NIVUS

Videos

Loading the player ...

- Offer Profile

- We are developer, manufacturer and supplier of measurement systems for the water industry. Since more than 45 years NIVUS is active in the field of flow and level metering and is one of the worldwide leading companies in this area. It is our claim to provide the best flow meters with the highest accuracy required for our customers' applications. A selection of various flow measurement technologies combined with individual advice based on comprehensive expertise enables us to provide our customers the optimum systems for the specific measurement site.

Product Portfolio

Flow Measurement for Liquids

- We provide reliable flow measurement devices for clean, slight and heavily polluted media as well as a very wide variety of sensors. Our hydraulic flow measurement systems as well as our radar and ultrasound-based flow measurement systems are supplemented by hydrostatic or ultrasonic level measurements.

Clean and Slightly Polluted Media

NivuFlow 650 Flow Meter

-

For pipes, open channels and water bodies

Allows high accurate flow measurements using the transit time method according to IEC 60041 for part filled and full pipes, open channels and water bodies. Up to 8 measurement paths.- Ultrasonic transit time measurement

- Single or multi path measurement (up to 32 measurement paths with extension modules - in preparation)

- Quick and easy initial start-up due to intuitive, modern operating concept

- The wide range of NIVUS transducers ensures suitability for each measurement application

- Online connection/data transmission and remote maintenance via Internet

- Uncomplicated integration into existing control systems via universal interfaces

- Weatherproof version for outdoor use available

- Compliant with ISO 6416 & IEC 60041

General description

The NivuFlow 650 is compliant with both ISO 6416 & IEC 60041 and has been developed for accurate flow measurement in open channels, part full and full pipes, and surface water bodies. To meet the highest possible accuracy requirements it is currently possible to utilise the NivuFlow 650 using up to 4 velocity paths, with up to 32 velocity paths available by beginning of 2017. The NivuFlow 650 operates over the full bi-directional flow range without causing obstruction or head loss where the large array of NIVUS transducer models makes flow measurement possible across the widest possible range of applications

The compact transmitter design is easily integrated into instrument cabinets using a DIN rail mounting system and is also available with a field enclosure that provides full protection under harsh environmental operating conditions.

The transmitter‘s large graphic display allows quick and easy commissioning of the flow metering system.

Typical NivuFlow 650 Applications- Fixed measurement of surface waters such as rivers, channels and similar

- Irrigation systems (volume distribution and billing)

- Hydropower plants (turbine efficiency and turbine optimisation etc.)

- Inlets and outlets conducting cooling water or circulation systems

- Industrial process waters

- and many more

NivuFlow 600 Flow Meter

-

flow measurement for full pipes

Allows high accurate flow measurement using the transit time method in full pipes. Up to 4 measurement paths.- Ultrasonic transit time measurement

- Single or multi path measurement (up to 32 measurement paths with extension modules - in preparation)

- Flow meter for insert or non-contact clamp-on-sensors

- Easy installation without process disruption

- Easy start-up due to menu guided sensor positioning

- High accurate flow measurement in clean and slightly polluted media

- Intuitive, modern operating concept

- High-resolution graphic daylight display

- Extensive diagnostic functions for reliable initial start-up and quick maintenance

General description

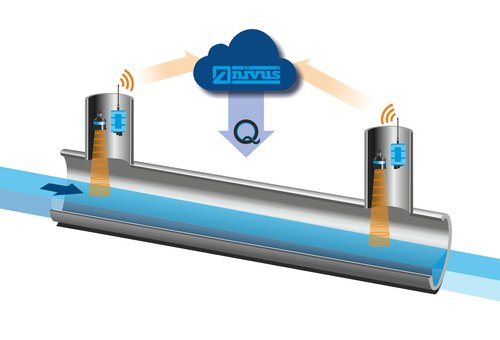

The NivuFlow 600 system was developed particularly for flow measurement in full pipes. To meet the highest accuracy requirements it is possible to equip the transmitters with up to 4 measurement paths, with up to 32 velocity paths available by beginning of 2017. There are pipe sensors as well as contactless clamp-on sensors available for the measurement system. It is not necessary to interrupt running processes to install both sensor types. The system is suitable for the detection of flow rates in various liquid media covering a wide range of applications.

Typical applications- Hydropower

- Leakage monitoring

- Irrigation systems (volume distribution and billing)

- Inlets and outlets conducting cooling water or circulation systems

- Industry: process water, slightly polluted water and more

- Comparative measurements

- Pump monitoring and verification

NivuChannel Flow Meter

-

For pipes, open channels and water bodies

Allows high accurate flow measurements using the transit time method according to IEC 60041 for part filled and full pipes, open channels and water bodies. Up to 8 measurement paths.- Ultrasonic transit time measurement with up to 8 measurement paths

- Flow meter for clear to slightly polluted water

- 8-path measurement according to IEC 60041 (ASME PTC 18)

- Flow meter for pipes, open channels and surface waters

- Easy, multilingual setting of parameters in dialog mode

- Large, back-lit graphic display

- Storage of all measurement data on Compact Flash Card

- Worldwide communication

- Online connection / data transmission and remote maintenance via Internet

- Distance between sensors and transmitters up to 300 meter

General description

NivuChannel is a fix installation flow meter for continuous flow measurement and storage of recorded measurement values and can be used in clean to slightly polluted media.

The flow measurement system is designed for use in part filled and full flumes, channels and pipes featuring various shapes and dimensions.

The NivuChannel measures the average flow velocity within the medium using ultrasound based on the transit time method. This standardised method provides a wide range of applications featuring high accurate results.

Typical NivuChannel applications- Fixed measurement of surface waters such as rivers, channels and similar

- Irrigation systems (volume distribution and billing)

- Hydropower plants (turbine efficiency and turbine optimisation etc.)

- Inlets and outlets conducting cooling water or circulation systems

- WWTPs: outlet, distribution of dirty water and many more

- Leakage investigation in river dam areas

- Industrial flow measurements

- and many more

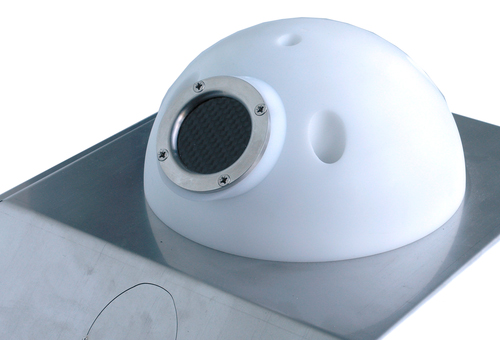

NOS Hemispheric and Ballhead Sensor

-

For measurement places with various geometries

For connection to NivuFlow 650 transmitters. High accurate flow measurement based on the transit time method for open channels and waters, mainly process water channels and natural water bodies.- Ultrasonic transit time sensor for connection to NivuFlow 650

- Hydrometry with highest measurement accuracy

- Measurement in clear to slightly polluted water

- For 8-path measurements according to IEC 60041 (ASME PTC 18)

- Measurement in open channels and surface water bodies

- Resistant sensor material for use in various media

- Up to 100 m of cable length between sensor and transmitter or adapter box

- NOS hemispheric and ballhead sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media in part filled and full flumes as well as channels featuring various geometries and dimensions.

Typical NOS hemispheric and ballhead sensor applications- Fixed measurement of surface water bodies such as rivers, channels and similar

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation systems

- WWTP outlets

- Investigation of infiltration/extraneous water or leakage

- Industrial flow measurements

- and many more

NOS Rod Sensor

-

For measurement places with rectangular geometries

For connection to NivuFlow 650 transmitters. High accurate flow measurement based on the transit time method for open channels and waters, mainly process water channels and natural water bodies.- Ultrasonic transit time sensor for connection to NivuFlow 650

- Hydrometry with highest measurement accuracy

- WRAS approval for some versions

- Measurement in clear to slightly polluted water

- For 8-path measurements according to IEC 60041 (ASME PTC 18)

- Measurement in open channels and surface water bodies

- Resistant sensor material for use in various media

- Up to 100 m of cable length between sensor and transmitter or adapter box

- NOS rod sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media. Due to their mechanic construction the sensors are particularly suitable for use in part filled flumes with vertical walls.

The sensor holders are designed to install the sensors above the water level. The water level hence does not need to be lowered and moreover divers are not needed.

Typical NOS rod sensor applications- Fixed flow measurements in channels with various dimensions and similar

- Irrigation systems

- Potable water systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets, distribution of dirty water and similar

- Industrial flow measurements, process water

- and many more

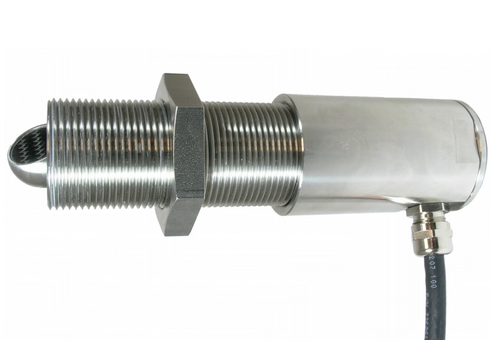

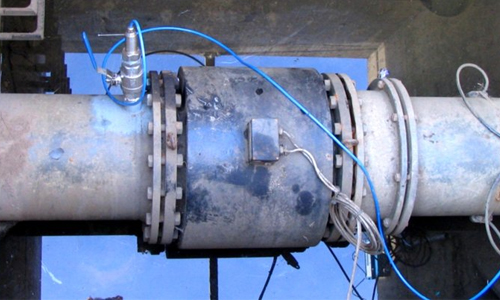

NOS Screw-in sensor

-

for pressurised pipelines

For high accurate flow measurement using the transit time method according to IEC 60041 process water and high pressure lines.- Ultrasonic transit time sensor for connection to NivuFlow 650

- High accurate monitoring of hydropower plants

- Resistant sensor material for use in various media

- Measurement in clear to slightly polluted water

- Hydropower plant monitoring with highest measurement accuracy

- For 8-path measurements according to IEC 60041 (ASME PTC 18

- Up to 100 m of cable length between sensor and transmitter or adapter box

- NOS screw-in sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media.

- NOS screw-in sensors are used for flow measurement in full pipes featuring various dimensions.

Readings are detected based on the ultrasonic transit time principle. Creating a standardised measurement network by installing up to 8 measurement paths according to IEC 60041 allows high accurate measurement results.

Typical NOS screw-in sensor applications- Fixed measurements in full pipes in hydropower plants, pump stations and similar

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets and many more

- Industrial flow measurements, process water, pressurised pipelines

- and many more

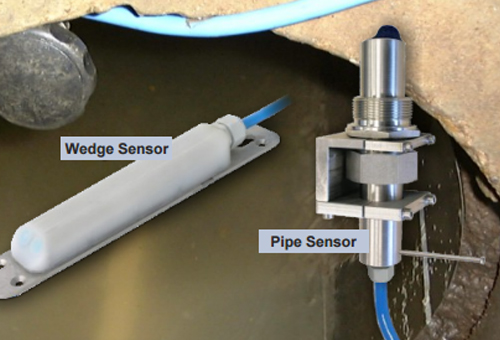

NIS Pipe Sensor

-

for use in pipelines

For full pipes. Ideal for flow measurement of process water and dirty water lines as well as hydropower pipelines.- Ultrasonic transit time sensor for connection to NivuFlow 650

- Resistant sensor material for use in various media

- Measurement in full pipes. Ideal for retrofitting or replacement.

- Measurement in clear to slightly polluted water

- One sensor for all diameters (DN 100 to DN 6.000)

- Up to 100 m of cable length between sensor and transmitter or adapter box

- NIS pipe sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media.

- NIS pipe sensors are used for flow measurement in full pipes featuring various dimensions.

Readings are detected based on the ultrasonic transit time principle which allows high accurate measurement results.

Thanks to perfectly matched mounting material ranging from ball valves to tapping saddles the system is ideal for retrofitting or for replacement of existing flow measurement systems.

Typical NIS pipe sensor applications- Fixed measurements in full pipes in hydropower plants, pump stations and similar

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets

- Dirty water pipelines

- Industrial flow measurements, process water

- Retrofitting and Replacement of existing flow measurement system

- and many more

NIS Wedge Sensor

-

for large pipes and channels

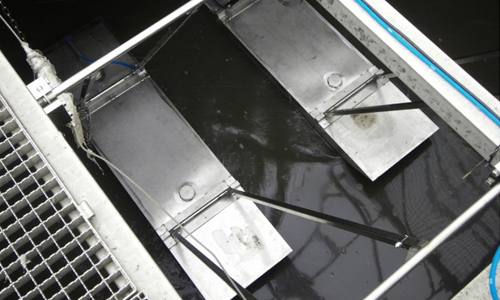

Suitable for flow measurement in part filled and full large pipelines and channels using up to 8 measurement paths.- Ultrasonic transit time sensor for connection to NivuFlow 650 and NivuFlow 600

- Flow measurement with highest accuracy

- Measurement in clear to slightly polluted water

- Measurement in part filled and full geometries

- Resistant sensor material for use in various media

- Up to 100 m of cable length between sensor and transmitter or adapter box

NIS wedge sensors are part of a fixed measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media.

NIS wedge sensors are used for flow measurement in full pipes featuring various dimensions.

Readings are detected based on the ultrasonic transit time principle which allows versatile use with high accurate measurement results. Thanks to perfectly matched mounting material the system is ideal for retrofitting of large geometries such as cooling water channels, pipes and surface waters or for replacement of existing flow measurement systems.

Typical NIS wedge sensor applications- Fixed measurements in full pipes in hydropower plants, pump stations and similar

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets

- Dirty water pipelines

- Industrial flow measurements, process water

- Retrofitting and Replacement of existing flow measurement system

- and many more

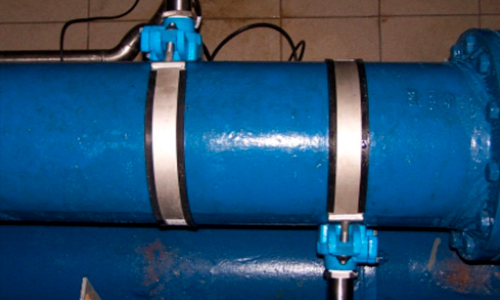

NIC Clamp-On Sensor

-

For contactless flow measurement in pipes

Clamp-on ultrasonic flow meter is ideal for retrofitting system at flow measurement places as well as for monitoring of drinking water networks. Unaffected by pressure and temperature.- Ultrasonic transit time sensor for connection to NivuFlow 600

- Clamp-on system. No contact to measurement medium

- 2-path measurement

- Measurement in clear to slightly polluted water

- Ideal for retrofitting or replacement in the drinking water area

- Up to 100 m of cable length between sensor and transmitter or adapter box

Clamp-on ultrasonic flow meter sensors are part of a measurement system for continuous flow measurement and storage of the recorded measurement data. They can be used for clean to slightly polluted media.

The sensors of this non contact flow meter are used for flow measurement in full pipes featuring various dimensions.

Thanks to the clamp-on design there is no contact between sensor and the measurement medium. The sensors therefore are particularly suitable for use in the drinking water area. Measurement tasks can be carried out very easy within very short time without any greater effort. This applies for high pressures as well as for aggressive and abrasive media.

Typical clamp-on sensor applications- Fixed measurements in full pipes in hydropower plants, pump stations and similar

- Monitoring of drinking water plants and networks

- Irrigation systems

- Inlets and outlets conducting cooling water or circulation

- WWTP outlets

- Dirty water pipelines

- Industrial flow measurements, process water

- Retrofitting and Replacement of existing flow measurement system

- and many more

OFR Radar sensor

-

OFR Radar – contactless flow measurement

Suitable for applications featuring high velocities and low levels.- Contactless flow velocity measurement

- Installation without interrupting processes

- Ex-Approval zone 1 optional

- Determination of surface velocity

- Low maintenance through contactless radar sensor

- Easy installation and operation

- For use in aggressive / abrasive media

- For measurement places with high pollution loads and sedimentation

- For shooting discharge and low flow level

- Improved accuracy in combination with bottom-mounted ultrasonic velocity sensors

By developing the OFR radar sensor in combination with our previous product range we are capable of providing the best possible measurement solution to detect any kinds of flow in each application.

Whether for measurement places with highest accuracy requirements or for applications with difficult media – we provide easy-to-install measurement systems achieving optimum results.

The unique combination of radar measurement and ultrasonic measurement provides previously unprecedented accuracy covering the entire measurement range.

Polluted Media

NivuFlow 550

-

Radar Flow Meter

Contactless flow measurement for open channels and part filled pipes- Low maintenance through contactless radar sensor

- Easy installation and operation

- Ideal for use with all liquids, even aggressive / abrasive media

- Modular flexible installation

- Contactless Radar Flow Metering

The contactless low-maintenance radar sensor provides reliable operation even at very high discharge velocities with low flow levels. Dynamic hydraulic models for various channel shapes based on varying filling levels enable accurate detection of the real flow rate.

Introducing the NivuFlow 7550 we provide a transmitter for Hybrid flow measurement using radar and ultrasonic technology.

Easy Installation and Handling

Due to DIN rail mounting options the compact transmitter saves space and can be installed easily in control cabinets. Moreover the NivuFlow 550 is available with a special protected field enclosure for use under harsh ambient conditions. The large graphic display permits quick and easy commissioning of the flow meter system.

Due to the modular construction of our radar flow meter system we can provide the appropriate solution for each application

NivuFlow 550 provides extended diagnostic options and facilitates in-depth analysis of running processes on site. The transmitter software is in line with current requirements. Future-proof protocols and versatile communication and integration options open many ways for operators to integrate the devices into higher systems such as SCADA or process control systems.

Typcal applications for NivuFlow 550- Measurement places with high pollutant load and sedimentation

- Measurement places featuring bed load / debris

- Measurement places with installation restrictions in the channel

- Shooting discharge at low flow levels and high velocities

NivuFlow 750 Flow Meter

-

High accurate with intuitive operation

For ultrasonic flow measurement of slight to heavily polluted media in part filled and full pipes and channels. Best possible results even under difficult conditions.- Very high accuracy flow meter by means of ultrasonic cross correlation method

- Certified according to MCERTS - Sira MC160303/00

- Up to 3 measurement spots as well as up to 9 flow sensors (Version M9)

- Real-time indication of real flow velocity profiles

- Suitable even for very demanding applications

- Intuitive, modern operating concept for quick and easy commissioning

- Large colour graphic display

- Integrated numeric flow models

- Ultrasonic flow measurement in all channels, part filled and full pipes as well as flumes

- No calibration required

- Comprehensive diagnostic functions for reliable commissioning and quick maintenance

- Spatial allocation of measured single velocities

- Compact DIN rail flow meter for narrow switching cabinets

- Field enclosure with large terminal housing for comfortable installation on site

- Quick wiring thanks to front-side access

- Universal standardised interfaces for easy connection

Flow metering at the highest technical level

The NivuFlow 750 flow meter is the successor to the well-known OCM Pro CF. Compact dimensions of the flowmeter allow DIN-rail installation and installation in switching cabinets even under confined space conditions and in narrow housings.

Combined front-side cage spring terminal clamps ensure quick and easy wiring as well as quick and easy transmitter exchange without tools.

The modern, intuitive one-hand operation using the rotary pushbutton in context with the high-resolution, easy-to-read graphic colour daylight display allows very quick and easy, cost-efficient commissioning on site. No extra input devices or software components are required.

Typical applications- WWTPs

- Channel networks

- Discharge structures

- Industrial wastewater networks

- Discharge

- Drainage lines

- Return sludge lines

- Recirculation lines

- and many more

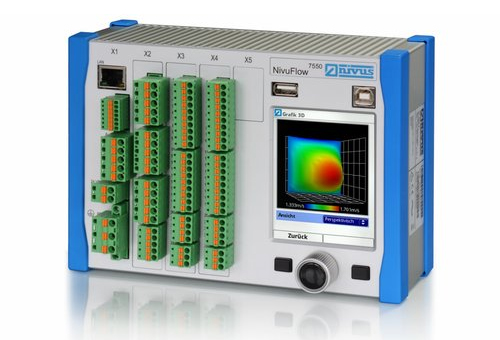

NivuFlow 7550

-

Hybrid Flow Measurement with Surface Radar and Ultrasonic Profile Scanner

Flow measurement for open channels as well as part filled pipes. Optimum results through combination of ultrasonic cross correlation and radar technology.

Hybrid Flow Measurement

NivuFlow 7550 is a hybrid measurement system which was particularly developed for flow metering in part filled pipes, channels and surface waters. Mainly in difficult applications the flow meter stands out for reliable results thanks to its advantages by using two measurement technologies.

Contactless Radar Flow Measurement

The contactless low-maintenance radar sensor provides reliable operation even at very high discharge velocities with low flow levels. Dynamic hydraulic models for various channel shapes based on varying filling levels enable accurate detection of the real flow rate.

Ultrasonic Flow Measurement as Overflow Sensor

The ultrasonic cross correlation sensor can be used as overflow sensor. In such cases the sensor provides reliable and accurate results in overflow situations where radar sensors cannot be used for measuring. Thanks to the flow profile detection and the detection of sedimentation on the bottom the flow rate is determined very accurately. Information on sedimentation is also considered for further measurements using the radar system.

Ultrasonic Flow Measurement as Redundant Measurement

The ultrasonic sensor can be used as permanent redundant measurement too. Installing the sensor on the side walls above the sedimentation helps to avoid soiling. The detection of local flow velocities covers the entire channel width and guarantees the determination of very accurate flow profiles. Pre-programmed hydraulic models increase the accuracy of the measurement system.

Typical NivuFlow 7550 Applications- Continuous and reliable flow metering in overflow situations

- Sedimentation detection with ultrasonic level measurement in case of overflow

- Measurement places featuring high dirt loads and sedimentation

- Measurement places featuring bed load / debris

- Measurement places with limited installation options within the channel

- Reliable flow metering in shooting discharge and low flow levels

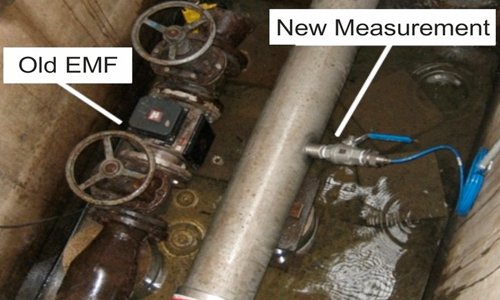

NFP Flow Meter

-

High accurate for full pipes

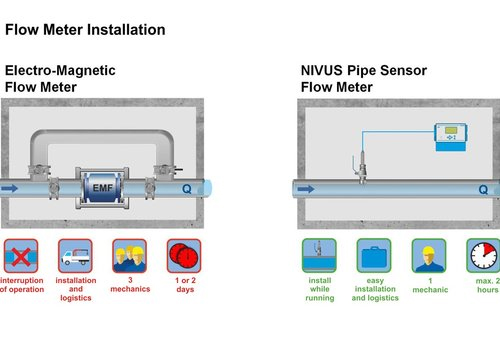

- Cost-efficient alternative to conventional EMFs/mag meters. For continuous flow measurement in slight to heavily polluted media in full pipes

- Cost-efficient alternative to EMFs/mag meters considering the total costs

- Very high measurement accuracy

- Quick and easy retrofitting for all pipe materials

- Uncomplicated and reliable commissioning even under process conditions

- Flow metr for river water, rainwater, dirty water, sludge, cooling water, domestic and industrial wastewater and more.

- ATEX approval for Ex-Zone 1

- Easy assessment of measurement places

- Easy-to-read display

- For use with Type POA pipe sensors

NFP (NIVUS Full Pipe) flow meter was developed particularly for flow measurement in full pipes from DN 100 to DN 800. The system is based on the cross correlation principle for slight to heavily polluted media. The NFP combines grid measurements featuring adapted weighting of areas with velocity profile correction.

The unit stands out for highest measurement accuracy and a very good price-performance ratio. Appropriate NIVUS accessories facilitate installation and maintenance at low costs. The NFP therefore is ideal also to replace obsolete or defective EMFs and other measurement systems. Existing flow meters do not have to be dismantled.

Typical NFP applications- Pump stations for rainwater, dirty water and combined water

- WWTPs

- Pressurised pipelines

- Drainage pipelines

- Return sludge pipelines

- Recirculation pipelines

- and many more

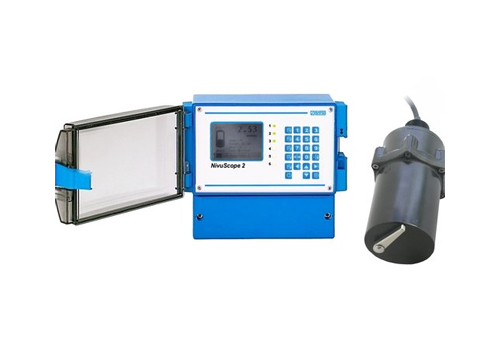

PCM Pro Flow Meter

-

for portable and high accurate flow measurement

For portable ultrasonic flow measurement of slight to heavily polluted media in part filled and full pipes and channels. Best possible results even under difficult conditions- Very high accuracy flow meter

- Can be programmed directly in Ex-areas

- Clear text menus

- Startup wizard

- Clear diagnostics and simulation functions

- Corrosion-proof enclosure

- Can be used without grounding

- Easy assessment of flow conditions through indication of the real flow profile directly on the flow meter display

- Redundant data storage

- Online-verification of measurement data

General description

Flow measurements are absolutely necessary when it comes to assess the hydraulic conditions of sewage networks or special constructions.

The importance of portable, power-independent flow meters for determination of infiltration, channel efficiency, sewerage master planning or influent control is hence continuously rising. Reliable and significant data representing typical operational conditions of the measurement places are to be gained with the help of these data.

It is very often required to carry out the measurements only for a few weeks or months to obtain representative data.

A measurement system for portable flow measurements basically consists of a transmitter Type PCM for power supply, data entry, indication and data storage plus a sensor for the recording of measurement data.

Sensor construction as well as the built-in pickups may be customised individually according to the conditions prevailing on site.

For flow velocity measurement starting at flow levels as low as 3 cm up to several meters there is a wide selection of sensors available.

Typical PCM Pro Ex applications- Channel networks: determination of infiltration, channel efficiency, influent control, determination of discharge volumes and creation of sewerage master plans

- Measurement campaigns

- Pump stations: verification of performance and wear

- and many more

PCM 4 Flow Meter

-

for portable and high accurate flow measurement

For portable ultrasonic flow measurement of slight to heavily polluted media in part filled and full pipes and channels. Best possible results even under difficult conditions.- Very high accuracy

- Clear text menus

- Startup wizard

- Clear diagnostics and simulation functions

- Corrosion-proof enclosure

- Easy assessment of flow conditions thorough indication of the real flow profile directly on the flow meter display

- Redundant data storage

- Online-verification of measurement data

- Direct sampler control

General description

Measurements are absolutely necessary when it comes to assess the hydraulic conditions of sewage networks or special constructions.

The importance of portable, power-independent flow meters for determination of infiltration, channel efficiency, sewerage master planning or influent control is hence continuously rising. Reliable and significant data representing typical operational conditions of the measurement places are to be gained with the help of these data.

It is very often required to carry out the measurements only for a few weeks or months to obtain representative data.

A measurement system for portable flow measurements basically consists of a transmitter Type PCM for power supply, data entry, indication and data storage plus a sensor for the recording of measurement data.

Sensor construction as well as the built-in pickups may be customised individually according to the conditions prevailing on site.

For flow velocity measurement starting at flow levels as low as 3 cm up to several meters there is a wide selection of sensors available.

Typical PCM 4 applications- Channel networks: determination of infiltration, channel efficiency, influent control, determination of discharge volumes and creation of sewerage master plans

- Measurement campaigns

- Pump stations: verification of performance and wear

- and many more

OCM F Flow Meter

-

for flow measurement based on the Doppler principle

For ultrasonic flow measurement of slight to heavily polluted media in part filled an full pipes and channels. Complete measurement system in connection with KDA sensors- Cost-effective to purchase

- Intelligent Doppler Technology

- Connection of Type KDA sensors

- Easy and multilingual programming in dialog mode

- All outputs can be simulated

- Integrated 3-step controller

General description

The OCM F flow meter utilises a fully bidirectional ultrasonic Doppler flow velocity sensor Type KDA. The newly developed intelligent Doppler sensor detects and directly evaluates the flow velocity.

Levels can be measured by either using the sensor-integrated pressure sensor or an external sensor.

Operation / Programming

Thanks to the intuitive user interface it is very easy to set up the OCM F for the requirements of various applications. Programmed settings are indicated clearly. This virtually eliminates mal-function due to faulty programming. Current readings are indicated clearly on the large back-lit graphic display.

Typical OCM F applications- Permanent measurements on storm water basin, storm water retention basin, storm water sedimentation tank

- Discharge volume measurements

- Flow measurements in channel networks

- WWTPs: intake, discharge, intake to activated sludge tanks, return sludge, recirculation

- Industrial wastewater networks

- and many more

NivuLog SunFlow Flow Meter

-

Solar-powered for full and partial filling

Self-sufficient measurement station with integrated data transmission via GPRS. For discontinuous flow measurement in slight to heavily polluted media- Solar-powered flow measurement station independent from mains power

- Extremely robust and compact IP68 enclosure

- Solar panel protected by armoured glass

- Integrated rechargeable buffer battery and charging control

- Direct connection of sensors using encapsulated terminal housing

- Adjustable measurement and transmission cycles

- Storing, processing, indication and calculation of measurement data using D2W – Internet portal Device to Web

The NivuLog SunFlow is a self-sufficient, solar-powered flow measurement station independent from mains power with integrated GPRS data transmission. The discontinuous flow measurement is suited for slight to heavy polluted media in open channels, flumes as well as in part filled and full pipes.

The NivuLog SunFlow is designed for flow measurement, storage and transmission of data in locations without mains power supply. The very robust aluminium cast enclosure with IP68 protection is covered with armoured glass and contains all necessary components such as data logger, modem, charging control and rechargeable batteries. Thanks to the compact construction it is perfectly suited for use in free and rough terrain. A Doppler flow velocity sensor type KDS with optional integrated level measurement is connected directly to the system.

Typical NivuLog SunFlow applications

Flow measurement in stormwater tanks, channel networks, irrigation channels, mine water cleaning plants, natural streams etc.

Optional Accessories

Robust mast holder set for fastening and adjustment of the measurement station on a mast with diameters between 70 – 90 mm. Material stainless steel 1.4571

PCM F Flow Meter

-

for portable flow measurement

For portable ultrasonic flow measurements from slight to heavily polluted media using the Doppler principle in part filled and full pipes and channels.- Clear text menus

- Startup wizard

- Clear diagnostics and simulation functions

- Corrosion-proof enclosure

- Redundant data storage

- Direct sampler control

- Flow measurement based on the Doppler principle

General description

Measurements are absolutely necessary when it comes to assess the hydraulic conditions of sewage networks or special constructions.

The importance of portable, power-independent flow meters for determination of infiltration, channel efficiency, sewerage master planning or influent control is hence continuously rising. Reliable and significant data representing typical operational conditions of the measurement places are to be gained with the help of these data.

It is very often required to carry out the measurements only for a few weeks or months to obtain representative data.

Typical PCM F applications- Channel networks: determination of infiltration, channel efficiency, influent control, determination of discharge volumes and creation of sewerage master plans

- Measurement campaigns

- Pump stations: verification of performance and wear

- and many more

OCM Pro CF Flow Meter

-

High accurate for slight to heavily polluted media

For ultrasonic flow measurements in slight to heavily polluted media in part filled and full pipes and channels. Best possible results even under difficult conditions- Very high measurement accuracy

- Certified according to MCERTS - Sira MC130219/01

- Absolutely stable zero point and drift-free

- No electrodes, no conductivity required

- Measurement in all channels, part filled and full pipes as well as flumes

- Measurement even in heavily polluted and abrasive media (e.g. return sludge and digested sludge)

- No calibration required

- Suitable even for very difficult applications

- Easy installation without additional constructions

- Ideal for retrofitting in existing applications

- Measures and indicates the real flow velocity profiles

- Spatial allocation of measured single velocities through cross correlation with digital pattern detection

- Ex approval Zone 1 according to ATEX

- Very easy, multilingual setting of parameters in dialog mode

- Large, back-lit graphic display

- Storage of all measurement data on Compact Flash Card

- Integrated Modbus TCP

- Worldwide TCP/IP communication online connection/data transmission and remote maintenance via Internet

- Exact flow measurement

NIVUS flow measurement systems stand for innovation and highest accuracy.

The OCM Pro CF, proven a thousand times, is a permanent measurement system for continuous flow measurement , flow control and storage of recorded flow data within the range of slight to heavily polluted media of various consistencies.

The system can be used as initial equipment or retrofitting in part filled and full flumes, channels and pipes featuring various shapes and dimensions.

OCM Pro CF provides fast processors for signal processing, Modbus TCP as well as online connection via Internet.

POA Correlation Wedge Sensor

-

Medium measurement range for levels up to ca. 1m

Ultrasonic sensors for flow measurement with very high accuracy in slight to heavily polluted media. For installation on channel wall or channel bottom- For high-accurate flow measurement by means of ultrasonic cross correlation method

- Interference-free connection over long distances through digital signal transmission

- Cables can be extended without any problems using standard cables

- Absolutely stable zero point and drift-free

- Measurement in heavily polluted and abrasive media

- Easy installation without additional constructions and perfectly matched mounting accessories

- Installation under process conditions possible

- Suitable for all channel cross sections

- The tailored selection of sensor constructions ensures the best possible solution for each application

POA flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media.

The wedge-shaped sensors are designed for installation on either the channel wall or the channel bottom. Combined with transmitter types such as NivuFlow 750 and an external level measurement the result is a complete flow measurement system.

Typical applications for POA wedge sensors- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Permanent measurements on stormwater treatment facilities such as stormwater overflow tanks, rainwater sedimentation and retention tanks

- Direct discharge control, infiltration (extraneous water) or leakage detection

- Industrial wastewater networks

- Measurement campaigns in channel networks

- and many more

POA Correlation Pipe Sensor

-

Medium measurement range for levels up to ca. 1m

Ultrasonic sensors for flow measurement with very high accuracy in slight to heavily polluted media. For installation in pipes from the outside- For high-accurate flow measurement by means of ultrasonic cross correlation method

- Interference-free connection over long distances through digital signal transmission

- Cables can be extended without any problems using standard cables

- Absolutely stable zero point and drift-free

- Measurement in heavily polluted and abrasive media

- Easy installation without additional constructions and perfectly matched mounting accessories

- Installation under process conditions possible

- Suitable for all channel cross sections

POA flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media.

The pipe-shaped sensors are designed for installation in pipes from the outside using a nozzle. Combined with transmitter types such as NivuFlow 750 and an external level measurement the result is a complete flow measurement system.

Typical applications for POA pipe sensors- Stormwater treatment plants: flow measurements and control of the discharge to the WWTP

- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Direct discharge control, infiltration (extraneous water) or leakage detection

- Industrial wastewater networks

- and many more

CS2 Correlation Wedge Sensor

-

Large measurement range for high flow levels

Ultrasonic sensors for flow measurement with very high accuracy in slight to heavily polluted media. For installation on channel wall or channel bottom- For high-accurate flow measurement by means of ultrasonic cross correlation method

- Interference-free connection over long distances through digital signal transmission

- Cables can be extended without any problems using standard cables

- Absolutely stable zero point and drift-free

- Measurement in heavily polluted and abrasive media

- Easy installation without additional constructions and perfectly matched mounting accessories

- Installation under process conditions possible

- Suitable for all channel cross sections

- The tailored selection of sensor constructions ensures the best possible solution for each application

CS2 flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media in channels mainly featuring high levels.

The wedge-shaped sensors are designed for installation on either the channel wall or the channel bottom. Combined with transmitter types such as NivuFlow 750 and an external level measurement the result is a complete flow measurement system.

Typical applications for CS2 wedge sensors- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Industrial wastewater networks

- Large Collectors

- Particularly suitable for large channels featuring levels starting at 500 mm

CS2 Correlation Pipe Sensor

-

Large measurement range for big pipes

Ultrasonic sensors for flow measurement with very high accuracy in slight to heavily polluted media. For installation in pipes starting at 1000 mm diameter- Very high accuracy by means of ultrasonic cross correlation method

- Interference-free connection over long distances through digital signal transmission

- Cables can be extended without any problems using standard cables

- Absolutely stable zero point and drift-free

- Measurement in heavily polluted and abrasive media

- Easy installation without additional constructions and perfectly matched mounting accessories

- Installation under process conditions possible

- Particularly suitable for pipe sections starting at 1000 mm diameter

CS2 flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media.

The pipe-shaped sensors are designed for installation in pipes from the outside using a nozzle. Combined with transmitter types such as NivuFlow 750 and an external level measurement the result is a complete flow measurement system.

Typical applications for CS2 pipe sensor- Channel networks: billing measurement places, flow measurement in large pipe sections

- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Industrial wastewater networks

- and many more

Mini Correlation Sensor

-

Measurements starting at flow levels of 3 cm

Ultrasonic sensors for flow measurement with very high accuracy in slight to heavily polluted media. For installation on channel wall or channel bottom

For high-accurate flow measurement by means of ultrasonic cross correlation method- Infiltration measurement (extraneous water)

- Influent control

- Billing measurement places

- Discharge constructions

- Precipitation discharge measurements

- The Mini sensor family provides the best possible sensors to detect lowest flow levels e.g. for infiltration measurement (extraneous water) or indirect discharge measurement.

- The sensors use the proven ultrasonic cross correlation method patented by NIVUS. This method allows to detect and to indicate flow profiles starting at flow levels as low as a few centimeters.

Due to their shape the sensors are particularly suitable for small geometries and help to avoid backwater effects, the risk of build-up and clogging.

Typical applications for Mini sensors- Measurement campaigns in channel networks

- Small WWTPs: intake and discharge

- Industrial wastewater networks

- Particularly suitable for channels featuring low flow levels

KDA Doppler Wedge Sensor

-

Wedge-shaped flow velocity sensor for channels

Ultrasonic sensors for flow measurement in slight to heavily polluted media. Wedge shape for installation on channel wall or channel bottom- Latest fourth-generation intelligent Doppler technology

- Cost-effective pricing

- Suitable for all channel cross sections

- Easy to install without the need for additional constructions

- Cables can be extended without any problems

- Measurement in heavily polluted and abrasive media

- Built-in pressure cell mechanically protected

KDA flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media. The wedge-shaped sensors are designed for installation on either the channel wall or the channel bottom.

Combined with transmitter types such as PCM F and OCM F the result is a complete flow measurement system.

Typical applications for KDA wedge sensors- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Permanent measurements on stormwater treatment facilities such as stormwater overflow tanks, rainwater sedimentation and retention tanks

- Direct discharge control, infiltration (extraneous water) or leakage detection

- Industrial wastewater networks

- Measurement campaigns in channel networks

- and many more

KDA Doppler Pipe Sensor

-

Flow velocity sensor for installation in pipes

Ultrasonic sensors for flow measurement in slight to heavily polluted media. Designed for fastening in pipes using a nozzle- Latest fourth-generation intelligent Doppler technology

- Cost-effective pricing

- Suitable for all channel cross sections

- Easy to install without the need for additional constructions

- Cables can be extended without any problems

- Measurement in heavily polluted and abrasive media

KDA flow velocity sensors are suitable for continuous measurement of slight to heavily polluted media. The pipe sensors are designed for installation in pipes from the outside using a nozzle. Combined with transmitter types such as PCM F and without OCM F the result is a complete flow measurement system.

Typical applications for KDA pipe sensors- Wastewater treatment plants: intake, discharge, activated sludge tank intakes, return sludge, recirculation, surplus sludge, digester discharge and flocculant dosage

- Permanent measurements on stormwater treatment facilities such as stormwater overflow tanks, rainwater sedimentation and retention tanks

- Direct discharge control, infiltration (extraneous water) or leakage detection

- Industrial wastewater networks

- and many more

OFR Radar sensor

-

OFR Radar – contactless flow measurement

Suitable for applications featuring high velocities and low levels.- Contactless flow velocity measurement

- Installation without interrupting processes

- Ex-Approval zone 1 optional

- Determination of surface velocity

- Low maintenance through contactless radar sensor

- Easy installation and operation

- For use in aggressive / abrasive media

- For measurement places with high pollution loads and sedimentation

- For shooting discharge and low flow level

- Improved accuracy in combination with bottom-mounted ultrasonic velocity sensors

By developing the OFR radar sensor in combination with our previous product range we are capable of providing the best possible measurement solution to detect any kinds of flow in each application.

Whether for measurement places with highest accuracy requirements or for applications with difficult media – we provide easy-to-install measurement systems achieving optimum results.

The unique combination of radar measurement and ultrasonic measurement provides previously unprecedented accuracy covering the entire measurement range.

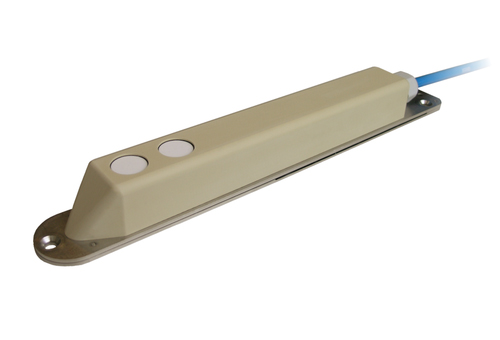

NivuGuard 2

-

Non-contact flow monitoring

Non-contact flow monitoring for polluted respectively high polluted media in full pipelines- Non-contact measurement

- No transmitter required

- Pressure and temperature independent

- Easy retrofitting without the need for pipe works and operational interruptions

- For use on pipes from DN50 to DN350

- Very robust enclosure

The NivuGuard 2 sensor is for flow monitoring in full pipelines by using a specially developed Doppler method. Thanks to the clamp-on technology the sensor can be installed very quick and easy from the outside. The integral signal evaluation allows to operate the sensor without transmitter. The sensor can be set up directly by using a free software. The very robust enclosure is perfect for use in harsh ambient conditions. Due to clamp-on installation the NivuGuard 2 can be moreover used on pipelines conducting highly abrasive and aggressive media.

Featuring cost-efficient commissioning and variable areas of use the measurement system is mainly suitable particularly for retrofitting. The NivuGuard 2 can be used on pipes made of plastic, stainless steel, steel or cast iron.

Der optionally available NivuGuard Monitor serves as indication instrument and provides more signal outputs. The sensor can be set up as well by using the Monitor‘s large keypad.

Typical Applications

Dry run protection and flow monitoring on:

- pump lines

- sludge lines

- wastewater pipelines

Hydraulic Flow Measurement

- Hydraulic flow measurement systems determine flow rates or overflow volumes on weirs with the aid of level measurement. The measurement is mostly applied on hydraulic constructions such as weirs featuring varying shapes or in Venturi flumes.

NivuSmart Q

-

Smart Flow Metering for part filled Pipes and Channels

Hydraulic flow measurement using two parallel level readings. Accurate, contactless and with low maintenance requirements.- Non-contact measurement

- Low maintenance

- Accurate method (calibration using cross correlation; <2% deviation)

- Detects negative flow

- Detection of backwater and free discharge

NivuSmart Q is a new measurement method for flow rate detection using two parallel level readings. The levels are measured in a known distance, e.g. by measuring in two consecutive shafts within a sewer system. The NIVUS exclusive metering system is putting geometrical conditions (such as slope, diameter and width of a channel etc.) and latest hydraulic flow models in relation to each other.

By using site-specific equations it is possible to compute flow rates with a remarkably high accuracy. The accuracy is comparable to other non-contact flow measurement systems. Calibrating the system provides an extra increase in accuracy.

The System

Level measurements and GPRS data loggers are battery-powered.

The level readings are transmitted automatically to a centralised data management system.- Independent from mains power

- Easy installation

- Long-life high performance battery

- Automatic and reliable data transmission

- Contactless

- Easy integration into SCADA or measurement data evaluation

- Ex version available

Typical Applications- Measurement sites featuring difficult maintenance conditions

- If it is not possible to install the measurement system in the channel, such as in glass fibre reinforced pipelines

- If there is no mains power or communication infrastructure available

- Redundant flow metering

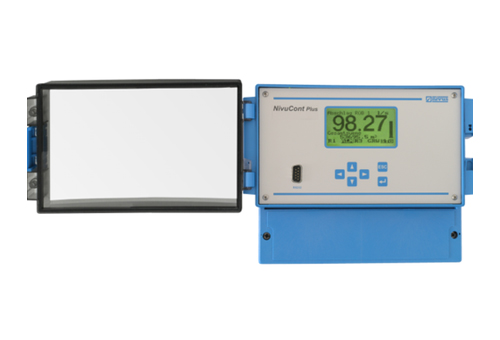

HydraulicCalculator Plus

-

Flow meter for discharge volume calculation

HydraulicCalculator Plus calculates discharge volumes on weirs with different shapes according to DWA A111

Flow calculator for discharge volume determination on weirs with different shapes according to DWA A111- Calculation methods according to DWA A111 implemented

- Correct discharge calculation even in backwater conditions and tangential flow

- Direct connection of 2- and 3-wire sensors

- Ex Zone 1 (option)

- Comfortable user menus in dialog mode

- Large graphic display with bargraph indicator

The HydraulicCalculator Plus flow meter provides integrated, DWA-conform calculation algorithms for discharge calculation on lateral weirs with tangential flow as well as weirs susceptible to backwater and compensates the calculation errors occurring with common discharge volume measurement systems.

Additional calculation methods for use with special constructions such as slot outlets with or without backwater formation, discharge below slide valves, water level correction on weir flaps etc. complete the performance profile.

The flow calculator features intrinsically safe power supply of 2-wire sensors for Ex-Zone 1 (such as NivuNivuBar Plus, NivuCompact) as well as 2 analog outputs and 5 relays. The device can be easily programmed by using the 6 keys in conjunction with dialog menus on a large back-lit graphic display.

Relevant calculation parameters can be selected easily and diagnostic tools for inputs and outputs, transmitter status, parameter modifications etc. are available as standard.

All required readings and calculation values are clearly indicated as digits or simultaneously as bargraph if desired.

Inclinometer

-

for slope detection of moving weir flaps

The new electronic NDW 2 inclinometer utilises a modern measurement method based on MEMS technology for gravitational inclination measurement (rotational angle measurement).- Ex approval II 2 G Ex ib IIB T4 (optional)

- Wear-free

- Corrosion-proof

- No moving parts

- Robust design

- High accuracy

- Maintenance-free

- Reliable

- High operational safety

- Fully immersible (IP68)

- Mercury-free

By detecting inclination without the use of shafts it is possible to capture the position of movable weir flaps or other movable and inclinable components such as sluice boards or slide valves without any problems. Overflow volumes or other flow volumes thus can be easily determined by using a Q/h relation or detected angles.

Existing weir flaps can be easily retrofitted by installing the unit on the inclined plane.

NDW 2 combines high accuracy and operational safety with robust design.

The compact unit is free of wear since the measurement principle does not use any movable parts and hence provides reliable measurement results even under flood conditions (IP68).

NDW 2 provides a 4 - 20 mA signal proportional to the angle of inclination (0 - 90° or 0 - 60°) to obtain overflow data.

Following devices such as HydraulicCal-culator Plus, NivuCont Plus, NivuFlow, NivuLog or PCS/SCADA systems use flap-specific data to compute accurate overflow volumes.

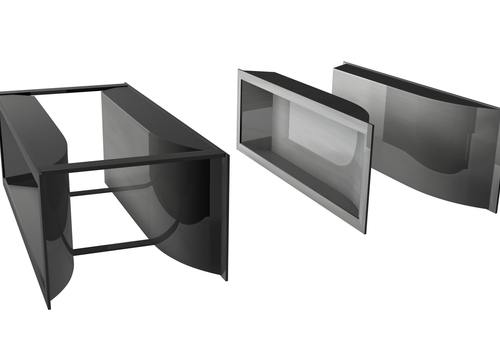

Venturi Half Shells

-

for classical flow measurement using Q/h

Corrosion-proof Venturi half shells according to DIN 19559/II for installation in various part filled channels with vertical walls- Corrosion-proof through stainless steel 1.4571 (V4A)

- Construction according to DIN 19559/II

- Individually made following existing channel dimensions and expected volumes

- Easy installation without chiselling and concreting works

- Uncomplicated correction of discharge curves in case of inappropriate dimensions

Venturi half shells

The durable corrosion-proof Venturi half shells are easily installed on vertical channel walls by using the accompanying fastening materials. This eliminates the common problems with compact Venturis regarding dimensional accuracy. – If the channel dimension should change simply a correct discharge characteristic based on the correct channel width is used.

Thanks to being manufactured from stainless steel possible weathering or corrosion due to unknown organic solvents partially contained within the wastewater is avoided. The risk of breaking is avoided as well and the lifespan of the stainless steel half shells is virtually unlimited.

Non-contact level measurement

- We provide reliable continuous non-contact level measurement using ultrasound or hydrostatically by using pressure cells as well as reliable measurement of level detection. Our ultrasonic or hydrostatic level measurement systems reliably and accurately detect the levels of liquid media.

Ultrasonic Level Measurement

- The range of our non-contact ultrasonic level measurement systems comprises ultrasonic sensors and meters. The ultrasonic sensors range from the i-Series sensors, the NivuCompact echo sounder to the P-Series sensors and the OCL air-ultrasonic sensor.

i-Series Sensors

-

Intelligent sensors for level measurement

Ultrasonic sensors with integrated transmitter for measurement of distance, level, empty space or volumes. Suitable for harsh ambient conditions.- Sensor as independent, comfortable level measurement

- Alarm output in case of flooding possible

- Pre-programmed measurement range steps of 3, 6, 10 and 15 m

- Ideally suitable for battery operation through quick measurement times

- Resistant to humidity, aggressive environments and heavy temperature fluctuations

- IP68 protection

- Can be directly connected to PLC

- Saves time and space, no transmitter installation needed

- DATEM - digital echo processing with automatic false echo avoidance

- Ex-approval according to ATEX for Zone 1; optional for Zone 0

- Easy wiring directly to terminal unit in Ex-areas (no Zener barrier required)

i-Series level sensors can be used to measure distance, level, empty space or volumes of liquids in any application where highly accurate level measurements are required.

The level sensors are designed for use in poor ambient conditions. Soiling as well as wear and tear is avoided thanks to non-contacting measurement.

Since transmitter and sensor share the same fully encapsulated enclosure the unit can be easily installed with low space requirements. Extensive programming works are not needed through pre-programmed measurement range steps. The sensors can be directly connected to any PLC, NIVUS GPRS data logger and all systems processing measurement values featuring an active mA-input.

Typical applications- Wastewater: stormwater overflow tanks and storage sewers, clarifiers, pump stations, screening plants, flow measurements, tank volume measurements, container monitoring, irrigation facilities

- Drinking water: tank level measurements, water treatment, sweater desalination plants, level measurements

- Flood protection: stormwater retention tanks, level measurements with remote data transmission, surface water bodies

- Power generation: cooling water circuits, hydropower plants

P-Series Sensors

-

Ultrasonic sensors for level measurement

P-Series sensors are suitable for continuous level measurement in the water and wastewater sector. For connection to NivuMaster-Series evaluation units. Suitable for harsh ambient conditions.- Very low in maintenance through non-contact measurement

- Extremely versatile thanks to measurement ranges from 0.07 m to 40 m

- Protection IP 68

- ATEX approval for Ex-Zone 0 and 1

- Alarm output in case of flooding possible

- Resistant to moisture, aggressive environments and heavy temperature fluctuations

The ultrasonic sensors with integrated temperature compensation for connection to NivuMaster- Series evaluation units provide a wide variety of measuring options for liquids.

The sensors provide accurate and reliable readings even in narrow tanks, no matter what measurement range or application. False echoes reflected from built-in obstructive constructions are negligible since they will be avoided automatically.

The sensors are available with 1"-thread or as flange version according to DIN and thus can be installed without any problems.

Typical applications for P-Series sensors- Level measurements in the water and wastewater sector

- Flow measurements in open flumes and weirs

- Volume measurements in tanks

- Comparative measurements on screens

- Pump control in pump stations

OCL Air-Ultrasonic Sensor

-

for level measurement in combination with flow measurents

Intelligent air-ultrasonic sensor for connection to flow transmitters such as NivuFlow 750, OCM Pro and PCM for non-contact level measurement in part filled flow measurement places.- Direct sensor connection to flow transmitters such as NivuFlow 750, OCM Pro and PCM

- Small construction height

- Low dead zone

- Digital echo processing and linearisationNarrow beam angle

- Optimised construction for small pipes

- Easy installation using pipe mounting system or direct fasting using bolts

- View echo profiles on the transmitter

- Integrated temperature compensation

- ATEX approval for Ex-Zone 1

The compact air-ultrasonic sensor Type OCL has been developed for direct connection to portable and permanent flow transmitters such as NivuFlow 750, OCM Pro and PCM.

Thanks to the slim construction it is ideally suitable for use in the crown of small and large pipes, on channel ceilings or other constructions.

The low dead zone allows to measure variable levels in flow applications almost up to full filling. The integrated temperature measurement ensures very high accuracies over the entire very wide measurement range.

The ATEX approval in Ex Zone 1 is a standard feature.

NivuCompact Echo Sounder

-

for level and volume measurement

Ultrasonic compact echo sounder in 2- and 3-wire version for non-contact measurement of distance, level, empty space or volume. Parameters can be set directly on site without the need to open the enclosure.- Combi unit with sensor and transmitter

- Measurement range from 0.2 to 10 m

- Digital echo processing and linearisation

- Ideal even for battery operation thanks to very short startup and measurement times

- View echo profiles on PC

- Unit can be programmed on sit without opening the enclosure

- Integrated temperature compensation

- ATEX Approval for Ex-Zone 1

The NivuCompact is a compact echo sounder for non-contact ultrasonic measurement of level, distance, space or volume. NivuCompact can be used wherever reliable non-contact level measurement is required.

Thanks to its very quick startup time of 4 seconds until value output, the NivuCompact is particularly suitable for battery-powered logger operation. High transducer power and tight beam angle in addition with digital echo pro-cessing make the NivuCompact an ideal tool for many "difficult" applications. The integrated display makes programming extremely simple. The NivuCompact is available as 2- or 3-wire version in one unit.

Typical Applications- Wastewater: screening plants, flow control sections in stormwater treatment plants, volume measurements in tanks such as precipitants and similar, irrigation plants

- Drinking water: tank level measurements, water treatment

- Power generation: cooling water circuits, hydropower plants

- Industry: liquid level measurement in tanks and containers

NivuMaster Transmitter

-

For level measurement using ultrasonic sensors

For the supply of connected ultrasonic P-Series sensors, processing of signal data and indication of computed readings. Ideal or measurement and control in level and volume applications- Measurement of level, distance, volume, difference and flow

- Alarm output in case of flooded sensor possible

- Pump control saves energy and costs thanks to intelligent pump management

- High measurement reliability through intelligent agitator avoidance

- Connection of maintenance-free, Ex-protected ultrasonic sensors

- Up to 6 relays and galvanically isolated mA outputs

- Easy echo analysis and setting of parameters using free PC software

- Integrated emergency power switchover

- Easy operation in dialog mode using back-lit graphic display

The NivuMaster series transmitters supply connected P-Series sensors, process measurement values and indicate readings. NivuMaster transmitters are ideally suitable for simple control tasks in level measurement applications. Flow measurements in open channel using a Venturi flume or Q/h-relations, on any kind of weir or discharge sills are possible without any problems.

NivuMaster is available with wall mount enclosure, as 19"-plugin or with panel mount enclosure.

The few parameters required for measuring can be entered easily on site in dialog mode thanks to the back-lit display and the integrated keypad.

Parameters can be evaluated using the free software “PC Software Suite” and the serial interface of the transmitter.

Typical NivuMaster Applications- Wastewater: stormwater overflow tanks and storage sewers, clarifiers, pump stations, screening plants, flow measurements, volume measurements in vessels, container monitoring, irrigation facilities

- Drinking water: tank level measurements, water treatment, seawater desalination facilities, level measurements

- Flood protection: stormwater retention tanks, level measurements with remote data transmission, surface waters

- Power generation: cooling water circuits, hydropower plants

Hydrostatic Level Measurement

- We provide reliable hydrostatic level measurement for various media. At NIVUS you can find a wide variety of sensors and transmitters.

NivuLevel 150N

-

elf-sufficient level measurement system

Level and temperature measurement with a system lifetime up to 5 years. Internal SD card up to 1.000.000 readings.

For use in ATEX Zone 1- Self-sufficient level measurement system

- Internal data memory for approx. 1.000.000 readings

- For use in ATEX zone 1

- Event control

- Acquisition of level and temperature readings

- Easy replacement of batteries by customer

NivuLevel 150 is a self-sufficient level measurement system for

use on measurement sites without public power supply. Due to

very low energy consumption the system provides very long

lifetimes. System programming and data readout can be carried

out very easy via USB interface.

The NivuLevel 150 measurement system acquires the parameters level and temperature. It consists of a datarecording module and a hydrostatic submersible pressure probe.

Depending on the memory cycle selected, the system lifetime is up to 5 years.The unit is powered using standard batteries (Type AA) which can be replaced

by the user on site.

This ensures efficient and economical operation over many years. Recorded data are saved in an internal memory and can be read out using the USB interface.

The capacity of the internal memory is approx. 1.000.000 readings. Once provided as CSV files, the readings can be processed further quickly and easily

Level Data Collector

-

Level measurement with remote data transmission via GPRS

Water level data logger for groundwater level measurement and GPRS data transmission in level pipes starting at 2“. System life up to 10 years.- Extremely robust stainless steel enclosure, IP68

- Data transmission via GPRS

- Automatic log-on with the most powerful service network without additional costs

- Extra-long lifetimes (typical 10 years) through MicroPower® technology

- Connection clamps for 2-wire system such as pressure probes

General description

Robust measurement system, consisting of transmitter and level probe, for data transmission to the server-based Internet portal "D2W" (Device to Web) via GPRS.

The water level data logger measuring and data recording system is for detection of analog readings from connected 2-wire sensors such as pressure probes. The measurement system operates independent from mains power. Sensor and radio transmission system are powered by high-performance Lithium batteries featuring a very long lifetime (approx. 10 years typical). Detected readings are saved on flash memory and will be transmitted to the server-based Device to Web (D2W) Internet portal via GPRS using the built-in quad band modem.

Typical level data collector applications- Groundwater level measurement

- Landfill level monitoring

- Raw water level for waterworks

- Levels in conservation areas and similar

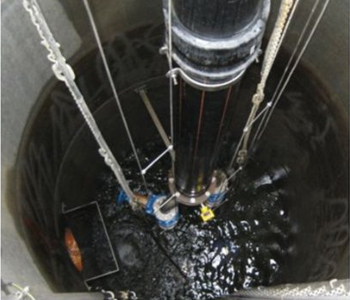

NivuBar Plus II

-

Hang-in probe with capacitive ceramic measurement cell

Submersible probe with 4 - 20 mA transmitter for hydrostatic level measurement in water and wastewater. Oil-free capacitive ceramic measurement cell- Capacitive ceramic measurement cell

- Large front-flush diaphragm

- 2-wire probe

- High overpressure resistance

- Integrated overvoltage protection

This hydrostatic level probe has been developed to meet the high demands of industry and environmental protection.

The stainless steel (1.4571) probe body is locked by a capacitive ceramic measuring cell at the bottom and is held by the self-supporting cable on the top.

The probe can be suspended by using a straining clamp.

The non-corrosive enclosure featuring protection IP68 permits universal use for reliable determination of levels in containers, basins, shafts and tanks. The large diaphragm has proven as very reliable, particularly in the wastewater sector.

Typical applications for NivuBar Plus II- Pump shafts

- Channels

- Stormwater treatment plants, storage sewers, retention tanks and discharge constructions

- WWTPs (screening control, tank levels, sludge tanks, levels in open channels)

- Industrial wastewater networks

- and many more

NivuBar H III

-

Hang-in probe with HART protocol

Submersible probe 4 - 20 mA for hydrostatic level measurement in water and wastewater. Oil-free capacitive ceramic measurement cell and free configurable measurement range via HART.- Capacitive ceramic measurement cell

- Large front-flush diaphragm

- 2-wire probe

- HART protocol

- High overpressure resistance

- Integrated overvoltage protection

- Ex protected

This hydrostatic level probe has been developed to meet the high demands of industrial and environmental protection.

The stainless steel (1.4571) probe body is locked by a capacitive ceramic measuring cell at the bottom and is held by the self-supporting cable on the top.

The probe can be suspended by using a straining clamp.

The non-corrosive enclosure featuring protection IP68 permits universal use for reliable determination of levels in containers, basins, shafts and tanks. The large diaphragm has proven as very reliable, particularly in the wastewater sector.

The probe is available also as Ex version and thus can be installed in any explosive.

Using a laptop with the NIVUS configuration software as well as the HART interface module, the HART protocol allows to universally change the probe’s measurement range.

The standard measurement ranges are 10mH2O and 20mH2O and can be at min. 20 % related to the nominal measurement range (FSO) of the probe (e.g. 0 to 2 m or greater with measurement range 10mH2O (FSO) or 0 to 4 mH2O or greater with measurement range 20mH2O (FSO)).

Utilising the widely used 2-wire technology, the installation costs are very low.

Typical applications for NivuBar H III

NivuBar G II

-

Hang-in probe with 1” thread and capacitive ceramic measurement cell

Submersible probe with 1” thread and 4 - 20 mA transmitter for hydrostatic level measurement in water and wastewater. Oil-free capacitive ceramic measurement cell- Capacitive ceramic measurement cell

- heavily polluted liquids, sludge as well as pasty and corrosive media

- Large front-flush diaphragm

- 1“ thread on sensor bottom

- 2-wire probe

- Ex Zone 0

- High overpressure resistance

- Integrated overvoltage protection

This hydrostatic level probe has been developed to meet the high demands of industry and environmental protection.

The stainless steel (1.4571) probe body is locked by a capacitive ceramic measuring cell at the bottom.

The probe is equipped with a 1“ thread at the bottom. This thread allows to extend the probe by using a protective tube. The probe then is protected against mechanical damage and the cable within the tube is protected against chemical solvents.

The non-corrosive enclosure featuring protection IP68 permits universal use for reliable determination of levels in containers, basins, shafts and tanks. The large diaphragm has proven as very reliable, particularly in the wastewater sector.

NivuBar G II features ex approval II 1G Ex ia IIC/IIB T4 for Zone 0 as standard and can be installed in any explosive area.

Utilising the widely used 2-wire technology, the installation costs are very low.

Typical applications for G II- Pump shafts

- Grease receiving stations

- Stormwater treatment plants, storage sewers, retention tanks and discharge constructions

- WWTPs (screening control, tank levels, sludge tanks, levels in open channels)

- Industrial applications

- and many more

AquaBar II

-

Submersible probe – piezo-resistive stainless steel measurement cell

Submersible probe with 4 - 20 mA transmitter for hydrostatic level measurement in clean to slightly polluted liquids. With piezo-resistive stainless steel measurement cell- Stainless steel diaphragm

- Piezo-resistive pressure sensor

- for clean to slightly polluted liquids.

- 2-wire probe

- High accuracy

- Integrated overvoltage protection

- High electrical operating safety

The hydrostatic level probe features a diameter of only 27 mm and hence can be installed in tubes as used mainly for groundwater level measurement and deep well measurements.

The mechanically robust sensor body made of stainless steel (1.4571) and the separating diaphragm (1.4435) are held from the top on a self-supporting cable made of PUR.

The probe can be strained using a straining clamp.

The proven piezo-resistive measurement principle guarantees high long-term stability and operational reliability. Furthermore the reverse polarity protection, the short circuit resistance as well as an integrated overvoltage protection within the sensor body ensure high operating safety.

Utilising the widely used 2-wire technology, the installation costs are very low.

Typical applications for AquaBar II- Deep wells

- Water levels

- Spring discharge

- Drinking water supply

- Raw water extraction

- Barrages

- River levels

- and many more

AquaBar BS Submersible Probe

-

Diameter 19 mm – ideal for deep wells

Submersible probe with 4 - 20 mA transmitter for hydrostatic level measurement. Suitable for measurements in deep wells through small diameter of only 19 mm. With piezo-resistive stainless steel measurement cell- Diameter only 19 mm

- For use level tubes and protective tubes with diameters starting at 1“

- Stainless steel diaphragm

- Piezo-resistive pressure sensor

- 2-wire probe

- High accuracy

- Integrated overvoltage protection

- High electrical operating safety

Die hydrostatic level probe features a diameter of only 19 mm and hence can be installed in level tubes and protective tubes with very small inside diameters as used mainly for groundwater level measurement and deep well measurements.

The mechanically robust sensor body made of stainless steel (1.4571) and the separating diaphragm (1.4435) are held from the top on a self-supporting cable made of PUR.

The probe can be strained using a straining clamp.

The very small outside diameter of the probe 19 mm allows the use even in very small level tubes and protective tubes with diameters starting at 1“.

The probes can be manufactured upon customer request as well.

Typical applications for AquaBar BS- Deep wells

- Water levels

- Spring discharge

- Drinking water supply

- Raw water extraction

- Barrages

- River levels

- and many more

HydroBar G II

-

Screw-in with capacitive ceramic measurement cell

Screw-in probe with internal 4 - 20 mA transmitter for hydrostatic level measurement in water, wastewater and gases. Oil-free capacitive ceramic measurement cell.- Robust and reliable screw-in probe with 1.5“ threaded connection

- Capacitive ceramic measurement cell

- for slight to heavily polluted liquids, sludge and pasty media

- Large front-flush diaphragm

- 2-wire probe

- Ex Zone 0

- High overpressure resistance

- Integrated overvoltage protection

The hydrostatic level probe with G 1.5” thread has been developed to meet the high demands of industry and environmental protection.

The corrosion-proof encapsulation featuring IP68 protection rating allows to use the unit for reliable level detection in containers, tanks and pipelines. The large resistant ceramic diaphragm has proven particularly in the wastewater sector as well as in the chemical industry. Due to the front-flush diaphragm the unit can be used even in viscous media and pastes. Diaphragm failures are virtually eliminated.The HydroBar G II can be used in aggressive media such as acids and caustic solutions as well.

Typical applications for HydroBar G II- Pump stations

- Pipelines

- Containers and tanks

- Digester outlets

- Industrial applications

- and many more

UniBar E II

-

Screw-in probe stainless steel measurement cell piezo-resistive

Screw-in probe with internal 4 - 20 mA transmitter for hydrostatic level measurement in water, wastewater and gases. With piezo-resistive stainless steel measurement cell.- Robust and reliable screw-in probe with ½“ threaded connection

- Piezo-resistive measurement cell

- for gases as well as clean to slightly polluted liquids

- 2-wire probe

- Ex Zone 0

- High overpressure resistance