- Offer Profile

FROM PIONEER TO WORLD MARKET LEADER.

Long-term success for more than 35 years.

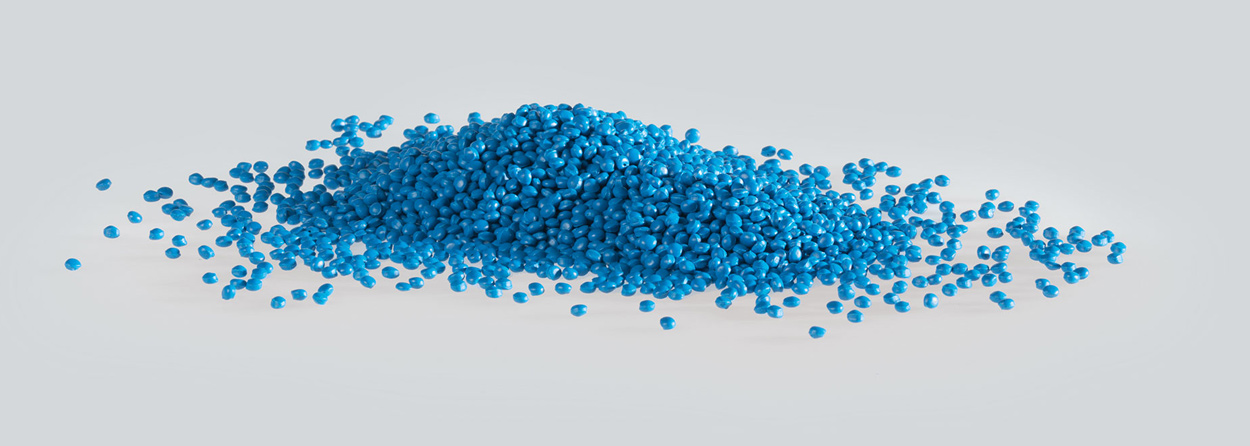

EREMA is the world's number one in developing and manufacturing plastics recycling machines and system components. Founded in 1983 as a pioneer in the industry, more than 6500 of our systems are now in operation around the globe. Highly respected for their level of innovation, durability and operational reliability. In total, they produce more than 14.5 million tonnes of plastics pellets every year. To the very highest, demand-specific quality.

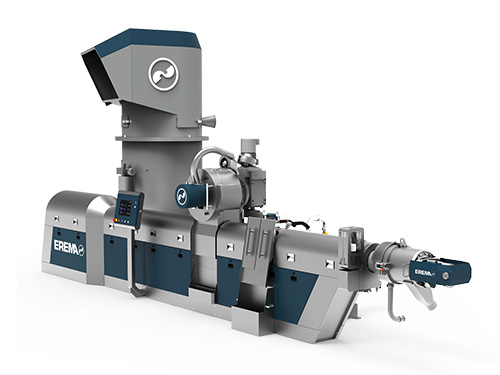

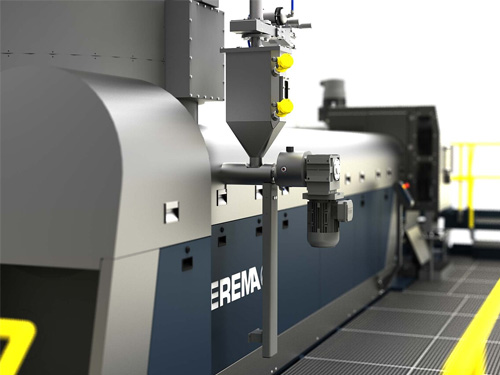

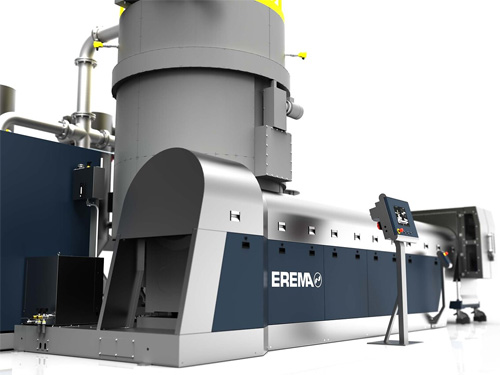

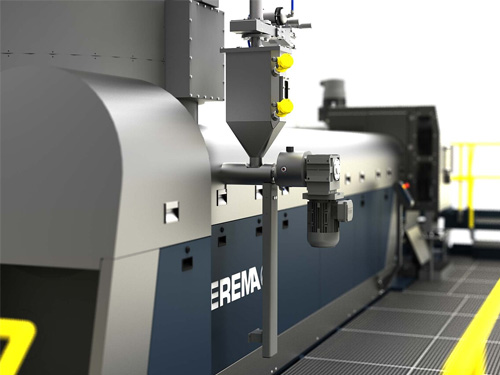

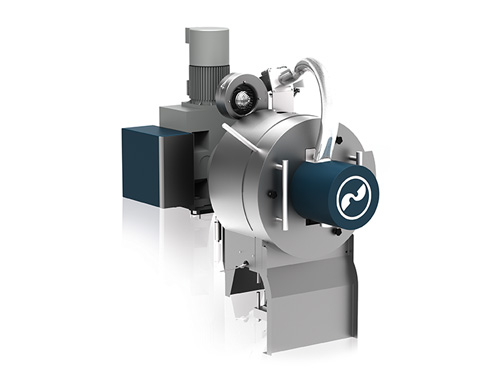

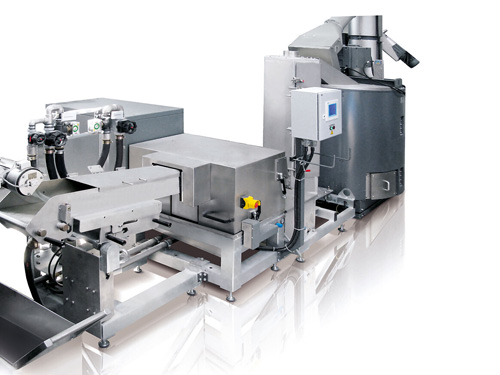

INTAREMA

PRODUCTION EFFICIENCY REDEFINED.

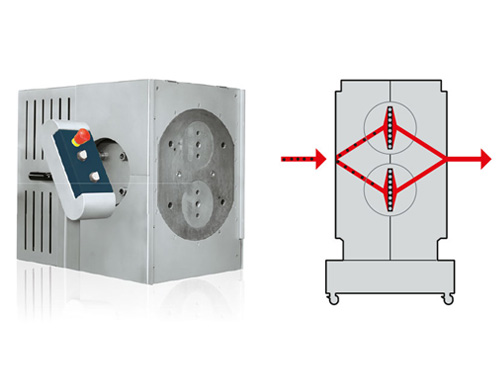

In terms of production efficiency, INTAREMA® is the benchmark in plastics recycling. It outputs the highest rate of recycled pellets per hour in consistent first-class quality thanks to a long-term stable process. This is due largely to the preconditioning unit developed by EREMA. At its heart is Counter Current technology. By changing the direction of rotation, the feed material is prepared ideally for processing in the extruder. An improved feed system is able to handle a wide range of materials. The output stays at a consistently high level within a very broad temperature range.

The easy operation of the machine is based on a new EREMA development: the Smart Start concept. In a nutshell, INTAREMA® virtually runs by itself. An ergonomic touch display provides an intuitive operator interface. Another highlight is the low energy consumption. INTAREMA® machines feature ecoSAVE®, a system that reduces energy requirements by up to 12 %. That brings considerable savings to your production costs.

INTAREMA® T, TE

-

High-performance thermoplastic plastics recycling

INTAREMA® T or TE. Two different series that are based on the same compact INTAREMA® recycling system featuring a short single-screw extruder. Including, of course, the INTAREMA® top technologies Counter Current, Smart Start and ecoSAVE®. For more efficiency and productivity in plastics recycling.INTAREMA® T without extruder degassing: ideal for non-printed edge trim, cutting waste, rolls, loose leftover film and regrind material.

TECHNICAL BENEFITS

INTAREMA® TE with double degassing: for flexible recycling of slightly printed production and industrial waste and technical plastics.- Enhanced material intake, greater flexibility and higher throughput rates thanks to Counter Current technology

- Preconditioning Unit ensures optimum material preparation for the extruder

- HG D (hot die face pelletising system with Direct Drive technology) – state-of-the-art pelletising technology

- Liquid-cooled extruder enables efficient and exact temperature control for the extruder zones and thus high-quality processing of the melt

- Large-area ultra-fine filtration as standard

- Innovative, patented additional technologies for the Preconditioning Unit – DD system and Air Flush module (optional) widen the scope of application

ECONOMIC BENEFITS- High-quality end product allows very high recyclate content when material is returned to the production cycle

- Extremely easy operation and maximum user-friendliness with the Smart Start principle

- ecoSAVE® reduces energy consumption by up to 12 % as well as production costs and CO2 emissions as a result

- Very low operating costs through extremely low specific energy and maintenance costs

- Reliable, high output thanks to Counter Current technology and very robust design

- Compact, space-saving design

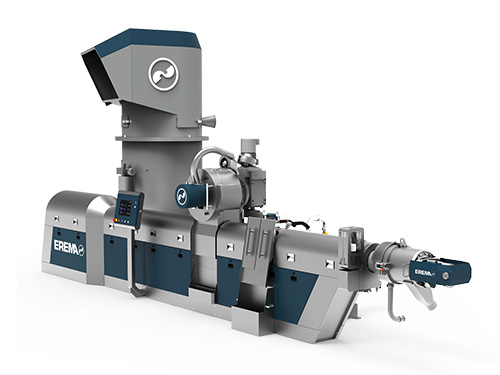

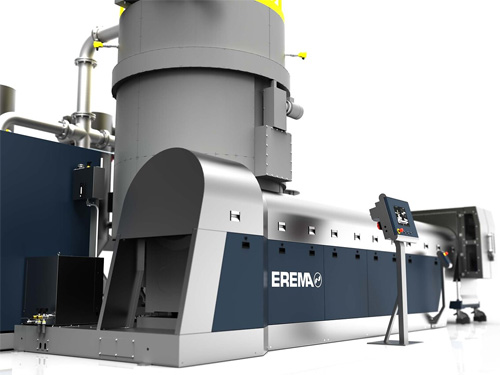

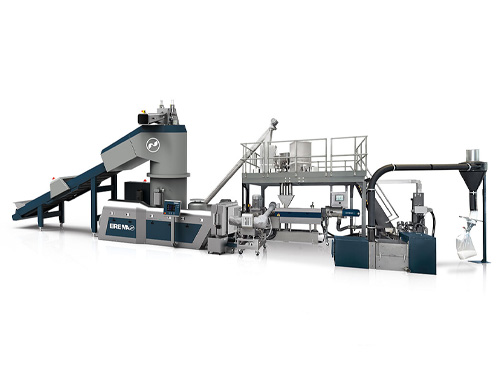

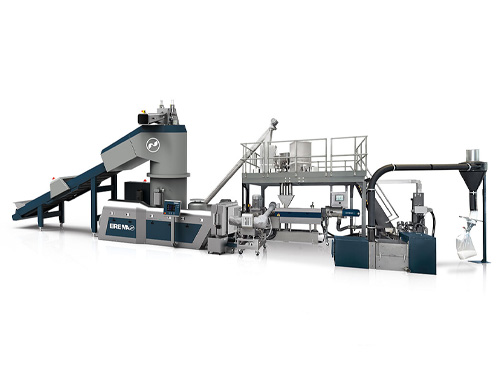

INTAREMA® TVEPLUS®

-

Filtration, homogenisation and degassing at the highest level

The patented extruder system INTAREMA® TVEplus® sets new standards in the recycling of materials that are difficult to process such as heavily printed films and/or very moist materials. This is made possible through ultrafine filtration, thorough melt homogenisation and high-performance degassing in a single step.

The proven basic principle of TVEplus® technology: melt filtration takes place upstream of extruder degassing. As a result, end products can be produced with the best quality and the highest possible recyclate content.

TECHNICAL BENEFITS- Enhanced material intake, greater flexibility and higher throughput rates thanks to Counter Current technology

- Optimised triple degassing with the preconditioning unit, optimum screw design and extruder degassing ensure highly effective degassing of the filtered melt

- Reduced shearing before the filter improves filter performance

- Greater homogenisation efficiency downstream of filtration and upstream of degassing enhances the subsequent degassing performance and improves the characteristics of the melt

- Innovative, patented additional technologies for the Preconditioning Unit – DD system and Air Flush module (optional) widen the scope of application

ECONOMIC BENEFITS- High-quality end product even with materials that are difficult to process such as heavily printed films and/or very moist materials; end products can contain a considerably higher share of recycled pellets

- Extremely easy to use thanks to the Smart Start principle

- ecoSAVE® reduces energy consumption by up to 12 % as well as production costs and CO2 emissions as a result

- Much higher outputs with the same screw diameter compared to conventional degassing extruders

- Compact, space-saving design

INTAREMA® RegrindPro®

-

The gentle way to success in regrind recycling

Are you looking for the ultimate way of producing top recycled pellets from thick-walled regrind? For end products with best performance properties and a particularly high recyclate content? The new INTAREMA® RegrindPro® offers the ideal solution: extremely gentle processing in combination with high-performance filtration. A true material all-rounder so you remain as flexible as possible. RegrindPro®. Go the gentle way.

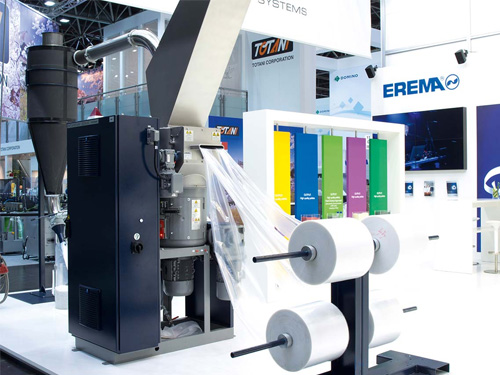

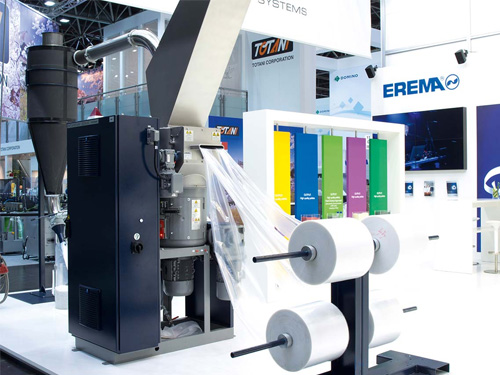

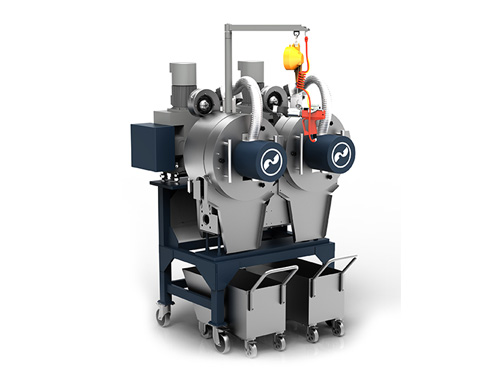

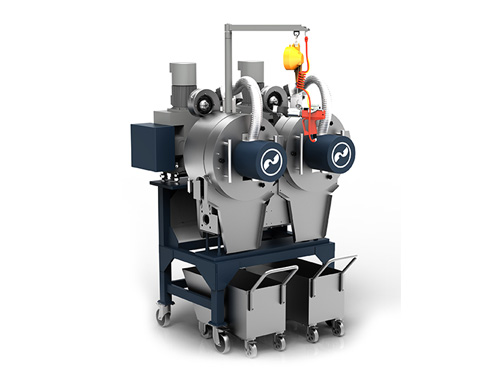

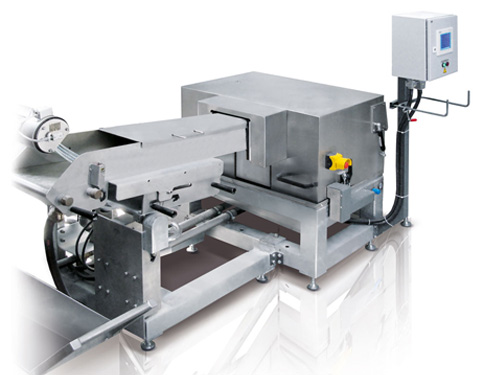

INTAREMA® K

-

Fully automatic recycling system for edge trim

Compactly designed, no operating personnel needed most of the time, top quality end products. INTAREMA® K transforms edge trim efficiently and carefully into high quality, clean pellets. Up to 100% of pellets returned to the production process. Saves raw material as well as disposal costs. That is how this investment practically pays for itself within the shortest time.

Cutting edge: impressive technology

This extremely high level of quality and cost effectiveness is possible thanks to the combination of three EREMA solutions: Counter Current technology, Smart Start operating concept and ecoSAVE® energy saving technology.

TECHNICAL BENEFITS- Fully automatic edge trim system including automatic throughput adjustment and standby mode

- No pre-cutting of the edge trim necessary

- Maximum flexibility: feeding possible via cyclone, roll feeder or conveyor belt

- Short extruder ensures careful material processing with minimum thermomechanical stress

- Enhanced material intake, greater flexibility and higher throughput rates thanks to Counter Current technology

ECONOMIC BENEFITS- High-quality end product: up to 100% of pellets returned to the production process

- Minimum labour required thanks to fully automatic operation

- Maximum user-friendliness thanks to intelligent Smart Start operating concept

- Short amortisation period

- Low production costs thanks to high energy efficiency: ecoSAVE® reduces energy consumption and lowers CO2 emissions

- Minimum service and maintenance

- Compact, space-saving design saves floor space

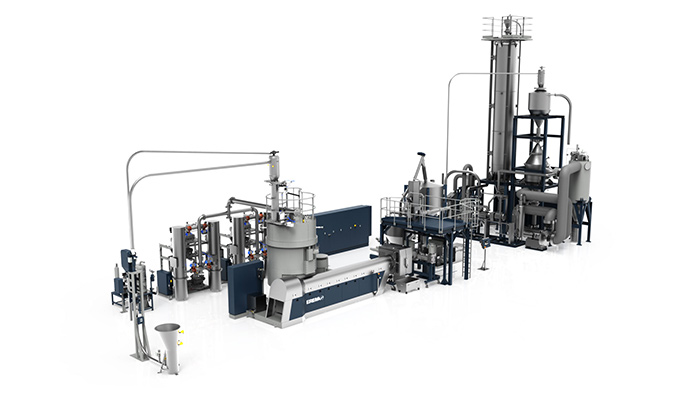

INTAREMA® REFRESHER

-

High-efficiency anti-odour technology.

For more value added and completely new sales markets

BENEFITS

Odour-optimised premium recycled pellets directly from contaminated post-consumer material? The efficient interplay of the innovative ReFresher technology with the proven INTAREMA® TVEplus® machine makes it possible. The unbeatable combination of top pellet quality and odour optimisation opens up completely new application opportunities for recycled plastics.

In other words: innovative premium products in living space, automotive, design and lifestyle sectors.

Higher value added and new sales markets

The direct way from post-consumer material to odour-optimised premium pellets- Opens up completely new application opportunities for recyclates in products, e.g. in living space, automotive, design and lifestyle sectors

- Ideal for particularly high-quality end products

Premium quality through unique technology combination INTAREMA® TVEplus® & ReFresher

- INTAREMA® TVEplus®: the quality of the pellets is extraordinarily high and stable already after extrusion – including partial odour reduction

- ReFresher: targeted, intense odour reduction raises pellet quality to a premium level

High economic efficiency and productivity

- High, constant throughput and stable quality ensure low pellet costs per tonne

- No vacuum necessary in the ReFresher, i.e. lower operating and maintenance costs

- Odour treatment without the use of additional, expensive additives

INTAREMA® ZeroWastePro

-

ZERO WASTE AT ITS BEST

Efficient, compact and energy-saving - this is how the new INTAREMA® ZeroWastePro transforms your film waste from production into high-quality recycled pellets. No compromise high quality. Use this system to feed up to 100% of the recy- cled material back into to your main production process.

The machine specialises in the recycling of PE and PP films, which can be processed either inline or offline. Efficient production waste recycling with ZeroWastePro. The new standard for standard applications.

Technology

-

ADVANTAGES

- High throughputs

- Top productivity and flexibility

- Reliable processes, constant output

- Easy operation

- Energy saving

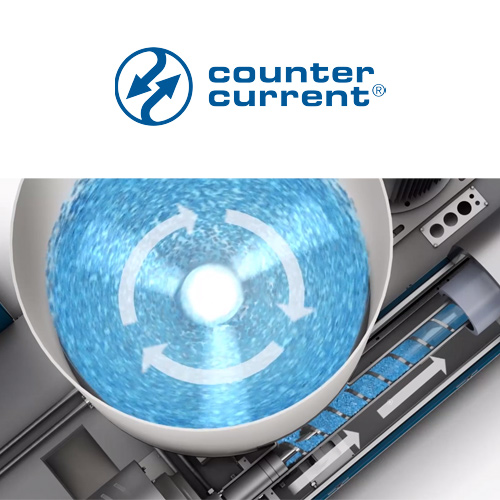

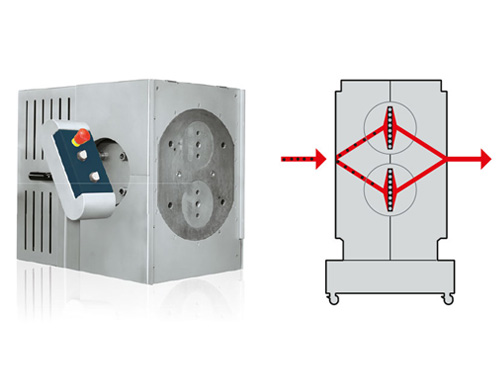

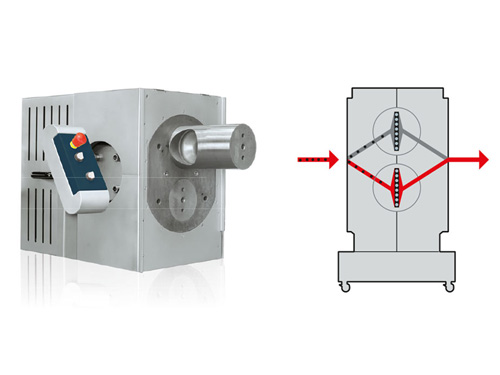

Counter Current technology

-

- Highest process stability through improved material intake ensures constantly high output over a considerably broader temperature range

- Higher flexibility and operational reliability with a variety of materials

- Increased throughputs with the same plant size for more productivity

Smart Start technology

-

- Remarkably easy to operate thanks to logical, clearly structured and simplified handling and ultramodern, ergonomic touch screen display

- Fewer buttons, more user-friendliness – thanks to high degree of automation including extensive control packages

- The right recipe for every application – saved processing parameters can be loaded easily and conveniently from the recipe management system at the push of a button

ecoSAVE® technology

-

- ower specific energy requirements thanks to a complete package featuring design and process engineering measures, such as the new direct-drive extruder screw

- Lower production costs through optimised control technology and high-quality, energy-efficient components such as high-performance motors

- Additionally, the practical energy display on your operating panel gives you a constant overview of energy consumption at all times, thus enabling you to take specific measures to optimise consumption

- Reduced CO2 emissions – an important contribution to environmental protection

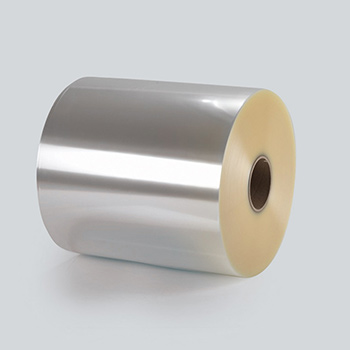

Vacurema

-

BETTER FOR PET.

Uncompromising food contact compliance, IV stability, reliability and top energy efficiency: there are many benefits when you start with the important things first. In bottle-to-bottle recycling this means: decontamination BEFORE extrusion. This is the straightforward but very effective basic principle of the VACUREMA® technology of EREMA. And using this technology you form the perfect basis for a top-quality end product right at the beginning of the process. As a result, IV value and further key parameters of your end product remain stable. And they stay stable even if the properties of your input material change all the time for example in terms of moisture and bulk density or through mixtures of PET material with differing IV values.VACUREMA®. Better for PET.

ADVANTAGES

- Extremely clean rPET

- For direct food contact

- Consistent product quality even with changing input material

- Easy to operate, high degree of automation

- Energy-saving and resource efficient

- Reliable and proven

Bottle-to-bottle

A SAFE CHOICE.

BECAUSE IT'S ABOUT YOUR BRAND.

Clean melt, clean recycled pellets, clean preforms. EREMA bottle-to-bottle systems stand for uncompromising food contact compliance, highly efficient decontamination, high-performance filtration and safe handling. For top-quality end products.IT'S SO EASY.

Stable processes and consistently high quality pellets and preforms: Production and plant managers appreciate these characteristics of VACUNITE® and VACUREMA® systems. Simple operation and a high degree of automation included. The fact that the end product remains stable even if the input material parameters change is a clear flexibility bonus. Safe and proven - around 250 VACUREMA® systems are in use worldwide.A RELIABLE INVESTMENT.

The best decision is a safe decision. EREMA bottle-to-bottle systems offer impressively low total cost of ownership, low energy consumption and high uptime. Fully in keeping with high productivity, cost effectiveness and efficiency. And that you can safely rely on.

VACUREMA® INLINE APPLICATIONS

The best way is the direct way

There is a way which takes you to your target faster. Without detours. A way which enables you to save energy and space, increase your productivity and reduce your costs. It is the direct way: the VACUREMA® Inline solution. With this solution you go from post-consumer PET flakes directly to finished thermoforming sheet or bottle preforms, to finished strapping or monofilaments. In a single process step.

We realise these direct benefits for you by combining the highly efficient VACUREMA® system with the appropriate downstream production line. Leading technologies which merge seamlessly. For more efficiency and cost-effectiveness at your production facility. Better solution. Better direct.

ADVANTAGES- VACUREMA® = 1 closed complete system:

- All functions, such as predrying and decontamination in the reactor, extrusion and filtration flow seamlessly into each other without interruptions (so no malfunction-sensitive conveyance/gravimetry is necessary – unlike other systems)

- Everything from a single source: all VACUREMA® core components such as the reactor, extruder or filter come from the EREMA Group

- High cost-effectiveness and production efficiency: end products directly from post-consumer PET flakes, in a single process step, without the detour via pellet production

- Extremely clean, top products, approved for direct food contact

- Flexible on input, stable on output:

- Broad range of PET input materials possible: bottle flakes, ground amorphous skeleton waste, edge trim, strapping production waste, virgin material, bulk densities from 250 to 850 kg/m3.

- Output: consistent end products in terms of IV value and colour despite varying moisture, IV values and bulk densities in the input material

MPR®

The perfect addition for your existing extrusion

From contaminated, moist flakes to clean, dry, dust-free, crystallised and food contact compliant flakes. This is the job of the Multi Purpose Reactor (MPR®) from EREMA. And the system takes care of this for you in an extremely reliable and energy-efficient way.

The Multi Purpose Reactor complements your existing extrusion system and ensures that your washed PET material is already food contact compliant prior to extrusion. In many countries the legal framework will continue to develop in this direction; in the EU it is already laid down in Commission* Regulation (EC) No. 282/2008. However, you can also use the MPR® as a stand-alone solution (without subsequent extrusion).

Flexible on input

he patented MPR® is a highly efficient crystallisation dryer, as also used (in a somewhat different form) in the VACUREMA® system. Washed PET bottle flakes, ground PET flat sheet waste and virgin PET material plus mixtures of them can be used as input material.* Commission Regulation (EC) No. 282/2008 of 27 March 2008 on recycled plastic materials and articles intended to come into contact with foods.

TECHNICAL BENEFITS

- Enhanced material intake, greater flexibility and higher throughput rates thanks to Counter Current technology

- Optimised triple degassing with the preconditioning unit, optimum screw design and extruder degassing ensure highly effective degassing of the filtered melt

- Reduced shearing before the filter improves filter performance

- Greater homogenisation efficiency downstream of filtration and upstream of degassing enhances the subsequent degassing performance and improves the characteristics of the melt

- Innovative, patented additional technologies for the Preconditioning Unit – DD system and Air Flush module (optional) widen the scope of application

ECONOMIC BENEFITS- High-quality end product even with materials that are difficult to process such as heavily printed films and/or very moist materials; end products can contain a considerably higher share of recycled pellets

- Extremely easy to use thanks to the Smart Start principle

- ecoSAVE® reduces energy consumption by up to 12 % as well as production costs and CO2 emissions as a result

- Much higher outputs with the same screw diameter compared to conventional degassing extruders

- Compact, space-saving design

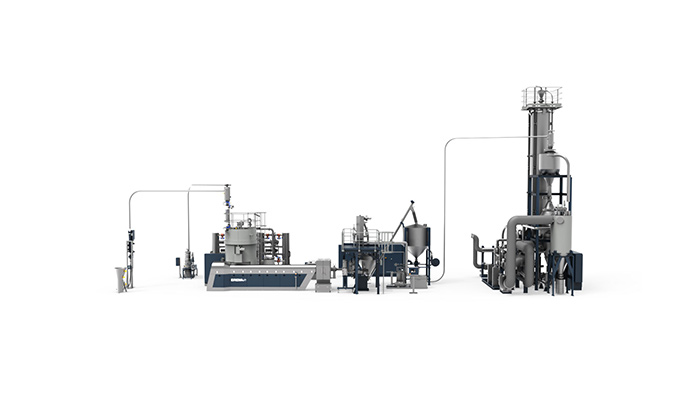

VACUNITE®

For the highest requirements. Impressive energy-ef?cient brand owner quality.

VACUNITE® redefines the benchmark for performance in bottle-to-bottle recycling: Uncompromising safety, productivity and quality are ensured thanks to the highest decontamination efficiency, rPET granulates with the best colour values, top IV stability, compactness of the system as well as low energy consumption throughout the entire process. Your combination for safety: Advanced VACUREMA® + Polymetrix SSP

This is made possible by the unique combination of two technologies: VACUNITE® unites VACUREMA® technology, which has been tried and tested for decades and has been further developed especially for this application - together with newly patented vacuum-assisted V-LeaN Solid State Polycondensation (SSP), which was also specially developed by Polymetrix (the manufacturer) for EREMA for this demanding application. Key quality and safety advantage: All thermal process steps take place in nitrogen and/or vacuum atmosphere.

VACUNITE®

-

For the highest requirements. Impressive energy-ef?cient brand owner quality.

VACUNITE® redefines the benchmark for performance in bottle-to-bottle recycling: Uncompromising safety, productivity and quality are ensured thanks to the highest decontamination efficiency, rPET granulates with the best colour values, top IV stability, compactness of the system as well as low energy consumption throughout the entire process.

Your combination for safety: Advanced VACUREMA® + Polymetrix SSP

This is made possible by the unique combination of two technologies: VACUNITE® unites VACUREMA® technology, which has been tried and tested for decades and has been further developed especially for this application - together with newly patented vacuum-assisted V-LeaN Solid State Polycondensation (SSP), which was also specially developed by Polymetrix (the manufacturer) for EREMA for this demanding application. Key quality and safety advantage: All thermal process steps take place in nitrogen and/or vacuum atmosphere.

Bottle-to-bottle

A SAFE CHOICE.

BECAUSE IT'S ABOUT YOUR BRAND.

Clean melt, clean recycled pellets, clean preforms. EREMA bottle-to-bottle systems stand for uncompromising food contact compliance, highly efficient decontamination, high-performance filtration and safe handling. For top-quality end products.IT'S SO EASY.

Stable processes and consistently high quality pellets and preforms: Production and plant managers appreciate these characteristics of VACUNITE® and VACUREMA® systems. Simple operation and a high degree of automation included. The fact that the end product remains stable even if the input material parameters change is a clear flexibility bonus. Safe and proven - around 250 VACUREMA® systems are in use worldwide.A RELIABLE INVESTMENT.

The best decision is a safe decision. EREMA bottle-to-bottle systems offer impressively low total cost of ownership, low energy consumption and high uptime. Fully in keeping with high productivity, cost effectiveness and efficiency. And that you can safely rely on.

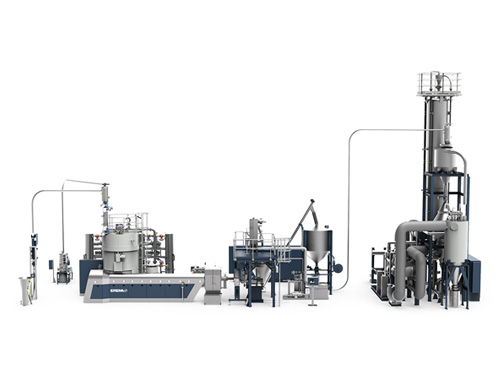

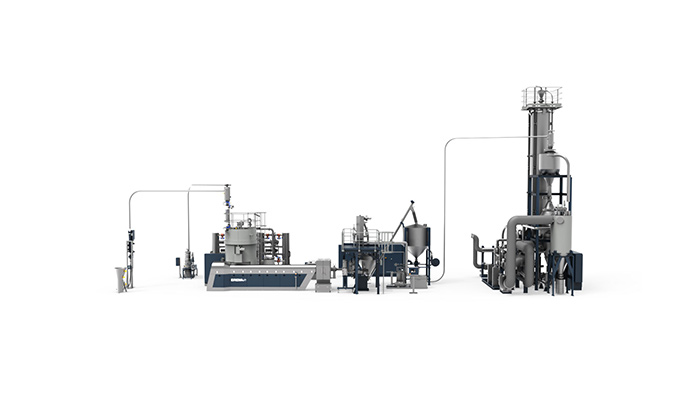

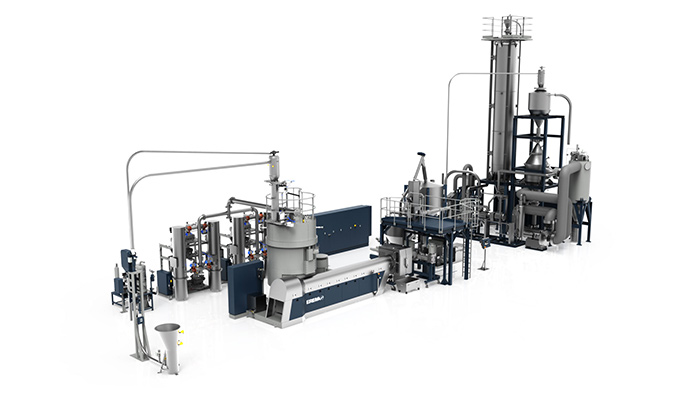

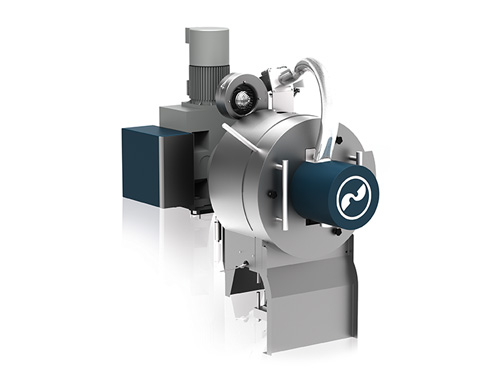

COREMA®

PRECISION RECYCLING COMPOUNDS

Plastics recycling with the decisive quality advantage - this can be achieved quickly and without difficulty through upcycling. For this purpose, EREMA has developed the COREMA® Technology, a combination of recycling and compounding in a single work step. The crucial advantage: The property profile of the recycled compound can be optimized precisely in accordance with requirements.

COREMA® systems convert raw recycling materials such as PP nonwoven, PE edge trims, PA fibres into filtered melt using proven EREMA technology. This melt is fed directly to a co-rotating twin-screw compounding extruder. Besides the dosing of a wide variety of additives, fillers and reinforcing agents can be admixed in doses that are higher than those previously possible with EREMA recycling systems. The result is customised plastic recyclate for high-quality applications.

Advantages- Increased value creation

- high quality, precision optimised plastic recyclate

- Highest productivity and flexibility

- Easy operation

- Very low operating costs and extremely low specific energy costs

COREMA®

Recycling and compounding in a single step

A powerful, energy and time-saving innovation from EREMA: COREMAc® combines the benefits of recycling and compounding in a single plant. This system produces tailor-made tunable recycling compounds for especially high quality applications.

Recycling raw materials such as PP fleece, PE edge trim, PA fibres are transformed into a filtered melt using proven, robust EREMA technology which is then fed directly to the Coperion co-rotating twin screw extruder.

With its excellent mixing and gas removal properties, this part of the system can handle all compounding tasks. Besides the dosing of a wide variety of additives, high amounts of fillers and reinforcing agents can be admixed.

TECHNICAL BENEFITS- Flexible input of various recycling raw materials thanks to the preconditioning unit and Counter Current technology

- Proven, robust EREMA technology for producing filtered melt material

- Minimum thermal stress through short, defined dwell times and direct dosing of the melt in the twin-screw/compounder/extruder

- Proven EREMA degassing technology with EREMA preconditioning unit and extruder degassing

- Central user interface to control the whole system

ECONOMIC BENEFITS- Increased value added thanks to the use of inexpensive raw materials (e.g. PP non-woven, PE edge trim, PA fibres etc.)

- Very low operating costs and minimal specific energy costs through direct dosing of the filtered melt and processing in a single heat

- Modular system concept offers optimum adjustment to the respective application

- Reliable production thanks to Counter Current technology and very robust design

- Compact, space-saving design

- ecoSAVE® reduces energy consumption by up to 12 % as well as production costs and CO2 emissions as a result

UPCENTRE®

-

Upcycling made easy

At the EREMA UpCentre® you can enter the future market of upcycling. In an easy and flexible way. You use ultramodern COREMA® recycling and compounding technology including expert support and know-how on-site without having to buy your own system. Fine-tuned to your customer's application (film, injection moulding, etc.), the recycling compound is precisely matched to their requirements. That is how you obtain precision samples quickly and cost-effectively.

YOUR BENEFITS- Use ultra-modern COREMA® 1108 T without having to buy

- Including on-site expert support and know-how

- For new recycling compound sampling

- Production quantities from 2 to 200 tonnes per month

- Easy, convenient, quick

- As flexible as you need

- No investment risk

- 24-hour operation possible

ECONOMIC BENEFITS- Increased value added thanks to the use of inexpensive raw materials (e.g. PP non-woven, PE edge trim, PA fibres etc.)

- Very low operating costs and minimal specific energy costs through direct dosing of the filtered melt and processing in a single heat

- Modular system concept offers optimum adjustment to the respective application

- Reliable production thanks to Counter Current technology and very robust design

- Compact, space-saving design

- ecoSAVE® reduces energy consumption by up to 12 % as well as production costs and CO2 emissions as a result

COMPONENTS

FILTRATION

The system that matches every requirement

Without efficient filtering it is not possible to obtain high quality recyclate. This applies to all application cases in plastics recycling. That is why from the very beginning, EREMA has made this quality-decisive aspect a core element of its systems. Perfectly implemented in innovations and partially patented filtration systems. Features they all share are process consistency and maximum filtration capacity.

Clean performance. Clean melt.

EREMA filtration solutions.

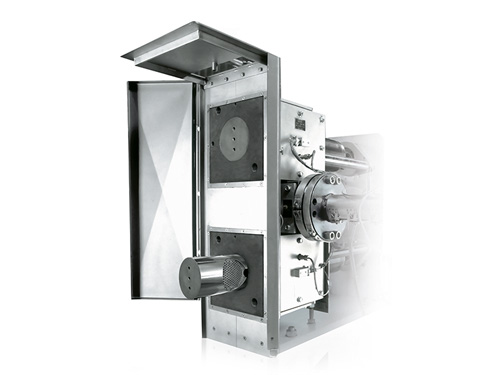

SW RTF®

-

The EREMA partial surface backflushing system

Robustness, high level of automation and highest possible availability. Available in different sizes and always with the right filtration fineness With these EREMA filtration systems it is the details that make the system really effective.

The way SW RTF® technology works is to clean a small surface area of the filter screen by directing a flow of clean melt from the back of the screen. A high velocity is possible at the screen due to the small surface area of screen to be flushed, resulting in optimum cleaning efficiency.

YOUR BENEFITS- Large active overall screen surface enables the processing of both high levels of contamination and surge contaminants in the melt

- Partial area backflushing with high cleaning efficiency through backflushing of individual screens

- Two opposing screens per carrier piston for balanced power distribution

- Lowest possible pressure fluctuations during screen changeover and backflushing

ECONOMIC BENEFITS- Fully automatic, efficient and reliable backflushing mechanism for maximum screen service life, long screen change intervals and reduced screening costs

- Less labour required thanks to automatic backflush control

- High end product quality

- Low melt loss

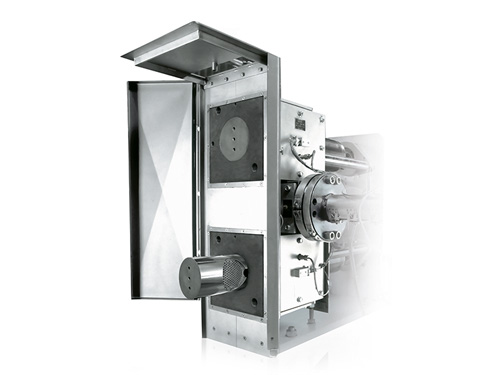

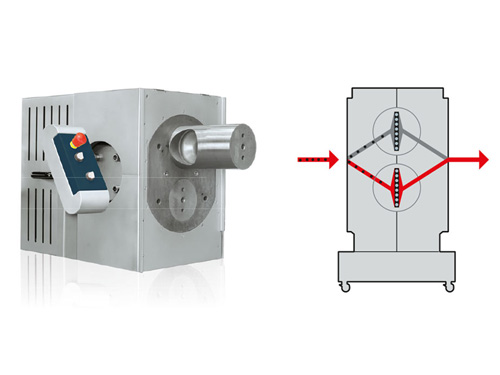

LASER FILTER

-

The high-performance filter system

The EREMA Laserfilter is a high-performance filtration system. Innovative scraper technology enables the highest possible throughputs while maintaining impressive melt quality. Specialising in high melt rates, when film-grade pellets are needed and for tasks that cannot be solved with conventional melt filters.

Thanks to the engineered scraper geometry design and discharge system, the filtered contaminants are removed even more quickly and more thoroughly. Maximum cleaning efficiency, the highest possible separation capacity and increased thickening are the direct result. And: the service lifetime of the screen is greatly increased.

YOUR BENEFITS- Self-cleaning filter system with rotating scraper disc enables days and weeks of continuous filtration

- Enhanced cleaning efficiency through redesign of scraper geometry and discharge system – for even faster removal of contaminants

- Greater discharge capacity for contaminants such as paper, wood, aluminium, copper

- Fully automatic, constant pressure operation

- Top filtration reliability: perfectly sealed system prevents any filtered out contaminants from getting into the high-quality plastic melt

ECONOMIC BENEFITS- Continuously high filtration performance ensures high melt throughput together with outstanding melt quality

- Considerably higher screen service life through increased cleaning efficiency

- Less labour required thanks to longer screen change intervals

- Simple and fast screen disc changeover

- Minimum melt losses through increased thickening up to 50 %

SW DIRECT FLOW

-

Efficient melt filtration. For minor contaminants.

Robust, reliable, efficient the new EREMA SW Direct Flow melt filter has the merits of the EREMA SW filter technology proven thousands of times in its genes.

Reduce to the max

The reduction and optimisation of the filter to the key, core functions which matter in the case of applications with only minor levels of contamination means for you: strong performance with a remarkable cost/benefit ratioDust & co. don't stand a chance

The new EREMA SW Direct Flow melt filter has minor contaminants such as dust under perfect control. It ensures high melt quality and combines productivity with easy operation and flexibility. And, thanks to a longer service life, it helps you to save both labour and material costs.ADVANTAGES

- Top melt quality

- Careful processing of the polymer through rheologically optimised melt channels and support breaker plates: short material dwell time in the filter, short transport distances and low pressure requirement. As a result it is also possible to process very sensitive polymers with great care

- Quality bonus through ultra-fine filtration: < 30µm filter discs possible (standard filter discs from 30 to 90µm)

- Long screen service life, longer filter change intervals

- Long filter service life thanks to large, open filter areas

- Optimised flow through the screen surfaces ensures an even build-up of contaminants inside the filter and thus prolongs filter lifetime

- Easy to use, easy to service

- Easy and quick screen change while production is running

- High flexibility, compact design

- Very broad scope of application: e.g. recycling, fibre, blown film, flat film and pipe production, repelletising/Masterbatch

- Saves space thanks to compact design

- Variable filter unit installation position (0, 90 or 180 degrees, depending on requirements)

- Best price/performance ratio

- Reliable EREMA SW filter technology, reduced to the most important core functions for relatively clean application

- Produce continuously – even during screen changes!

- 50% of the filter areas remain active during screen changes because material continues to pass through the second flow channel in the filter

- Top melt quality

PELLETISING

-

- HG D: Hot die face pelletising systems with Direct Drive technology

- HG Air: Hot die face pelletising systems with air technology

- ASP: Semi-submerged strand pelletising systems for low-viscosity thermoplastics

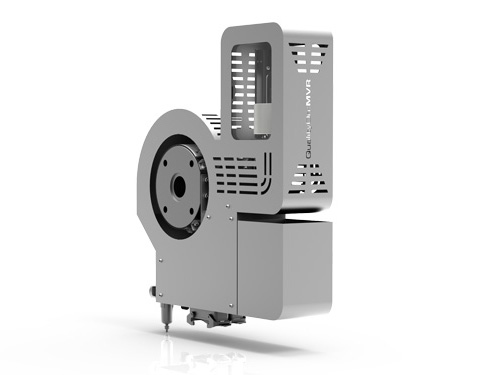

HG D

-

Hot die face pelletising systems with Direct Drive technology

Simple handling and maintenance have always been the trademarks of EREMA hot die face pelletising systems. Ongoing development of Direct Drive technology has added even more operational reliability, ease of use and flexibility.

YOUR BENEFITS

- Direct Drive technology with vibration-free design

- Lifetime lubrication of the drive shaft

- Very long pelletiser service life thanks to special cutting geometry and automatic pneumatic knife pressure

- Automatic pelletiser function supervision with alarm signal and automatic shutdown in the event of a malfunction

- Optional automatic pelletiser speed adjustment control ensures reliable operation with constant pellet size, even with fluctuating melt throughput

- hing

ECONOMIC BENEFITS- Suitable for use with virtually all standard extruders

- High degree of operational reliability and considerable reduction in maintenance costs

- Simple and rapid pelletiser knife changeover without adjustment work saves time

- Flexible configuration of equipment downstream of pelletiser

- Reduced cooling water costs thanks to efficient pellet cooling system

HG AIR

-

Hot die face pelletising systems with air technology

Robust implementation proven again and again. For automatic repelletising of different thermoplastic materials, compounds and wood/plastic composites (WPC).

The series HG AIR 80K, HG AIR 120K, HG AIR 120 and HG AIR 240 set new standards in terms of operational reliability, straightforward operation and flexibility.

TECHNICAL BENEFITS- Robust, compact design

- Air as transport / cooling medium

- Easy handling

ECONOMIC BENEFITS- Simple and fast pelletiser knife changeover

- Air cooling requires less infrastructure

- High operational reliability

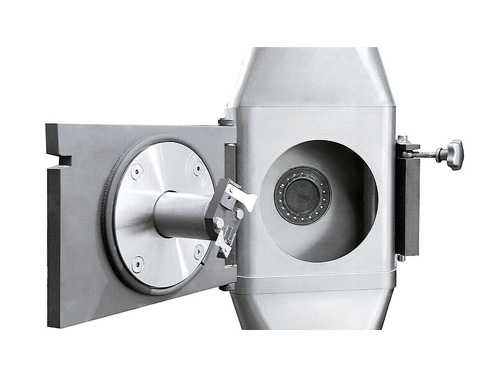

ASP

-

Semi-submerged strand pelletising systems for low-viscosity thermoplastics

EREMA's semi-submerged strand pelletising systems are used to pelletise technical thermoplastics such as PET. Straightforward operation and minimum labour requirements contribute to the very high degree of operational reliability.

Easy start-up, fast cleaning when changing over material and automatic self-feeding if strand breaks occur make these systems indispensable. Integrated crystallisation is also possible for PET.

YOUR BENEFITS- Easy start-up with no bypass valves and lowest possible material loss

- Fully automatic self-feeding if strand breaks occur

- Cooling water removes cutting dust

- Adjustable spray heads for the effective cooling of the polymer strands

- Optional CIC (Compact Inline Crystallisation) for the integrated, energy-efficient and compact crystallisation of PET or PLA

ECONOMIC BENEFITS- Cylindrical pellets on a par with virgin material

- Reduced wear on tooling thanks to wet cutting

- Minimum personnel costs thanks to easy operation and fast cleaning and maintenance of the easily accessible components of the complete system

- Avoiding downtime caused by strand breaks increases productivity

- Extremely reliable and operator-friendly

ASP-CIC

-

Compact Inline Crystallisation

A system for the integrated and energy-efficient crystallisation of PET or PLA. The melt-filtrated strands are cooled briefly in water and then cut into pellets. The material is then fed immediately into a container.

The latent thermal energy inside the pellets is used for crystallisation without additional energy input required from the outside and without interrupting the process.

TECHNICAL BENEFITS- Homogenous pellets in terms of properties such as degree of crystallisation, pellet geometry, pellet weight, colour, etc.

- The degree of crystallisation achievable is between 30 and 40 %

- Trace elements are reduced without influencing the IV

- No sticking occurs, thanks to the careful and homogeneous crystallisation over the whole cross section

ECONOMIC BENEFITS- Low production costs because no additional energy is needed

- Easy operation and low personnel costs thanks to the high degree of automation

QUALITYON

QUALITYON

-

Measure quality online: Continuous quality monitoring of colour and MVR values directly at the machine

QualityOn sets a new standard in quality monitoring in plastics recycling. Because thanks to the innovative EREMA online measuring features you are informed about the current MVR and colour values already while the machine is processing and do not have to wait until later in the laboratory.

You are notified automatically as soon as the values measured leave the defined tolerance range and can thus take remedial action in the process at an early stage or remove any defective material immediately from the current process.

This ensures that you and your customers have recycled pellets with consistent properties. For more quality and higher process stability. Another bonus: QualityOn saves considerable time and labour compared to conventional laboratory methods.

-

Continuous quality monitoring of colour and MVR (melt volume-flow rate) values at the machine during processing – no need to wait until later in the laborator

- Quality in control: consistent recycled pellet properties, assured process quality – permanent quality control, quickly detecting and reacting to deviations from the target state

- Alarm if not within defined tolerance range

- Option: integration of a defl ector for the immediate deflecting out of defective material and for sorting into various quality grades

- Saves time and labour: QualityOn saves considerable time and labour compared to manual laboratory methods.

- Robust, straightforward and reliable design of measuring units

- Geared to the higher requirements in recycling

-

QUALITYON:MVR

-

Continuous online measuring of melt volume-flow rate (MVR) in real time direc tly at the machine

- Automated measuring process based on standardised laboratory method

- Straightforward and robust system

- Designed especially for recycling: unlike well-known online viscosity measuring systems which use gear pump technology and are designed primarily for clean polymers in the virgin material sector, the QualityOn:MVR measuring unit is designed especially for the higher requirements of recycling processes. It is, for example, insensitive to extremely small contaminant particles of 100-1000 µm which are common in post-consumer recycling.

- Possible to sort quality according to different viscosity grades by means of a downstream recycled pellet deflector

THE BENEFITS- Exact and representative data

- Representative measuring: ingenious design ensures lowest possible influence on removed measuring charge through residence time

- “Clean” data: thanks to the innovative ContiFlush rinsing mechanism the measuring system is cleaned quickly and efficiently after every measurement; this means that results are not influenced by residues from previous measuring processes or contaminants in the volume measured

- Option: re360, the new EREMA Manufacturing Execution System, for transparent and clear visualisation, processing, analysis and long-term storage of the MVR data

- Available as a standalone system for retrofitting or for integrating in a new machine

QUALITYON:COLOUR

-

Continuous online measuring of pellet colour in real time directly at the machine

- Online spectrophotometer detects the slightest differences in colour: High-resolution grid spectrometer ensures reliable detection of the smallest differences in colour which are not visible to the human eye – this means the information is available long before thresholds are reached

- Perfect deflector setting: recycled pallets with the wrong colour are deflected out until production has become stable again this means that a light production colour is not contaminated with darker material

- An alarm is given if the colour is not within the defined tolerance range

- Practical teach function enables the straightforward learning of the desired production in line with the current colour

THE BENEFITS- Visualisation of colour values:

- Standard: the practical trend display on the machine gives you a quick picture of time-dependent colour deviations

- Option: the new EREMA MES re360 offers even more transparancy, overview and analysis possibilities, including long-term data storage

- Low maintenance

- Available as a standalone system for retrofitting or for integrating in a new machine

DIGITAL SOLUTION

DATA TRANSPARENCY IN REAL TIME re360: The new Manufacturing Execution System from EREMA

If you have the overview, you can make decisions. A fast overview means: faster and better decisions. re360 supports you ideally in the process. This is because the new Manufacturing Execution System (MES) from EREMA provides you with production and machine data at the press of a button directly on your desktop. Regardless of whether you have one, two or a dozen machines. And regardless of whether they are EREMA recycling machines or film or other plastics production facilities. Take advantage of the information lead you gain from clear, real-time data to make sure that everything is running smoothly in your production processes. And to make sure that you can react quickly to deviations from plan at short notice, too. Look back for a sharper future focus. re360 can, however, do much more. This is because it is also a perfect analysis tool. Thanks to the long-term storage of your production data you can look back over weeks, months and even years to establish trends and important fi ndings for future decisions and optimisation. For more quality and productivity at your production facility.

RE360- Transparency instead of data overload: perfect overview from your desktop, data in real time, top visualisation with different depths of detail

- Increase productivity: make better use of machine capacity, raise throughput, reduce waste, lower downtime and identify its causes more quickly

- Continuous quality: recipe management, fast identification of deviations, continuity in maintenance work, comparison between different locations

- More data security: documented quality data, centralised storage of know-how

THE BENEFITS

- Optimise production and workflow processes

- Greater flexibility: faster remedial action in the event of deviations from plan

Strong customer focus: interconnection of the individual re360 modules with the individual customer order, strengthening of long-term customer relationships by securing constant, customer-specific (repelletised) quality

Applications

-

MAKING SOMETHING NEW, MADE EASY.

Partner for efficient special recycling applications.

We search for solutions for you. Day after day. And we find them. For your recycling requirements today. And for those of tomorrow. Even if you are talking about complex special applications such as in the fields of automotive, compounding, bioplastics and wood-plastic composites (WPC).

What motivates us? Pioneering spirit, our more than 30 years' experience in finding solutions in plastics recycling, and our passion for taking on brave new challenges. That is why we can offer you the decisive competitive edge for your specific special application.

Inhouse and Industrial Plastic Recycling

-

COMPLETELY PROFITABLE.

WHO SAID ANYTHING ABOUT WASTE?

With our inhouse recycling systems we redefine cost effective plastics processing. What was previously regarded as waste material is transformed on-the-spot into new raw material. With refeeding rates of up to 100 %. Technological ingenuity, seamless integration into existing processes and probably the easiest operation in the world speak for themselves.

All of our inhouse recycling systems are equipped with EREMA Counter Current technology. That ensures the highest throughput and increased flexibility regarding materials. And, thanks to ecoSAVE® and a series of other ecological measures, these machines are also masters at saving energy, setting the benchmark for energy efficiency.

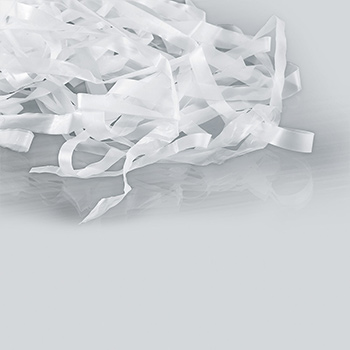

Non-printed films

Non-printed edge trim

Edge trim

Lightly printed films

Heavily printed / metallised films

BOPP films

BOPET films

Multiple-layer films (e.g. PET/PE)

PP filaments

PP non-woven

PP sacking fabric / Raffia

PP fibres

Post consumer plastic recycling

-

THE TECHNOLOGY IS DECISIVE.

Recycled raw materials help the environment - and your business.

In an era of diminishing and expensive primary raw materials, post consumer waste is becoming more attractive in the plastics industry. Reprocessed to a very high quality standard, it becomes a lucrative and almost inexhaustible resource. It boosts your own business and helps to prevent environmentally unfriendly waste depots. Heavy contamination and mixing are just two of the many complex challenges in processing post consumer plastics.

EREMA would not be number one worldwide if it were not for the fact that we also offer dynamic, high-performance, environmentally friendly technolgies in this special sector as well. Best possible quality, highest possible performance, maximum output – that is exactly the strengths of our recycling systems. Including with post consumer waste.

PE washed shreds

Washed shreds, agricultural sheeting

PE film with paper labels

PP film / non-woven fleece with solid content

Regrind material, thick

Regrind material, thin

HDPE regrind material

PET recycling

-

IMPRESSIVE R-PET. SAFE AND SOUND.

Top quality solutions for bottle-to-bottle recycling and rPET inline applications

Uncompromising food contact compliance, IV stability, reliability and the best energy efficiency. We know what is important in bottle-to-bottle recycling and in rPET inline applications. Something we have proven with our leading VACUREMA® and VACUNITE® Systems, that worldwide processes more than 1.2 million tonnes of PET to rPET every year.

The EREMA technology ensures that the quality of your end product not only is - but also stays - consistently high. And they stay stable even if the properties of your input material change all the time – for example in terms of moisture and bulk density or IV values. That is what we mean with flexibility.

PET bottle flakes

HDPE bottle flakes

Special materials

-

MAKING SOMETHING NEW, MADE EASY.

Partner for efficient special recycling applications.

We search for solutions for you. Day after day. And we find them. For your recycling requirements today. And for those of tomorrow. Even if you are talking about complex special applications such as in the fields of automotive, compounding, bioplastics and wood-plastic composites (WPC).

What motivates us? Pioneering spirit, our more than 30 years' experience in finding solutions in plastics recycling, and our passion for taking on brave new challenges. That is why we can offer you the decisive competitive edge for your specific special application.

Regrind material, automotive

Recycling and compounding

Recycling and compounding

Bioplastics: PLA

WPC