- Offer Profile

- FAGOR AUTOMATION is a company

with great experience in the development and manufacturing of products for

machine automation and control. It excels by its capability to develop

software and the versatility of its productive process to offer solutions

tailored to the needs of their customers.

Historically, we at FAGOR AUTOMATION have focused our efforts on the machine-tool sector where we are one of the world leaders. Besides, its wide technical and sales network spread out in more than 50 countries through its own branch offices and distributors.

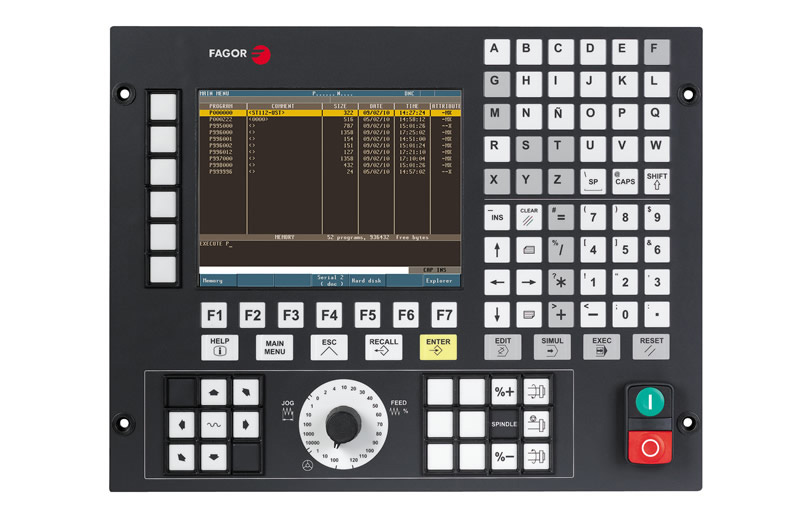

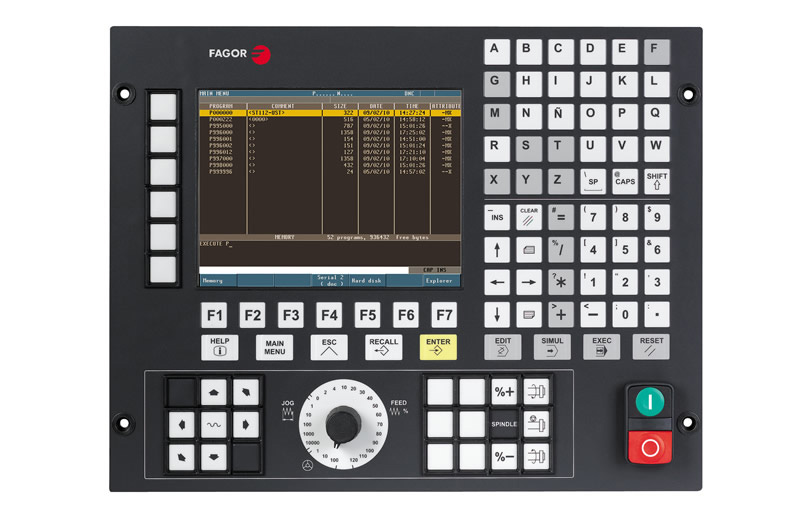

CNC Numerical Control Systems

-

Fagor Automation offers an integral solution to high performance machining centers and production lathes because of our large selection of features. Our CNC systems meet the most demanding requirements. The range of CNC’s goes from conversational programming CNCs for short production series that require quickness to high-speed CNCs with nanometric accuracy for machines of high technological value or CNC systems for specific applications such as Laser cutting, etc.

Fagor CNCs are designed for all kinds of machines with additonal benefits:

- Easy programming. There is no need to know ISO programming language.

- Algorithm that provides the best performance, speed and accuracy in the machining process.

- Ergonomic and functional design (touch-screen, easy navigation, integrated manuals, sms communication, high-resolution graphics, keyboards and monitors with the highest level of sealing protection, etc.)

- Interface customizing tools.

- Free software download with no time limit to work at any PC.

- Axis position control (position loop) every 250 µs.

- Technological features like Look-Ahead. The CNC analyzes in advance the changes in the movements of the axes providing high speed machining. Our CNCs analyze 2,400 blocks in advance and block processing time is 0.25 ms.

Fagor Automation offers drive and feedback systems which represents a great advantage because the customer only deals with a single contact person or supplier who gives him an integral solution that speeds up his work process.

Thanks to Fagor Automation’s presence in five continents, we can guarantee professional and efficient technical service as quickly as possible.

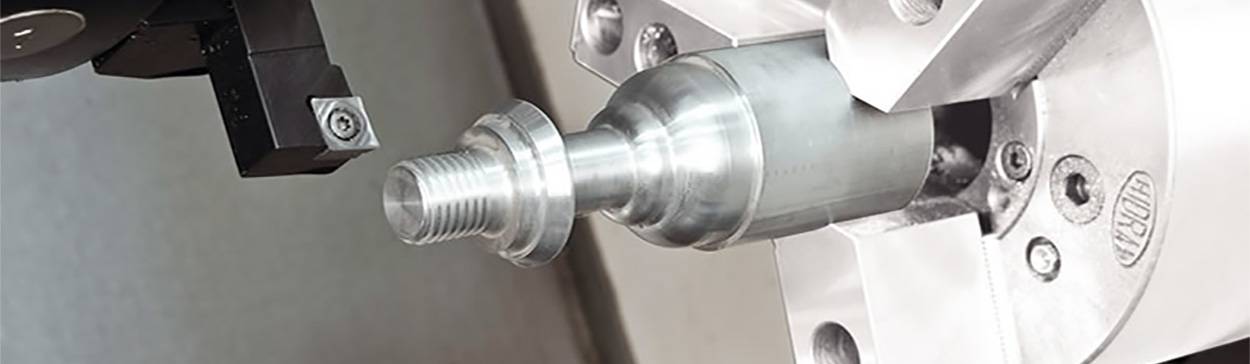

CNC for lathes

CNC 8065 for lathes

-

Designed to control high-production turning centers, vertical lathes, slanted-bed lathes, parallel lathes, dual-turret (TT) lathes, lathes with several turrets and spindles and dual-purpose (mill-lathe) machines.

Ergonomic and robust design.

- New line of keyboards with touch screen, integrated mouse and USB connector.

- Very visual browsing.

- Mounting design and component technology that meets sealing standard IP65 (NEMA12).

High speed machining

- Polynomial interpolation (splines) that provides an excellent part surface finish and high machining speed.

- More accurate finish, adapting the machining conditions to the dynamics of the machine evaluating in advance the programmed tool path changes.

- HSSA (High Speed Surface Accuracy) machining system that reduces mechanical strain on the machine and achieves smoother movements.

Optimizes machine efficiency

- Makes it easy to set up all kinds of machines and offers adjusting tools that make them most efficient.

- Finetune. Autotuning software for machining optimization.

Operation close to user’s needs

- Operation based on popup type browsing and an interface easily adaptable to the work environment.

- Higher environmental protection, its software includes all the manuals.

In the vanguard of machine-tool technology

- Wide range of tools to help achieve the tightest tolerances and the best surface quality.

- ARFS adaptive control for considerably shorter machining time.

CNC 8060 for lathes

-

CUTTING EDGE TECHNOLOGY WITHIN YOUR REACH

The CNC 8060 is a product adapted to the requirements of production lathes, high speed machining centers or machines demanding high accuracy and high-end features.

All the advances to make your job easier

- Touch screen

- High definition graphics

- More than 500 Mb of memory as standard in all CNC models, expandable via Compact Flash.

- Free simulator on PC

- Pop-up-based browsing (Fagor exclusive)

High speed machining

- HSSA (High Speed Surface Accuracy) machining system (Fagor exclusive)

- Nanometric accuracy, splines, etc.

- Automatic tool management in long machining operations

Choose from four programming methods

- Standard ISO language

- Parametric language

- ProGTL3 language

- IIP interactive language (Interactive Icon-based Pages)

- Also supporting Cad-Cam programs and programs generated by other CNC’s

A wide variety of canned cycles for milling and turning

- Many turning cycles.

- Many facing cycles.

- Wide selection of drilling and threading cycles.

- Constant-pitch and variable-pitch threading.

- Wide selection of threading cycles.

- Many grooving cycles.

- Profile cycle along the X axis.

- Profile cycle along the Z axis.

- Pocket cycles in the XC, ZC planes.

- Pocket cycles in the XY, YZ planes.

- Multiple pocket cycles.

- 2D pockets for user-defined shapes.

CNC 8055 for lathes

-

WITH THE USER IN MIND. MORE POWERFUL THAN EVER

Designed for controlling high-production turning centers, vertical lathes and parallel lathes.

High speed machining

- Advanced algorithms for very accurate parts.

- Adaptive machining dynamics for best execution time.

- Work in inclined planes.

Easier machine setup

- Setup systems with graphic assistance.

- Oscilloscope function to help optimize axis behavior.

- Circularity (roundness) test that helps improve the behavior of the machine when reversing the moving direction.

Operation with the user in mind

- Operation designed for operators of conventional machines without prior programming knowledge as well as for experts on ISO-coded language.

Part preparation assistance

- Manual and automatic tool calibration.

- Part centering and part measuring cycles.

- Management of multiple part zero offsets.

- Part damage estimation.

Programming languages

- ISO-coded language for large series where optimizing the program is most important so execution time is as short as possible.

- Conversational language for small series or unitary (single) parts. It has been conceived for shops where programming time is a critical factor.

CNC 8037 for lathes

-

IDEAL SOLUTION FOR SIMPLE APPLICATIONS

Designed for controlling lathes and turning centers having 2 axes and 1 spindle.

Small

- Compact and small for simple machines.

Designed to make the operator's job easier

- ISO language programming.

- Interactive editor in machining canned cycles.

- Teach-in editing.

- Tool Inspection.

Analog and digital solution

- Makes retrofitting with an analog servo system easier.

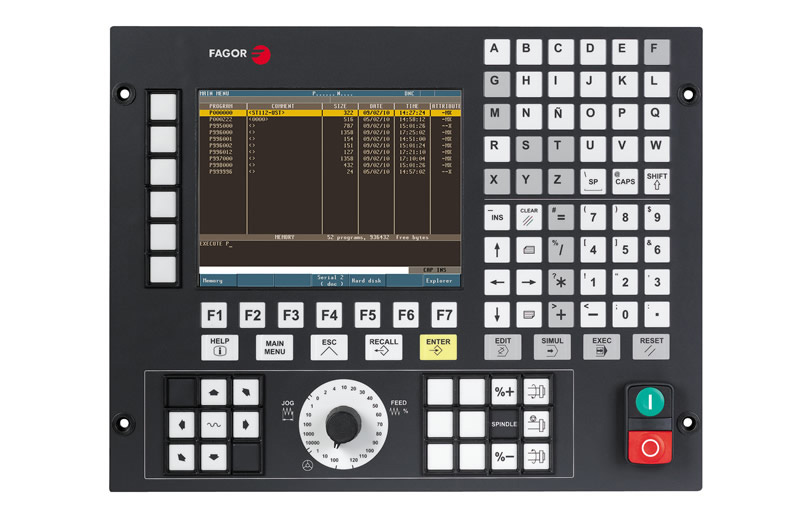

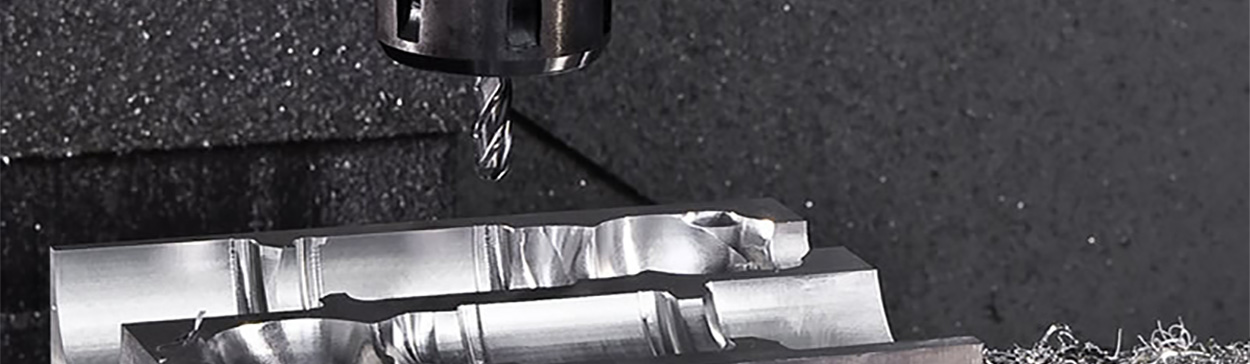

CNC for milling machines

CNC 8065 for milling machines

-

EASY AS ALWAYS. MORE POWERFUL THAN EVER

Designed to provide a solution to highly demanding machines in speed and accuracy: 5-axis machining centers with RTCP, portal mills and boring mills.

Ergonomic and robust design

- New line of keyboards with touch screen, integrated mouse and USB connector.

- Very visual browsing.

- Mounting design and component technology that meets sealing standard IP65 (NEMA12).

High speed machining

- Polynomial interpolation (splines) that provides an excellent part surface finish and high machining speed.

- More accurate finish, adapting the machining conditions to the dynamics of the machine evaluating in advance the programmed tool path changes.

- HSSA (High Speed Surface Accuracy) machining system that reduces mechanical strain on the machine and achieves smoother movements.

Optimizes machine efficiency

- Makes it easy to set up all kinds of machines and offers adjusting tools that make them most efficient.

- Finetune. Autotuning software for machining optimization.

Operation close to user's needs

- Operation based on popup type browsing and an interface easily adaptable to the work environment.

- Higher environmental protection, its software includes all the manuals.

In the vanguard of machine-tool technology

- Wide range of tools to help achieve the tightest tolerances and the best surface quality.

- ARFS adaptive control for considerably shorter machining time.

CNC 8060 for milling machines

-

CUTTING EDGE TECHNOLOGY WITHIN YOUR REACH

Designed for high speed machining centers, precision mold making and for industries like automotive and aerospace.

All the advances to make your job easier

- Touch screen

- High definition graphics

- More than 500 Mb of memory as standard in all CNC models, expandable via Compact Flash.

- Free simulator on PC

- Pop-up-based browsing (Fagor exclusive)

High speed machining

- HSSA (High Speed Surface Accuracy) machining system (Fagor exclusive)

- Nanometric accuracy, splines, etc.

- Automatic tool management in long machining operations

Choose from four programming methods

- Standard ISO language

- Parametric language

- ProGTL3 language

- IIP interactive language (Interactive Icon-based Pages)

- Also supporting Cad-Cam programs and programs generated by other CNC's

A wide variety of canned cycles for milling and turning

- Tapping / rigid tapping

- Helical interpolation

- Wide selection of drilling cycles

- Threading, boring and reaming cycles

- Rectangular and circular pocket cycles

- Bore milling cycle

- Thread milling cycles

- 2D pockets for user-defined shapes

- 3D pockets with islands for user-defined shapes

CNC 8055 for milling machines

-

WITH THE USER IN MIND. MORE POWERFUL THAN EVER

Designed for controlling milling machines and Machining centers both horizontal and vertical.

High speed machining

- Advanced algorithms for very accurate parts.

- Adaptive machining dynamics for best execution time.

- Work in inclined planes.

Easier machine setup

- Setup systems with graphic assistance.

- Oscilloscope function to help optimize axis behavior.

- Circularity (roundness) test that helps improve the behavior of the machine when reversing the moving direction.

Operation with the user in mind

- Operation designed for operators of conventional machines without prior programming knowledge as well as for experts on ISO-coded language.

Part preparation assistance

- Manual and automatic tool calibration.

- Part centering and part measuring cycles.

- Management of multiple part zero offsets.

- Part damage estimation.

Programming languages

- ISO-coded language for large series where optimizing the program is most important so execution time is as short as possible.

- Conversational language for small series or unitary (single) parts. It has been conceived for shops where programming time is a critical factor.

CNC 8037 for milling machines

-

IDEAL SOLUTION FOR SIMPLE APPLICATIONS

Designed for controlling milling machines and machining centers having 3 axes and 1 spindle.

Small

- Compact and small for simple machines.

Designed to make the operator's job easier

- ISO language programming.

- Interactive editor in machining canned cycles.

- Teach-in editing.

- Tool Inspection.

Analog and digital solution

- Makes retrofitting with an analog servo system easier.

Laser CNC

Laser 8060 CNC

-

The Laser 8060 CNC (CNC 8060 L) is specifically designed for 2D laser sheet cutting machines that are highly demanding in terms of speed and precision.

High-speed cutting

- High precision finish, adapting the cutting conditions to the dynamics of the machine, evaluating in advance the programmed tool path changes.

- HSSA (High Speed Surface Accuracy) cutting system that increases the productivity of the machine while reducing the mechanical strain on the machine and achieving smoother movements.

New laser specific HMI

- Specially designed while taking into consideration the distinctive features of laser cutting machines.

- Intuitive and maximizes programming capabilities while reducing the number of steps.

- Fully customizable to the preferences of each user.

Specific functions to maximize the performance of the laser cutting

- PWM

- Power Control

- Synchronized switching

- Laser path compensation

- GAP control

- Leap Frog

Laser 8070 CNC

-

The Laser CNC 8070 (CNC 8070 L) is specifically designed for laser cutting machines that are highly demanding in terms of speed and precision: 5-axis 2D/3D RTCP sheet cutting machines. With only a loop time of 2 ms and a block processing time of 0.25 ms. For governing up to 28 axes and 4 execution channels. Capable of installing third party software.

High-speed cutting

- More precise finish, adapting the cutting conditions to the dynamics of the machine, evaluating in advance the programmed tool path changes.

- HSSA II (High Speed Surface Accuracy II) cutting system that increases the productivity of the machine while reducing the mechanical strain on the machine and achieving smoother movements.

New laser specific HMI

- Specially designed while taking into consideration the distinctive features of laser cutting machines.

- Intuitive and maximizes programming capabilities while reducing the number of steps.

- Fully customizable to the preferences of each user.

Specific functions to maximize the performance of the laser cutting

- PWM

- Power Control

- Synchronized switching

- Laser path compensation

- GAP control

- Leap Frog

Supports touch screens and mouse integrated into keyboard

- Comes with the option to connect to external peripherals, such as screens with different formats: 15”, 19” and 21” views.

- Multi-touch capability.

CNC for other applications

CNC 8070 for other applications

-

THE PERFECT SOLUTION FOR YOUR NEEDS

It adapts itself perfectly to all kinds of machines: Grinders, saws, press brakes, machines for wood, marble, stone and glass laser, plasma cutting machines, etc.

CNC 8055 for other applications

-

ADAPTABLE TO ANY APPLICATION

Fully customizable interface with Fagor's own tools. For governing up to 7 axes, 2 spindles and 1 execution channel.

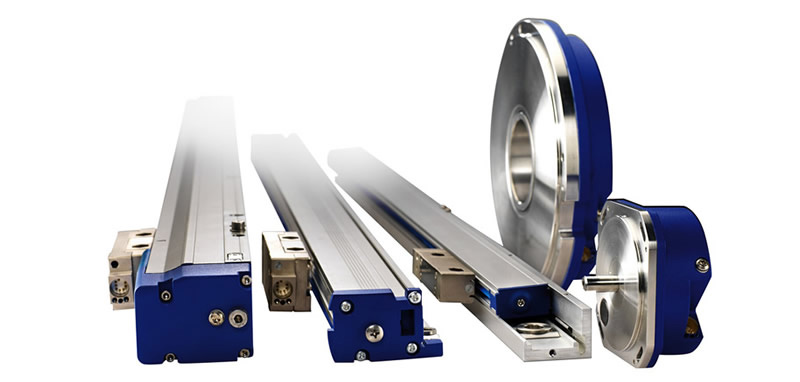

Feedback systems

-

Fagor Automation’s experience and knowledge has made us the first and only company manufacturing an enclosed steel-tape linear encoder of up to 50 meters with absolute technology and 10 nm resolution.

At Fagor Automation we use propietary technologies in all four fields in encoder manufacturing: mechanics, optics, electronics and software.

Features:

- Linear and angular encoders – absolute or incremental- in different sizes for different space requirements. The measuring distance of linear encodersrange from 40 mm to 60 m, and the diameter of angular encoders range from 90 mm to 200 mm.

- Non-contact linear encoders, absolute or incremental.

- Absolute encoders with digital communication to CNCs from Fagor, Fanuc, Mitsubishi, Siemens, Panasonic, etc.

- Linear encoders with 3 micron accuracy and 10 nm resolution.

- Angular encoders with 2 arc-second accuracy and 0.01 arc-second resolution.

- Steel tape linear encoders with mechanical tensor for reader insertion and extraction at both ends.

- Patented own opto-electronic components.

- Proprietary etching technology on several substrates: glass, steel tape and others.

- Single window scanning.

- IP-64 ingress protection against pollutants.

- Accuracy certificate guaranteeing encoder quality..

High-end linear and angular encoders

- Linear Encoders

Fagor Automation uses two measuring methods in their absolute linear encoders:- Graduated glass: Linear encoders with a measuring length of up to 3040 mm.

- Graduated steel: Linear encoders with a measuring length over 3040 mm.

Angular and Rotary Encoders

Fagor Automation uses the graduated glass measuring method in their absolute angular and rotary encoders.

This measuring method has two different graduations:- Incremental graduation: Used to generate square incremental signals for systems that use digital position input and are counted internally by the reader head. Alternatively 1 Vpp analog signal is also produced based on the system requirement.

- Absolute graduation: It is a unique binary code which is imprinted along the measuring length of encoder.

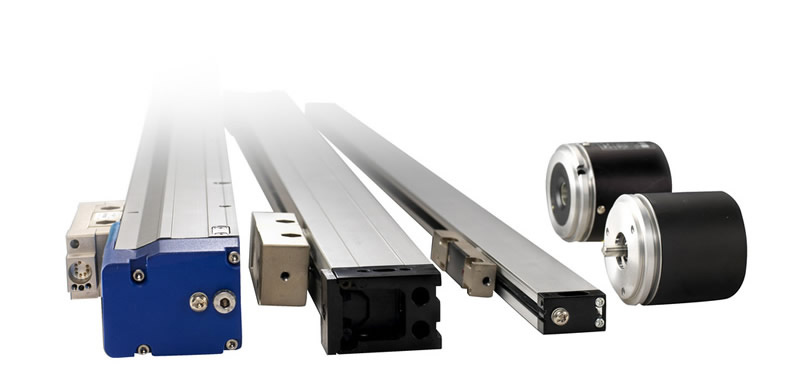

Linear and rotary standard range encoders and linear self-guided

-

Types of incremental encoders

- Linear encoder: Ideal for milling, grinding, lathe and boring mill applications requiring federates of up to 120 m/min and vibrations of up to 10 g.

- Rotary encoder: Used as a measuring sensor for rotary movements, angular speeds and also linear movement when connected to a mechanical device like ball screw. They are also used on various types of machine tools and robotic applications.

Measuring Methods

Fagor Automation uses two measuring methods in their incremental encoders:- Graduated glass: Linear encoders with a measuring length of up to 3 040 mm and rotary encoders.

- Graduated steel: Linear encoders over 3 040 mm measuring length.

Non-contact encoders

-

FAGOR open linear measuring systems are designed to be used on machines and installations that usually require great accuracy at high feed rates.

- Production and measuring equipment in the semi-conductor industry.

- Machinery for circuit assembly.

- Very high precision machine tool.

- Measuring and comparison machines, measuring microscopes and other precision devices.

- Linear motors.

DRO (Digital readouts)

-

Fagor Automation’s digital readouts offer advanced features, designed to optimize the performance of milling machines, lathes, boring mills, EDM machines and grinders.

Fagor’s Innova DRO series with significant features:

- For lathes, milling machines and boring mills of up to 4 axes, with 5.7″ TFT monitor.

- For EDM machines and grinders of up to 3 axes, with LED display.

- Part programming.

- Constant surface speed.

- 3D graphic assistance for programming and simulation.

- Intuitive operations.

- Best view from any angle.

- USB connection for copying data.

- Axis preset.

- Easy setup and auto-off.

- Dimensions in mm and inches.

Fagor Automation offers their customers technical support and service for application installation and setup.

DRO 20i for lathes

-

2-axis DRO for lathes: Innova 20i T

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Z axis coupling

- Up to 20 tool references

- Preset in HOLD mode

- CE and UL certified

DRO 30i for lathes

-

3-axis DRO for lathes: Innova 30i T

- Preset function.

- Absolute, Incremental and Io reference (home) signals.

- Resolutions from 0.1 microns on.

- Feedrate and movement alarms Innova 30i T

- Axis coupling.

- Hysteresis factor.

- Linear axis sag compensation.

- Calculator function.

- Easy setup and diagnosis.

- Energy saving mode.

- Software limits.

- Multi-point compensation.

- PC communication through a USB adapter.

- Taper calculation.

- Z axis coupling.

- Up to 20 tool references.

- Preset in HOLD mode.

- Axis feedrate display.

- CE and UL certified.

DRO 40i for lathes

-

DRO from EDM and Grinders for 2 and 3 axes lathes

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Turning

- Facing

- Assisted threading (easy threading)

- Z axis coupling

- Up to 100 tool references

- Preset in HOLD mode

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- CE and UL certified

- 5.7" color TFT screen

DRO 40i TS for lathes

-

DRO for up to 4 axes lathes: Innova 40i-TS

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Taper calculation

- Turning

- Facing

- Assisted threading (easy threading)

- Z axis coupling

- Up to 100 tool references

- Preset in HOLD mode

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- CE and UL certified

- 5.7" color TFT screen

- Constant Surface Speed (CSS)

- Special inputs: Emergency input, analog input for the potentiometer, external push buttons (M3, M4, Stop, etc.)

- Analog and digital outputs

- It admits an encoder at the spindle

DRO 20i M

-

2-axis DRO for milling machines and boring mills: Innova 20i M

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Bolt-hole drilling

- Linear drilling calculation

- Tool radius compensation

- Part centering

- Up to 20 tool references

- Part alignment

- Corner rounding/machining of arcs

- CE and UL certified

DRO 30i for milling machines and boring mills

-

3-axis DRO for milling machines and boring mills: Innova 30i M

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Bolt-hole drilling

- Linear drilling calculation

- Tool radius compensation

- Part centering

- Up to 20 tool references

- Part alignment

- Corner rounding/machining of arcs

- CE and UL certified

DRO 40i

-

DRO for 2 and 3 axes milling machines and boring mills: Innova 40i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Bolt-hole drilling

- Linear drilling calculation

- Grid pattern drilling

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- Tool radius compensation

- Part centering

- Up to 100 tool references

- Part alignment

- Corner rounding/machining of arcs

- CE and UL certified

- 5.7" color TFT screen

DRO 40i-P for milling machines and boring mills

-

DRO for 2, 3 and 4 axes milling machines and boring mills: Innova 40i P

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Bolt-hole drilling

- Linear drilling calculation

- Grid pattern drilling

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- Tool radius compensation

- Part centering

- Up to 100 tool references

- Part alignment

- Corner rounding/machining of arcs

- CE and UL certified

- 5.7" color TFT screen

- Part-program programming and backup

- X, Y, Z, W machining plane selection

- Up o 4 feedback axes and display on the main screen

- independent linear and angular feedback, 4-axis display, slope of each axis

- Probe

DRO 10i

-

1-axis DRO for general purpose applications: Innova 10i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Display of maximum, minimum coordinates and the difference between them

- Connection to linear and angular axes

- CE and UL certified

DRO 20i for general purpose applications

-

2-axis DRO for general purpose applications: Innova 20i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Display of maximum, minimum coordinates and the difference between them

- Connection to linear and angular axes

- CE and UL certified

DRO 40i for general purpose applications

-

DRO for grinders and general purpose applications: Innova 40i

- Preset function

- Absolute, Incremental and Io reference (home) signals

- Resolutions from 0.1 microns on

- Feedrate and movement alarms

- Axis coupling

- Hysteresis factor

- Linear axis sag compensation

- Calculator function

- Easy setup and diagnosis

- Energy saving mode

- Software limits

- Multi-point compensation

- PC communication through a USB adapter

- Go to a particular position

- Axis feedrate display

- On-screen guided help, with graphics

- CE and UL certified

- 5.7" color TFT screen

DRO 10i for EDM

-

Digital readouts for EDM and Grinders: E series

- 6 digital output

- 4 digital inputs

- Electrode length compensation

- Linear and angular encoders

- Travel limit alarm

- LED display

- Zero setting of the axes

- Hysteresis factor

- EDM mode

DRO 20i for EDM

-

Digital readouts for EDM and Grinders: E series

- 6 digital output

- 4 digital inputs

- Electrode length compensation

- Linear and angular encoders

- Travel limit alarm

- LED display

- Axis coupling

- Zero setting of the axes

- Hysteresis factor

- EDM mode

DRO 30i for EDM

-

Digital readouts for EDM and Grinders: E series

- 6 digital outputs

- 4 digital inputs

- Electrode length compensation

- Linear and angular encoders

- travel limit alarm

- LED display

- axis coupling

- zero setting of the axes

- hysteresis factor

- EDM mode

- Bolt-hole drilling

- Linear drilling

- Hold