- Offer Profile

-

High process stability, extended plant effi ciency, longservice life—FLT develops, produces and installs intelligent automation solutions for customers worldwide. The expertise here lies in developing industrial applications for handling, transport and assembly sequences in the automotive, aerospace and general industry sectors. The product portfolio is designed to be modular, and in addition to standard components and axis- and gantry systems, also includes complete process cells and linked systems. For the best possible results, the integral parts are combined in a needs-oriented way to develop made-to-measure solutions that meet individual customer requirements.

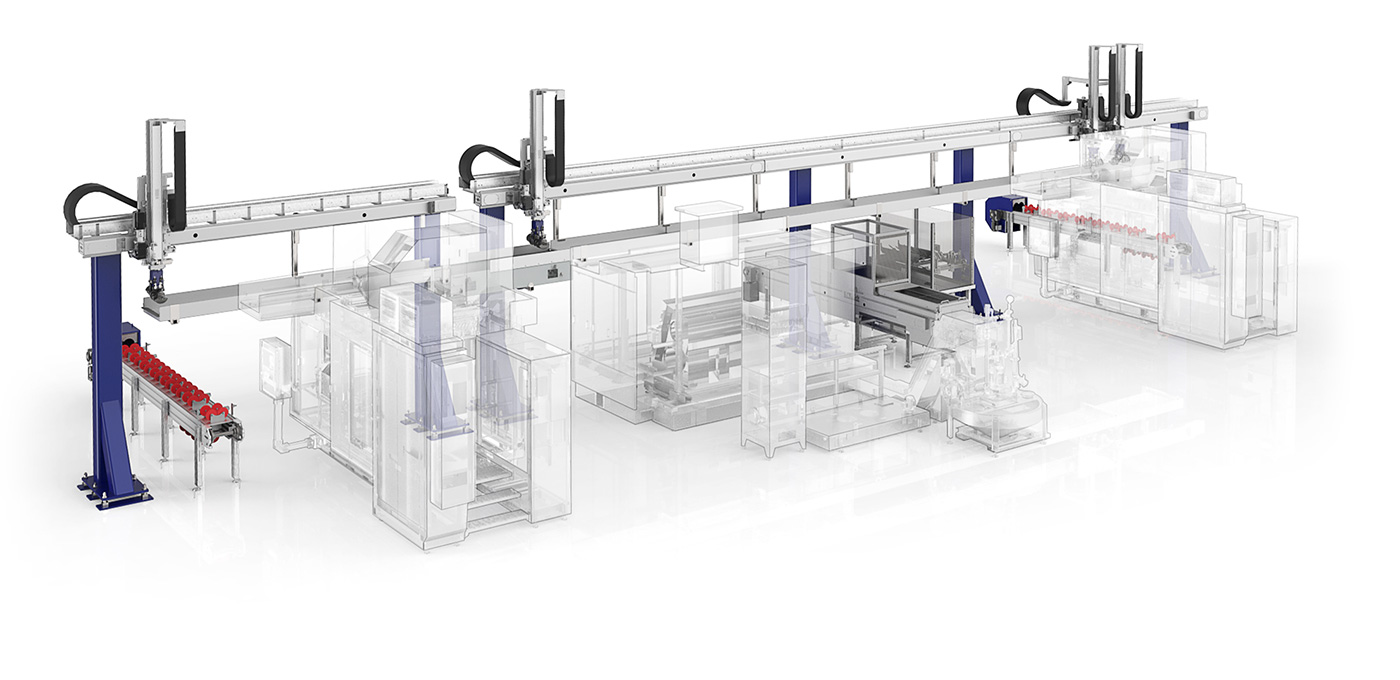

MODULAR AXIS AND GANTRY SYSTEM

-

Thanks to the modularity of the components, they can easily be used as a single-axis system or combined to create multi-axis systems. The basic unit of the systems is made up of linear axes with moveable carriages to which further axes, grippers or rotation units can be attached. This provides the greatest possible degree of flexibility depending on the design required.

This makes it possible to find the best solution for particularly heavy loads, long travel distances, or small workspaces, for example, depending on the requirements.

The modular FLT axis and gantry system therefore provides the perfect basis for applications relating to loading and unloading machines, processing centres and parts transfer as well as transporting fixtures, tools and processing systems, etc., within the fields of production and logistics.- A variety of sizes means loads up to 3000 kg are covered

- Dependent on type and load:

- horizontal travel paths over 100 m and vertical strokes up to 3 m

- Speed and acceleration:

- horizontally up to 4.5 m/s – 6 m/s² and

- vertically up to 2 m/s – 4 m/s²

- With or without control

- Standalone solutions or inline integration

LVA

LINEAR VERTICAL AXIS- The linear vertical axis LVA is used as a stationary lifting device for workpieces or as an additional axis to increase flexibility in assembly and production. It allows a stroke of up to approx. 3 m and, with its aluminium and steel axes, can take a transport load of up to 1500 kg. Its components mean that the axis is not just flexible – it also enables exact positioning and the transmission of large forces.

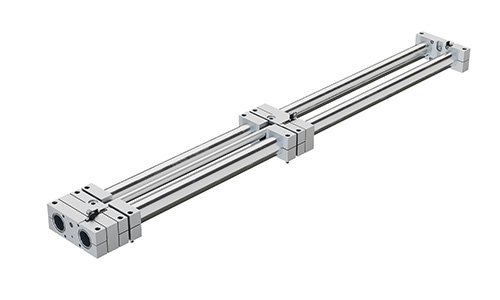

LHA

LINEAR HORIZONTAL AXIS- With a maximum total axis length of more than 100 m and a stroke of up to 40 m per carriage, the linear horizontal axis LHA is ideal for transporting and handling fixtures. It can be integrated into systems as an additional axis, is suitable for attaching further axes or can be used as the seventh axis for robots. It can also be mounted. Its flexibility, strength and accuracy set this axis apart. With its aluminium and steel axes, the LHA is able to take a transport load of up to 1600 kg.

LFA

LINEAR FLOOR AXIS- The linear floor axis LFA is ideal as a seventh axis for robots or for transporting fixtures using floor positioning units. Its strength, accuracy and flexibility set it apart. This is primarily down to its stroke of up to 40 m per carriage and a possible total length of max. 100 m. Its maximum transport load of up to 6000 kg is possible due to the aluminium and steel axes. The LFA is also available in a separate drive module and transport carriage version.

LGR

LINEAR GANTRY ROBOT- With its two axes, the linear gantry robot LGR is ideal for loading and unloading machines and fixtures, as well as handling components between different stations. The system, made up of aluminium and steel axes, can transport loads of up to 1500 kg and has a stroke of up to 40 m per carriage. The total length of the robot axis is up to 100 m.

AGR

AREA GANTRY ROBOT- With its three axes, the area gantry robot AGR is ideal for covering large working areas, particularly in intralogistics and for loading large machines. This is primarily down to the potential span of approx. 12 m and stroke of up to 60 m. The maximum transport load of the axes is 3000 kg.

AGC

AREA GANTRY CANTILEVER- The area gantry cantilever AGC is ideal for handling and transporting workpieces and pallets in a compact installation space. The AGC provides a stroke of up to 40 m for cross arms of up to approx. 3 m. The system, made up of aluminium and steel axes, can transport loads of up to 600 kg.

LINKED SYSTEMS

-

Thanks to intelligent system interlinking, FLT connects different processes and machining stages of workpieces. This means that output can be increased, quality raised, capacities adjusted flexibly and the level of automation expanded.

When it comes to using technology to link individual production process stages, FLT utilises its product, solutions and process expertise to configure the individual requirements of the relevant applications. In the process, we combine all individual modules and system components in the most effective way possible to create a complete system.

Here, customers benefit from a wide range of services from a company that is able to offer both individual components and turnkey systems.

- Two or more gantries operating in sync

- With or without control

- Including all peripheral technology

- Individual interlinks or complete system options

- Product is fully developed in-house: project management,

- design and simulation, control technology and commissioning

- Can be delivered as a complete package, including CE markings, safety technology and legal protection

PROCESS CELLS

-

Virtually all sectors of industry demand custom solutions for creating

automated processes using robot technology. FLT responds to these demands in

production with process cells. These have a modular design with space-saving

configuration options and offer flexible solutions for assembly processes.

Optimum solutions for complex conceptual formulations can be created via custom programming. The different process sequences are interlinked via the processing stations.

The FLT process cells can be used as flexible standalone cells or integrated into an inline system.- Maximum flexibility

- Including control and technology processes

- Customer-specific solutions

- Wide-ranging expertise for a large number of processes

- Numerous applications can be integrated

- Spot applications

- Path applications

- Measurement applications

MECHANICAL COMPONENTS

STANDARDISED MODULES FOR INDIVIDUAL SOLUTIONS

-

We offer carefully conceived, individually designable module solutions for automation in a wide variety of industries. Transport and logistics as well as assembly and handling are the most important areas of application.

Our modules for translation, rotation and gripping can be used as individual modules or combined in a wide variety of ways to form a host of devices and systems  from simple pick-&-place units to multi-axis robots. The modules are available either with or without electrical, pneumatic or hydraulic installation.

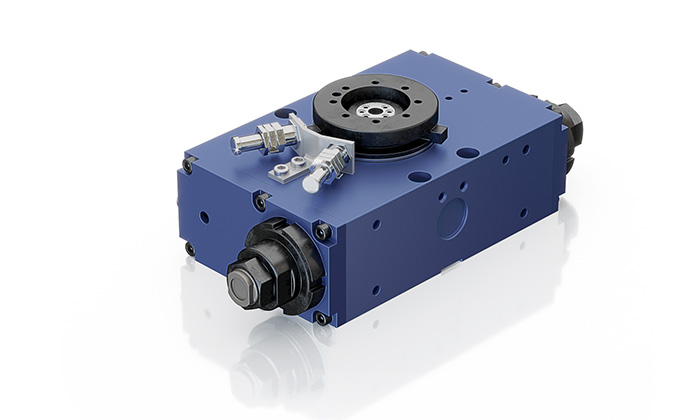

ROTATION MODULES

-

Our high-performance rotation modules for pneumatic, hydraulic and electrical applications offer a high level of quality.

The electrical modules are normally driven by servomotors, achieving high performance levels with high acceleration and speed and optimum positioning accuracy.

The pneumatic rotation modules offer a compact, integrated damping system that permits optimum end position damping to be achieved with a short cycle time in just a few steps.

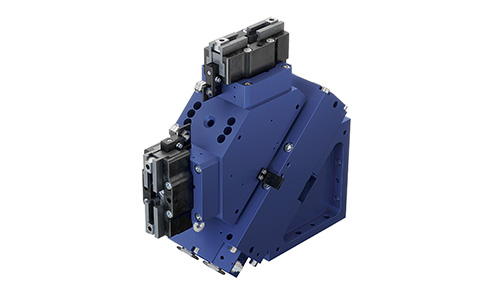

GRIPPERS

-

Our comprehensive standard range of parallel and angle grippers features high product quality and precision.

The series feature optimum grading and include a wide range of sizes for transporting workpieces with weights of up to 440 kg.

For rapid tool changeover, we also offer a pivoting twin gripper with two integrated gripper modules in an angled layout, combined with a rotation module with rotary union.

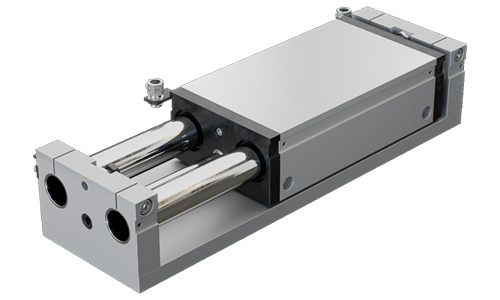

LINEAR MODULES

-

We offer a range of high-performance, compact modules such as short-stroke modules and translation modules for loading and unloading machines and for use in assembly areas as well as linear axes.

These are driven either hydraulically and pneumatically via a cylinder with end position damping or electrically via servomotors.

This design ensures optimum speed and positioning accuracy.

AFTERSALES SERVICES

-

FOR THE ENTIRE PRODUCT LIFE CYCLE

Our service team ensures that FLT modules and systems always provide maximum performance. Whether you need expert advice over the phone, spare parts in a hurry, or installation support on-site, FLTÂs service technicians are ready to help with their knowledge, quick response times and reliability. If you need us, weÂll be at your side with our comprehensive range of services.

Telephone hotline

- Our telephone hotline means that we are here if you have any queries relating to our production systems.

Repairs

- Our service personnel are on hand worldwide and can quickly be on-site for repairs.

Spare parts

- We keep supplies of standard spare parts on hand in our spare parts warehouse, meaning we can offer you high levels of availability and a speedy spare parts service.

Commissioning

- During the construction process, we offer services tailored specifically to your needs. All our systems are built and commissioned by our specialist personnel. In the process, we provide high-quality instruction for your personnel at an early stage.

Production supervision

- To ensure high system availability, we provide an additional start-up supervision service. Your system operators are trained in the plant technology so that they can respond quickly and appropriately in the event of a fault.

Training courses

- We offer individual training concepts on-site at your location or at the FLT site so that your employees are properly prepared for actual use.

Inspection

- We test and monitor your systems in line with the relevant directives and guidelines and analyse their condition, thus avoiding production downtimes.

Maintenance

- We offer you comprehensive, individually customised maintenance concepts for your production plant.

Retrofitting and conversions

- We provide concepts for modernising or expanding your existing systems and implement them accordingly. If there are changes in production, we are also happy to help with relocating or rebuilding your systems.