ANGER MACHINING

Videos

Loading the player ...

- Offer Profile

- ANGER systems are perfectly suited for solving production challenges from demand of scalable productivity, lower life cycle cost, demand of flexibility, to requirement of precision and volume. Leading automotive companies such as Chrysler, Daimler, VW, ZF, Magna and many more rely on ANGER technology.

Product Portfolio

Machines

ANGER SP SERIES

-

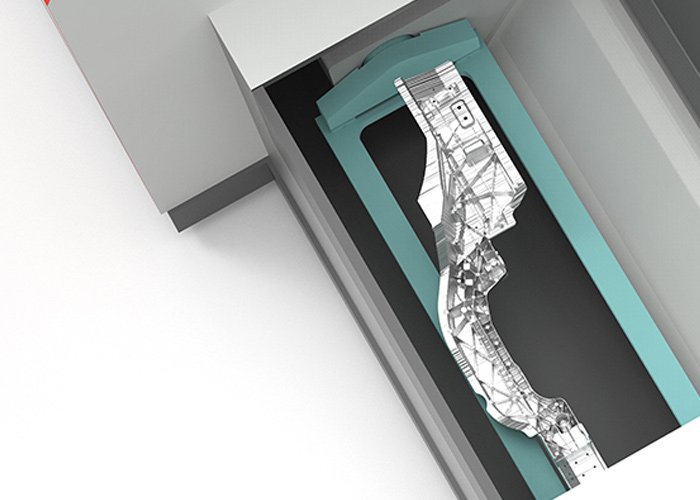

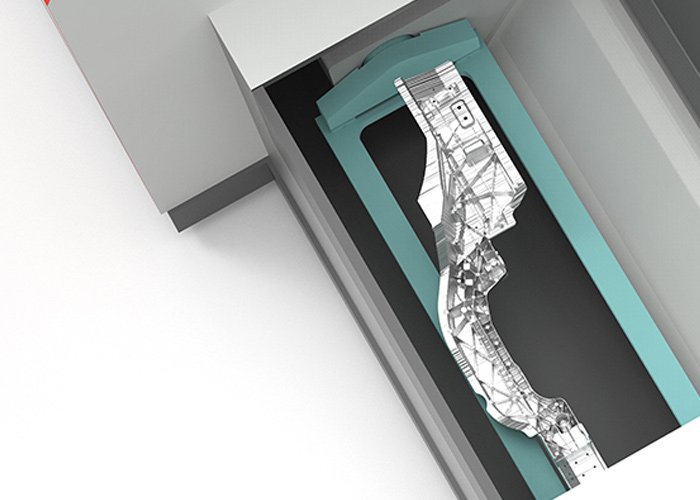

Machining solutions for the structural part and E-architectures

The ANGER SP machine is a machining center for the 5-axis processing in big volume of structural parts e.g. longitudinal beam, cross beam, profile part, battery tray, subframe or others. The modular concept from singel- / double spindle machine, different solutions and loading, as well as clamping concepts ensure you the optimized solution and 100% flexibility.

YOUR ADVANTAGES- double machining for parts up to max. 1000x3300mm

- flexible 5-axis machining

- bigger working area

- one or two independent machining units

- easy and quick loading and unloading with pallet changer

- ideal for battery trays, longitudinal beams, A/B-pillar, profile parts

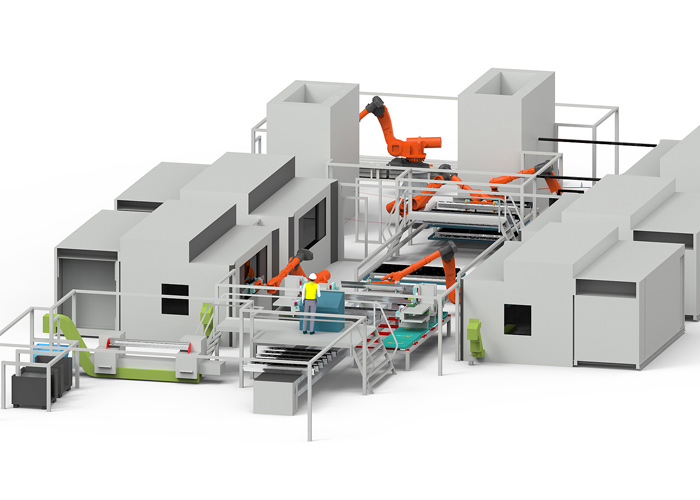

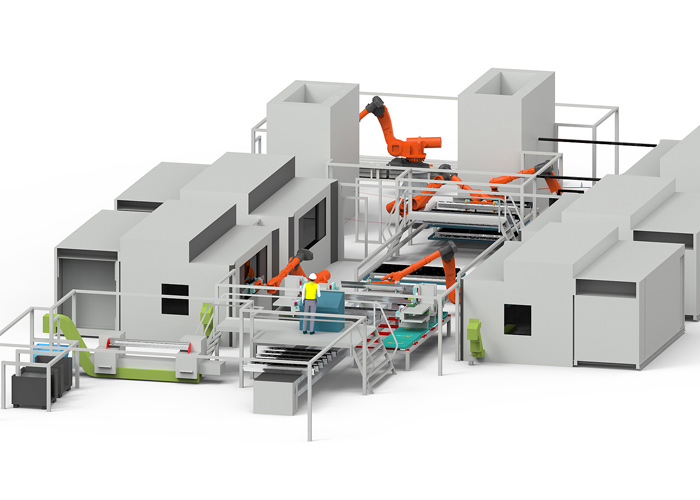

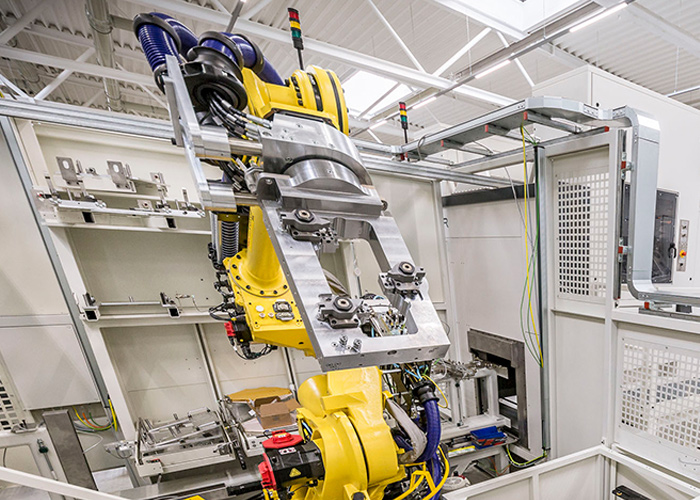

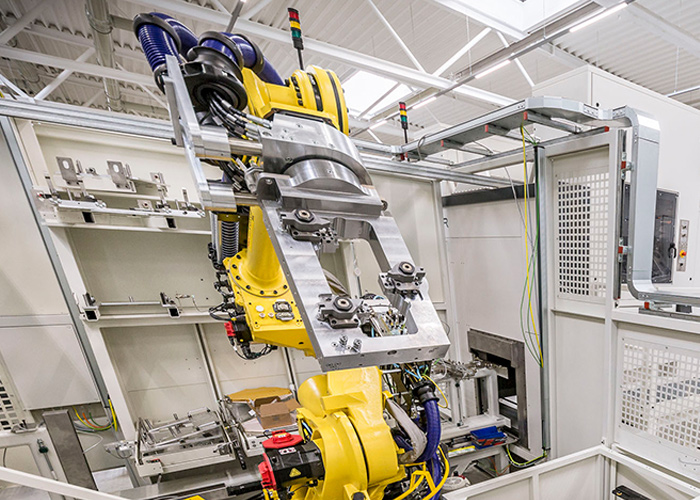

FLEXIBLE AUTOMATION, OPTIMAL INTEGRATION

From machining, automation to cleaning and measuring, ANGER takes care of optimal integration of several different machining technologies in a complete process for you.- main time parallel loading and unloading

- part pickup from the box: raw part intake and finished part deposit

- part recognition with camera

- DMC writing and reading

- sawing

- additional part cleaning

- master computer interfacing

- plant linking

- punching

- fully automatic machines

- loading with robots or gantry system

- part examination

- assembly (insert nut, Helicoil, etc.)

- NIO- /Measuring part deposit slot

- laser marking

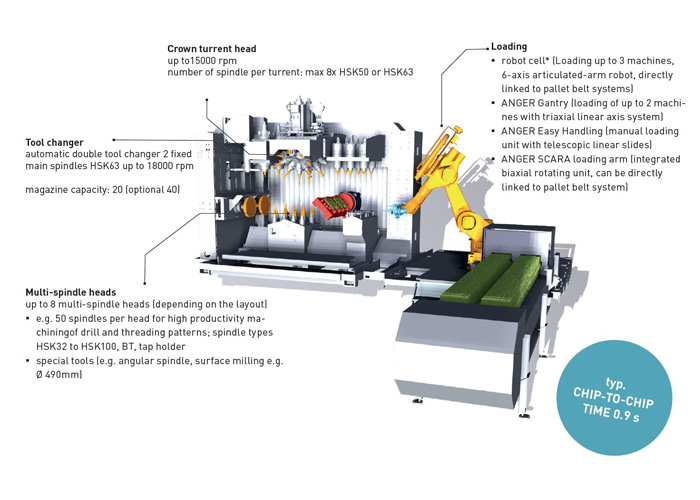

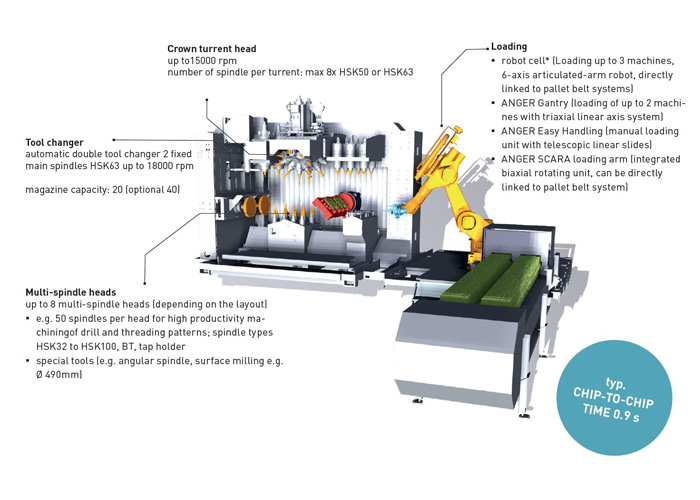

HCX

-

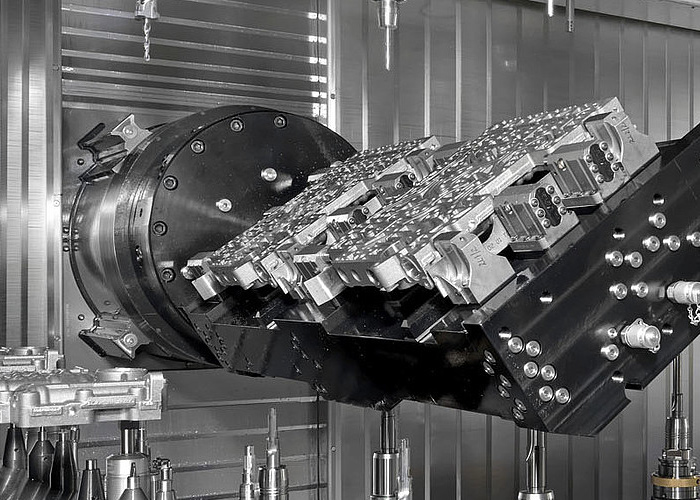

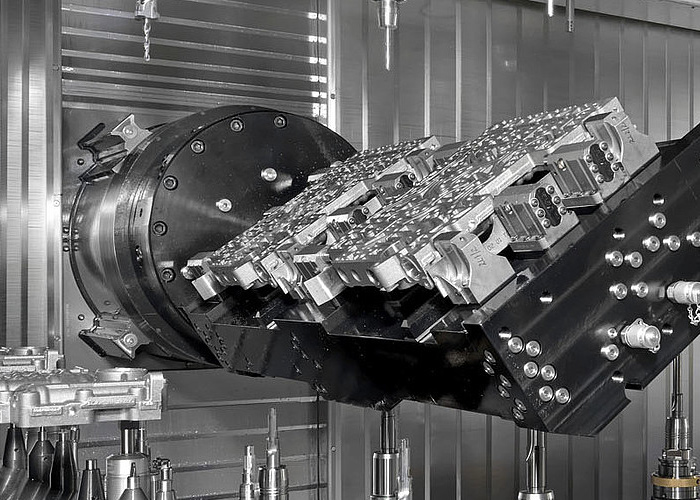

Part-specific transfer centers for high volume production

The ANGER HCX turnkey systems are tailored to the client's specific needs. The system is designed with specific parts, constructed and then programmed. As a result the highly productive HCX systems can achieve very short cycle times while achieving high accuracy. These systems are designed to be highly productive for the manufacture of large volumes.

One ANGER HCX machine can, depending on the complexity of the work piece, achieve a cycle time and production quantity equivalent to two double-spindle traditional machining centers. When compared with a single-spindle traditional machining center, the HCX can replace 4 and sometimes even 8 of them.

YOUR ADVANTAGES- Shortest chip-to-chip time guarantees the maximum production quantity

- Lowest TCO reduces your manufacturing costs

- Highest accuracy guarantees very high part-quality

- Longer spindle lifetime thanks to optimized processes

TECHNICAL SPECIFICATIONS

accuracy- repeatability acc. VDI 3441/2617 0.002 mm

spindle- speed project-dependent rpm

- power (S1/S6) project-dependent kW

- torque (S1/S6) project-dependent Nm

tool magazine- tool holder HSK63-A

- tool capacity* 2x 20 piece

- max. tool diameter 93 (125) mm

- tool length 350 mm

- tool weight 12 kg

- chip-to-chip time from 0.3 s

2PLUS

-

The Fastest Double Spindle Machine in the World

The new ANGER double spindle machine increases the productivity of your production thanks to two double tool changers and a clamping cycle time of 1.2 seconds. In pendulum operation, the workpiece is moved from one tool changer to the other. While one side is being machined, the tool is changed on the other, reducing non-productive time to a minimum.

Depending on the number of tool-change processes, the 2PLUS is up to 30 percent faster than a conventional double spindle machine. The ANGER 2PLUS can be used to great advantage especially for components with many different machining processes, which take a long time on a conventional machining center due to the multiple tool changes.

YOUR ADVANTAGES- Shortest chip-to-chip time guarantees the maximum production quantity

- Lowest TCO reduces your manufacturing costs

- Highest accuracy guarantees very high part-quality

- High flexibility allows easy changeover to other parts

TECHNICAL SPECIFICATIONS

accuracy- repeatability acc. VDI 3441/2617 0.002 mm

spindle- speed* 0-15000 rpm

- power (S1/S6) 26.4/26.4 kW

- torque (S1/S6) 84/110 Nm

tool magazine- tool holder* HSK63-A

- tool capacity* 4x20 piece

- max. tool diameter 93 (125) mm

- tool length 350 mm

- tool weight 12 kg

- chip-to-chip time at 1800 rpm from 0.65 s

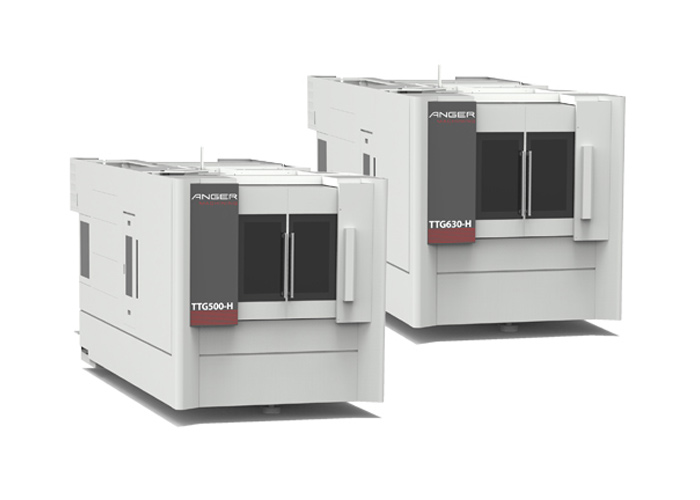

TTG500-H / TTG630-H

-

the cost-effective single spindle horizontal machining center

The TTG500-H and TTG630-H are 4-axis single spindle horizontal machining centers. The machine is optimized with an automatic pallet changer system as an option. Machine is designed for high accuracy, high rigidity and high power machining.

YOUR ADVANTAGES- Specially designed for easy use of pallets

- Automatic pallet changer increases your productivity

- Small installation area reduces floor space

- Efficient drives reduce your energy costs

TECHNICAL SPECIFICATIONS TTG500-H - TTG630-H

accuracy- positioning accuracy acc.VDI 3441/2617 0.006 - 0.006 mm

- repeatability acc. VDI 3441/2617 0.002 - 0.002 mm

spindle- speed 0-18000 - 0-18000 rpm

- power (S1/S6) 30/50 - 30/50 kW

- torque (S1/S6) 45/80 - 45/80 Nm

tool magazine- tool holder HSK63-A - HSK63-A

- tool capacity* 40 - 40 piece

- max. tool diameter 170 - 170 mm

- tool length* 550 - 550 mm

- tool weight* 8 - 8 kg

Solutions

TRANSFER CENTER ADVANTAGES

-

a single transfer center can replace multiple machining centers

In a traditional machining center, the work piece is clamped in a fixed position and the tool is loaded for machining by the tool changer in the main spindle. By contrast, in a transfer center the components can be (milled, drilled, threaded etc.) processed with just one set-up. The processing method of the work piece is therefore the opposite than in a traditional machining center. Work pieces are automatically clamped into position and are then moved, controlled by the CNC, from one tool to another. By this process, multiple work pieces are often machined simultaneously.

It thereby also reduces floor space, energy, servicing and labor requirements. The total costs (TCO) can be reduced significantly with this technology. With fixed-position spindles and by implementing special tools, you can achieve the highest levels of accuracy.

SMART PRODUCTION

flexible production of small quantity with optimized conversion time

ANGER MACHINING has developed a solution that opens new possibilities for different workpieces with a lot sizes from 10.000 pieces. With ANGER 2PLUS, a new system concept was introduced to the market, which allows considerably greater variability. It allows the flexible production of small quantity with a significantly reduced conversion time thanks to the innovative "SmartFix" zero point clamping system

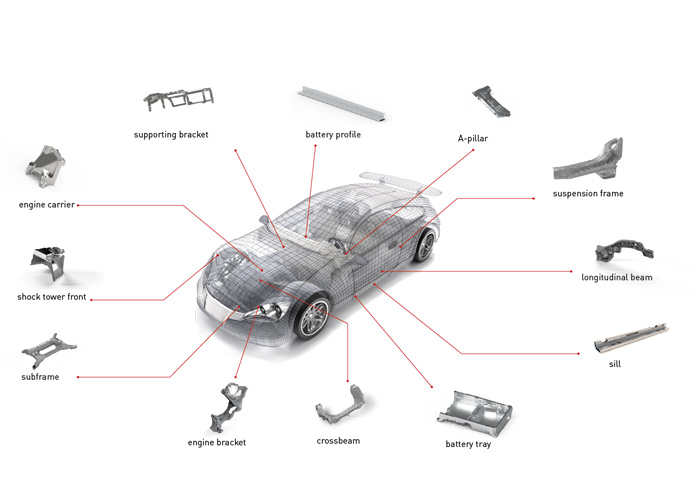

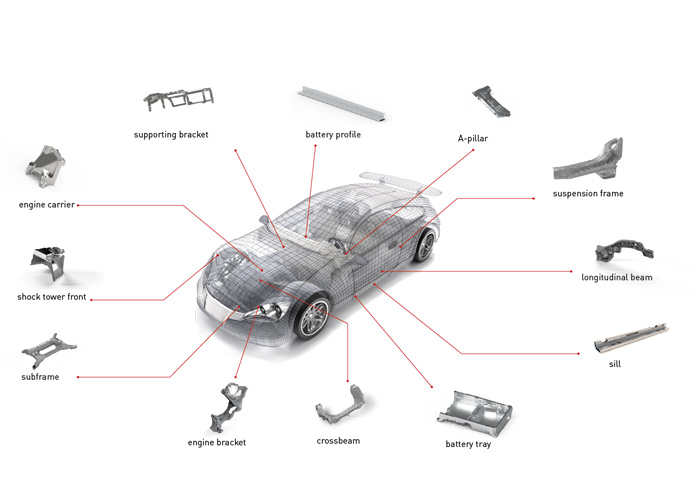

ABOUT STRUCTURAL PARTS

-

Increasingly intensified environmental requirements have a great impact on the development of new vehicles architecture. The manufacturers have to develop ever smaller and more efficient engines and have to drive the vehicle weight further downwards without losing the weight or the quality. In this lightweight construction, more and more aluminum is used as a material. On the other hand, composite materials are used.

Currently, an average of 140kg of aluminum is built in one vehicle. According to current development, within 5 years, this proportion will increase to over 30%.

CHALLENGE OF MANUFACTURING STRUCTURAL PARTS

Big parts such as longitudinal beam or battery tray are too big for standar machines nowadays.

Integration of new machining technologies in the process chain.

The processing machines currently available on the market are therefore unnecessarily precise for the processing.

SMART PRODUCTION

-

"smart" conversion in cycle time

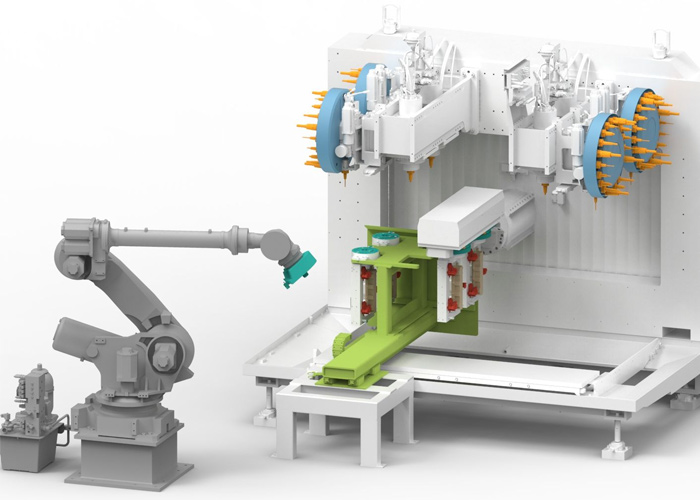

Industry 4.0, smart production, digitalization – no matter how we call it, eventually it is always about seamless connection of the digital and the real world. Digitally connected processes in the industry 4.0 enable the products to be manufactured more flexibly, energy efficiently, individually and cheaply. This also results in totally new possibilities in the field of machine tool. However, the basic principle of cutting machines can hardly be changed due to the physical limits.

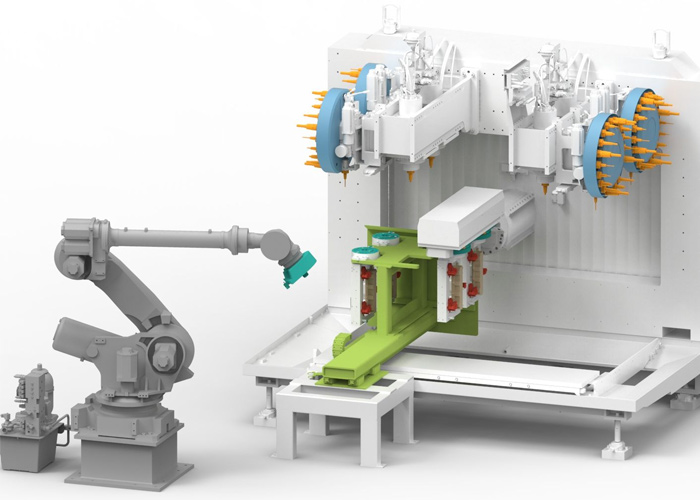

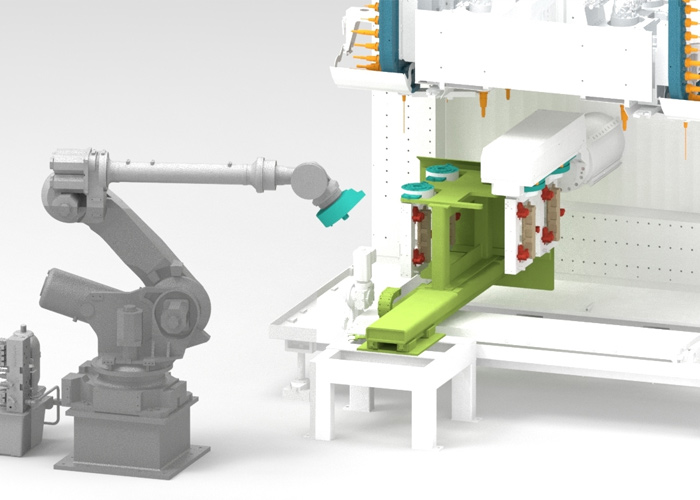

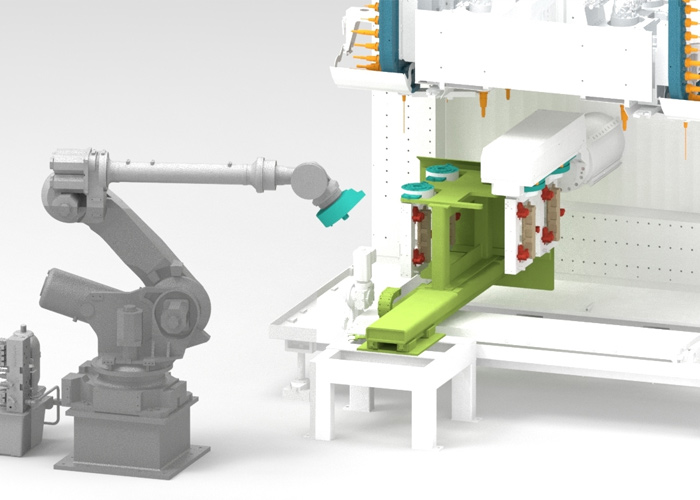

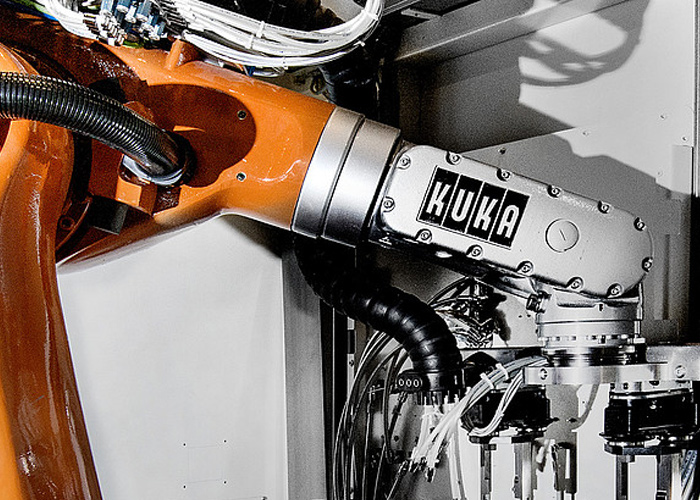

The focus is on the integrated view of the automated production cell. ANGER MACHINING has identified the major challenges for the cost-effective operation of these cells (robot, machine tool, storage): cost-effective production of a variety of series – the typical challenges of many OEMs, T1, T2, and SME factories dealing with the machining of the serial parts. In many cases, changeover processes during the workpiece changing are very tiresome and cost-intensive. Due to lack of specialists, the necessary expertise is missing.

ANGER MACHINING has developed a solution that opens new possibilities for different workpieces with a lot sizes from 10,000 pieces. With ANGER 2PLUS, a new system concept was introduced to the market, which allows considerably greater variability. It not only allows the flexible production of smaller batches but also the production in chaotic workpiece sequence, with minimum changeover time and without any intervention of a person.

The intelligent system uses all the information about the process: the workpieces are tracked via QR-Code and tool and clamping data are transmitted by RFID chips. The robot, which takes over the handling, has the same standardized interface as the processing machine. It takes up the clamping device, takes the raw part, and hands it over to the loading shuttle of the machine in the clamped state.

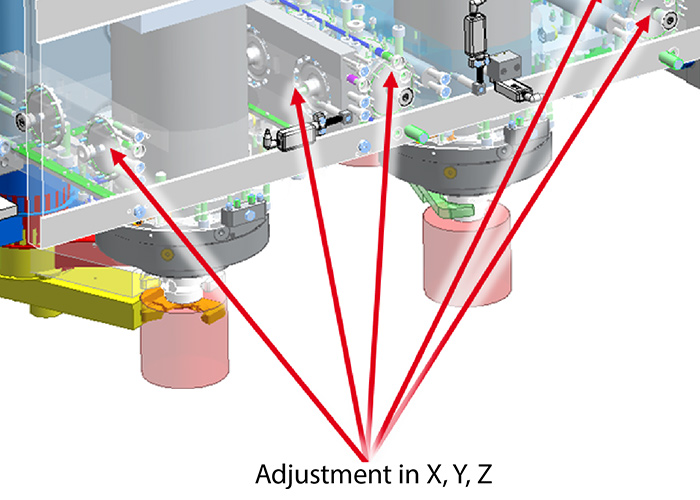

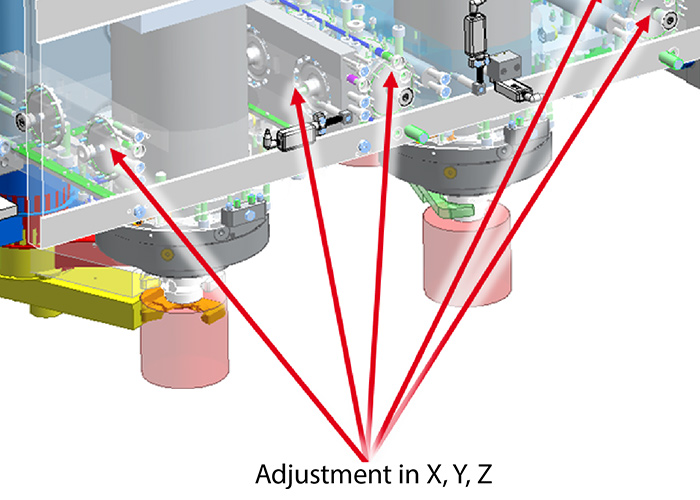

The system works fully automated and adapts the data corresponding to the entire process of the next components to the master computer system. Depending on the component type to be manufactured, the right clamping devices, tools, and even the machining spindles of the two component nests in the cutting machine are adapted thanks to automatic micro fine-adjustment.

The ANGER MACHINING solutions achieve an extremely low chip-to-chip time of about one second between the processing steps. Such record-breaking values reduce downtime to minimum. In combination with a continuous networked process, high profitability is achieved with full flexibility.

SMARTFIX

-

innovative loading method

When machining different parts in the past, it was always necessary to replace the robot gripper with each specific clamping fixture. ANGER is set to change that situation, however, and bring complete flexibility to production with its new "Industry 4.0-type" loading concept. A universal robot arm & machine table interface makes it possible to machine different parts or operations in one machine (e.g. pre-machining or fine machining) without the need for manual retooling or conversion.

The new ANGER clamping fixtures SmartFix are fitted with a universal interface. On the robot, the clamping fixture also becomes the gripper that picks up the raw parts and hand over the Smartfix to the machine by the use of a loading shuttle.

INDUSTRY 4.0

ENSURING THE FLEXIBILITY TO ACCOMMODATE VARYING QUANTITIES OR CHANGES TO PARTS

"Changeover" to other parts is fully autonomous and does not require any form of manual intervention whatsoever. This means not only that conversion (retooling) can be done during the machine's cycle (e.g. "chaos operations"), but also that any subsequent changes made to the part will only affect the clamping fixture for the part in question. New parts only need one tool change.

TECHNICAL SPECIFICATION- 4- and 5-axis machining possible

- Clamping system repeatability: 5 μ process capability

- Total pallet weight: up to 150 kg

TCO SAVING

-

Your maintenance cost is only 1.72%!

Taking the whole product life cycle into consideration, ANGER MACHINING systems score well with its total costs (TCO) in many application areas, which are by far the lowest compared with other solutions. Because of the usage of the different machining modules combined with the customer fitted automation, the result is a perfect system.

The lower total costs (TCO) are thanks to:- lower per unit costs due to high productivity

- high process capability and capacity

- and low running costs

TCO ANALYSIS- Your maintenance cost is so low

- 6 ANGER HCX machines incl. 3 robot cells for a total automatic loading and transport belt with automatic part-feeding.

AUTOMATION

-

ANGER MACHINING automation systems enables you to increase the productivity of you production systems. We supply our customers for the increasing demands regarding quality requirements and of course the increased amount of processes on one single part. ANGER MACHINING is taking care of peripheral applications of part tracking, mounting, handling, washing or other automation steps. Flexibility is one essential point of interest in our system design regarding the shortened interval of part changes and part production time.

MACHINE CHAIN LINKING

Automation of handling process by use of:- articulated robots

- gantry systems

- pallet Systems

- conveyor systems

PALLET SYSTEMS

Implementation of pallet system in the manufacturing system. This includes the logistics of the pallets as well as the control and management of the pallet system.