- Offer Profile

- The core competence of SINGLE Temperiertechnik GmbH is the development and production of high-performance, energy-efficient temperature control and cooling technology. With about 140 staff members and representations in more than thirty countries we have become firmly established among the leading providers in the market.

Smart Line

-

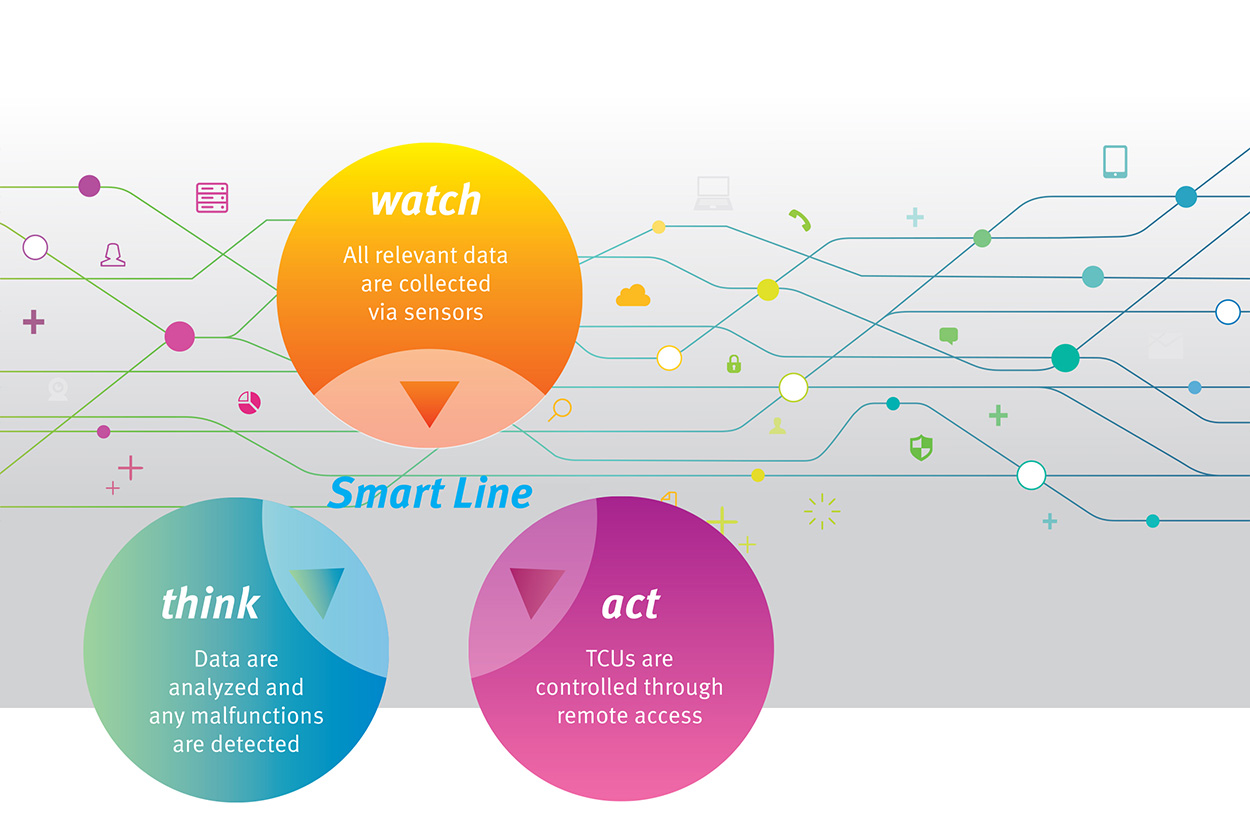

Watch Think Act

We make it easy for you to manage, analyze and operate temperature control units on a single platform.

While future challenges are becoming increasingly complex, solutions must remain simple. And this is where SmartLine comes in. At Single, we are here to accompany you on your journey to connecting machines and processes. We are making sure that our temperature control units are Industry4.0-ready. All temperature controllers are linked through a local website where data can be managed, analyzed and controlled.

And this is what you get:

- higher availability

- reduced downtime

- increased productivity

- reduced workloads

- improved part quality

- reduced in-house staff cost

- savings in external labor cost

- time savings

- transparent processes

- predictive maintenance

Data Mining

- The temperature control units are linked to the local network, allowing the local smarthub to download their process data, parameters and messages.

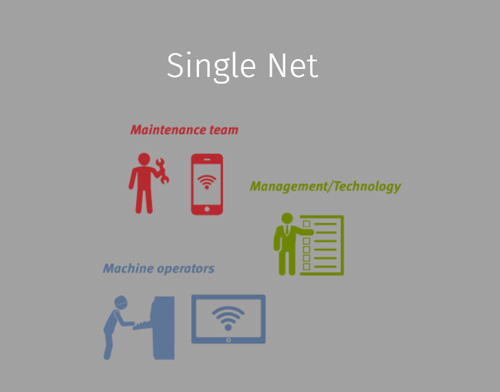

Single Net

- The Smart Hub provides a website which can be accessed through a browser on a PC or tablet. Each user group has views tailored to their needs.

Smart Hub

- The Smart Hub is a mini server, the size of your hand, which you can connect in your local network. There it will connect to all available SINGLE temperature control units with a Smart Controller. Also available as virtual server.

Single Data Portal

- The machine data collected by the Smart Hub is transmitted to the Single Data Portal through an encrypted HTTPS connection.

Secure Access

-

Device independent local webpage ensures easy access to your device data. No software installation is required to monitor and control your temperature control unit.

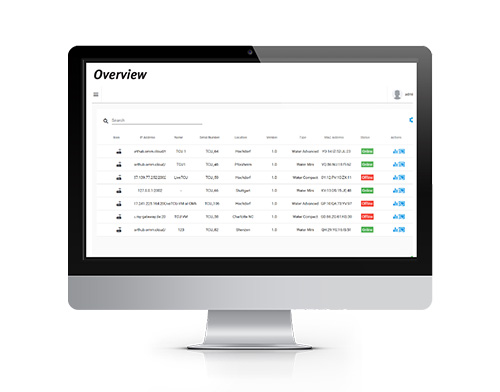

- TCU List: Live overview shows all temperature control units, including serial number, location and status. You can give each device a name and location of your choice.

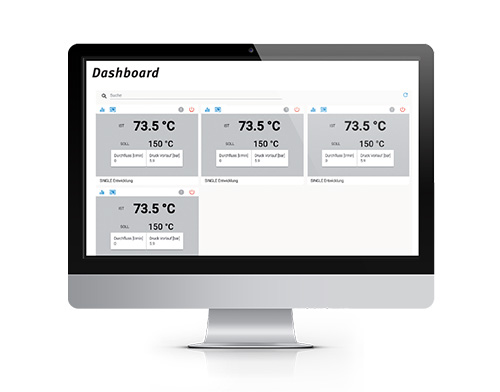

- The dashboard displays all key process data and the status of every device. You can use the search function to look for an individual device which can then be operated via the controller’s remote control feature.

- Displays historical data for a freely selectable time period. Process data can be selected individually.

- Lists all function-related system parameters and detailed process data.

Recorded Data

-

- Access to historical process data, including any type of messages (info, alerts, alarms).

- Displays all relevant process data for a graphical overview of TCU behavior.

- Select flexible time axes and areas for a comparison of layers to facilitate optimization and troubleshooting.

- Off line data caching.

- Query historical data.

- Alternative method of data synchronization in case of connection failure.

Direct Access (VNC)

-

- Users may request remote support and grant visual access to the controller.

- Single Service teams can provide remote support, if both parties have access to the PC/mobile device.

- Service hotline.

Smart Controller

-

At the heart of the device and Smart Line is the new Single controller. Its so ware regulates the temperature control unit and ensures that it is Industry4.0-ready.

The Smart Controller is used to control device functionality. It off ers users a comprehensive range of options to manage control behavior.

The controller has an extensive array of Fieldbus interfaces: 20mA TTY, RS232, RS485, Euromap 66, Profibus, OPC UA. These are hardware components which are enabled via an activation process.

Cooling and temperature control

Water - operated

WATER ADVANCED G

-

SINGLE WATER-OPERATED TEMPERATURE CONTROL SYSTEMS UP TO 180°C

- heating capacity: up tp 72 kW

- cooling capacity: up tp 400 kW

- max. flow rate: 400 l/min

- max pressure: 4,4 bar

As part of Water Advanced product family, the all-purpose, high-temperature water-operated temperature control systems of the N-G and H product lines are equipped for operation far above the atmospheric boiling point with temperatures of up to 225 °C. With their wide temperature and dimensional range which covers medium to very large capacities, they provide the basis for numerous special projects. Thanks to their high reliability and precision and virtually unlimited application options they meet a variety of requirements.

Compared to heat transfer oil, the use of water as a circulating medium provides several physical and economic benefits – particularly when operating with higher temperatures. In addition to the benefits mentioned above, superior pump technology enhances the economic advantages of the Water Advanced product family. The systems are mainly equipped with high-quality, multi-stage centrifugal pumps with a high level of efficiency, which can directly affect the system’s energy consumption.

WATER ADVANCED G2

-

SINGLE WATER-OPERATED TEMPERATURE CONTROL SYSTEMS UP TO 225°C

- heating capacity: up tp 96 kW

- cooling capacity: up tp 144 kW

- max. flow rate: 650 l/min

- max pressure: 4,0 bar

As part of Water Advanced product family, the all-purpose, high-temperature water-operated temperature control systems of the N-G and H product lines are equipped for operation far above the atmospheric boiling point with temperatures of up to 225 °C. With their wide temperature and dimensional range which covers medium to very large capacities, they provide the basis for numerous special projects. Thanks to their high reliability and precision and virtually unlimited application options they meet a variety of requirements.

Compared to heat transfer oil, the use of water as a circulating medium provides several physical and economic benefits – particularly when operating with higher temperatures. In addition to the benefits mentioned above, superior pump technology enhances the economic advantages of the Water Advanced product family. The systems are mainly equipped with high-quality, multi-stage centrifugal pumps with a high level of efficiency, which can directly affect the system’s energy consumption.

WATER ADVANCED HIGH TEMP H0

-

SINGLE WATER-OPERATED TEMPERATURE CONTROL SYSTEMS UP TO 225°C

- heating capacity: up tp 12 kW

- cooling capacity: up tp 42 kW

- max. flow rate: 60 l/min

- max pressure: 6,0 bar

As part of Water Advanced product family, the all-purpose, high-temperature water-operated temperature control systems of the N-G and H product lines are equipped for operation far above the atmospheric boiling point with temperatures of up to 225 °C. With their wide temperature and dimensional range which covers medium to very large capacities, they provide the basis for numerous special projects. Thanks to their high reliability and precision and virtually unlimited application options they meet a variety of requirements.

Compared to heat transfer oil, the use of water as a circulating medium provides several physical and economic benefits – particularly when operating with higher temperatures. In addition to the benefits mentioned above, superior pump technology enhances the economic advantages of the Water Advanced product family. The systems are mainly equipped with high-quality, multi-stage centrifugal pumps with a high level of efficiency, which can directly affect the system’s energy consumption.

Advanced Water WP4 / 90-150-180-200°C

-

EFFICIENT PERFORMANCE

Options:

- Reinforced pumps

- Tool emptying sucking/by means of compressed air

- Ecotemp

- Different interface

It is the inner values that matter: In the WP4 series we use only high-quality materials and innovative technology. Stainless steel, non-ferrous metal and well thought-out construction ensure a long service life. Intelligent control allows the WP4 devices to work with maximum safety and efficiency. The WP4 - water temperature control units for applications and requirements in the medium to upper performance range and temperatures up to 200 °C are particularly common in plastic injection moulding, but are also used in other processes. They are suitable for temperature control of high quality applications and allow documentation of process parameters.

Advanced Water WP5 / 90-150-180- 200°C

-

WP5 SETS STANDARDS !

The WP5 is one of the core pieces of the Single water temperature control units. The WP5 units are available in a wide performance range of 90°C / 150°C / 180°C and 200°C, and with almost unlimited options. Whether for injection moulding, extrusion or numerous other applications, the WP5 series can be used universally. Thanks to its reliability and its features, this series is our contribution to increasing your productivity and improving your uptime.

WATER ADVANCED HIGH TEMP HK

-

SINGLE WATER-OPERATED TEMPERATURE CONTROL SYSTEMS UP TO 225°C

- heating capacity: up tp 6 kW

- cooling capacity: up tp 5 kW

- max. flow rate: 25 l/min

- max pressure: 4,5 bar

As part of Water Advanced product family, the all-purpose, high-temperature water-operated temperature control systems of the N-G and H product lines are equipped for operation far above the atmospheric boiling point with temperatures of up to 225 °C. With their wide temperature and dimensional range which covers medium to very large capacities, they provide the basis for numerous special projects. Thanks to their high reliability and precision and virtually unlimited application options they meet a variety of requirements.

Compared to heat transfer oil, the use of water as a circulating medium provides several physical and economic benefits – particularly when operating with higher temperatures. In addition to the benefits mentioned above, superior pump technology enhances the economic advantages of the Water Advanced product family. The systems are mainly equipped with high-quality, multi-stage centrifugal pumps with a high level of efficiency, which can directly affect the system’s energy consumption.

Easitemp 150 2.0

-

WATER-OPERATED SYSTEM SERIES UP TO 200°C

With easitemp150, we concentrate on the essentials when it comes to temperature control. In many industrial applications, temperatures up to a maximum of 150°C are sufficient. In this segment, SINGLE easitemp150 convinces with good features and highest precision in a compact design. With easitemp 150, you make no compromises in terms of robustness, quality and safety.

Thus, we guarantee maximum continuous running capability with economical operation.

Easitemp 6/95 2.0

-

WATER-OPERATED SYSTEM SERIES

The new easitemp 95 series is concentrating on what's important. In many industrial applications temperatures of 95°C. In this segment, SINGLE easitemp impresses with equipment and highest precision in a compact design. The easitemp series includes all the technological functions that characterize SINGLE temperature control technology. This ensures maximum continuous operation with economical operation.

WATER ADVANCED WP7

-

WATER-OPERATED SYSTEM SERIES UP TO 200°C

- heating capacity: up tp 54 kW

- cooling capacity: up tp 300 kW

- max. flow rate: 230 l/min

- max pressure: 4,7 bar

The water temperature control systems of the WP7 series up to 200 °C are the core of the product range. The universal applications of the WP7 series range from injection moulding to extrusion.

MINI WM3 SERIES

-

SMALL FORMAT. STRONG PERFORMANCE

High tech in the smallest space. The new SINGLE Mini WM3 series convinces in the demanding performance class up to 160° C with maximum precision and reliability.With their compact design, the WM3 mini temperature control units take up extremely little space in production. All in proven SINGLE quality. This means: long service life and low energy consumption. Mini WM3 - the state-of-the-art temperature control unit.

WATER COMPACT TANK TKG

-

WATER-OPERATED SYSTEM SERIES UP TO 90°C

- heating capacity: up tp 72 kW

- cooling capacity: up tp 300 kW

- max. flow rate: 233 l/min

- max pressure: 4,2 bar

In contrast to heat-transfer oil, water used as a circulating medium provides numerous physical and economic benefits – particularly for high operating temperatures. The heat transfer characteristics of water are far superior to those of oil: its high specific heat transfer capacity is second to no other liquid media. Water also provides many ecological benefits.

The KN size of the Water Compact product family are equipped for operation far above the atmospheric boiling point with temperatures of up to 180 °C. They meet the most stringent safety requirements. The systems are extremely compact and are built exclusively with high-quality components.

WATER COMPACT TANK TKN

-

WATER-OPERATED SYSTEM SERIES UP TO 90°C

- heating capacity: up tp 24 kW

- cooling capacity: up tp 80 kW

- max. flow rate: 51 l/min

- max pressure: 3,9 bar

In contrast to heat-transfer oil, water used as a circulating medium provides numerous physical and economic benefits – particularly for high operating temperatures. The heat transfer characteristics of water are far superior to those of oil: its high specific heat transfer capacity is second to no other liquid media. Water also provides many ecological benefits.

The KN size of the Water Compact product family are equipped for operation far above the atmospheric boiling point with temperatures of up to 180 °C. They meet the most stringent safety requirements. The systems are extremely compact and are built exclusively with high-quality components.

Oil - operated

OIL ADVANCED D1

-

OIL OPERATED SYSTEM SERIES UP TO 350°C

- heating capacity: up tp 20 kW

- cooling capacity: up tp 50 kW

- max. flow rate: 60 l/min

- max pressure: 6,0 bar

High-temperature oil-operated temperature control systems for temperatures up to 350 °C are recommended for applications that rule out other temperature control media due to high temperature requirements. Thanks to its wide variety of options for capacity, temperature range and dimensions, the Oil Advanced product family is suitable for many different processes and requirements within a wide capacity range. With its virtually unlimited amount of options and equipment variations, maximum reliability and precision, the systems meet every demand. General

OIL ADVANCED D2

-

OIL OPERATED SYSTEM SERIES UP TO 350°C

- heating capacity: up tp 36 kW

- cooling capacity: up tp 116 kW

- max. flow rate: 100 l/min

- max pressure: 11,0 bar

High-temperature oil-operated temperature control systems for temperatures up to 350 °C are recommended for applications that rule out other temperature control media due to high temperature requirements. Thanks to its wide variety of options for capacity, temperature range and dimensions, the Oil Advanced product family is suitable for many different processes and requirements within a wide capacity range. With its virtually unlimited amount of options and equipment variations, maximum reliability and precision, the systems meet every demand. General

OIL ADVANCED D3

-

OIL OPERATED SYSTEM SERIES UP TO 350°C

- heating capacity: up tp 54 kW

- cooling capacity: up tp 116 kW

- max. flow rate: 360 l/min

- max pressure: 4,2 bar

High-temperature oil-operated temperature control systems for temperatures up to 350 °C are recommended for applications that rule out other temperature control media due to high temperature requirements. Thanks to its wide variety of options for capacity, temperature range and dimensions, the Oil Advanced product family is suitable for many different processes and requirements within a wide capacity range. With its virtually unlimited amount of options and equipment variations, maximum reliability and precision, the systems meet every demand. General

OIL ADVANCED D4

-

OIL OPERATED SYSTEM SERIES UP TO 350°C

- heating capacity: up tp 144 kW

- cooling capacity: up tp 232 kW

- max. flow rate: 550 l/min

- max pressure: 4,7 bar

High-temperature oil-operated temperature control systems for temperatures up to 350 °C are recommended for applications that rule out other temperature control media due to high temperature requirements. Thanks to its wide variety of options for capacity, temperature range and dimensions, the Oil Advanced product family is suitable for many different processes and requirements within a wide capacity range. With its virtually unlimited amount of options and equipment variations, maximum reliability and precision, the systems meet every demand. General

OIL ADVANCED Do

-

OIL OPERATED SYSTEM SERIES UP TO 350°C

Compact oil-operated temperature control systems are recommended for applications that rule out water-operated systems due to high temperature requirements. The Oil Compact systems offer the benefit of operating without pressure blanketing. Distinguished by their keen price/performance ratio, these compact systems are suitable for a variety of processes and tasks in the lower capacity range. With their high reliability and precision they accommodate many options and equipment variations to meet every requirement.

Variotherm Temperature Control

ATT H

-

Alternating temperature system Series up to 200°C

- heating capacity (cooling circuit /heating circuit): up tp 36/6 kW

- cooling capacity (cooling circuit /heating circuit): up tp 270/42 kW

- max. flow rate: 200 l/min

- max pressure: 8,0 bar

Variotherm temperature control used in combination with suitable mould inserts allows variations in temperature of more than 100 °C in critical areas or in complete moulds. In order to achieve this, the SINGLE ATT system operates with two separate circuits that contain thermal fluid with a different temperature. Both ATT circuits contain the same fluid. Water is recommended for temperatures of up to 200 °C, while oil is suitable for applications that operate with temperatures of up to 300 °C.

ATT K

-

Alternating temperature system Series up to 160°C

- heating capacity: up tp 18 kW

- cooling capacity (cooling circuit /heating circuit): up tp 50/23 kW

- max. flow rate: 60 l/min

- max pressure: 6,0 bar

Variotherm temperature control used in combination with suitable mould inserts allows variations in temperature of more than 100 °C in critical areas or in complete moulds. In order to achieve this, the SINGLE ATT system operates with two separate circuits that contain thermal fluid with a different temperature. Both ATT circuits contain the same fluid. Water is recommended for temperatures of up to 200 °C, while oil is suitable for applications that operate with temperatures of up to 300 °C.

ATT N1

-

Alternating temperature system Series up to 180°C

- heating capacity (cooling circuit /heating circuit): up tp 36/6 kW

- cooling capacity (cooling circuit /heating circuit): up tp 150/35 kW

- max. flow rate: 75 l/min

- max pressure: 7,3 bar

Variotherm temperature control used in combination with suitable mould inserts allows variations in temperature of more than 100 °C in critical areas or in complete moulds. In order to achieve this, the SINGLE ATT system operates with two separate circuits that contain thermal fluid with a different temperature. Both ATT circuits contain the same fluid. Water is recommended for temperatures of up to 200 °C, while oil is suitable for applications that operate with temperatures of up to 300 °C.

ATT S

-

Alternating temperature system Series up to 180°C

- heating capacity (cooling circuit /heating circuit): up tp 60/12 kW

- cooling capacity (cooling circuit /heating circuit): up tp 220/220 kW

- max. flow rate: 200 l/min

- max pressure: 8,0 bar

Variotherm temperature control used in combination with suitable mould inserts allows variations in temperature of more than 100 °C in critical areas or in complete moulds. In order to achieve this, the SINGLE ATT system operates with two separate circuits that contain thermal fluid with a different temperature. Both ATT circuits contain the same fluid. Water is recommended for temperatures of up to 200 °C, while oil is suitable for applications that operate with temperatures of up to 300 °C.

Cooling technology

CHILL ADVANCED

-

Cooling system Series +5 ... +30°C

- heating capacity:optional

- cooling capacity: up to 40 kW

- max. flow rate: 240 l/min

- max pressure: 4,7 bar

Cooling systems of the Chill Advanced product family are suitable for industrial applications that require liquid cooling. Equipped with their own cooling circuit and a medium-level cooling capacity range from 6kW up t 70kW, they are suitable for all purpose and numerous applications across all industries. Maximum quality and process reliability distinguish the open-circuit, contamination-free systems which can be adapted for special requirements and operating conditions with numerous hydraulic, electric and control options.

CHILL COMPACT

-

Cooling system Series +5 ... +30°C

- heating capacity:optional

- cooling capacity: up to 4 kW

- max. flow rate: 60 l/min

- max pressure: 4,5 bar

Compact cooling systems of the Chill Compact Product family are suitable for all applications that repuire liquid cooling in the smaller capacity range. Equipped with their own cooling circuit, they are used for small and laboratory tasks as well for special applications across all industries - from 1kW upto 5kW cooling capacity. Premium quality and process reliability characterise these open-ciruit and contamination-free systems with a veriety of special customizing options to meet special requirements and operation contitions.

CHILL PLUS

-

Cooling system Series +10 ... +90°C

- heating capacity:up to 24 kW

- cooling capacity: up to 30 kW

- max. flow rate: 240 l/min

- max pressure: 4,7 bar

Chill Plus series cooling systems have their own cooling circuit and a large cooling capacity range from 200 to 1000 kW. They are established as central systems in all industrial sectors. Highest quality and process reliability charaterise the open and contamination-free systems, which can be designed with numerous options for special performance requirements and operating conditions.

EASICHILL

-

Cooling system Series +6 ... +20°C

- cooling capacity: up to 140 kW

- max. flow rate: 410 l/min

- max pressure: 4,0 bar

easichill sets the new standard for cooling systems with their own cooling circuit. Particularly cpmpact space-saving cooling units are cost-effective alternative for standard applications that require liquid cooling. The wide cooling capacity spectrum covers the requirements of all industrial sectors. Highest quality contamination-free units, which prove to be particularly economical in purchase and operation.

easichill - the compact and economical alternative !

Sulutions

-

SOLUTIONS INSTEAD OF JUST PRODUCTS

In addition to know-how and experience, tailor-made and customer-specific solutions of the highest quality are a special feature of Single .Our engineers know exactly what the specific requirements in the various industries are - and provide the right answers. To meet the challenges of a networked (industrial) world, we have developed Smart Line, a future-oriented IoT solution. And our solution-oriented thinking and action is not limited to hardware alone, but offers comprehensive engineering and the entire process chain from a single source - from the idea to design, production and final assembly to on-site commissioning.

We are sure to have the right solution for your individual needs. Talk to us.