- Offer Profile

- SUMITOMO ELECTRIC Hartmetall GmbH is a world leading manufacturer of modern standard and special tools for demanding machining tasks in turning, milling and drilling.

As part of the Japanese SUMITOMO ELECTRIC GROUP, we are specialized in the development of cutting materials like carbide, cermet, CBN (SUMIBORON) and PKD (SUMIDIA).

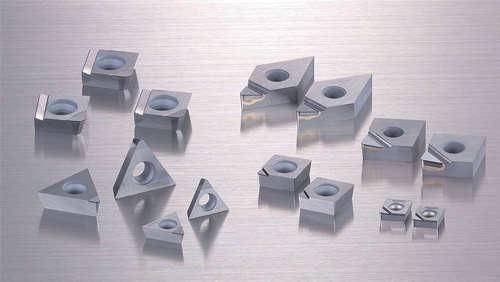

TURNING

- Sumitomo is a world leading manufacturer of turning tools and cutting materials such as carbide, cermet, CBN and PCD.

AC1030U GRADE

-

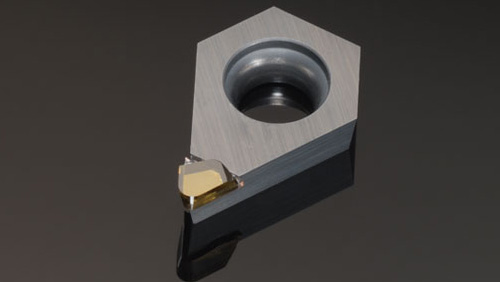

COATED GRADE FOR HIGH PRECISION SMALL PARTS TURNING

- PVD coating „Absotech Bronze“ and special substrate are applied

- High quality cutting edge realizes excellent resistance against adhesion and micro chipping

- Excellent surface finish quality

- High performance turning of small precision parts

- Suitable for small inner diameter grooving applications

AC4000K GRADES

-

COATED CARBIDE GRADES

Newly developed grades for longer and stable tool life in machining of various cast irons - from grey cast iron (FC) to high-strength ductile cast iron (FCD).

- High adhesion technology provides smooth cutting edge treatment for drastically improved peeling resistance

- Crystal orientation control technology doubles crater wear resistance for high-speed machining

- Special surface treatment achieves more than twice the compressive stress and 2x chipping resistance

AC5000S GRADES

-

COATED CARBIDE GRADES

Our new PVD coated grades named AC5015S and AC5025S achieve excellent crater and notch wear resistance thanks to tough substrate combined with new adhesion technology.

- Stable and reliable machining of nickel and titanium based alloys

- Excellent oxidation resistance

- Low reactivity composition with exotic material

- Crater and notch wear resistance doubled

- High peeling resistance

AC6000M GRADES

-

COATED CARBIDE GRADES

AC6000M Series offer grades for stainless steel cutting with excellent wear and fracture resistance.

- Absotech Platinum Technology

- Extended tool life & reduced tool costs

- Wide application range

AC8000P GRADES

-

COATED CARBIDE GRADES

Besides our general purpose grade AC8025P, the AC8000P Series have been expanded with two new grades named AC8015P for high speed cutting and AC8035P for heavy interrupted cutting.

- Absotech Platinum Technology

- Excellent stability

- Reliable processes

- Excellent wear resistance

T1500A/T1000A CERMET GRADES

-

UNCOATED CERMET GRADES

T1500A is a general purpose uncoated cermet that provides stable finish quality in finishing and medium cutting. This cermet grade features varying levels of granularity that leaves a beautiful glossy finish while achieving excellent resistance against wear and fracture.

T1000A is an uncoated high speed finishing grade designed with wear resistance in mind that provides long tool life and excellent wear resistance in continuous finishing and profiling applications.

T1500Z CERMET GRADE

-

GENERAL PURPOSE COATED CERMET FOR STEEL TURNING

PVD coating process "Brilliant Coat" for glossy finished surface with excellent adhesion resistance. A general purpose coated cermet grade capable of maintaining high-quality finished surfaces while providing excellent wear resistance.

- PVD coating process ,,Brilliant Coat"

- Excellent wear resistance and fracture resistance

- Low reactivity with work materials for beautiful finished surfaces

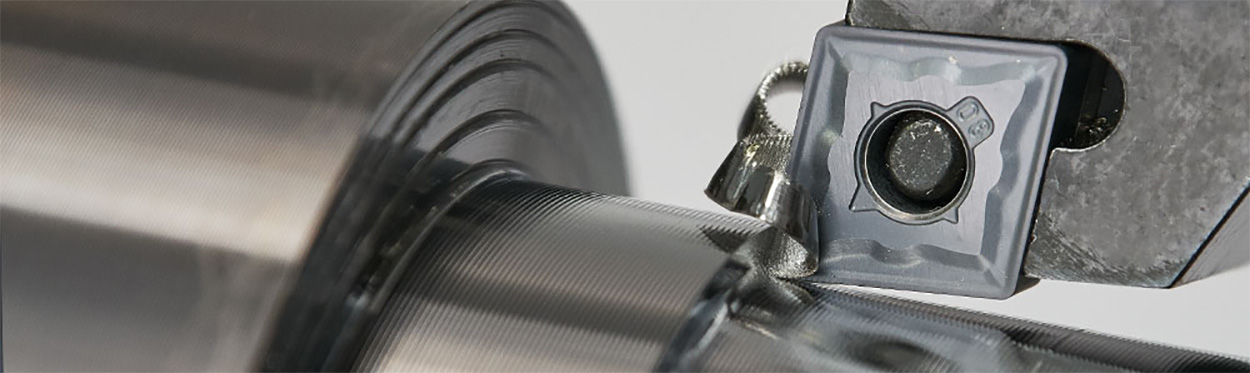

NGU TYPE CHIPBREAKER

-

NGU TYPE CHIP BREAKER FOR POSITIVE INSERTS

Newly developed NGU chip breaker for positive inserts enables a wide range of cutting conditions thanks to its wide chip pocket. The smooth and inclined plane of the chip breaker reduces cutting forces and prevents vibrations.- Available for wide range of conditions

- Cutting force reduction and preventing chattering

- Tough cutting edge

M-Class Positive Chip breaker

- Wide chip pocket enables wide range of cutting conditions

- Main breaker absolutely controls chips in shallow cutting

- Sub breaker controls chips to flow smoothly in deep cutting

- Two step rake geometry provides excellent sharpness and toughness

T2500Z CARMET GRADE

-

COATED CERMET GRADE T2500Z FOR STEEL TURNING

The coated cermet grade T2500Z for steel turning achieves longer and reliable tool life thanks to excellent resistance of notch wear and adhesion fracture.- Improved notch wear resistance by Brilliant Coat

- Improved heat resistance by higher toughness

- Stable, long tool life with excellent surface quality

Excellent Surface Quality

Features- Improve thermal crack resistance and notch wear resistance by high thermal conductivity of substrate

- Improve wear resistance and to prevent adhesion by Brilliant Coat

- Cutting speed up to Vc = 300m/min

- Can be used for continuous and interrupted cut

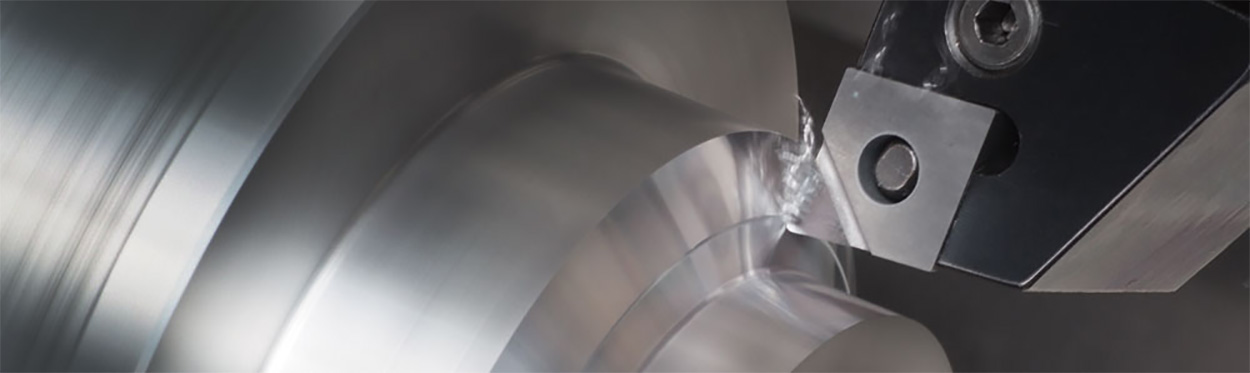

GND GROOVING SYSTEM

-

HIGH PRECISION GROOVING TOOL HOLDERS

- Applicable for grooving, turning, profiling, facing, necking, internal grooving and cut-off

- Grooving insert width tolerance of ±0,03mm over the entire range

- Grooving width from 1,25mm - 6,0mm

- 30% reduced vibration compared with conventional types

- 9 different chipbreakers achieve outstanding chip control

SUMIPOLYGON GROOVING SYSTEM

-

MODULAR CASSETTE GROOVING SYSTEM

- ISO PSC 40 / 50 base holder

- Modular system with compact, stable design

- Cassettes for soft and hard grooving (GND / TGA / CGA)

- Repeatability of interface ± 2 μm

- Internal coolant supply directly to the cutting edge

DRILLING

- Increase profitability with our reconditioning and coating service as well as exchangable drill heads.

MDF FLAT DRILLS

-

SOLID CARBIDE FLAT DRILLS FOR SPOT FACING

The MultiDrill MDF Type can be used for various purposes including high-efficiency spot facing and drilling in inclined and curved surfaces thanks to its point angle of 180°.

- Available as standard and long type as well as with internal cooling system

- Reduces burrs at hole exits

- Obtains excellent chip evacuation

- Diameter range from Ø 0.3mm to Ø 20.0mm

MLDH MICRO LONG DRILLS

-

SOLID CARBIDE MICRO LONG DRILLS

MLDH micro long drills are oil-hole drills for high efficiency drilling that were developed for drilling deep, small-diameter holes. These next-generation, small-diameter hole drills feature improved strength which is often a problem area with small-diameter drills. Special PVD coating provides long tool lfe with a wide variety of work materials.

- High efficiency drilling to depths of over 20x drill diameter at over Vf= 500mm/min

- Hole depth (L/D): 2D / 5D / 12D / 20D / 30D

- Excellent wear and fracture resistance

SDM SOLID CARBIDE DRILLS

-

ALLROUNDER FOR DRILLING OF STAINLESS STEEL

The SDM SumiDrill Power-Series offer an optimized design for drilling of stainless steel. Provided with latest technology of Sumi-Power Coating there are high adhesion resistance and high wear resistance to achieve a long tool life.

- High process reliability in stainless steel and low carbon steel

- High drill hole quality

- Latest technology of Sumi-Power Coating

- Can be used on low-performance machines (avoids overload)

SDP SOLID CARBIDE DRILLS

-

ALLROUNDER FOR DRILLING

The SumiDrill Power-Series SDP-Type offers high efficient drilling in wide application range. Provided with latest technology of Sumi-Power Coating there are improved anti-adhesion as well as high wear resistance. Top performance parameters with maximum feed and stable long tool life are given.

- Wide application range

- Maximum performance by increased feed capabilities

- Latest technology of Sumi-Power Coating

- Double margin for excellent hole accuracy

- Elliptical flute design for improved chip evacuation

XHGS DEEP HOLE DRILLS

-

SOLID CARBIDE DEEP HOLE DRILLS

The Super MultiDrill XHGS Type is a next-generation drill for deep hole drilling, features stable chip control and improved strength to further enhance efficiency of deep hole drilling. The application of our special thinning shape "RX thinning" reduces cutting resistance during high efficiency drilling. Improved chip evacuation makes it possible to reduce spindle load fluctuation, ensuring stable, long tool life. The XHGS Type provides excellent guide performance due to the unique design when compared to the conventional drill.

- Deep hole drills: 12D / 15D / 20D / 25D / 30D

- DEX coating provides long tool life

- Compatible with MQL system

PDL / PCT INDEXABLE PLUNGE TOOLS

-

ECONOMICAL 4-CORNERED INSERT

PDL/PCT tools cut in the Z axis direction where tool rigidity is highest, allowing high efficiency roughing for aeronautic components and dies with long tool overhang must be used to machine deep holes and pockets.

- Diameter range: 16,0 - 40,0 mm

- Holder 2D / 3D / 5D

- Internal coolant supply

- Producing nearly flat-bottom profiles

- Use SumiDrill WDX type inserts

MFS DETACHABLE HEAD DRILL

-

FLAT MULTIDRILL

Our SMD MultiDrill MFS Type expands our line-up of detachable head type drills. Thanks to a point angle of 180° MFS Type is applicable to high-efficiency spot facing, drilling in non-flat surfaces such as inclined and cylindrical surfaces and interrupted drilling.

- Various drilling operations thanks to a point angle of 180°

- Reduces burrs at the hole exit

- Obtains excellent chip evacuation

SMD DETACHABLE HEAD DRILLS

-

DRILLS WITH REPLACEABLE HEADS

The SMD MultiDrill Series are detachable head type drills using a radial serrated connection design for high precision and strength. The exchangeable drill head provides a new cutting edge, higher productivity and cost efficiency with easy tool management. Regrinding allowance of 1,5mm to 3,0mm makes further tool cost reductions possible.

- Drill diameter up to Ø 42,5mm

- Holder 3D / 5D / 8D / 12D

- High rigidity & low costs

- High precision & strength

WDX INDEXABLE INSERT DRILLS

-

ECONOMICAL INDEXABLE INSERT DRILLS

SumiDrill WDX type has excellent cutting balance that provides stable hole drilling in a wide application range. Available in three original chipbreaker styles, the WDX type features improved chip management and reduced cutting resistance for use in low rigidity set ups.

- Diameter range: 13,0 - 55,0 mm

- Holder 2D / 3D / 4D / 5D

- High rigidity & low costs

- Excellent hole accuracy

- Four different grades available

MILLING

- To achieve a reliable milling process the combination of milling cutter and inserts is the most important factor.

DFC SHOULDER MILLING CUTTER

-

HIGH-EFFICIENT SHOULDER MILLING CUTTER

The SumiDual Mill DFC Type is a high-efficient shoulder milling cutter with double-sided 6-cornered inserts.

- Stable and reliable machining

- Cutter body as shank and shell type available

- Standard / Medium / Fine pitch

- Wide milling cutter range with diameter from Ø 25mm to 160mm

TSX SHOULDER MILLING CUTTERS

-

HIGH PRECISION TANGENTIAL SHOULDER MILLING CUTTERS

The SumiDual Mill TSX Type is a new high-efficient and high precision shoulder milling cutter with tangentially mounted carbide inserts.

- Cutter body as shank and shell type available

- Special orders repeater and side cutter available

- Standard / Medium / Fine pitch

- Wide milling cutter range with diameter from Ø 16mm to 160mm

WEX SHOULDER MILLING CUTTERS

-

STABLE CUTTER DESIGN FOR RELIABLE MACHINING

The cutter body of WEX Type offers a high resistance against both abrasion and corrosion. Additionally the chip evacuation is supported by inner coolant and air pressure. The wave shaped cutting edges generate lower cutting forces whilst the high shear cutting action ensures smooth reliable cutting even when deep slotting or milling with low rigidity machines.

- Shank Type / Shell Type / Modular Type

- Standard, medium or fine pitch

- Wide milling cutter range with diameter from Ø 10mm to 100mm

- Wide variety of inserts

MTIX SHOULDER MILLING CUTTER

-

MILLING CUTTER FOR TI-BASED ALLOYS

The MTIX shoulder milling cutter is suitable for aerospace structure parts and enables a wide application range thanks to its large ramping angle.- Cutter body as shank and shell type available

- Standard / Medium pitch

- Milling cutter range with diameter from Ø 32mm to 63mm

Flexible tooling with large ramping angle

MTIX provides a stable and reliable tool life and covers various applications with wide insert range.- Roughing of Ti-based alloys combined with ACM300 grade

- Stable and reliable tool life

- Wide insert range to cover various applications

- Suitable for aerospace structure parts

WEZ SHOULDER MILLING CUTTERS

-

High-efficiency shoulder milling cutter

The combination of the SEC-WaveMill WEZ shoulder milling cutter with our new universal grade ACU2500 enables a wide range of applications in the machining of steel, stainless steel and cast iron.- Stable and reliable machining

- Enables large ramping

- Cutter body as shank and shell type available

- Standard / Medium / Fine pitch

- Wide milling cutter range with diameter from Ø 14mm to 160mm

New universal milling grade ACU2500

Thanks to an optimised cutting edge shape and a high-precision molding technology, superb wall surface accuracy and surface finish quality are achieved.- New universal milling grade ACU2500

- Excellent sharpness with low resistance

- Reduces machining noise and suppresses burrs

- 2 different insert size series with 6 chipbreaker range

WFX MILLING CUTTERS

-

HIGH PRECISION SHOULDER MILLING CUTTERS

Wave Mill WFX type for shoulder milling is a screw-locking type cutter capable of using four corners. Ideal cutting edge design delivers good squareness.

- Stable machining due to sharp cutting edge

- Shank type / Shell Type / Modular Type

- Standard / Fine pitch / Extra-fine pitch

- Wide milling cutter range with diameter from Ø 20mm to 100mm

SSEH ENDMILLS

-

Radius Endmill for exotic alloys

- Unique, smooth radius design

- Radius type / Anti-vibration type

- Number of teeth: 4 flutes

- Endmills from Ø 4,5mm - 16,0mm

- HAIMER's SAFE-LOCK TMapplicable endmills available

SSEH Radius Type

- Steep helix (45° helix) improves sharpness

- Combination of unique flute design and semi-mirrored surface improves chip evacuation and adhesion resistance

- Ultra-smooth coating with improved hardness and heat resistance combined with tough carbide substrate improves tool life when working with heat resistant alloys

- Unique, smooth radius shape mitigates cutting impact and improves fracture resistance

- Both coated and uncoated types are available in stock to meet various conditions

ASM ENDMILLS

-

HIGH PRECISION SHOULDER MILLING CUTTERS

- DLC (Diamond like carbon) coating

- ASM square type / SNB ballnose type

- Number of teeth: 2 / 4 flutes

- Endmills from Ø 2,0mm - 16,0mm

GSX ENDMILLS

-

Solid carbide endmills

- Improved thermal resistance thanks to Super ZX Coating

- Square type / Ballnose type

- Number of teeth: 2 / 3 / 4 flutes

- Endmills from Ø 0,5mm - 25,0mm

EPMP HIGH EFFICIENCY ENDMILL

-

EPMP - High Efficiency Endmill for Steel Machining

- The optimised flute geometry ensures reliable chip removal.

- Anti-vibration design - the irregular pitch and irregular lead of the mill prevent vibrations.

- Stable cutting corner increases process reliability and productivity. Enhanced cutting edge stability due to double relief angle.

- The Power-Mill coating and a newly developed carbide substrate ensure high wear protection with long tool life.

CBN

- SUMIBORON is the brand name for our CBN tools which are suitable for the machining of hardened steel, high cast iron and exotic metals.

BNC2010/BNC2020

-

COATED CBN GRADES

BNC2010 and BNC2020 are the latest additions to the coated SUMIBORON Series, to provide even better stability and longer tool life for hardened steel machining.

- BNC2010 for high precision

- BNC2020 for general purpose

- High-efficiency machining

- Stable long tool life

NCB100 BINDERLESS CBN GRADE

-

SUMIBORON grade

SUMIBORON Binderless is a polycrystalline cubic boron nitrid (CBN) that directly binds nanometer- or sub-micron-level CBN particles without binder materials. Binderless CBN is harder and has better thermal conductivity. Therefore, it enables higher efficiency and longer tool life in machining of hard-to-cut materials, such as titanium alloy and cobalt-chromium alloy.

- Higher efficient machining and longer tool life have been realized by the effects of higher hardness and thermal conductivity

- Achieves high precise machining and better surface integrity because of less adhesion by not containing any binder materials

- High-efficient finishing of hard-to-cut materials, such as titanium alloy and cobalt-chromium alloy, cemented carbides and cermets

CBN MINI BORING BAR SYSTEM

-

ULTRA SMALL BORING BAR WITH CBN CUTTING EDGE

The CBN boring systems BSME and SEXC were developed specifically for the machining of ultra small diameter holes in hardened steel. The entire boring bar series is equipped with internal cooling. In order to achieve high rigidity and accuracy, all boring bars are designed in carbide. For easy setup and handling, the use of a clamping sleeve, which can take all boring bar sizes by the unified shaft, is provided.

- Internal coolant

- Easy setting & handling

- High accuracy & high rigidity

- One sleeve for different diameters

HIGH FEED TURNING

-

HFT SYSTEM

Our innovative HFT System combined with new 8-cornered CBN insert achieves a cycle time that is 6-times faster than conventional ones.

- 8 times higher productivity than conventional hard turning

- Good surface roughness (Rz < 4 μ) even at elevated feed rates of f = 1,2 mm/rev

- High stiffness monoblock design holders based on HSK, ISO-PSC, VDI or DIN coupling

- High metal removal rate

BNC2115 / BNC2125 GRADE

-

Coated SUMIBORON

BNC2115 and BNC2125 have been added to our coated SUMIBORON series and are our first recommendations for hardened steel machining, for even higher efficiency machining. It's the pinnacle of high accuracy and high efficiency cutting.- BNC2115 for high-accuracy machining

- BNC2125 first recommendation for hardened steel machining

- High-efficiency machining

- Long stable tool life

BN7115 GRADES

-

CBN Grades for sintered alloy finishing

- Excellent Stability in High-Precision Finishing of Sintered Alloy.

- Good wear resistance through high CBN content also delivers superior fracture resistance by increasing the binding strength between CBN particles.

BN7115

- BN7115 provides stable performance for high-speed finishing work and is ideal for finishing of sintered alloys.

- New cutting edge treatment with an emphasis on fracture resistance: “US” type chipbreaker now available.

INSERTS CBN FOR MEDICAL

-

For finish turning of Titanium and Co-Cr Alloys

- Excellent surface quality

- Stable and long tool life

- Suitable for hip-joints, knee-joints and screws

BNC8115 / BNS8125 GRADES

-

From roughing to finishing of cast iron and hardened steel

Coated SUMIBORON BNC8115 and uncoated SUMIBORON BNS8125Coated SUMIBORON BNC8115

PVD coating with excellent wear resistance suppresses flank wear in machining of cast iron and hardened steel. Ideal for roughing and 0,5 mm to 0,3 mm depths of cut can also be used for roughing and finishing of grey cast iron. Gold-colored coating for improved visibility of used corners.

IT105 CBN GRADE

-

CBN grade for finish turning of heat-resistant alloys

The new CBN grade IT105 has been specially developed for finish turning of heat-resistant alloys. With a cutting speed of up to 300m/min, IT105 achieves high productivity with stable tool life and excellent surface finish quality.- Finish turning of heat-resistant alloys

- Stable and reliable tool life

- Excellent surface finish quality

- Suitable for aerospace engine parts

PCD

- SUMIDIA is the brand name for our PCD tools which are specially developed for the machining of plastics and non-ferrous metal finishing.

DA1000 PCD GRADE

-

PCD grade for machining of aluminium alloy

DA1000 is a high density, ultra-fine grained sintered PCD grade with high toughness similar to that of carbide. Excellent micro cutting edge geometry, optimum wear and fracture resistance facilitate high performance, longer tool life and achieve high efficiency machining especially during milling of aluminium alloys.

- PCD grade for aluminium alloys

- Significantly improved surface roughness

- Minimization of burr formation on workpiece

- Even more cost effective combined with NF type inserts

DA90 PCD GRADE

-

SUMIDIA grade for carbide and hard brittle material

The PCD grade DA90 is our first recommendation for roughing of cemented carbides and hard and brittle materials.

- A grade made by sintering rough-grained polycrystalline diamond which contains the highest amount of diamond

- Achieves stable tool life by excellent wear resistance

- Cost performance achieved by optimal design and development of mass production technology, utilizing the SUMIDIA NF

NLD / NGD PCD INSERT

-

PCD insert with chip breaker for aluminium alloys

NLD/NGD type chipbreakers achieve outstanding chip control in semi-and fine-finishing of aluminum alloys. The employment of high toughness grade DA1000 achieves stable, long tool life.

- PCD insert with chip breaker for aluminium alloys

- Excellent chip control in finishing applications

- Improved work efficiency by solving chip control problems

- Stable long tool life with high-toughness grade DA1000

NPD10 BINDERLESS PCD GRADE

-

SUMIDIA grade for carbide and hard brittle material

The binderless PCD grade NPD10 is our first recommendation for high-precision machining of tungsten carbide as well as hard and brittle materials.

- Excellent wear reasistance

- Extreme performance due to nano-polycrystalline diamonds offering superior dimensional stability

- Reduces tool replacing time compared to conventional tools

- Great advantages in improving work quality and achieving total cost savings by higher productivity

ANX HIGH-SPEED CUTTERS PCD

-

High-speed PCD Cutter for aluminium alloys

With the steel and lightweight aluminium body lineup, the ANX milling cutter series is suitable for high-speed machining of aluminium alloys.- Steel or lightweight aluminium alloy body

- Achieves feeds of over vf=30,000mm/min

- Cutter body as shank and shell type available

- Standard / Medium / Fine pitch

- Wide milling cutter range with diameter from Ø 32mm to 160mm

SUMICRYSTAL

- SumiCrystal ® is synthetic single diamond which is suitable for the machining of industrial materials.

SUMICRYSTAL FOR MACHINING OF INDUSTRIAL MATERIALS

- SumiCrystal is synthetic monocrystalline diamond, that Sumitomo Electric manufactures under strict quality requirements. Diamonds are famous for being the hardest known material offering a maximum of heat resistance. Due to these characteristics combined with low thermic spread and high electric resistance diamonds are important for today's high-precision technologies. Compared with natural diamond SumiCrystal shows up an excellent uniformity of product characteristics and is therefore very much suited for industrial applications.