through to the edge.

TOOL SYSTEMS

AMS - ARNO MINI-SYSTEM

-

CENTRING MADE EASY.

Modular and precise: the ARNO Mini-System AMS for internal machining starts at a diameter of 0.7 mm and reaches drilling depths of up to 50 mm.

Rigid centring, guaranteed tip height and absolute dimensional accuracy – it's so easy with AMS for flexible operations in holes with small diameters.

This is how it works: The insert is clamped rigidly in central position by a ground chamfer on the shank and a tapered pin. A fixed stop guarantees repeatable positioning at tip height. Besides tool holders, there are also inserts with inner cooling to achieve optimised wear protection and precise coolant supply. This results in reliable processes, maximum precision even at tight tolerances and an increase of one to four times in tool life.

ATS-SYSTEM

-

VERSATILE FOR PRECISE PARTING OFF: THE ATS-SYSTEM FROM ARNO

Efficient thanks to 3-edged inserts and fast tool changes.

Efficient thanks to 3-edged inserts; fast tool changes and rigid due to the Torx-Plus screw clamping system to offer optimised clamping and insert location: The ATS tool system for external parting off has many strengths. One of them is versatility: the countersunk clamping screw and the compact design make the ATS system ideal for applications like shoulder grooving or Swiss type machining. The optimised coolant supply to the cutting edge and tool flank ensure smooth chip evacuation and long tool life.

CLIP-GROOVE GROOVING SYSTEM

-

3-EDGED INSERTS FOR MANY DIFFERENT APPLICATIONS.

Perfect for short grooves: CLIP-GROOVE for radial or axial machining.

Tried and tested for external and internal grooving, efficient due to 3-edged inserts, fast tool changes and rigid thanks to screw clamping of the indexable insert to ensure optimised clamping and insert location: CLIP-GROOVE is a tool system you can always rely on. The highlight features of CLIP-GROOVE focus specially on circlip grooves. Its range of geometries and grades permits the efficient machining of high strength materials. Due to the compact design this system can be used for Swiss type turning.

NC UNIVERSAL GROOVING SYSTEM

-

ONE SYSTEM FOR ALL CASES.

Shows genuine all-round talent: the NC groove turning system for external and internal turning.

Radial or axial grooving, internal or external machining, inward or outward copy turning – if you�re looking for a versatile tool system, you�ve come to the right place with the NC groove turning system. Two modular basic holders for internal and external machining are adaptable to every application by a number of different support blades and clamps. The range of applications are further extended by a monoblock holder and a boring bar. Together with inserts with two cutting-edges in various geometries and grades, this system equips you for almost every machining application.

PROFIL-CUT FORM GROOVING SYSTEM

-

PERFECT POTENTIAL SAVINGS.

Perfect for mass production: PROFIL-CUT – the profil grooving system for custom profiling of inserts.

Profile inserts offer enormous potential savings. We grind profile inserts to your requirements fast and precisely in-house for various profile grooves. Alternatively we offer you semi-finished products for you to grind your own profiles. In addition PROFIL-CUT is easy to fit for fast tool changes. This ensures high process reliability, reduce tool costs and shorten machining times all at the same time.

SA AND SE GROOVING SYSTEMS

-

CUT OUT THE COMPETITION WITH CERTAINTY.

Extremely efficient and flexible for parting off and grooving diameters up to 140 mm: the ARNO SA grooving system.

When it comes to efficiency, our SA system is almost unbeatable for parting off and grooving. The rigid insert clamping guarantees maximum process reliability. It's even better in combination with our patented ACS – ARNO Cooling System: it helps you to achieve an average of 300 per cent longer tool life in your grooving operations and can increase speed – even with narrow part-off operations or materials which are difficult to machine.

SHORT-CUT GROOVE TURNING SYSTEM

-

ROBUST SPECIALISTS FOR ROUGH GROOVE-TURNING.

Assured rigidity: the SHORT-CUT system for external and internal grooving starting at 29.5 mm minimum diameter.

Monoblock holders and boring bars with short overhang lengths and periphery ground or precision sintered inserts make SHORT-CUT a powerful combination for radial machining operations. SHORT-CUT tools with their special chip geometries and cutting edge executions are ideal for rough machining tasks. The patented clamping system holds the double-sided inserts rigidly in place even under heavy stresses.

SIM | INTERNAL MACHINING

-

UNRIVALLED RIGIDITY AND PRECISION.

Perfect for internal machining starting at 6.7 mm bore diameter: the modular ARNO SIM System.

Perfect repeatability and rigidity due to oval shaped shank and patented ARNO interface: The 3-point right angled location ensures optimised transfer of cutting forces. At the same time, you benefit from absolute repeatability of insert positioning. Inserts are easy and fast to change as there is only one screw.

SWISS TYPE MACHINING

-

With ARNO you benefit from reliable processes, long tool life, a revolutionary tool changing system and more productivity in your Swiss type machining production shop.

If you have long lathes in your production, it�s time to discover ARNO. If you mass-produce thin-walled parts, our tool systems score with very long tool life and maximum precision. We have the greatest diversity of positive and high-positive indexable inserts in the world – and the right solution for every application. We developed the AFC system with two-part tool holders for fast and simple tool changes despite the limited space in Swiss type machines – and AWL sliding heads with integrated coolant supply also provide more convenience and are neater. The result: With ARNO, Swiss type machining work becomes reliable, easy and convenient as never before – for smooth work flows and more productivity in your production.

SYSTEM-HIGHLIGHTS

ACS - ARNO COOLING-SYSTEM

-

THE UNRIVALLED ORIGINAL.

The ACS - ARNO Cooling System: the patented cooling system for efficient parting off, grooving and groove turning with the SA and SE grooving systems.

There's no cooler and more precise way: In the ACS Cooling System developed and patented by ARNO, coolant is fed directly along the insert seat to optimise insert cooling. Coolant enters the cutting zone, gets underneath the chip and ensures efficient chip removal.

In addition, the ACS2 cools the tool flank from underneath. This results in an average increase in tool life of 300 per cent, higher speed and greater process reliability. Summarizing, the patented ACS Cooling System makes our outstanding SA and SE grooving systems into outstanding productivity boosters.

AFC – ARNO FAST CHANGE

-

SWISS TYPE MACHINING, FAST CHANGES.

AFC tool holders: the revolution in fast tool changes - patent applied.

Your solution for easy tool changes despite limited space in Swiss type machines: the two-part AFC holder - even untrained staff can replace tools fast and reliably.

This is how it works: The rear part of the tool holder (AHA fixed stop) is first fixed in place. Only the front part is removed to replace the tool. This eliminates the need to restart and recalibrate the zero point since the length to the insert tip is always the same � whether the grooving system or the turning system is used. When the two holder parts are plugged back together, they are immediately connected by an O-ring to prevent the tool from falling into the machine accidentally. At the same time, the floating mount provides enough clearance to compensate for angle offset. The two parts then fit together perfectly. Now you benefit from a high level of precisions when changing tools and a leak-proof coolant hole.

AWL sliding heads

-

COOL RIGHT FROM THE START.

AWL sliding head*: with integrated coolant supply - patent applied.

Practical to achieve reliable efficient cooling: the integrated coolant feed on the AWL sliding head redudantise complex installations with coolant hoses and space-consuming set-ups. Thanks to two separate coolant channels, you can cut off coolant supply completely or partially at any time - even at 130 bar everything stays absolutely leak-proof.

Another clever feature: the counter nuts on the clamping claw screws raise the wedges when turned. This makes it easier to remove the holder to facilitate tool changes. The clamping claws mounted on the side also enhance the clamping force and have a low height of only 5.5 mm.

Indexable inserts for Swiss type machines

-

TOP FORM FOR SWISS TYPE MACHINES.

Your Swiss type machining specialists: indexable inserts with PS geometries and high-positive indexable inserts for high surface quality.

No-compromise quality is required for indexable inserts to machine long thin workpieces. Top surface quality can only be achieved straight away by a combination of an ultra-fine grain substrate, precision ground cutting edges and highly polished chip breakers.

This is why ARNO developed indexable inserts with the PS geometry especially for Swiss type machines. They achieve excellent results and long tool life. If the requirement is for particular precision and top surface quality, our extremely sharp high-positive ASF, ACB, AWI and ALU inserts are the ideal supplement. That is why you do not have to compromise on precision, you�ll find we have a range of different corner radius, grades and both sharp and edge-honed inserts. In this way you can set up your Swiss type machine for any challenge.

TOOL SYSTEMS

AMS - ARNO MINI-SYSTEM

-

CENTRING MADE EASY.

Modular and precise: the ARNO Mini-System AMS for internal machining starts at a diameter of 0.7 mm and reaches drilling depths of up to 50 mm.

Rigid centring, guaranteed tip height and absolute dimensional accuracy – it's so easy with AMS for flexible operations in holes with small diameters.

This is how it works: The insert is clamped rigidly in central position by a ground chamfer on the shank and a tapered pin. A fixed stop guarantees repeatable positioning at tip height. Besides tool holders, there are also inserts with inner cooling to achieve optimised wear protection and precise coolant supply. This results in reliable processes, maximum precision even at tight tolerances and an increase of one to four times in tool life.

DECO-CUT GROOVE TURNING SYSTEM

-

PRECISION AND VERSATILITY GUARANTEED.

Parting off, grooving, groove turning, thread milling: the modular DECO-CUT system from ARNO does it all and with absolute precision at the same time.

DECO-CUT was specially developed for Swiss type machining and impresses all along the line in this sector. For example, the vee-shaped insert seat with 3-point location for maximum rigidity and repeatability of length and tip height. Or the central clamping screw for extremely fast tool changes. The ground and polishing cutting edges to efficiently machine demanding materials even at low speeds and feeds - without build-ups.

It's obvious what the benefits are for you: smooth, efficient work flows and precision results right from the start. In addition, it's a system which is hard to beat when it comes to versatility starting at workpiece diameters of 2.5 mm.

ISO TURNING FOR SWISS TYPE MACHINING

-

ALL AROUND GREAT PERFORMANCE.

Extremely versatile: the ARNO system for ISO turning for Swiss type machines offers tool holders, boring bars, AFC holders and indexable inserts for almost every application.

If you're looking for an all-round system for reliable and profitable machining work – here it is: At ARNO you'll find tool holders with different clamping systems, with or without internal cooling, and – absolutely new in the portfolio – AFC tool holders for fast, simple and convenient tool changes.

We offer the largest standard portfolio of high-positive indexable inserts in the world as well as PS chip breakers specially developed for Swiss type machining applications – perfect for materials that are difficult to machine.

SA AND SE GROOVING SYSTEM

-

CUT OUT THE COMPETITION WITH CERTAINTY.

Extremely efficient and flexible for parting off and grooving diameters up to 65 mm: the ARNO SA grooving systems.

When it comes to efficiency, our SA system is almost unbeatable for parting off and grooving. The rigid insert clamping guarantees maximum process reliability. It's even better in combination with our patented ACS – ARNO Cooling System: it helps you to achieve an average of 300 per cent longer tool life in your grooving operations and can increase speed – even with narrow part-off operations or materials which are difficult to machine.

AWL sliding head

-

AWL sliding head with integrated coolant supply.

Practical to achieve reliable efficient cooling: the integrated coolant feed on the AWL sliding head redudantise complex installations with coolant hoses and space-consuming set-ups. Thanks to two separate coolant channels, you can cut off coolant supply completely or partially at any time – even at 130 bar everything stays absolutely leak-proof.

Another clever feature: the counter nuts on the clamping claw screws raise the wedges when turned. This makes it easier to remove the holder to facilitate tool changes. The clamping claws mounted on the side also enhance the clamping force and have a low height of only 5.5 mm.

TOOLMANAGEMENT

-

The ARNO StoreManager gives you the benefit of 100 % access control with guaranteed individual removal – simple and fast.

Are you looking for the right tool management solution for your production? Then take a look at ARNO StoreManagers. Our tool cabinets come in three versions and their user-configurable compartments help you keep everything in order. Guaranteed individual removal also ensures 100 per cent cost transparency – on a long-term basis since the rugged construction of the StoreManagers easily withstands tough everyday work conditions. Of course, the cabinets are equipped with interfaces to all common ERP and tool management systems to ensure simple integration into any production environment. As the StoreManagers are easy to operate, you benefit immediately from automated tool management without long periods of training – and they have an immediate impact on productivity in your production.

SYSTEM-HIGHLIGHTS

STOREMANAGER HARDWARE

-

PLENTY OF STOWAGE SPACE FOR EVERY WORKSHOP.

Three systems for all requirements: The carousel system in the StoreManagerPRO is rugged and space-saving. StoreManagerSTART is the ideal addition for large items. StoreManagerDUO combines both systems in one and is therefore perfect for small companies or production cells.

STOREMANGER SOFTWARE

-

EFFICIENCY MADE EASY.

Whether you opt for RFID chip or fingerprint sensor, you have full access control to StoreManagers and a quick overview of tool consumption. A software module lets you make settings from the convenience of your workplace PC.

STOREMANGER SYSTEM ENVIRONMENT

-

WELL CONNECTED IN ALL DIRECTIONS.

ARNO StoreManagers are so flexible: they can simply be integrated in any type of company structure – with interfaces to all common ERP and tool management systems. ARNO StoreManagers also adapt flexibly to new challenges and are expandable at any time, even across several locations.

TOOL SYSTEMS

ARNO StoreManagerDUO

-

STRONG COMBINATION.

ARNO STOREMANAGERDUO COMBINES THE ADVANTAGES OF A CAROUSEL AND A DRAWER SYSTEM

Ideal for small companies or production cells: StoreManagerDUO is equipped with an upper section consisting of 360 individual compartments in a carousel system to store tools and small parts. The lower section has four drawers providing additional space for larger items. With the ARNO StoreManagerDUO you have everything under control and in view: indexable inserts, drill bits, milling cutters, holders, measuring devices, special tools and much more

Why not see for yourself and be impressed by the benefits of automated tool management – thanks to the ARNO rental scheme which comes with a 30-day trial period, no risk and no major investment. It brings the future to companies of any size.

ARNO StoreManagerPRO

-

IT SIMPLY OFFERS YOU MORE!

UP TO 2,160 COMPARTMENTS ON A FOOTPRINT OF 1.5 M2, FLEXIBLE CONFIGURATION, EXTREMELY RUGGED, EASY TO OPERATE AND AVAILABLE 24/7.

With the ARNO StoreManagerPRO you benefit from smooth functioning tool management, tool tracing and tool replacement – and with that from more efficient internal production processes. The modular system has many software options to adapt the system to your requirements with up to 2,160 configurable compartments to ensure controlled individual removal and a return option for each tool.

It makes tool management and repurchasing simpler and more efficient. You can trigger, orders to any number of suppliers at any time or production workers can easily generate order proposals for the purchasing department. The practical orientation of the software design permits you to conveniently edit data from a workplace PC.

ARNO StoreManagerStart

-

SMALL CABINET FOR LARGE ITEMS.

DER STOREMANAGERSTART – THE DRAWER SYSTEM FROM ARNO.

Der StoreManagerSTART is the best expansion for the StoreManagerPRO. If the size of the compartments on the carousel system is too small, we offer our StoreManagerSTART which has a number of different compartment sizes and drawer configurations to choose from. The number and height of the drawers are user-configurable as well as the configuration of the individual drawers.

Of course, StoreManagerSTART also has a system expansion option by connecting Plus variants. As with StoreManagerPRO you benefit from the easy to operate software with its many practical functions and the convenient option of managing data from a PC.

ROTATING TOOLS

-

When you use ARNO tools in your production, you benefit from reliable processes, multi purpose tools and increased productivity in your drilling and milling operations.

With ARNO solid carbide and indexable insert drills and milling cutters, you have a wide range of reliable, efficient drilling and milling solutions at your disposal. They help you optimise production processes and minimise downtimes by reducing the number of tool changes. With our multi purpose drilling and milling systems, we offer you tool systems with a wide range of applications. Each system helps you benefit from high quality, simple handling and outstanding performance.

TOOL SYSTEMS

AKB - FLEXIBLE INDEXABLE INSERT DRILLING SYSTEM

-

STABLE DIVERSITY.

Flexible and extremely rugged for drilling holes up to 5 x D: the ARNO AKB system with diameters ranging from 14 to 55 mm.

The AKB system just keeps on running – on milling or turning machines, with interrupted cuts, at low and high feed rates and for drilling offsets. How does it work? For example, it's due to the coated and polished tool holder with large chip chambers, including optimised run-out in the collar for smooth chip evacuation. Or due to the large ground collar which ensures a stable flat face in the holder. Much longer tool life and best results come from the through tool coolant supply, the robust centre flute, the strong cutting edges and the corner radii of the indexable inserts.

Besides its stability, the quality of the results, its handling and versatility of the AKB are its strong features: The positive drift leaves no retraction marks on the workpiece. The indexable inserts with four efficient flutes are identical on the inside and outside – a practical feature when fitting. Torx Plus screws ensure the inserts have a stable, secure and solid seat. And the four indexable insert geometries makes this system ideal for a wide range of applications at different feed rates.

FD-MILLING SYSTEM

-

FAST OR FINE? BOTH!

The multifunctional system for HFC and square shoulder milling for diameters ranging from 25 to 160 mm with four efficient cutting edges: ARNO FD milling system.

Whether you require high speed HFC milling or prefer good surface finish: the FD milling system from ARNO is your solution. With a nickel-plated long-life holder for square shoulder and HFC indexable inserts, you are well equipped to do both, so achieving savings on holder costs and warehouse space. Integrated through tool cooling, Torx Plus screws and unequal pitch of the cutting edges also ensure minimum vibration, long tool life and easy handling.

These indexable inserts come in sizes of either 10 mm or 15 mm. The smaller insert offers high surface quality due to the large wiper geometry whereas the 15 mm insert is particular strong and therefore ideal for rough cutting. Two HFC milling geometries and four square shoulder milling cutters provide absolute flexibility in 13 grades to match each application perfectly. The precision-engineered positive chip breakers for indexable inserts guarantee soft cutting. And the polished peripheral ground PMA geometry is ideal for machining aluminium and non-ferrous metals.

FE-MILLING SYSTEM

-

FOR CLEANLY MACHINED CORNERS AND HIGH SPEED.

A holder for square shoulder and high feed (HFC) indexable inserts with diameters ranging from 16 to 80 mm; the FE milling system from ARNO.

The ARNO FE system gives you a choice:

you can opt for efficient 90° shoulders or high speed during HFC milling. In both cases you benefit from high feed rates, an extremely smooth cutting action and excellent cutting ability. This makes the system a genuine alternative to solid carbide milling cutters. This is due to the extremely positive mounting position of the indexable inserts and the spiral shape of the cutting edges, ensuring smooth material cutting. The unequal pitch also minimises vibration reliably.Other FE system features:

The double-sided indexable inserts come in five geometries and six grades and are therefore capable of machining different types of material. The fully nickel-plated holders fixed by Torx Plus® screws offer excellent handling.

FO-MILLING SYSTEM

-

ROUND OR SQUARE – BUT FLEXIBLE, WHATEVER THE CASE.

A holder for round and octagonal indexable inserts with diameters ranging from 40 to 160 mm; the FO milling system from ARNO.

Copy milling, helical interpolation, pocket milling, slot milling and of course normal face milling including ramping and plunge milling: The FO milling system from ARNO can do all this – and you can also use either round or octagonal indexable inserts. Each type comes in five geometries and grades, giving you a wide range of applications. The positive mounting position and basic shape of the inserts ensure soft cutting for machining difficult materials. The matching wiper insert gives the final finish to your workpieces in no time.

And as always, you can depend completely on ARNO quality: The holders are fully nickel-plated and equipped with through tool cooling and Torx Plus screws to achieve stability and user convenience. Coupled with the unequal pitch of the cutting edges to reduce vibration, the FO milling system ensures reliable processes and long tool life.

FT-FACE MILLING SYSTEM

-

HIGH CUTTING RATES. GENTLE ON THE SPINDLE.

Stable and efficient: the FT face milling system from ARNO with 45° approach angle and eight efficient cutting edges.

Maximum stability, soft cutting and smooth action to minimise spindle wear: The FT system from ARNO lets you benefit from all these advantages. This is provided by the large flat face on the holders, a positive rake angle despite the negative mounting position and the unequal pitch of the cutting edges. You are then well equipped for a wide variety of applications to machine steel – from castings through to aluminium – with five different geometries and grades for each type.

In addition the nickel-plated holders, Torx Plus screws and through tool cooling ensure long tool life and easy handling. And as always with ARNO, you can rely on the excellent price-performance ratio of the FT face milling system.

SHARK-CUT - MULTI PURPOSE TOOL SYSTEM

-

MULTI PURPOSE. ULTRA PROFITABLE

Boring and turning with only one tool: the ARNO multi purpose tool system SHARK-CUT.

Do you want to save space and money, produce faster and shorten set-up times? No problem with SHARK-CUT. This multi purpose tool lets you carry out turning and boring operations without changing the tool. You need fewer tool positions on the machine and you save space in the store. You reduce programming work and presetting time. The SHARK-CUT boring and turning system achieves high surface quality and reduces the number of operations required to finish the hole.

You are equipped for every requirement with three variants: Choose between SHARK-CUT Mini, which is a solid carbide tool starting at 4 mm, and SHARK-CUT Standard, which has indexable inserts in various geometries starting at 8 mm diameter. For boring out and reaming operations, SHARK-CUT Rebore has two or three flutes with various indexable insert geometries and diameters from 12 or 24 mm. All variants benefit from optimised chip evacuation with the ARNO Coolant Booster, which is a special through tool coolant supply which has up to three coolant channels. For extra stability, all the larger versions have an axial location flat. It ensures that the SHARK-CUT reliably achieves the best results in every application.

SHARK-DRILL - UNIVERSAL DRILLING SYSTEM WITH INSERTS

-

UNIVERSAL APPLICATION. RELIA BLE RESULTS.

Rugged and flexible: SHARK-DRILL with spiral and straight fluted drill holders, for diameters ranging from 9.5 to 114 mm and drilling depths to over 900 mm.

Are you looking for an all-round problem solver? Then you need the SHARK-DRILL: This drilling system with inserts is always the right tool, whether it is stationary or rotating, whether you are drilling large or small diameters, machining bottom faces, finishing counterbores or very deep drill holes, or machining cast metal, steel, non-ferrous metals or titanium.

We supply HSS inserts in 3 geometries and 9 styles, 12 different tool holder series for various diameter ranges, and spiral and straight flutes for Weldon and Morsetaper holders. All drills are nickel-plated and equipped with integrated through tool cooling and Torx Plus screws for more convenience and long tool life. So you see, you can totally rely on this system.

SHARK-DRILL2 - HIGH-PERFORMANCE DRILLING SYSTEM WITH REPLACEABLE INSERTS

-

THE SOLID CARBIDE ALTERNATIVE.

For top drilling performance: SHARK-DRILL2 for diameters ranging from 14 to 32 mm and drilling depths from 2, 3, 5 and 8 x D.

Extremely strong, stable and precise: If you are looking for an alternative to solid carbide drills with replaceable inserts, you're spot on with the SHARK-DRILL2. High chip volumes and high feed rates are what this system is all about – that's due to its through tool cooling with optimised coolant outlets, wide chip chambers, full coating and smooth chip chamber run-out in the collar. The optimised location flat in the holder ensures extra stability.

The SHARK-DRILL2 is capable of machining steel, stainless steel, non-ferrous metals and cast materials with excellent precision. That's because of the solid carbide inserts, each in 5 styles and geometries with point grinding that ensures excellent centring. The inserts are easy and quick to change in mounted position. Torx Plus screws with pull-down effect make for a secure and stable seat. As one holder fits several drilling diameters, you save both time and money. The result: You benefit from very good drilling tolerances and high feed rates – similar to solid carbide drills, but at an absolutely affordable price-performance ratio.

VHM - SOLID CARBIDE DRILLStle

-

TOP PROCESS RELIABILITY FOR ECONOMICAL MANUFACTURING.

ARNO solid carbide drills are ideal for high-speed drilling and precision drill holes.

ARNO solid carbide drills make for optimised production processes – with reduced downtimes due to fewer tool changes. The constant optimised material quality achieves good performance with steels, grey cast iron, tool steels, steel alloys and with stainless and acid-resistant steels. They are also suitable for aluminium and hardened materials. Our specially developed flute geometries ensure rapid chip evacuation and excellent chip breakage.

VHM – SOLID CARBIDE MILLING CUTTERS

-

THE PRODUCTIVE, RELIABLE, EFFICIENT MILLING SOLUTION.

Solid carbide milling cutters for steel, cast materials, stainless steels, exotic materials, aluminium, non-ferrous metals and hardened steels.

Solid carbide drills make for optimised production processes – with reduced downtimes due to fewer tool changes. ARNO solid carbide milling cutters are made of fine grain solid carbide (ultra-micro grain) and have constant material quality. Grains sizes are 0 - 0.5 µm. Depending on the geometry, the solid carbide milling cutters are provided with various coatings (TiAlN or TiCN).