- Offer Profile

-

As one of the leading manufacturers of automated guided vehicles and mobile automomer robotics, we offer automated transport and assembly solutions to our customers worldwide. We set ourselves the standard of increasing the competitiveness and autonomy of our customers with our products and services. Our nearly 40 years of experience with AGVs and our drive to always find the best ways to make new technologies work for us and our customers help us to do this.

It all started with the idea of simplifying processes in the automotive industry. Today, we are one of the world's leading suppliers of automated guided vehicles and autonomous mobile robotics. This is how we combine our experience with the trends of the future.

Productlaunch - Compact mobile robot AMY

-

Compact mobile robot AMY from DS Automotion with smart load transfer: Efficiency through agility

With AMY, DS Automotion is launching an extremely compact and maneuverable autonomous mobile robot (AMR) for transporting loads of up to 25 kg. The smallest vehicle in the fleet of the established manufacturer from Linz offers full flexibility with predictable autonomy and can be easily integrated into larger fleets. Its load handling, which is as revolutionary as it is simple, enables the creation of cost-effective and low-maintenance intralogistics solutions, especially for handling small parts.

Efficiency booster for small parts handlingSpecially designed to be used in industrial production and intralogistics processes, AMY is designed for the driverless transportation of small loads weighing up to 25 kg. AMY can transport these in the form of standardized small load carriers or in several smaller containers from or to manual workstations and exchange them automatically with conveyor systems or passive transfer stations available from DS Automotion as a supplement via a dynamic load handling device.

Vehicles for transport solutions

- Our innovative transport vehicles leave nothing to be desired. DS Automotion offers you a variety of automated guided vehicles, which can be easily integrated into your existing plant or used in completely new plants.

AMADEUS - Automated forklift for next generation

-

Classic | Wide | Low | Counter | Grip

Compact stacker with optimized size and numerous variants

- Maximum lifting weight of 2,000kg / 4,400 lbs

- Maximum lifting height 2,800mm / 110 inch

- Maximum speed 1.8m/s / 6 f/s

- Smart navigation

ARNY- Counterbalanced forklift

-

Classic | HD | Duplex | Triplex

The counterbalanced truck that wants to reach high.

- Compact design for narrow aisles

- Wide range of applications

- Lifting height up to max. 8.5 m / 278 ft

- Payload up to max. 2.5 t / 5,500 lbs

Versatile heavyweightWhen we developed our ARNY counterbalanced truck, we focused on one central requirement: high load capacity at great heights. But that wasn't enough, we packed its strength into a compact housing so that despite its size it has the necessary flexibility for narrow warehouses.

LUCY

-

Compact wheel arm AGV for tight spaces

- Compact design

- Maximum driving flexibility even in tight spaces

- Modular load handling device can be adapted to requirements.

Wide range of applications and various transport options

Thanks to its modular design, LUCY is suitable for various transport goods. Pallets, roll containers, floor rollers with small load carriers and much more can be picked up, transported and set down automatically. Adaptation to customer-specific load carriers is easy to implement.

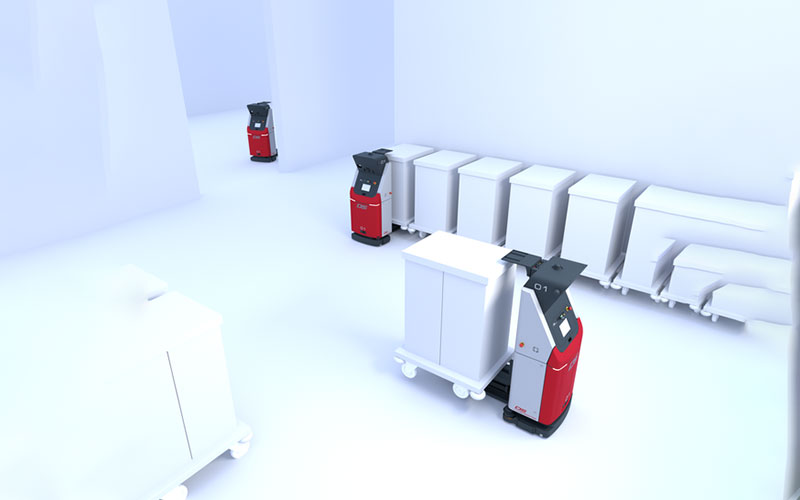

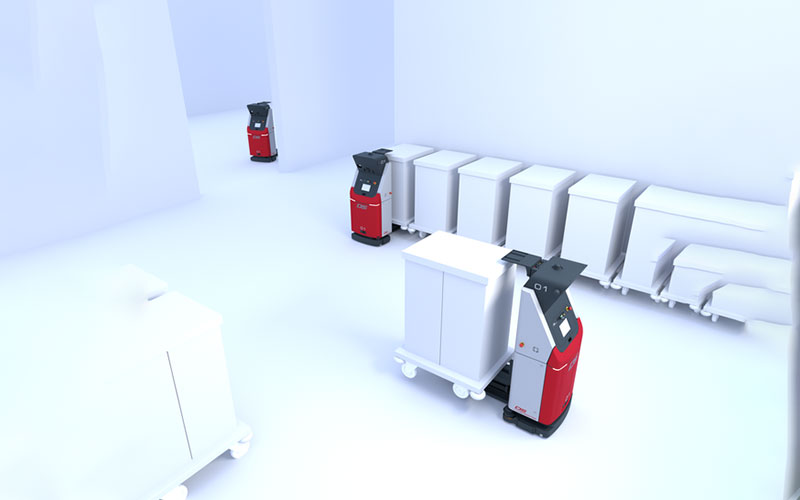

CAREY - Proven solutions with customers since decades.

-

The icon in automated hospital operation

- stainless steel cladding meets high protection class and hygiene requirements

- Latest battery technology for 24/7 use

- Energy-saving drive technology

- High range possible with only one charge

Energy efficient and low maintenance

Powerful drives guarantee safe transport of containers over long distances in medical facilities. The 24-hour / 365-day availability of the driverless transport systems ensures a steady flow of materials without legal restrictions.

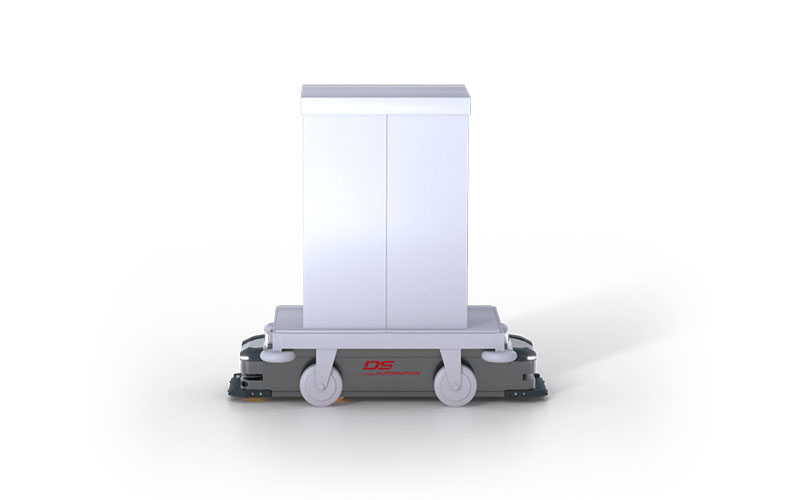

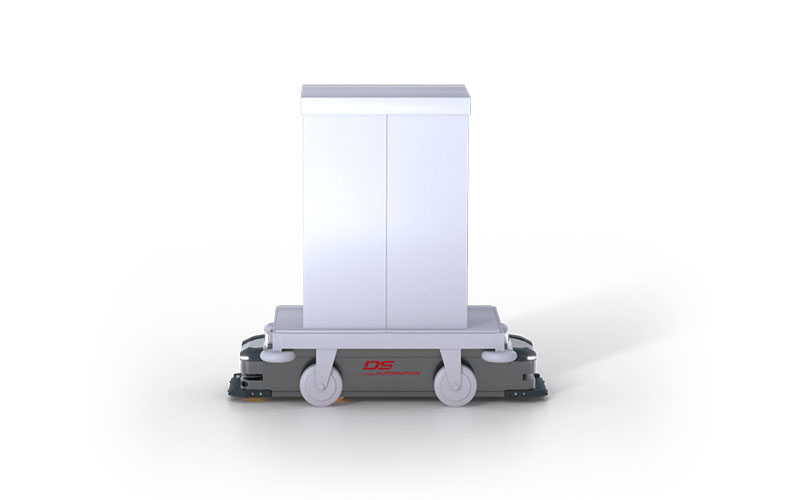

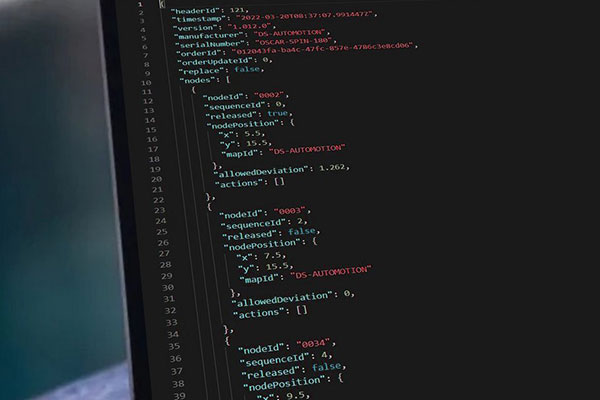

OSCAR - The lift deck AGV of a new generation.

-

The platform vehicle with the highest performance

- Compact design

- Highest driving flexibility even in confined spaces

- Sturdy steel construction with high load capacity

- Automatic load change by means of integrated lift drive

Wide range of applications and many transport options

Thanks to the extremely low design, our OSCAR is suitable for a large number of undercarriage transports. Whether undercarriages, racks, boxes or roll carts, all this can be picked up, transported and set down automatically. A high payload of 1000kg makes the OSCAR an absolute transport specialist.

SALLY - the small load carrier - Direct human-machine interaction for agile production

-

Flexible mini AGV for small loads

- Our smallest vehicle

- Can be combined with various superstructures

- Can be used in both the industrial and public sectors

Last mile delivery

Due to its compact and sterile design, SALLY is particularly suitable for use in the healthcare sector - both for transporting sterile goods and as a supplier directly on the wards.

Roller table

-

Mono | Double

Mobile counterpart for stationary conveyor technology

Our driverless transport vehicles with roller or chain conveyors reliably connect material flows without taking up valuable logistics space.

- solid mechanical construction

- harmonious coordination of all components

- uncompromisingly suitable for industrial use

Suitable for any pallet dimension

The driverless transport vehicle is designed for Euro and industrial pallet dimensions, but can be flexibly adapted to your load carrier. Thus, we can give maximum consideration to your environment and reliably connect your flow of goods. The material flow is continuously processed, around the clock!

Flexihauler

-

Cost-effective solution for in-plant logistics

- Simple and robust design

- Track guided

- No system control necessary

The simple solution is on the move

When it has to be quick and easy, our FLEXIHAULER is the perfect solution. For commissioning in your plant, only one track has to be glued and the vehicle can start moving - without any complex plant control. By means of extendable pins, the FLEXIHAULER docks onto mobile transport racks and pulls them to their destination with track guidance. The standardized PLC control is low-maintenance and can be adapted to individual interfaces.

Vehicles for assembly solutions

- Our innovative vehicles for assembly solutions leave nothing to be desired. In addition to three standard vehicles for your assembly lines, you also have the option of requesting an individual vehicle. These can be easily integrated into your existing plant, or can also be used in completely newly designed plants.

CHASSIS-MOVER

-

The driverless transport vehicle for picking up and transporting vehicle bodies

- Customizable load handling device

- Cycle & flow assembly

- Ergonomics and accessibility in the foreground

FLEXIMOVER Trike

-

The flexible mounting standard that adapts to your needs

- Compact design

- High ease of maintenance

- Focus on ergonomics

FLEXIMOVER Spin

-

The compact mounting solution for station linking in confined spaces

- Turns on the stand

- two directions of travel

- 360° all-round protection

Technology

Plannable Autonomy

- Plannable autonomy is a term coined at DS Automotion. What is meant by this is the possibility of being able to navigate with vehicles both (virtually) lane-guided and autonomously. The basic building blocks for this are so-called autonomy zones in which the vehicles are allowed to move autonomously. Many AGV manufacturers navigate exclusively lane-guided, while most AMR manufacturers navigate fully autonomously. Our approach is to combine the world of AGVs with the world of AMRs to provide the benefits of both approaches.

PLC Technology

- Our PLC-based control system stands for stability and openness, offers a high degree of flexibility and allows the use of standardized or customer-specific interfaces. It interacts with the AGVs on the one hand and with higher-level customer systems, third-party systems and stations on the other. The master controller is thus the linchpin of the automated guided vehicle (AGV) system. Our customers benefit from the know-how of our experts on Siemens S7 and TIA Portal as well as other manufacturers.

Energy Management

- In the case of automatic charging, the energy concept is usually designed for 24/7 continuous operation. The fleet control AI recognizes early on when an energy carrier reaches a critical level and proactively stops issuing new driving orders to the vehicle. Instead, the AGV is sent to a charging station, where it is recharged in the shortest possible time. With this type of charging strategy, the focus is on the highest possible charging currents in order to minimize downtimes. It is always taken into account whether peak loads are to be expected during operation and charging is avoided during these periods

NAVIGATION

-

An important focus is our broad spectrum of diverse navigation technologies. These basic technologies are among our core competencies and are thus firmly in our own hands.

Different areas of application require individual navigation and localization technologies. Through our years of experience, we have the expertise of all market-relevant navigation types in house and offer the coordinated solution for your area of application. From track guided to autonomous we can connect your system with the help of our technologies to increase efficiency and flexibility.

Navigation types:- Autonomous navigation

- Virtual guidance

- Physical Guidance

Autonomous navigation

-

Autonomous navigating vehicles determine the lane independently and act reactively on sensor data. This enables them to avoid obstacles and react flexibly to different situations.

Excerpt of possible areas of application:

- Healthcare, hospitals

- Order picking

- Small parts transport

- Area linking

- Production supply/disposal

Virtual guidance

-

Virtual guidelines guide the vehicle along a planned path and ensure high efficiency of the transport system. In the process, the vehicle also follows a lane, although this is no longer physically located in the real world. The lanes are planned computer-aided and can be flexibly adjusted at any time.

Excerpt of possible areas of application:- Strictly structured production environments

- Plant with large throughputs and high efficiency requirements

- Area warehouse

- Production areas with strong change

Physical guidance

-

Physical guidance guide the vehicle along a planned path and ensure high efficiency of the transport system. Suitable sensors are used to detect the physical lane, with magnetic tape guidance lane and active-inductive guidance lane with inductive energy transfer available as technologies. In the event of deviations between the vehicle and the guidance line, the steering motor steers the vehicle back to the desired lane.

Excerpt of possible areas of application:- Assembly lines

- Simple logistics applications

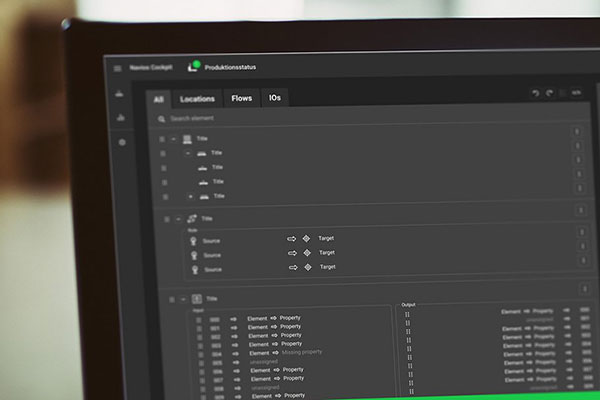

Fleet manager NAVIOS

-

The central intelligence behind our AGV and AMR systems

Our fleet manager NAVIOS is characterized equally by its stability acquired over the years and a wide range of functions, as well as by the ongoing further development with the latest technologies. Every development step is completely in the hands of DS Automotion. Due to the complete integration of the VDA 5050 interface, our systems can be extended with compatible vehicles at any time.

Fleet and energy management

-

Once an order has been received, NAVIOS uses the current order pool to check which vehicle is most suitable. This ensures that the individual vehicles are always sufficiently loaded, that there are no empty runs and that orders are completed as quickly as possible.

At the same time, routes can be dynamically recalculated at any time if, for example, orders with higher prioritization arrive or other vehicles have to use the same route. Route planning can also take place over several floors.

Material flow control

-

Orders can be generated in a variety of ways: automatically via sensors, the comparison of target/actual stock levels and the definition of time windows, as well as manually via touch terminal, directly at the vehicle terminal or via the connection to an ERP system.

Through intelligent order optimization, the individual transport trips are linked together, held back where necessary, prioritized or rerouted to avoid congestion. In addition, in the event of short-term changes to the stations, these can even be adjusted during operation.

Storage and parking space management

-

In addition to material flow and fleet control, NAVIOS can also be used to implement warehouse or storage location management. Especially where precisely timed storage and collection of goods is necessary, you benefit from the fact that everything is mapped within one software and thus no communication difficulties can arise.

Vehicle software ARCOS

-

The intelligence in the vehicle

To enable vehicles to make their own decisions in certain situations, we equip them with our ARCOS vehicle software. This not only ensures that a destination is reached in good time, but also a high level of safety for the plant and your employees. Obstacles can be avoided efficiently and people are protected by the vehicle recognizing and stopping them immediately.

Plannable autonomy

In many areas of production, it is becoming increasingly important for vehicles to be able to make their own decisions in certain situations: If an obstacle appears on the specified route or if people cross the path. To ensure that efficiency does not suffer as a result of too much autonomy, the ability to plan this is an essential part of our systems.

ARCOS user interface

ARCOS offers a simple user interface that allows the status of individual vehicles to be called up at any time and system parameters to be updated during runtime. To optimally support maintenance, the user interface is compatible with all common web-enabled end devices.

- Web-based user interface

- Responsive design

- Commissioning and trouble-shooting wizards

- Multilingual output

- User and rights management

DETAILS AT A GLANCE

VDA Interface

-

To enable the individual vehicles to communicate with the master controller, ARCOS uses the standardized VDA-5050 interface. This not only allows communication with the VDA-compatible NAVIOS master control system, but also enables vehicles to be connected to an existing VDA master control system. This ensures that a vehicle not only finds the right path to its destination at all times and is informed of current changes, but also that vehicles from different manufacturers can be combined with each other.

Navigation and localization

-

Depending on the area of application, ARCOS can be used for various types of navigation and localization:

- Navigation

- Virtual Guided

- Autonomous

- Localization

- Contour-based

- Laser

- Magnetic points

- Navigation

Safety

-

As a rule, automated guided vehicles operate in areas where people also work. To ensure the safety of personnel at all times in these cases, we work with state-of-the-art safety components. In addition, these also allow a high degree of protection for objects in the way, which can be bypassed without any problems thanks to rapid detection.