- Offer Profile

- The company and the team –

competence in the field of material transport

Telelift GmbH has been a household name in machine and system construction since it was founded in 1964. We rank among the leading manufacturers of conveyor systems for transporting light goods in-house. Approximately 100 employees now work at our site in Maisach, Germany. The company is certified in accordance with DIN EN ISO 9001:2008.

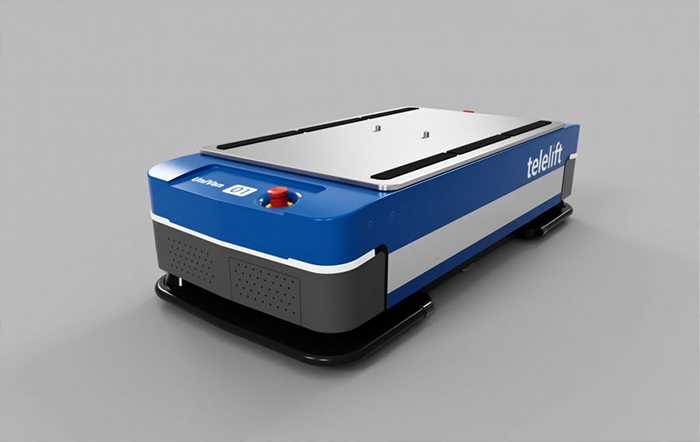

MultiCar

-

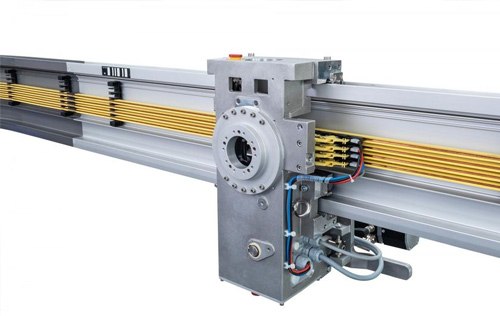

Telelift MultiCar – Lots of functions, just one technology

The MultiCar has been specially developed for use in industry. It enables customised, flexible solutions for almost all types of transported goods. Due to the use of various load-carrying attachments, components and many other things can be sent exactly where they’re needed.

With the aid of modular rail technology, the MultiCar conveys goods in even the tightest spaces, and in all directions, horizontally or vertically. The MultiCar system’s flexibility enables it to be adapted to new processes, easily and without complications. Different conveying systems are therefore no longer necessary for different production processes. Small number of components – One system

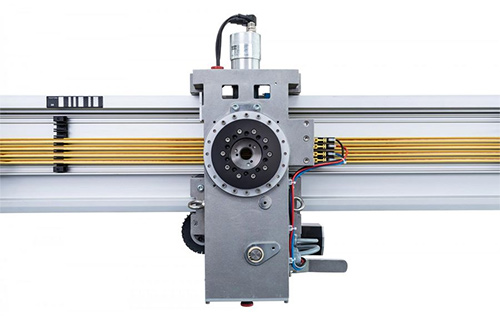

MultiCar chassis

- The standard chassis can be combined with a number of customised load-carrying attachments, in order to cover all customer applications. Regulated, brushless drives ensure configurable transport speeds in both transport directions, and precise positioning in the loading and unloading area.

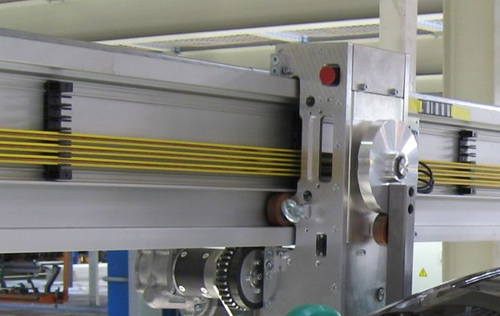

MultiCar rail

- Thanks to the rail system’s modular design, virtually all transport routes can be realised. Straight rail elements, curves for horizontal changes of direction and bends for vertical changes of direction make the MultiCar system highly flexible.

In combination with points, material flows can be distributed to multiple places or brought together in one place.

MultiCar control system

- The decentralised, PLC-based Telelift TeleControl control system controls the transport jobs, as well as taking care of system monitoring and visualisation.

The control systems communicate via a TCP/IP network, with characteristic communication occurring via a communication rail installed in the rail profile.

System analyses can be carried out via the central visualisation, individual operator terminals or using service laptops.

Upon request, the TeleControl control system can be integrated into the customer’s own control system and monitoring peripherals (connection to MES or ERP system, head control).

Design of the load-carrying attachments tailored to meet customer requirements

- Depending on the transport task that needs to be accomplished, custom design of an individual load-carrying device is usually required. Depending on the form, route and goods to be transported, there are fundamentally three different methods of connecting the load-carrying device

Rigid connection

-

The load-carrying attachment is fixed directly to the chassis, meaning that no relative movement is possible. When travelling along bends, the load-carrying attachment does not therefore rotate.

Rigid load-carrying attachments are particularly suitable for purely horizontal or vertical transport.Characteristics: Greatest load capacity, transport in closed boxes

Gravity-controlled connection

-

The load-carrying attachment is connected to the base chassis by means of a freely rotatable flange with bearing. Due to the goods being transported having a lower centre of gravity than the bearing point, the position corrects itself on the basis of gravity, therefore enabling gentle transport.

Rotatable load-carrying attachments with bearings are particularly suitable for suspended transport.Characteristics: Medium load capacity, gentle transport

Actively controlled connection

-

The load-bearing attachment is connected to the chassis by means of a rotatable flange with bearing, which in turn can be actively turned via a separate drive and a bevel gear. The direction is actively regulated and controlled by a position control drive. In basic functionality, this therefore ensures angle compensation when moving along bends, so that the load-carrying attachment is always kept horizontal. Optionally, the load-carrying attachment can also be actively turned at certain positions. Compared to the gravity-controlled connection, more compact envelope curves are achieved, because no eccentricity is required between the axis of rotation and centre of gravity.

Characteristics: Lower load capacity, gentle transport, smaller envelope curves, additional function due to active positioning of the load-bearing attachment.

UniCar closed – Trolley models H10 and W15 for hospital transport

-

Trolley models H10 and W15 have been specially developed for transport duties within hospitals.

They are the perfect solution for quick, reliable transport between operating theatres, pharmacies, laboratories, storage areas and nursing stations in hospitals.

The secure, locked and electronically monitored transport containers guarantee hygienic, secure transport from the pickup point to the destination, with complete transport documentation. The TeleControl transport job management system ensures that the transport jobs are processed quickly via the shortest possible route.In hospitals, the UniCar takes care of transport logistics for:

- Medication (single and consolidated transport possible)

- Infusions

- Blood and urine samples

- Tissue samples (single and consolidated transport possible)

- Blood reserves and plasma

- Vaccines

- Sterile items

H10 container

-

- Load capacity up to 10kg

- Vehicle width: 185mm (internal dimensions)

- Transport volume: approx 38 litres

- Narrow conveying containers to take up the least amount of space in buildings (narrower distance between rails, narrow points and fire doors)

- Antimicrobial surface coating

W15 container

-

- Load capacity up to 15kg

- Vehicle width: 234mm (internal dimensions)

- Transport volume: approx 37 litres

- Lower (but narrower) conveying containers for more ergonomic manual loading and unloading.

- Antimicrobial surface coating

UniCar open trolleys, self-aligning

-

The open UniCar trolleys are loaded and unloaded manually and are designed to handle sensitive goods in hospitals and libraries, as well as to transport production parts or tool / gauge supplies in industrial manufacturing environments.

UniSafeCar™ - Modern technology for gentle transport

The UniSafeCar™ has been specially developed for handling sensitive goods. It is primarily used for gentle consolidated transport in libraries, with manual loading and unloading.

The UniSafeCar™ ensures particularly gentle transport and is ideal for valuable ancient manuscripts, prints, maps, incunabula, microforms and of course any other items held in stock, such as books, CDs and DVDs.The vehicle is loaded and unloaded manually. It can handle transport weights up to 10kg and sizes up to A3. Thanks to the container being suspended via a pendulum bearing, the contents never move when the vehicle changes from vertical to horizontal or overhead transport. Rather, they are always kept horizontally aligned.

UniCar - B320 - Gentle transport of larger items

-

The B320 conveying container is ideal when larger items, or a number of smaller items, need to be gently transported at the same time.

Typical transport tasks include palletised blood samples in laboratories or the delivery of production parts, tools or measuring instruments in industrial manufacturing environments.

As is the case with the UniSafeCar, the B320 container is also manually loaded and unloaded. It similarly features a pivotable container suspended via a pendulum bearing.

Thanks to its large capacity (internal dimensions: 436mm x 316mm x 205mm (L x W x H)), even larger items can be transported in the UniVersalCar without problems. The vehicle’s load capacity is 8kg.It is mainly used in the healthcare and industrial sectors.

UniLabCar – Efficient technology for gentle transport

- The UniLabCar has been specially developed for use in laboratories.

It is especially suitable where multiple samples need to be transported quickly, gently and efficiently.

As is the case with the UniSafeCar and B320, the UniLabCar features open containers attached via a pendulum bearing, and which are fixed to the transport vehicle. A special feature of the UniLabCar is the use of an additional, removable stainless steel transport container, which holds the samples. The stainless steel containers can be removed separately, enabling on the one hand samples to be pre-packed and on the other, time-delayed processing of the samples, therefore achieving extremely high system availability. The stainless steel containers can be sterilised in an autoclave, and secured in the transport vehicle by means of locking bolts.

The UniLabCar can generally transport weight up to 5kg

UniSortCar - Modern technology for efficient media sorting

-

The UniSortCar has been specially developed for use in libraries. It provides ongoing simplification of book sorting, as books can be pre-sorted and transported to all storeys and all sections of the library. The UniSortCar also makes pre-sorting for different library sites easily possible.

From any desired starting point, the media slide from the sorting belt and into the trolley. Thanks to an elastic coating, gentle transport of individual media is guaranteed. An electronic locking system prevents the trolley contents being removed from the conveyor before they have reached their intended destination.The UniSortCar can be unloaded in both directions, making greater route variation possible. At the destination, and depending on needs, up to twelve individual unloading points can be controlled. The UniSortCar only needs a few seconds on the sorting belt in order to accept the book and send it straight on its way. Multiple trolleys are automatically activated at busy times.

For libraries, use of the UniSortCar means quicker provision of media. Even 24/7 operation is possible, without the need for additional personnel resources. UniDrop – Automatic waste and laundry transfer system for hospitals (PWCS/AWLS)

-

A hospital produces a huge amount of waste and laundry every day that must be collected and transferred out of wards. At wards the lingering waste and laundry bags are first and foremost a healthy risk for patients and healthcare workers, but they also occupy rooms, corridors and lifts, look bad, and can smell.

Today, in many hospitals the waste and laundry are still collected manually by logistics personnel travelling across the hospital, all the way from the hospital’s waste terminal. This entails risk of spreading bacteria and other pathogens between wards and around the hospital. Moreover, hiring several people just for transferring and lifting heavy waste and laundry bags is expensive.

Telelift’s UniDrop, the automatic waste and laundry transfer system for hospitals and care facilities, eliminates all above mentioned negative effects of manual collection of waste and laundry. With UniDrop the wards’ own personnel will drop waste and laundry bags through inlet doors, locating at the wards, into the system and thereafter the bags are vacuumed hygienically, invisibly, and quietly through a pipeline into a specific waste or laundry container locating at the hospital’s waste or laundry terminal.

Your benefit:

- Improved hygiene at wards,

- Improved people and material flow that is vital for care work,

- Time and money savings

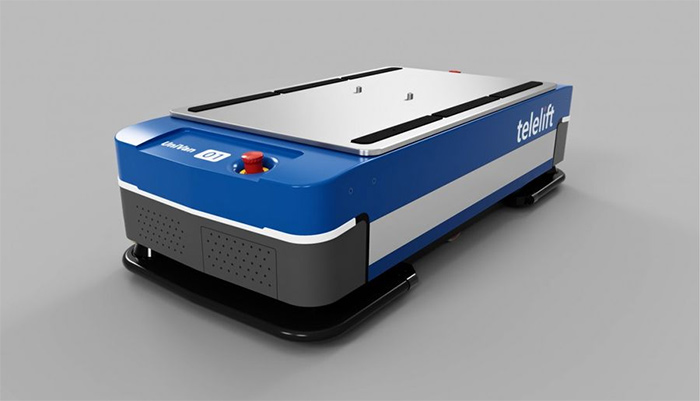

Telelift UniVan - The automatic-guided transport system for hospitals

-

The Telelift UniVan is a classic Mobile Robot, i.e. a transport system with automatic-guided vehicles (AGV) that can move around in buildings without the help of an operator. The path specifications are preset and the map is saved automatically.

The navigation is done by laser scanning and does not require installation of devices on the floor, on the walls or on the ceiling. This allows maximum freedom when changing the paths.

In addition, the system is extremely user-friendly and handles all processes autonomously.The UniVan takes over the efficient transport logistics for:

- Meals

- Laundry

- Waste and Refuse

- Sterilizarion

- Pharmacy

- Warehouse

The Telelift UniVan guarantees the safe and efficient transport of all materials. The vehicles can be traced at any time.

Benefits

-

- Automatic navigation

The automatic navigation is based on a comparison between the information from the on-board sensors and the room measurement, which is implemented with a laser scanner, without the help of markings along the route. Detailed maps with reference points for orientation and a predefined route are loaded on the on-board computer. - Automatic completion of tasks

The Telelift UniVan is able to carry out all transport tasks using laser navigation. Floor or wall installations are not necessary. If an obstacle appears along the route, the AGV is able to autonomously check an alternative route and bypass the obstacle.

A task can also be transferred to a vehicle that is already running. - High safety

Telelift Mobile Robot UniVan is equipped with safety laser scanners that ensure an all-round scan of 360 °. This is irrespective of whether the vehicle is loaded or not. This ensures a high level of safety to avoid collisions. - Maximum payload

UniVan can transport loads with a maximum gross weight of more than 380 kg.

- Automatic navigation

Telelift UniVan

-

- Dimensions: 1.350 x 620 x 355 mm

- Standard hook system: Automatic – lift up to 100 mm

- Maximum payload: > 380 kg

- Kinematics: Equilateral, 4 wheels fully bidirectional

Solutions

Total Total Solution for Healthcare

-

At Telelift we see the needs of our customers as the basis for all our developments. This ensures that we can always offer logistics´ solutions that are ideally suited to the processes.

To solve the circulation problems caused by the rapid development of hospital logistics, we have developed a total solution for hospitals.The intelligent logistics system is the optimization and integration of four systems:

- Telelift UniCar - ETV-System (Electrical Track Vehicle),

- Telelift UniDrop - AWLS (Auto Waste / Linen Collection System),

- Telelift UniVan - AGV-System (Auto Guided Vehicle)

- UniTube - PTS (Pneumatic Tube system).

Telelift UniCar

-

The Telelift UniCar (ETV) System can cover more than 80% of medical small and medium - sized items, for example: infusion bags/bottles, medicine, samples, small-sized instrument packages, pathological samples, documents, etc., and it has features of several types of transportation, single weight capacity (10-15kg), a high degree of intelligence, high safety and flexible installation possibilities.

The Telelift UniCar has an antimicrobial surface coating that prevents the growth and spread of most bacteria and germs over a long period of time.

Telelift UniDrop

- The Auto Waste/Linen Collection System UniDrop can be applied for automatic and rapid closed transmission of large-sized dirty clothes/bedlinen, household and kitchen waste, which has the advantage of improving the hospital's sensory control level, enhancing the efficiency of waste recycling and improving the medical environment.

Telelift UniVan

- The Mobile Robot (or Auto Guided Vehicle - AGV) UniVan is suitable for bulk material transportation, like daily meals, cleaning clothes/bedlinen, large-sized surgical instrument packages and automatic batch transportation of unopened packages between the first- and second-floor stores. It fulfills high quality standards and has high single weight capacity (above 380 kg), real-time laser detection, auto-navigation and driving, auto-call response and self-access to entrance/ elevator, self-execution of the delivery task.

Telelift UniTube

- The Pneumatic Tube System (PTS) UniTube is suitable for emergency/temporary small batch delivery of items between departments, such as temporary medicine, surgical pathology samples, etc.. It is characterized by its high transmission speed and flexible installation. It works as a supplement to the Telelift UniCar

Telelift Solutions for libraries

-

Today, libraries function as multimedia providers and modern educational and cultural centres that are accessed by children, young people and adults, irrespective of education or nationality. They enable free access to information and promote research, study and lifelong learning. Libraries impart the media skills necessary in our digitalised and networked society.

As a so-called ‘third place’, libraries serve to enable communication and human encounters. They therefore promote cultural identity and social integration.Against this background, innovative library technology represents a key component.

It enables libraries to concentrate on their valuable role promoting cultural essence and education, and to serve growing demands in the context of digital transformation. Thanks to our future-orientated logistics´solutions, employees are relieved of burdens, meaning additional personnel resources are won.Optimal design of the return and sorting processes

Telelift’s integrated libraries solution enables return and sorting processes in large public or academic libraries to be optimised over multiple storeys. Automated return and sorting systems, along with automated transport, are important components of a modern library’s self-service concept, enabling 24/7 library operation.

The process from return to placing back on the shelf

- A book return machine accepts the media quickly and easily. On the touch screen the booking of the returned item into the library system is confirmed immediately and updates the user’s account automatically.

Sorting belt

- In no time at all, it arrives on the sorting belt, to begin its journey. Then, according to defined sorting criteria, the item is conveyed to a UniSortCar™ or sorted directly into a library trolley for reserved items.

All items are therefore transported efficiently and sorted in accordance with the LMS-based sorting strategy. The number of sorting destinations can be freely chosen, and increased at any time.

Automated transport

- Telelift’s automated transport system transports the individual media item to its final destination in the public area or book storage – even in different floors or even different buildings – gently, quietly and without the need for additional reloading.

Telelift logistics solutions for industry

-

Telelift’s overhead, track-based conveying systems are the ultimate aid for modern production sites and modular production structures. You have a choice of the Telelift UniCar, which can carry up to 15kg, and the Telelift MultiCar, which can carry up to 40kg.

The goods being transported are conveyed overhead to production machinery or machine operators, using one system. The solution is also tailored to individual customer requirements.You have different transport tasks - we are all-rounders

The automated, track-based conveying system Telelift MultiCar gets your intralogistics moving. Customer-specific solutions and cost-effectiveness are always paramount.

Customer-specific load-carrying attachments

- Thanks to the use of customer-specific load-carrying attachments, the MultiCar enables customised, flexible solutions for virtually all types of transportable goods, with a load-bearing capacity of up to 40kg.

You can therefore transport components, complex assemblies, containers full of small parts and many other things to exactly where they’re needed. The load-carrying attachments are tailored individually to customer requirements.

Modular system design

- Thanks to its modular system design, the MultiCar enables overhead conveying of goods, transporting them in even the tightest spaces, and in all directions, horizontally or vertically.

The MultiCar system’s flexibility enables it to be adapted to new or existing processes, easily and without complications.

Its high degree of reliability and responsiveness minimises replenishment times and stock levels in day-to-day production.

‘Just in sequence’ deliveries – No problem for Telelift

- Continuing production specialisation presents new challenges for internal transport logistics. Components must be supplied to the production line ‘just in sequence’. Telelift’s MultiCar provides a dependable solution.

Thanks to its modular, flexible construction, our modern transport system can be adapted to the widest range of transport tasks and requirements. It can even also be used as an intermediate buffer.

The Telelift MultiCar also gains you space, as previous storage spaces can once again be used as production space. The transport system can also be suspended from the ceiling, which creates additional space. This therefore frees up your usual transport routes.