Harvard Biodesign Lab

Videos

Loading the player ...

- Offer Profile

- The Harvard Biodesign Lab brings together researchers from the engineering, industrial design, medical, and business communities to develop technologies for smart medical devices. These technologies are inspired by the results of experiments in human biomechanics and their development is influenced by time spent in the operating room to understand the unmet needs from clinicians. Lab members work closely with the Wyss Institute's industrial partners and technical experts to translate these technologies into products that meet real-world medical needs.

Product Portfolio

Soft Exosuits

- We are developing next generation soft wearable robots that use innovative textiles to provide a more conformal, unobtrusive and compliant means to interface to the human body. These robots will augment the capabilities of healthy individuals (e.g. improved walking efficiency) in addition to assisting those with muscle weakness or patients who suffer from physical or neurological disorders. As compared to a traditional exoskeleton, these systems have several advantages: the wearer's joints are unconstrained by external rigid structures, and the worn part of the suit is extremely light. These properties minimize the suit's unintentional interference with the body's natural biomechanics and allow for more synergistic interaction with the wearer.

Structured functional textiles

- We are creating innovative textiles that are inspired by an understanding of human biomechanics and anatomy. These wearable garments provide means to transmit assistive torques to a wearer’s joints without the use of rigid external structures. In order to obtain high-performance soft exosuits, some considerations should be taken into account in the design process. Exosuits should attach to the body securely and comfortably, and transmit forces over the body through beneficial paths such that biologically-appropriate moments are created at the joints. In addition, these garments can be designed to passively (with no active power) generate assistive forces due to the natural movement of the wear for particular tasks. A key feature of exosuits is that if the actuated segments are extended, the suit length can increase so that the entire suit is slack, at which point wearing an exosuit feels like wearing a pair of pants and does not restrict the wearer whatsoever.

Lightweight and efficient actuation

- In order to provide active assistance through the soft interface, we are developing a number of actuation platforms that can apply controlled forces to the wearer by attaching at anchoring points in the wearable garment. We are developing lightweight and fully portable systems and a key feature of our approach is that we minimize the distal mass that is attached to the wearer through more proximally mounted actuation systems and flexible transmissions that transmit power to the joints. While most of our recent work is on cable-driven electromechanical approaches, we have also pursued pneumatic based approaches. This early work with McKibbon actuators in 2013 was the first demonstration that a soft exosuit can have a positive effect on mobility.

Wearable sensors

- New sensor systems that are easy to integrate with textiles and soft components are required in order to properly control and evaluate soft exosuits. Rigid exoskeletons usually include sensors such as encoders or potentiometers in robotic joints that accurately track joint angles, but these technologies are not compatible with soft structures. Our approach is to design new sensors to measure human kinematics and suit-human interaction forces that are robust, compliant, cost effective, and offer easy integration into wearable garments. In addition, we use other off the shelf sensor technologies (e.g. gyro, pressure sensor, IMU) that can be used to detect key events in the gait cycle. These wearable sensors can be used as part of the control strategy for the wearable robot or alternatively to monitor and record the movement of the wearer (when wearing the exosuit or as a standalone sensor suit) for tracking changes over time or determining what activities they are performing (e.g. walking vs running).

Intuitive and robust control

- We are also developing rapidly reconfigurable multi-actuator systems that provide more flexibility for lab-based studies. Such an approach allows us to rapidly explore the basic science around human-machine interaction with such systems that can then be used to guide the design of our portable systems. A robust, intuitive and adaptive human-machine interface is a necessary component for a wearable robot to interact synergistically with the wearer. Our focus is to provide assistance in a manner that does not disrupt the natural, passive dynamics that make walking or running so efficient. To achieve this, we develop approaches to non-invasively estimate the intent so that any actuation applied assists that from the appropriate biological muscles. A key feature of our approach is to leverage integrated sensors that monitor the wearer interaction with the compliant textile that interfaces to the body as well as other sensors that detect key moment during the gait cycle.

Experimental biomechanics

- Our motion capture lab utilizes a Vicon T-series 9-camera system for motion capture, together with a Bertec fully instrumented split-belt treadmill to measure GRFs. By comparing the average profile and range of motion of each joint in the three conditions, we can identify how the soft exosuit itself impacts gait and how the assistance applied by the exosuit changes kinematics. Our hypothesis is that it is desirable that such changes are minimal and in any case not disruptive to natural gait. We study to what extent the active exosuit is assisting the human by analyzing gait dynamics and kinetics (joint moments, power, force delivered by the exosuit). Inverse dynamics is an effective way to determine to what degree the exosuit is augmenting the body function at a joint level. The comparison of joint moments and suit assistive forces allows us to monitor the degree of synchronicity between the user and the robot. Surface electromyography (sEMG) can be used to selectively monitor muscular activity focusing on the muscle groups that are most relevant for the task under consideration. Comparing the ensemble average profiles of sEMG activity between the unpowered, active and no suit conditions allows us to determine effects on the maximum force being delivered by each muscle (peak sEMG activation) and on the energy cost of each muscle activation (integral sEMG). We use the metabolic cost of walking as a global physiological measurement to determine to what extent the suit is assisting the wearer and if assistance offsets the weight of the device.

Translational applications

- In addition to our work on basic research and system development, we are highly interested in pursuing applications of our soft wearable robots. Through our DARPA funded work, we are interested in developing exosuits that can assist soldiers walking while carrying heavy loads. Our belief is we can create passive and active systems that offload the high forces in the muscles and tendons in the leg – thus reducing the risk of injury and increasing the walking efficiency of the wearer. Another translational focus of our group is on gait assistance for medical applications. We foresee soft exosuits being able to restore mobility on patients with muscle weakness (e.g. elderly) or who suffer from a neurological disease such as a Stroke. Beyond our active systems, we envision translational potential in the area of sports and recreation where fully passive soft suits with structured functional textiles can provide small amounts of assistance during walking, hiking, running and other activities.

Soft Robotics

Multi-material fluidic actuators

- Soft fluidic actuators consisting of elastomeric matrices with embedded flexible materials (e.g. cloth, paper, fiber, particles) are of particular interest to the robotics community because they are lightweight, affordable and easily customized to a given application. These actuators can be rapidly fabricated in a multi-step molding process and can achieve combinations of contraction, extension, bending and twisting with simple control inputs such as pressurized fluid. In our approach is to use new design concepts, fabrication approaches and soft materials to improve the performance of these actuators compared to existing designs. In particular, we use motivating applications (e.g. heart assist devices, soft robotic gloves) to define motion and force profile requirements. We can then embed mechanical intelligence into these soft actuators to achieve these performance requirements with simple control inputs.

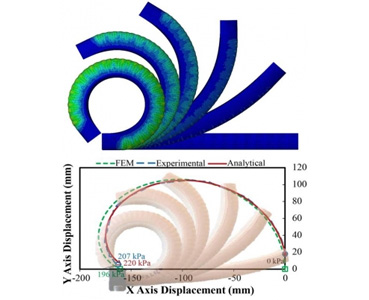

Modeling of soft actuators

- Characterizing and predicting the behavior of soft multi-material actuators is challenging due to the nonlinear nature of both the hyper-elastic material and the large bending motions they produce. We are working to comprehensively describe the principle of operation of these actuators through analytical, numerical and experimental approaches and characterize their outputs (motion and force) as a function of input pressure as well as geometrical and material parameters. Both models and experiments offer insight into the actuator behavior and the design parameters that affect it. We envision this work will lead to improved predictive models that will enable us to rapidly converge on new and innovative applications of these soft actuators.

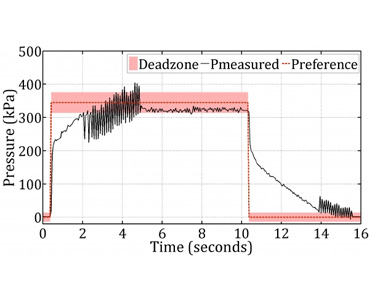

Sensing and control

- In order to control soft actuators, we need means of monitoring their kinematics, interaction forces with objects in the environment and internal pressure. We accomplish this through the use of fully soft sensors, developed with collaborators, and miniature or flexible sensors that can be incorporated into the actuator design during the manufacturing process. For power and control, we use off the shelf components such as electronic valves, pumps, regulators, sensors, and control boards etc. to rapidly modulate the pressure inside the chambers of the actuators using feedback control of pressure, motion and force. In addition, we can use the analytical models we develop to estimate state variables that may be difficult to measure directly.

Translational applications

- There are approximately four million chronic stroke

survivors with hemiparesis in the US today and another six million in

developed countries globally. In addition, there are millions of other

individuals suffering from similar conditions. For the majority of these

cases, loss of hand motor ability is observed, and whether partial or total,

this can greatly inhibit activities of daily living (ADL) and can

considerably reduce one’s quality of life. To address these challenges, we

are developing a modular, safe, portable, consumable, at-home hand

rehabilitation and assistive device that aims to improve patient outcomes by

significantly increasing the quantity (i.e. time) and quality of therapy at

a reduced cost while also improving independence of users with chronic hand

disabilities by enabling them to perform activities of daily living.

In the United States, the lifetime risk of developing heart failure is roughly 20%. The current clinical standard treatment is implantation of a ventricular assist device that contacts the patient’s blood and is associated with thromboembolic events, hemolysis, immune reactions and infections. We are applying the field of soft robotics to develop a benchtop cardiac simulator and a Direct Cardiac Compression (DCC) device employing soft actuators in an elastomeric matrix. DCC is a non-blood contacting method of cardiac assistance for treating heart failure involving implantation of a device that surrounds the heart and contracts in phase with the native heartbeat to provide direct mechanical assistance during the ejection phase (systole) and the relaxation phase (diastole) of the cardiac cycle.

Related Articles

Walsh to advance wearable robot design

- Cambridge/Boston, Mass. - September 11, 2014 - The Wyss

Institute for Biologically Inspired Engineering at Harvard University

announced today that it was awarded a first-phase $2.9 million follow-on

contract from the Defense Advanced Research Projects Agency (DARPA) to

further develop a biologically inspired smart suit. The device, the Soft

Exosuit, is intended to be worn comfortably under clothing and could enable

soldiers to walk longer distances, keep fatigue at bay, and minimize the

risk of injury when carrying heavy loads. Alternative versions of the suit

could eventually assist those with limited mobility as well.

DARPA’s Warrior Web program seeks to develop technologies to prevent and reduce musculoskeletal injuries for military personnel, but the same technologies could also have civilian applications. A reduction in such injuries could reduce long-term healthcare costs and enhance quality of life for wearers of the suit.

This is the first of a potentially two-phase contract, which enables Wyss Institute Core Faculty member Conor Walsh, and his team to build upon their earlier work, also funded by DARPA, demonstrating the proof-of-concept of this radically new approach to wearable robot design and fabrication. Inspired by a deep understanding of the biomechanics of human walking, the Soft Exosuit technology is spawning the development of entirely new forms of functional textiles, flexible power systems, soft sensors, and control strategies that enable intuitive and seamless human-machine interaction.

“While the idea of a wearable robot is not new, our design approach certainly is,” said Walsh, who is also an Assistant Professor of Mechanical and Biomedical Engineering at the Harvard School of Engineering and Applied Sciences (SEAS) and founder of the Harvard Biodesign Lab.

The lightweight Soft Exosuit is designed to overcome the challenges of traditional heavier exoskeleton systems, such as power-hungry battery packs and rigid components that can interfere with natural joint movement. It is made of soft, functional textiles woven together into a piece of smart clothing that is pulled on like a pair of pants and intended to be worn under a soldier’s regular gear. Through a biologically inspired design, the suit mimics the action of the leg muscles and tendons when a person walks, and provides small but carefully timed assistance at the joints of the leg without restricting the wearer’s movement.

In a current prototype, a series of webbing straps positioned around the lower half of the body contain a low-power microprocessor and network of supple strain sensors that act as the “brain” and “nervous system” of the Soft Exosuit, respectively—continuously monitoring various data signals, including the suit tension, the position of the wearer (e.g., walking, running, crouched), and more.

“Over just a couple of short years, Conor and his team will work to fundamentally shift the paradigm of what is possible in wearable robotics,” said Donald Ingber, who is the founding director of the Wyss Institute, Judah Folkman Professor of Vascular Biology at Harvard Medical School and Children’s Hospital Boston and Professor of Bioengineering at Harvard SEAS. “Their work is a great example of the power of bringing together people from multiple disciplines with focused resources to translate what first seems like a dream into a product that could transform people’s lives.”

In addition to its military application, the team will collaborate with clinical partners to develop a medical version of the suit that can help stroke patients, for example, who often experience a slow, inefficient gait and could greatly benefit from walking assistance.

Collaborators include Wyss Institute and SEAS faculty member Robert J. Wood and visiting professor Ken Holt, and Terry Ellis at Boston University’s College of Health and Rehabilitation Sciences. Critical to this project’s success to date has been a team of Harvard postdoctoral fellows (Alan Asbeck, Stefano de Rossi, Ignacio Galiana, Yigit Menguc) and graduate students (Ye Ding, Jaehyun Bae, Kai Schmidt, Brendan Quinlivan), as well as staff from the Wyss Institute (Zivthan Dubrovsky, Robert Dyer, Mike Mogenson, Diana Wagner, Kathleen O’Donnell). Boston-based New Balance will also be a key collaborator on this new phase of the project, bringing expertise in textile and apparel innovation.

Under the terms of the contract with DARPA, the Wyss Institute will receive up to $2.9 million for its work on Warrior Web, with full funding contingent on meeting a series of technical milestones.

Soft robot survives fire and ice

- When it comes to soft robots, researchers have finally

managed to cut the cord.

Developers from Harvard’s School of Engineering and Applied Sciences and the Wyss Institute for Biologically Inspired Engineering have produced the first untethered soft robot—a quadruped that can stand up and walk away from its designers.

Working in the lab of Robert Wood, the Charles River Professor of Engineering and Applied Sciences, a team of researchers that included Kevin Galloway, Michael Karpelson, Bobak Mosadegh, Robert Shepherd, Michael Tolley, and Michael Wehner was able to scale up earlier soft-robot designs, enabling a single robot to carry on its back all the equipment it needs to operate—microcompressors, control systems, and batteries. The design is described in a paper in Soft Robotics that appeared online Sept. 1.

“Earlier versions of soft robots were all tethered, which works fine in some applications, but what we wanted to do was challenge people’s concept of what a robot has to look like,” said Tolley, a research associate in materials science and mechanical engineering at the Wyss Institute and the study’s first author. “We think the reason people have settled on using metal and rigid materials for robots is because they’re easier to model and control. This work is very inspired by nature, and we wanted to demonstrate that soft materials can also be the basis for robots.”

Compared with earlier soft robots, which were typically no larger than a steno pad, the system designed by Tolley and colleagues is huge, measuring more than a half-meter in length and capable of carrying as much as 7½ pounds on its back.

The design process, however, was about more than scaling up the smaller robots.

“As soon as you start thinking about putting the basic components you need to make this work—microcompressors, controllers, and batteries—on an untethered robot, you need a design that can carry those parts,” Tolley said. “You need to think about something that can handle much higher pressures, so there are materials challenges and there are design challenges and there are control challenges.”

Conor J. Walsh

- Conor is Assistant Professor of Mechanical and Biomedical Engineering at the Harvard School of Engineering and Applied Sciences and a Core Faculty Member at the Wyss Institute for Biologically Inspired Engineering at Harvard. He is the founder of the Harvard Biodesign Lab, which brings together researchers from the engineering, industrial design, apparel, clinical and business communities to develop new technologies and translate them to industrial partners. His research focuses on applying disruptive technologies to the development of robotic devices for augmenting and restoring human performance. His current research interests include new approaches to design, manufacture and control of wearable robotic devices and characterizing their performance through biomechanical and physiological studies. He leads a team of researchers on the DARPA Warrior Web project to develop a soft exosuit that can assist with locomotion that can perform small levels of assistance to a wearer. The exosuit's function is based on a detailed understanding of human walking and is soft and pliable, unlike traditional exoskeletons that use rigid components. The long term goal is to develop fully portable wearable robots to assist the disabled and able-bodied and further the scientific understanding of how humans interact with such machines. His group is also working on the modeling and design of fluidic-based soft robotics for cardiac applications and applying emerging meso-scale manufacturing approaches to the design of smart medical tools for the minimally invasive diagnosis and treatment of disease. Given his broad interests in medical devices and robotics, he collaborates closely with Wyss staff in the Biorobotics and Anticipatory Medical and Cellular Devices platforms. In addition, he is passionate about educating future innovators and he has established the Harvard Medical Device Innovation Initiative that provides students with the opportunity to collaborate with clinicians in Boston and emerging regions such as India. Conor received his B.A.I and B.A. degrees in Mechanical and Manufacturing engineering from Trinity College in Dublin, Ireland, in 2003, and M.S. and Ph.D. degrees in Mechanical Engineering from the Massachusetts Institute of Technology in 2006 and 2010. He has been the recipient of over a dozen invention, entrepreneurship, and student mentoring awards including the MIT $100K business plan competition, Whitaker Health Sciences Fund Fellowship, and the MIT Graduate Student Mentor of the Year.