- Offer Profile

-

With 35 years of experience in innovative modular solutions for industrial production, elcom presents a unique range of aluminium profiles and accessories, conveyors and modular linear transfer systems. As a FrenchFab manufacturer of aluminium profiles and accessories, elcom offers total design freedom.

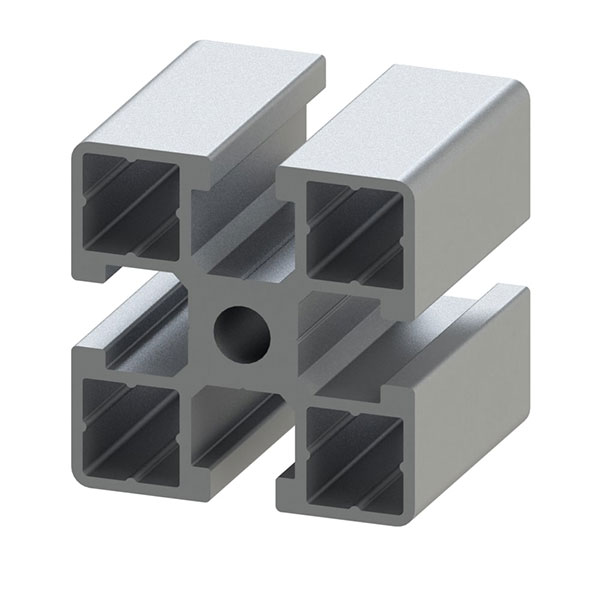

Aluminum profile

-

Aluminum profiles are construction elements widely used in many industrial sectors due to their remarkable properties. They are made from aluminum, a light, strong and malleable metal. This combination of characteristics makes it a versatile material, suitable for a variety of applications.

One of the main advantages of aluminum profiles is their lightness. In fact, aluminum is approximately three times lighter than steel, making them easier to handle, transport and install.

In addition to being light, aluminum profiles offer high mechanical resistance. They can support significant loads and resist compressive, tensile, bending or shear stresses. Their structural strength makes them a preferred choice for applications requiring increased reliability and durability. In addition, aluminum has excellent corrosion resistance, thanks to the formation of a thin protective oxide layer on its surface. This makes it a material suitable for outdoor, humid and aggressive environments.

Aluminum profiles are recyclable, making them an ecological and sustainable option.

Aluminum profiles are essential elements in various industries, offering great versatility, high strength and exceptional lightness

Aluminum profile 40x40mm h’8 40

-

H’ 8 40 , 3000 ACCESSORIES AND ALUMINIUM PROFILES FOR INDUSTRIAL SUB-ASSEMBLIES.

With more than 3000 accessories and aluminium profiles, h’8 40 is the standard of reference for designing and building mechanically assembled solutions in 40×40 sections.

The first profile offered on the French market for over 30 years is available in 5, 6, 8 and 10 h’8 40 grooves, allowing solutions to be created in the following areas

Aluminum profile 45x45mm h'8 45

-

With more than 2000 accessories and aluminium profiles, h’10 45 is the reference standard for designing and building mechanically assembled solutions in 45×45mm sections.

Aluminum profile 45x45mm

-

Aluminum profile 45x45mm

With a selection of more than 1,500 accessories and aluminum profiles, the H' 8 45 range stands out as an essential standard in the line 8 category, offering a 45x45 section.

Tubular range

-

The aluminum profiles of the D28 and D30 tubular range offer you a useful solution for the construction of various light and robust structures.

Accessories

- When assembling a modular aluminum workstation, accessories play a crucial role in enhancing the functionality, versatility, and efficiency of the workstation. Accessories are additional components or attachments that can be integrated into the workstation system to meet specific requirements and provide added convenience to the users. Here are some common roles of accessories in a modular aluminum workstation.

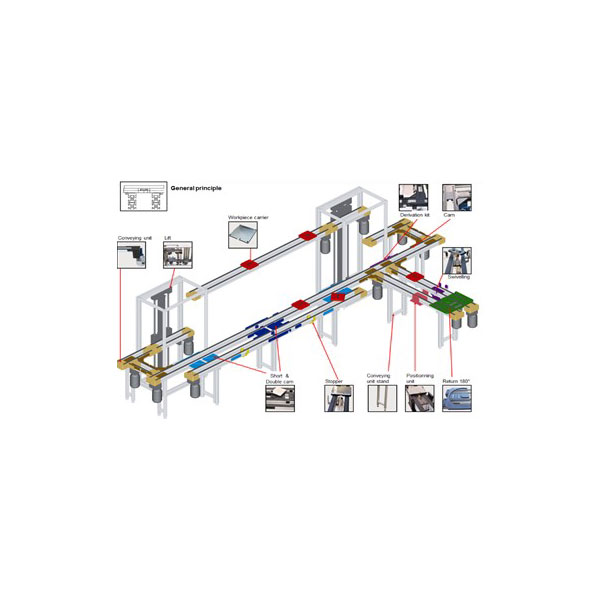

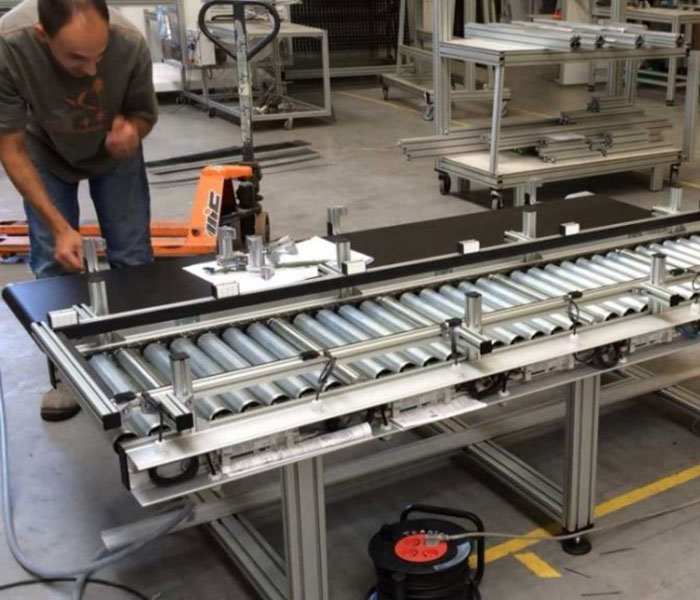

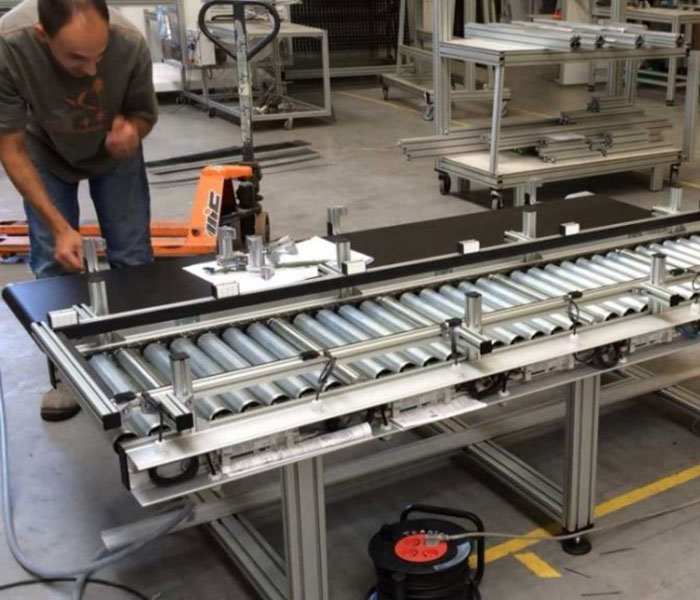

Pallet Transfer Systems

-

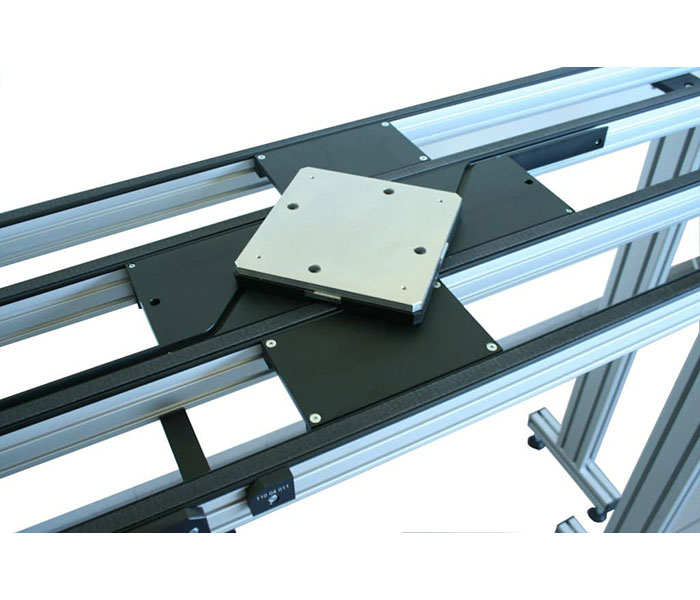

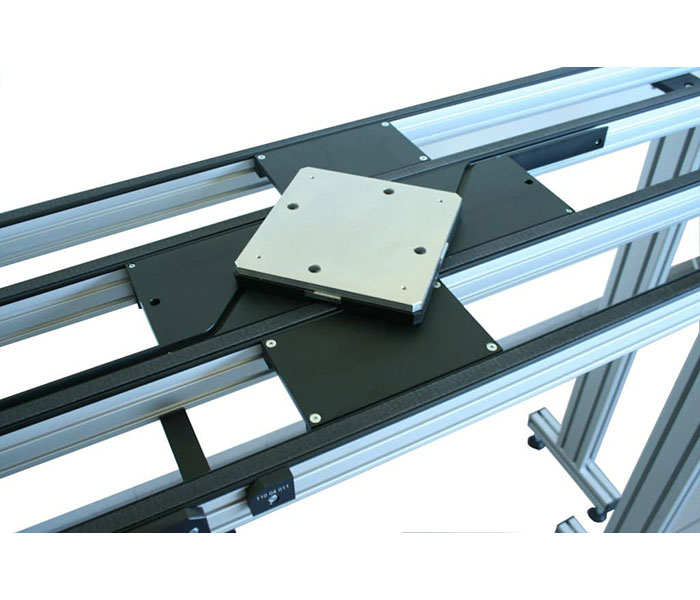

Transfer systems is a specific conveyor technology in which standardised workpiece carriers are used in connection with conveyor belts tailored to these workpiece carriers in order to move the workpieces through the various stations they must pass through.

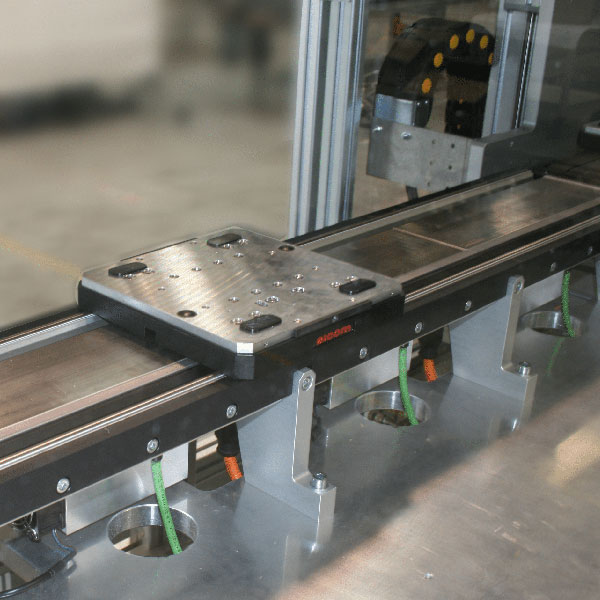

Transfer MCS

-

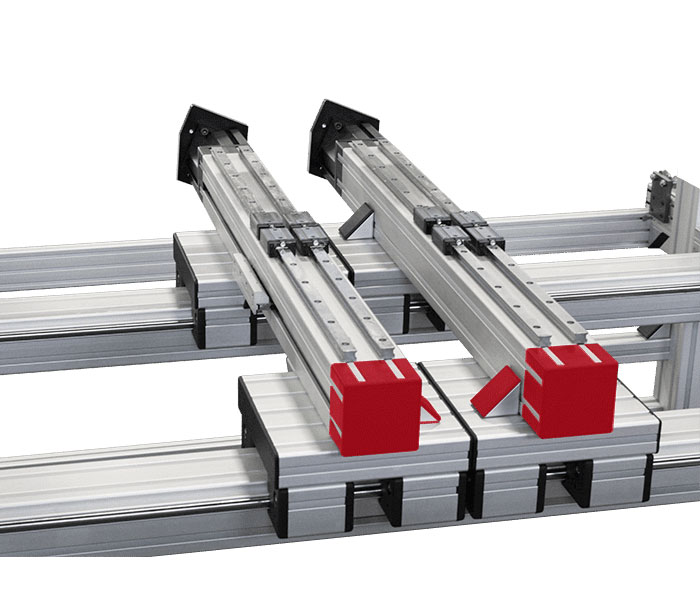

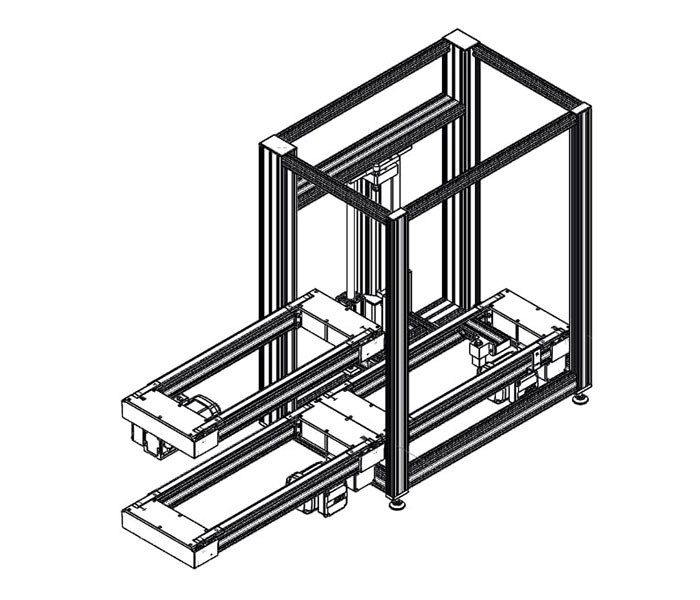

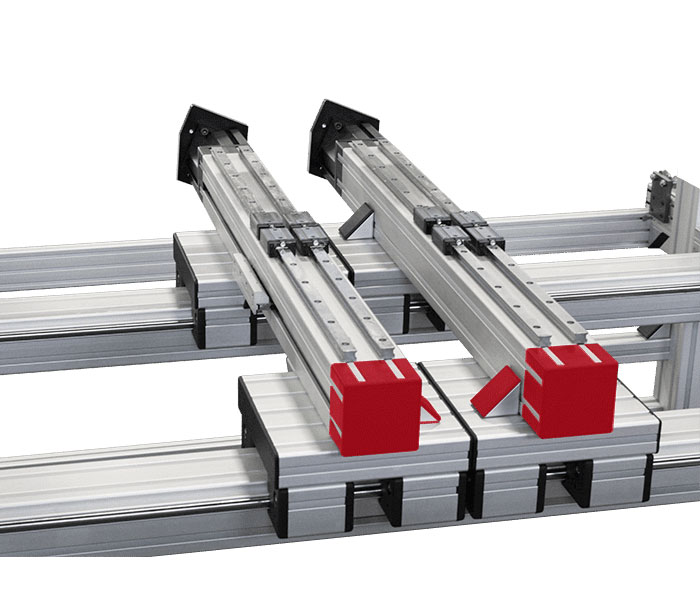

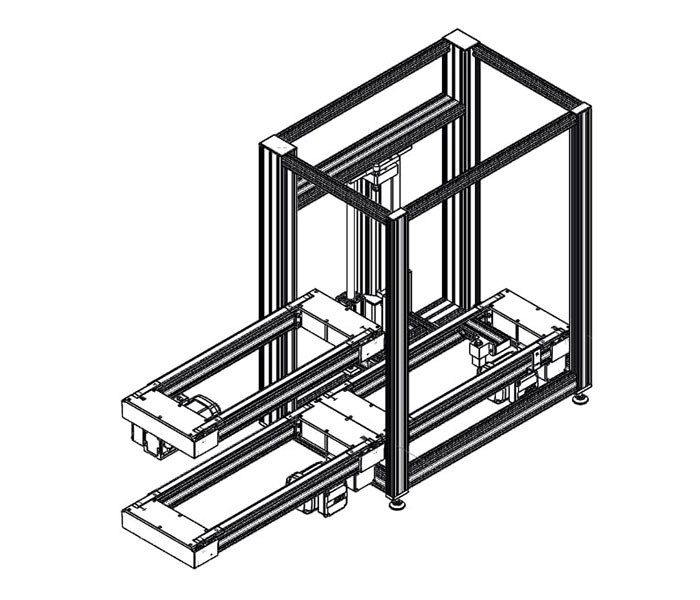

The Multi-Carrier-System (MCS) transfer is an innovative and flexible transportation system based on linear motors. Thanks to its modular structure, it can be freely configured and adapted to your specific needs.

The Multi-Carrier-System (MCS) transfer is an innovative and flexible transportation system based on linear motors. Thanks to its modular structure, it can be freely configured and adapted to your specific needs. What makes MCS® unique is its ideal combination with elcom transfer systems and conveyors. For this purpose, modular sets, standardized supports, and adapted hellomoov™ guidance systems have been developed.

Pallet transfer system ITS 24V

-

The ITS 24V Modular Transfer maintains the movement characteristics of the workpiece pallets provided by two parallel belts, facilitating the installation of stops, indexing and direction change accessories. However, it also incorporates additional features.

This transfer is equipped with two parallel belts for the movement of workpiece pallets, facilitating the installation of stops, indexing and direction change accessories. It moves and accumulates 100×100, 150×150, 200×200, 300×300 and 400×400 pallets for non-continuous flows, thus enabling automatic or individual workstations to be managed.

Pallet transfer system TLM 1000

-

The TLM 1000 transfer system is particularly suitable in a standard system for loads with total weight up to 2 kg per pallet (workpiece carrier + product holder + product). The maximum traction in accumulation mode is 50 kg or 25 kg, depending on the configuration (with reference to a transfer unit length of 3 m).

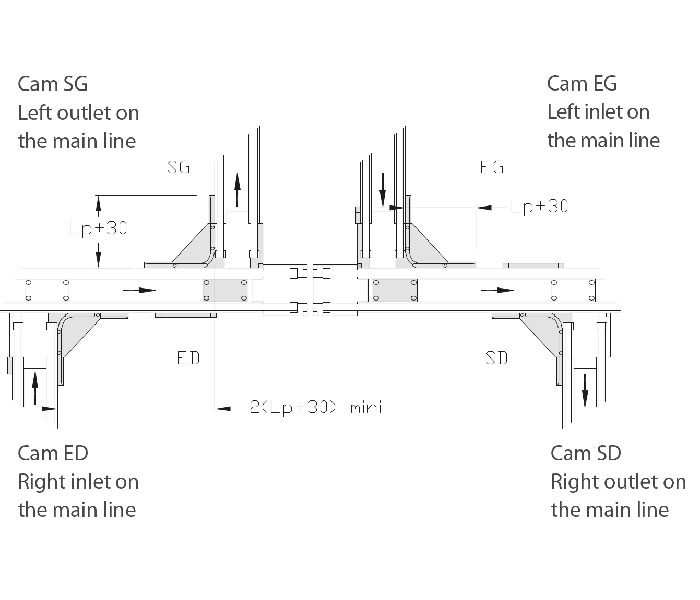

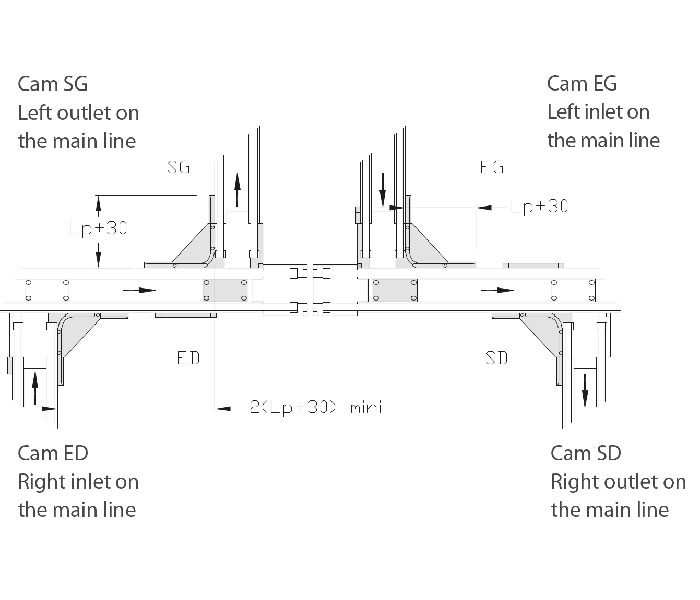

The movement of the workpiece pallets is ensured by two parallel bands, smooth ones or notched ones, which facilitates the installation of stops, indexing and other elements. Retractable pawns, housed under the pallet, play several roles:

Guidance by the 4 pawns in the right parts.

Guidance in the cams carried out by 2 pins inside the turns and diversions, the other 2 pins being retracted.

Transfer TLM 1500

-

The new TLM 1500 transfer system features a 150×150 mm width workpiece carrier and uses elcom’s patent with retractable pins, guides and derivation sets.

This new system benefits from the advantages of our TLM 2000‘s range (workpiece carriers with dimensions from 200×200 to 400×400) with a straightforward management and a very affordable short cam derivation system.

Workpiece carriers of a total weight of 4 kg can be conveyed thanks to a timing belt drive.

Pallet transfer system TLM 2000

-

The TLM 2000 transfer system is particularly suitable as a standard system for loads with total weight up to 10 kg per pallet (workpiece carrier + product holder + product).

The maximum traction in accumulation mode is 60–150 kg, depending on the configuration (with reference to a transfer unit’s length of 6 m).

Transfer TR

-

The design and configuration of the TR transfer system is based on the use of high quality materials such as stainless steel, anodised aluminium extrusion and polyamid or acetal.

Its modularity ensures that installation of a system is quick and easy. Fixture modifications and expansion of lines is also made simple due to its architecture.

This transfer system is ideal when products to move is less than 10kg, in harsh environments.

Transfer TLM 5000

-

The pallet transfer systemTLM 5000 is ideal for assembly of large products from 500×500 mm to 1000x100mm in ESD or cleaning room environements . It has been designed with a specific inflatable technology.

The TLM 5000 is an industrial system developed by elcom, leader in the field of conveying solutions designed for the movement of bulky part-carrying pallets, this system offers exceptional modularity and adaptability. Pallets with dimensions ranging from 500×500 to 1000×1000 can be easily moved with great precision and efficiency

Transfer TRM

-

The heavy load pallet conveyor TRM has been designed to move heavy products (until 100kg) on pallets sizes from 436×436 mm to 836×836 mm in all conditions thanks to the mechanical transmission by chain and steel rollers. It offers a good positioning repeatability of (+/-)0,1 mm.

Transfer TM

-

TM monorail transfer system has been designed for heavy duty working areas, and suited for moving heavy parts (up to 300 kgs)

lts compact overall dimensions and the optimal ergonomics provided by the system facilitate the arrangement of the working place

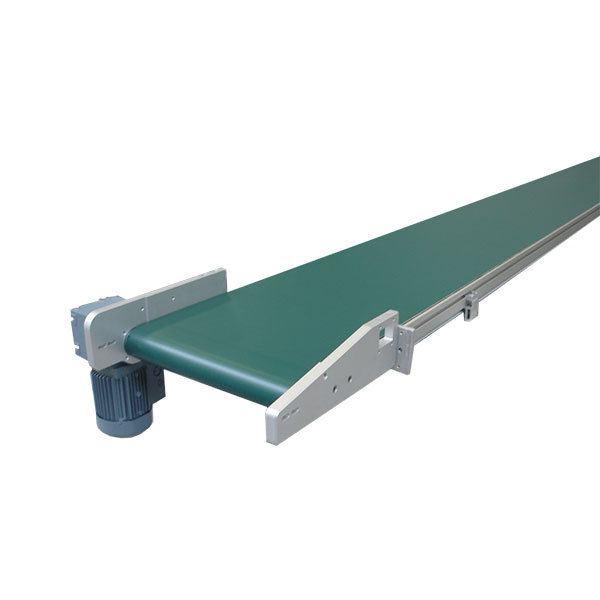

Conveyer Systems

-

Conveyors are essentially used for the continuous management of the flow of goods or products.

The choice of the conveyor belt depends on the application but also the field of activity.

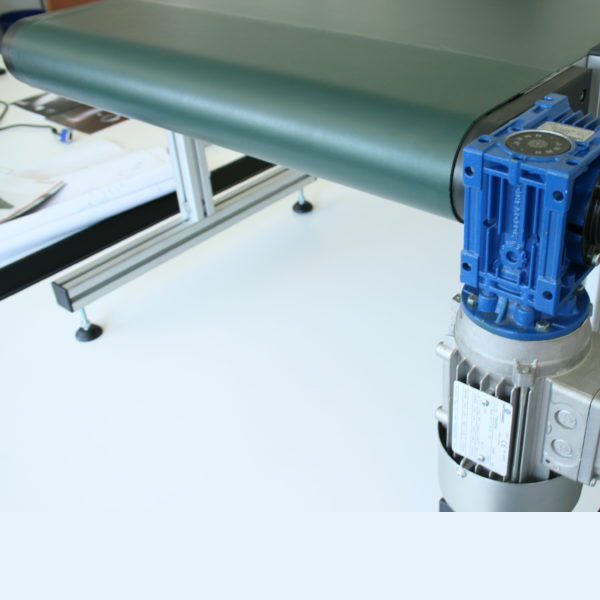

CONVEYOR C20

-

The design of elcom belt conveyors is based on the use of profiles from the elcom range, which gives them exceptional modularity. This modularity allows great flexibility in adapting belt conveyors to the specific needs of each project. Our experienced technical teams are available to assist and advise you in carrying out your specific projects.

Whether transporting small, lightweight parts in a confined space or for custom projects, elcom’s 20mm belt conveyors offer a reliable and adaptable solution.

CONVEYOR C40

-

The flat belt conveyor 40 from elcom is a compact conveyor designed on a 40 mm profiles, and a Ø 40 mm pulley. It can fit for all types of part thanks to the wide range of belts (Widths available from 40mm to 400mm) and speed drive portfolio (2 to 24 m/min)

Stainless steel underside available as an option

CONVEYOR C80

- Belt conveyors are built around an 80 diameter drive pulley. They are equipment specially designed for the transport of light and bulky loads. These conveyors are manufactured in France and are distinguished by their ability to adjust the width to the nearest millimeter, making them extremely precise and suitable for various industrial applications.

CONVEYOR C90

-

The 90 mm conveyor is a high-performance handling equipment, specially designed for the efficient transport of heavy and large volume parts. Made from base 8 aluminum profiles and with a width of 90 mm, this conveyor offers a robust and reliable solution for the most demanding industrial applications. Two types of 90 conveyors are available, namely the diameter 90 belt conveyor with end drive and the diameter 90 belt conveyor with end drive and motor underneath.

The design of elcom belt conveyors is based on the use of profiles from the elcom range, which gives them great modularity. Thanks to this modularity and the technical experience of their teams, elcom is able to support its customers in carrying out specific projects.

CONVEYOR C90 TB24

- The main use of belt conveyors TB24 is to transport materials or goods from one location to another in a smooth and efficient manner. Belt conveyors TB 24 consist of a continuous loop of melted belt material, which is stretched over a series of 2 rollers and pulleys to control the tension. The belt is powered by a motor, enabling it to move along the conveyor system, carrying the materials or products with it.

CONVEYOR TB50

- In manufacturing and production facilities, belt conveyors are commonly employed in assembly line operations. They transport components, parts, or products between workstations or stages of the production process, allowing for efficient and continuous manufacturing operations. Belt conveyors TB 50 can be designed to accommodate different assembly line layouts, including straight, or inclined paths. They offer a wide range of belt (width, material) and drive settings (direct, remote or intermediate) depending of the flow speed, product to be transported, and work environment.

CONVEYOR TB90

-

The TB90 belt conveyor is a versatile industrial solution that provides numerous benefits in various industries. Thanks to its specific characteristics, it responds to various transport and product delivery issues.

The TB90 belt conveyor is designed to efficiently move products from point A to point B in production and material handling processes. Its use helps optimize production lines, improve efficiency and reduce handling costs.

Inflatable belt conveyor

-

An inflatable belt conveyor, also known as an air-supported belt conveyor, is a type of conveyor system where the conveyor belt is supported and propelled by air pressure. Here are some characteristics of inflatable belt conveyors

This conveyor is suitable for workpiece pallets or boxes with flat bottoms.

The line can be motor-driven or operated by hand.

Load transfer of the weight of the product is implemented via ball bearings mounted on the aluminium profiles. The profiles simultaneously serve to guide the workpiece pallets or boxes.

These are moved forwards by a continuously-running conveyor belt whose pressure against the bottom of the workpiece pallets is controlled pneumatically. The pressure of the conveyor belt moves the workpiece pallets, which can also easily be running in accumulation mode using stoppers. Indexing units are also possible.

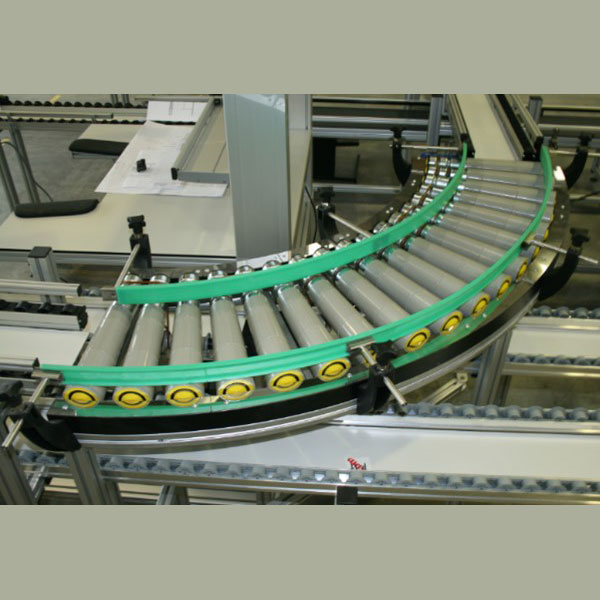

Roller conveyor

-

Free roller conveyors are simple and economical transport systems. They are made of zinc-plated steel rollers with a diameter of 50 mm. These rollers are placed at regular intervals along the conveyor structure, forming a support surface for the packages.

Besides belt conveyors, roller conveyors are standard conveyor technology. They are used frequently, especially for plastic containers or packages with heavy weights. As with all our standard modules, the support is based on elcom aluminum profiles. Therefore, it is easy to incorporate these modules into your production environment. Besides standard roller conveyors, curved roller conveyors are available. Furthermore, the systems can be designed as driven roller conveyor or gravity roller conveyor.

Applications

Aluminium profiles

-

- Workstation

- Trolleys

- Stairway and platform systems

- Lean solutions

- Nuclear containment airlocks

- Casing and framing

Conveyers

-

- Accumulate products

- Feeding a machine

- Sort parts (rejecting)

Pallet transfers

-

- Control or orientate a product flow

- Indexing and positioning for a robot

- Positioning for a workbench

- Increase product flow

Motion

-

- Elevating

- Move and guide

- Move on X-Y axis

Industries

Automotive

-

Over the past forty years, we have invented and deployed the concept of modular creation.

Today, we’re enriching it with the multi-modularity of our entire profile range, so that you can design freely and without constraint.

Interoperability with our “Moovitics” range ( i.e our intelligent transitic systems) is also guaranteed.

Last but not least, we’re always ready to listen to your concerns and innovate on an ongoing basis. That’s why we created our Hellomoov’ Performance Institute.

Cost, quality, deadlines: we impose the Operational Excellence to ourselves, like it is required by our customers in the automotive industry.

As a result, our h’elcom aluminum profile solutions and applications, designed by the elcom engineering departments, have become the automotive world’s benchmark for their robustness, aesthetics and ergonomics, which are also recognized by operators.

Aerospace

-

The aeronautics industry and elcom, a long history of collaboration.

The aerospace sector has always been a cutting-edge industry, and the entities of the hellomoov’ ecosystem have always supported it.

Our geographical locations enable us to be a privileged partner for the specific problems of the aeronautics industry.

The wide range of elcom products naturally finds its place in such diverse environments as assembly workshops, test areas and control laboratories.

Electronics and Electro-technics

-

h’elcom offers the widest range of modularity both in terms of profile sections and accessories.

Aware of the constraints faced by the high-tech industries, h’elcom offers complete solutions to meet protection requirements against the risk of electrostatic discharge.

Intralogistics

-

Intralogistics refers to the management, control, and optimization of internal logistics processes within an organization. It focuses on streamlining the flow of materials, information, and goods within a company’s premises, typically within a warehouse or distribution center. The goal of intralogistics is to improve efficiency, reduce costs, and enhance customer satisfaction through effective material handling, storage, and distribution.

intralogistics covers different aspects such as warehousing, material handling, inventory management, and order fulfillment. Elcom concentrates its efforts on material handling.

Machine builders

-

With over 30 years’ experience in supporting manufacturers of special-machines and integrators, elcom has supplied thousands safety housing systems and pallet transfer equipment to design impactful machine to be integrated on production and assembly lines.

Industrial robots are increasingly utilized in various industries to automate repetitive tasks and increase efficiency. Machine builders appreciate robots that are versatile, offer high precision and speed, and can be easily integrated into their machine designs.

Elcom is the expert in supplying safety solutions for industrial robots cells thanks to the widest multi-modular aluminum profiles range and transitic solutions with conveyors and pallet trasfer systems.

These equipement are designed for safety and productivity purposes.

Medical and Pharmaceutical

-

Why choose h’elcom aluminum profile and motion solutions in the medical and pharmaceutical industries?

Our products are designed to respond to a number of constraints:

- Be able to rapidly reorganize a production flow when changing packaging

- being able to manufacture customized products at high-rate production, at the best cost/quality/time ratio

- overcome environmental constraints – clean or grey rooms, aggressive, humid, dusty environments, etc.

- organize the ergonomics of your operators’ workstations

Nuclear

-

The h’elcom range has been supporting the French nuclear power industry for many years. From furniture and changing rooms for operating facilities to dynamic containment airlock for decommissioning, we can meet the needs of the entire life cycle of a nuclear facility.

Based on our R&D capabilities, we have created a composite profile that enables you to store more contaminated material in the same volume, thanks to reduced outgassing.Elcom and H’Factory are here to support you and offer you the most reliable technical and economic solution, in line with your specifications.

Consumer goods

- Elcom supports manufacturers in the consumer goods and packaging sector who need to plan a rapid transformation. This transformation is fueled by increased competition that demands both improved productivity while maintaining high quality standards, as well as increasing consideration of product flexibility and individualization.

Industrial goods manufacturing

- To transport industrial goods, the main technology uses is linear transfers or conveyors. In addition, workstations and Kanban cabinets are also very much in demand for the manufacture of industrial goods. As safety remains crucial, aluminium carterizations are commonly designed.