- Offer Profile

-

HELLER is a global manufacturer of 4- and 5-axis CNC machining centres, flexible manufacturing systems and crankshaft and camshaft machines and employs a staff of around 2,470 people worldwide.

The company is headquartered in Nürtingen in the Stuttgart region. The company's customers come from a variety of industries including automotive manufacturers and their suppliers, machine building industry, contract manufacturers, power engineering, mould and die manufacturers as well as aerospace companies.

HELLER

New Products

HELLER Tokn

-

Tokn is the worlds first proprietary 5-axis training machine tool equipped with high end components to give young generations an opportunity to experience the world of machine tools and actively improve it.

- 5-axis machine concept

- Siemens SINUMERIK ONE Control Unit

- mobile and adjustable Control Unit

- 200mm stroke

- speed up to 15m/min in 3 axes

- Tilting Table with +30° to -120° A-Axis and 360° B-Axis

- HELLER Spindle (max. 9,000 rpm / 2.75 Nm)

- integrated illumination and tool storage

- fully mobile plug and play construction

- MADE BY HELLER

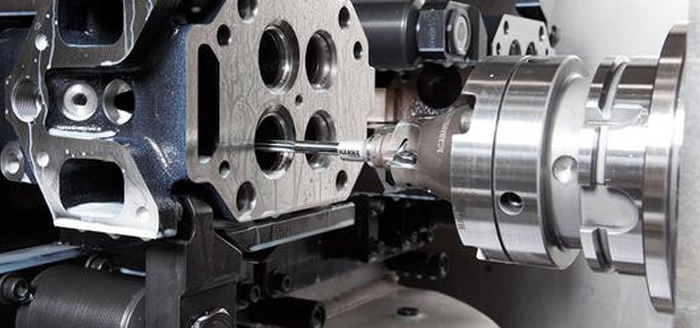

WH 10000 - Parallel processing from two sides

-

The WH 10000 is a horizontal 5-axis machining center for large aluminum castings. Based on HELLER standard components and Wenzler kinematics, the WH 10000 is the ideal machining center for extremely large die-cast aluminum structural parts.

The design of the WH 10000 offers decisive advantages for the machining process of large aluminum structural components. Two linear 3-axis units face each other on one machine bed. The centered workpiece is located on a horizontal swivel axis (A-axis) and can be machined from both sides simultaneously in double-spindle mode in a single clamping operation. Each linear unit is equipped with a 5-axis milling head with two NC rotary axes per head.

5-axis machining centres F 5000-8000

- With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

HELLER state-of-the-art machine tools and production system

-

More than just machine tools

HELLER is synonymous with state-of-the-art CNC machine tools and manufacturing systems for metal-cutting machining. The broad HELLER product range comprises 4- and 5-axis machining centres, milling/turning machining centres, custom machines and process machines, coating modules, as well as machines for crankshaft and camshaft machining.

With HELLER4Industry and HELLER4Use, we offer our customers an extended range of solutions to achieve increased productivity and flexibility in production.

From this range, HELLER generates customer-oriented complete solutions – from the stand-alone machine to the fully-automated turnkey production system.

5-axis machining centres HF

-

Productivity in 5 axes: 5-axis machining centres with the 5th axis in the workpiece for dynamic and productive machining

HF-series 5-axis machining centres are designed for robust processes. Thanks to 5-side machining and simultaneous 5-axis machining, you perform a number of jobs on just one machine. Highly productive and flexible, easy to operate and maintain, with table loading or with pallet changer: the HF series is optimally-equipped for the tough demands of modern production processes. The ideal machining centre for complex workpieces. With a HF machine from HELLER, you have taken a sound decision and benefit from both productivity and availability – from the very first minute.

4-axis machining centres H

-

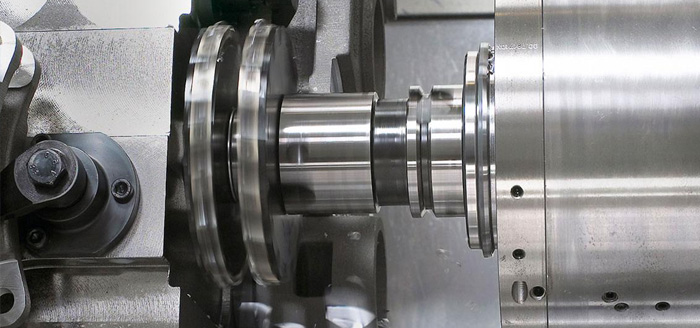

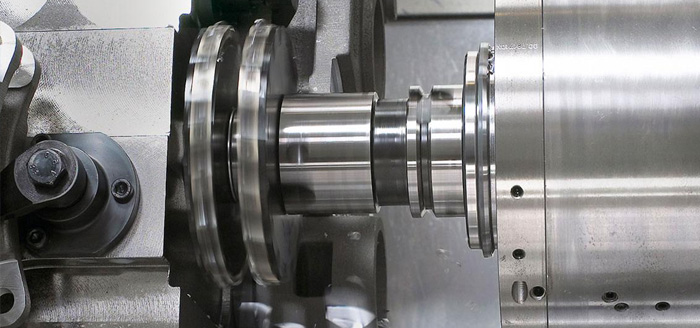

Tailor-made off the peg: flexibly configurable 4-axis machining centres with unbeatable productivity and unparalleled resilience

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centres. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes – even at their limits, seven days a week in 3-shift operations.

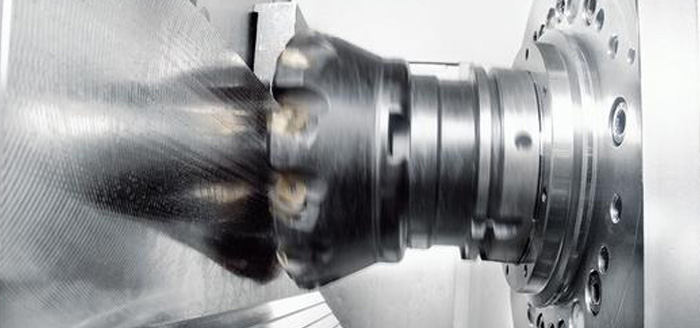

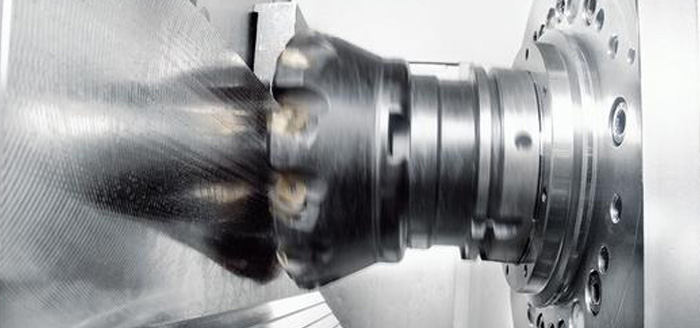

5-axis machining centres F 5000-8000

-

Designed for Production: The new generation of 5-axis machining centres F sets a new benchmark for cutting performance and precision

With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

4-/5-axis machining centres MC 20

-

Conversion artist for flexible manufacturing systems: modular 4-/5-axis machining centres for direct loading in the light-duty automotive sector

Our modular 4- or 5-axis machining centres MC 20 are optimally suited for integration into flexible manufacturing systems and for the efficient series production of light-duty vehicle components. These powerful machining centres are so versatile that they can be configured for specialised tasks in any production system. They score in the line with the typical HELLER attributes: Extreme reliability, minimum chip-to-chip times, fast tool change, highly precise results.

Custom machines and process machines

-

Highly productive series manufacture of light-duty to heavy-duty automotive components

When it comes to maximum productivity and special challenges in the automotive sector, HELLER offers custom and process machines for the various production tasks. The existing MC 20 4-/5-axis machining centres are complemented by other machines, such as direct loading machines, process modules or the robust 4-axis machining centres with automatic MPC 10000 head changer. HELLER offers the TRS modular transfer systems, a powerful customised solution for producing high volumes. VKM/VPM 5-axis machining centres are available for the series production of lightweight structural and body parts

.

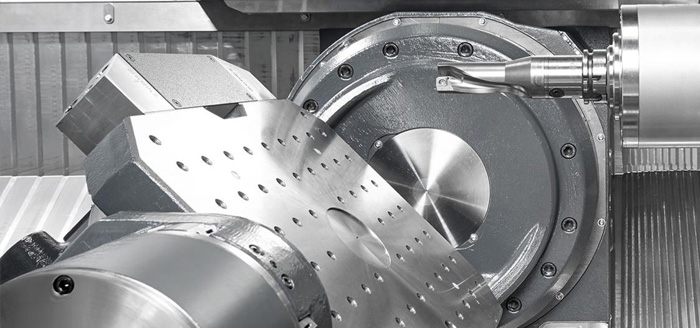

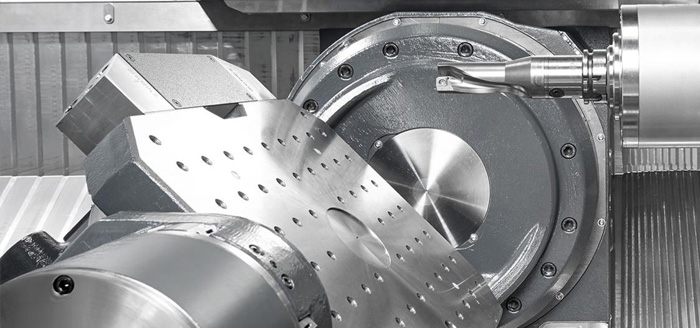

5-axis machining centres F 10000-16000

-

Solid machine construction, sound process experience, a wealth of milling expertise – these are the basic ingredients for our F series 5-axis machining centres. The benefits to you are obvious: 5-axis machining with maximum output and top quality, even during continuous operation. The HELLER F-series 5-axis machining centre is the right choice for anyone wanting to perform numerous functions on one machine and produce reliably, not just today but in the future too.

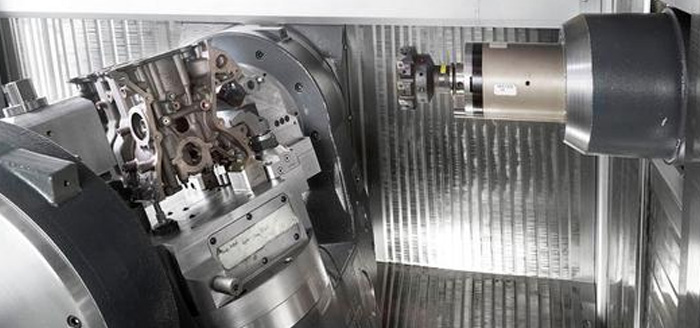

4-axis machining centres MPC 10000

-

HELLER MPC 10000 4-axis machining centres are optimally suited for integration into flexible manufacturing systems and for the efficient series production of heavy-duty vehicle components. The one thing that's needed is: power. Wherever machining centres have to work to their limit, MPC 10000 4-axis machining centres are within their comfort zone. Extremely high feed forces ensure performance and the special machine concept guarantees stability with maximum precision. The automatic head changer also achieves maximum flexibility in production.

Transfer line systems TRS

-

HELLER offers the TRS modular transfer line system, an efficient special solution for high volumes in the series manufacture of light-duty to heavy-duty automotive components. Available as stand-alone machines and as transfer lines with integrated workpiece transport system for the cyclical transport of workpieces from one station to another. Dedicated for special applications, HELLER TRS transfer line systems are always optimally tailored to the requirements of the workpiece type to be produced and to the machining operation.

5-axis machining centres VKM/VPM

-

The VKM/VPM 5-axis machining centres are vertical machining centres for the complete machining of lightweight structural components (VKM) and body parts (VPM) in the automotive industry. Lightweight construction is one of the key areas of modern industrial production. Reducing weight and achieving high strength at the same time is a typical requirement for structural components and body parts. To be able to offer our customers a powerful and reliable solution in lightweight construction too, we have expanded our product range by the VKM and VPM 5-axis machining centres.

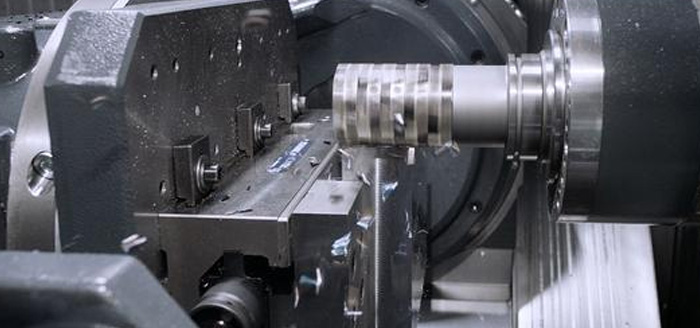

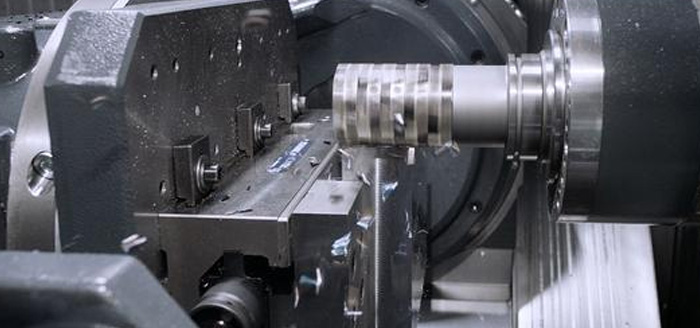

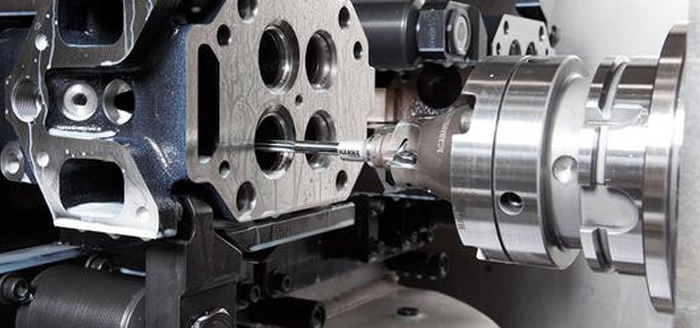

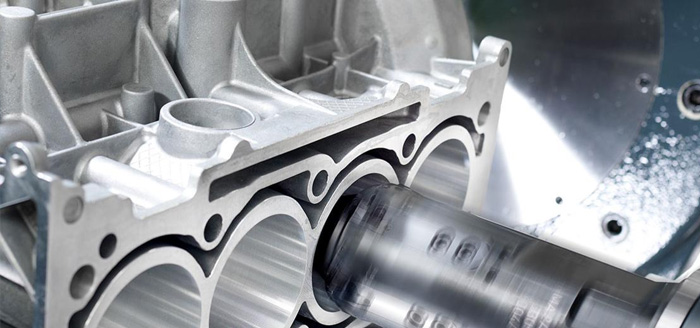

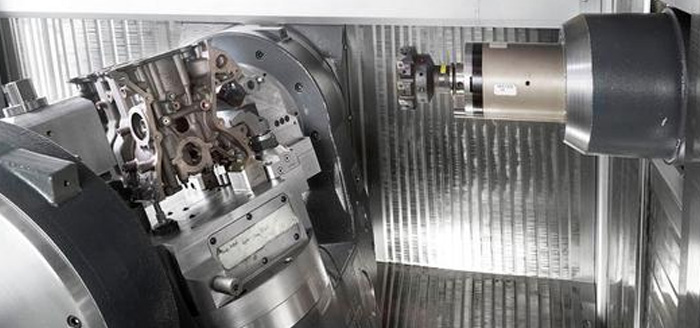

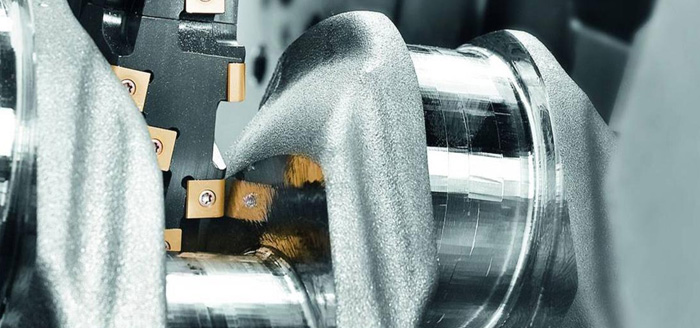

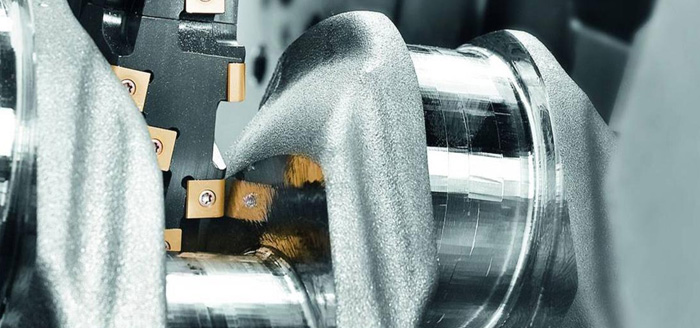

Crankshaft/camshaft production systems RFK/DRZ/MCC 15/RFN

-

Crankshaft/camshaft production systems for the flexible complete machining of crankshafts and camshafts – as a stand-alone machine or interlinked production system.

As a system supplier to the automotive industry, HELLER develops manufacturing solutions for the flexible complete machining of crankshafts and camshafts. We are one of the few suppliers worldwide that has extensive experience across the entire process chain. The HELLER RFK/DRZ/MCC 15/RFN production systems and various machining centres offer the core processes for pre-machining crankshafts and camshafts. These efficient custom machines can be equipped as a stand-alone solution or as interlinked individual machines within a manufacturing system.

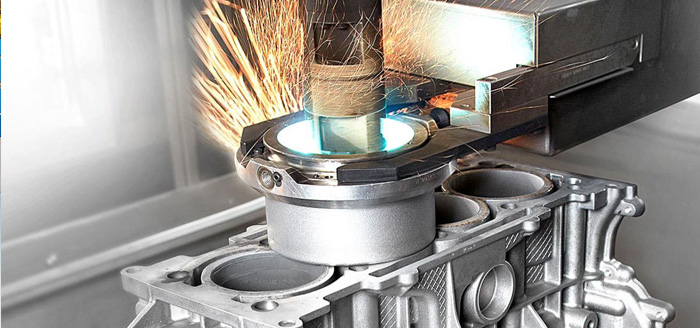

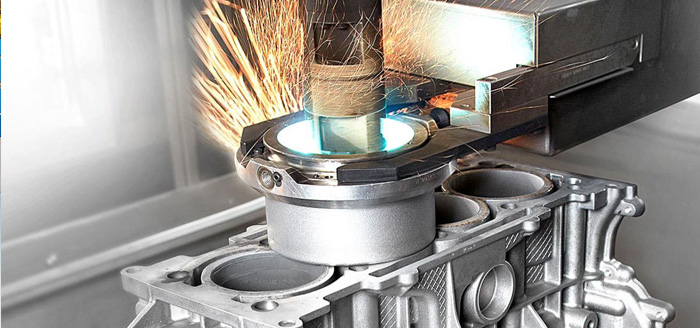

Coating modules CBC 200

-

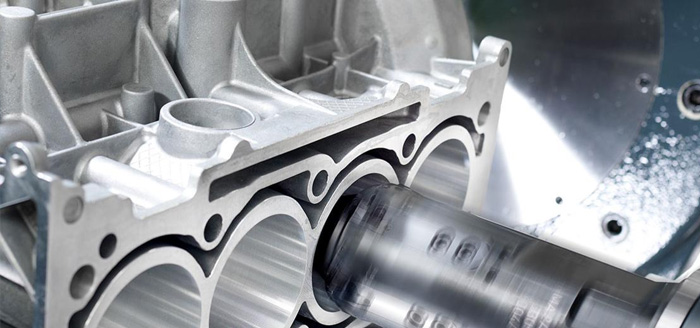

Series production coating of cylinder bores using CBC technology (CylinderBoreCoating)

CBC 200 HELLER coating modules are used for coating cylinder bores in aluminium crankcases using CBC technology (CylinderBoreCoating). The CBC thermal coating process, developed in cooperation with Daimler, is based on LDS two-wire technology and is the only process that can be used for higher production volumes. HELLER CBC, therefore, is expanding our process chain in crankcase production by a crucial operation. As flexible as you like – as a bypass solution or a precisely tailored manufacturing concept.