KILDE Automation

Videos

Loading the player ...

- Offer Profile

- KILDE is your professional

automation partner. In close cooperation with you we develop flexible

machine solutions optimizing your production. When you choose a KILDE

solution you are sure to get a robust and future-proof high quality solution

that contributes to the continued development of your competitiveness. We

have more than 40 years of experience in designing and building machines and

automating production processes.

Product Portfolio

Thermoforming

-

HANDLING SOLUTIONS FOR THERMOFORMING INDUSTRY

At Kilde A/S we deliver custom end-of-line solutions for the thermoforming industry.

With an automated production process, we can free your employees from stressful tasks, such as heavy lifting, repetitive tasks and so on. Our customers experience a much higher utilization of their production line and less waste.

The optimal solution for you depends on many factors, such as; product mix, production line speed and many other variables. We will guide you through the process, in order to give you the best solution now and for the future.

Based on our OCTOPUS concept, we can deliver state-of-the-art solutions, which improves your competitiveness. Your OCTOPUS solution is custom designed to match your products and production lines.

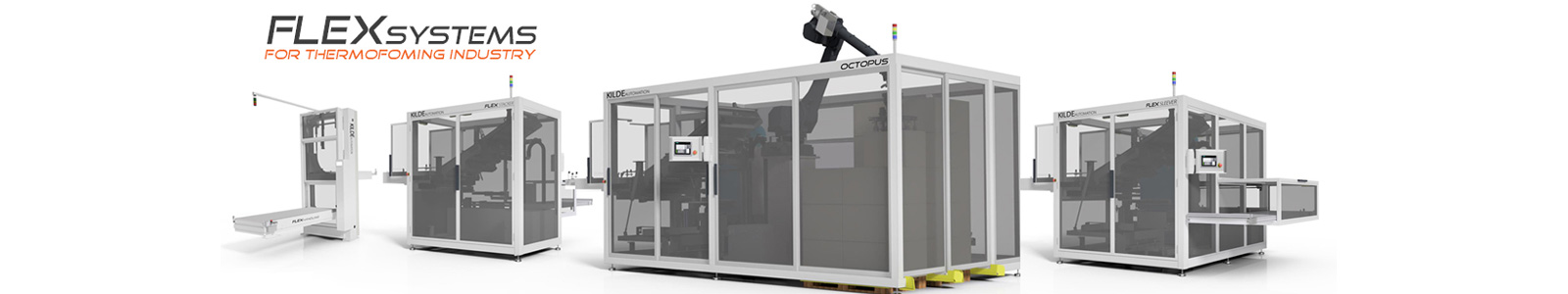

With our new FLEXsystems we have developed a very flexible modular-based system for thermoforming which consists of our FLEX products:

FLEX PACKING TABLE

-

The FLEX Packing Table transfers the stacked products from the out conveyor of the thermoforming machine and down to packaging level, which eliminates the need of a packing platform.

The height of the packing conveyor can be adjusted to fit the height of the operator, in order to secure ergonomically correct working conditions.

Process overview- Infeed buffer

- Handling & bring down

- Buffer packing

Datasheet & options

The FLEX Packing Table is easily integrated, with its infeed buffer and height adjustable packing height and options like telescopic conveyors and much more.

Download our brochure and read our complete datasheet and options for the FLEX Packing Table.

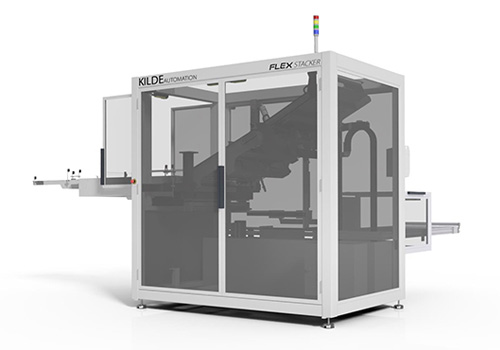

FLEXSTACKER

-

The FLEX Stacker combines stacks of thermoformed parts to a predefined stack length and delivers them on a conveyor belt ready for packing.

Process overview- Infeed buffer

- Handling & stacking

- Buffer for packing

FLEXSLEEVER

-

FLEXsleever is our newest member of the KILDE family. More than 40 years of experience with production automation went in to the design and development of this new solution for the thermoforming industry.

The FLEXsleever stacks thermoformed parts to stacks of a predefined height, seals them in foil bags (Sleeving) and delivers them on a conveyor belt ready for packing.

The FLEXsleever can be integrated seamlessly into your existing production line, where the infeed of the FLEXsleever receives the thermoformed units ready for handling and stacking. From here the units are sealed in foil bags (Sleeved) and ready for packaging.

The FLEXsleever can handle between 597 and 1578 stacks per hour, depending on your production capacity and needs.

Datasheet - Max sleeved stacks/hour

1 stack per bag = 597 stacks/hour

2 stacks per bag = 1019 stacks/hour

4 stacks per bag = 1578 stacks/hour

Options- Intermediate buffer conveyor belt

- Transverse pusher for automatic removal of test parts

- Printer

- Format set; For every new product, for unsleeved operation and for removal of excess foil

FLEX PAD INSERTER

-

Due to the fact that the PAD INSERTER unit and the dispenser unit can be placed virtually anywhere, the solution is very flexible. The PAD INSERTER unit can be built in-line with the thermoforming machine or placed in an outside line. The dispenser unit can be placed close to the absorber padding unit - even on another floor.

The PAD INSERTER as standard, offers 4 rows of absorber pads. They are cut into the required length and are placed on the conveyor.

A Scara robot with a suction head picks up the pads and places them in the trays. Different suction heads cover different trays. As an option the suction head can rotate 90° if required. The cycle is 30 pick-ups per minute.

The PAD INSERTER unit can be fitted with glue applicator heads. The glue is sprayed on the trays just before the absorber pads are placed.

If the absorber pads are welded into the trays, the unit can be fitted with an ultrasonic welder. The pads are placed and welded to the tray by the suction head in one operation.

Process overview- Unrolling

- Cutting

- Placement & fixing

Datasheet & options

The dispenser unit handles as standard 4 x Ã1200mm rolls with a width of 75 – 150 mm.

When the rolls are empty a loading system replaces the empty rolls. You can reload the system with new rolls during normal operation.

The new absorber rolls are welded together with the ends of the remaining absorber lengths. A buffer system ensures that the PAD INSERTER unit runs continuously during refill.

Download our brochure and read our complete datasheet and options for the FLEX Pad Inserter.

OCTOPUS

-

The OCTOPUS is our fully automated machine, for stacking thermoformed parts to stacks of a predefined length. After being stacked, the parts are sealed in foil bags (Sleeved). The OCTOPUS erects cardboard boxes and packs the sleeved units into the boxes.

From here, the boxes are palletised and ready for shipping!

Process overview- Handling & stacking

- sleeving

- box erecting

- packing

- palletising

Datasheet & options

Want to know more about the OCTOPUS? Download our brochure from the link box and read more about the data and options for our new OCTOPUS.

OCTOPUS I

OCTOPUS I is the smallest basic configuration of the OCTOPUS program. Even in the smallest execution it is possible to configure the robot cell to full functionality.

All functions are performed by only one robot. Therefore the capacity is limited compared to that of OCTOPUS I HS and OCTOPUS II.

We live in a dynamic world and sometimes the conditions, which existed at the time the machine was bought, change. Options which are deselected when buying an OCTOPUS I can later be integrated without significant extra costs.

OCTOPUS I HS

OCTOPUS I HS is, besides the robot, equipped with a unit, which picks the parts from the buffer conveyor, makes the double stacking and feeds the parts to the sleeving unit.

Thus robot capacity is freed meaning that OCTOPUS I HS is much faster than OCTOPUS I

Furthermore OCTOPUS I HS has the advantage compared to OCTOPUS I that there is only one simple tool, which is placed on the infeed side. Thus the costs in connection with introduction of new products are reduced.

OCTOPUS II

OCTOPUS II is equipped with two robots carrying out all handling tasks. OCTOPUS II is the product of the OCTOPUS family, which offers the highest degree of flexibility and the highest number of functions.

In addition to the functions, which are offered by OCTOPUS I HS, OCTOPUS II is able to rotate the parts in the stacking tower. This function is used for turning the products according to the specified packaging pattern.

By rotating the parts it is possible to work with packaging patterns in cartons and gitterboxes where some of the stacks are turned in order to optimise use of space.

KILDE MOVER

-

The KILDEMOVER is an AIV(Autonomous Intelligent Vehicle), which fully automatic handles and transports goods and materials. Unlike an AGV (Autonomous Guided Vehicle) the KILDEMOVER makes no use of magnets or other signaling devices in floors/walls which saves you up to 15% deployment costs. The basis unit is an ADEPT LYNX from the company Omron, one of the world’s leading producers of AIV’s. By means of intelligent software and laser technology, the KILDEMOVER can safely self-navigate at the workplace among permanent or moveable obstacles, crowded, peopled environments or other places where the space is cramped. With an integrated conveyor our standard model of the KILDEMOVER can automatize receipt and delivery of goods, boxes and other units. The opportunity for integration of an AVI in your company are numerous and therefore we design custom-made solutions together with our customers, thereby securing stabile CE-approved solutions.

FEATURES- Simplifies payload integration with a small mobile platform

- Self-navigation software safely avoids people and obstacles

- Reliable drive system optimized for self-navigation

- Navigates through the use of a digital map

- Easy to deploy, no facilities modifications required

- Manages power and self-charging operations

- CE compliant

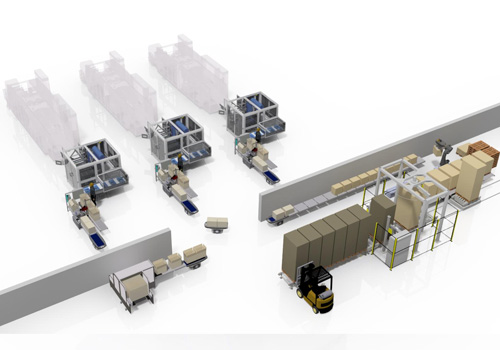

CENTRAL PALLETERING

-

Central palletization automates the transport of products to automated palletizing systems. The palletization system is located, for example. Close to warehouse or shipping department where the finished pallets can be easily or efficiently stored or shipped. This minimizes the transport of products, fewer employees, and creates greater efficiency.

FEATURES- Use of AIV and/or conveyor solutions

- Automated box errecting

- Robot solution for palletizning

- Automated pallet wrapping

- Buffer system box and pallet

INDUSTRY

-

At KILDE we have more than 40 years of experience. We have a strong position as supplier of automation for industrial production. Our team of specialists is dedicated to industrial automation. Working closely with our customers we create a solution that automates and optimises the individual processes. We use our experience and technical competence for creating solutions ensuring the future production of our customers.

Concept development

We are happy to take part already at the idea phase of the project and enter into close partnership with our customers. At this stage a lot of decisions are made, which have large influence on integration, flexibility, costs and future-proofing. Small changes of products can simplify the production significantly and thus both improve quality and make production cheaper. In that way the possibilities of achieving a high degree of automation in production, assembly and packaging of your products get better.

Good solutions for demanding automation tasks

We are innovative and have many years of experience in selecting and integrating new technology. We constantly monitor which technological opportunities can be used to our advantage and keep an eye on when the technologies are ready to live up to the large demands of the industry. KILDE has supplied solutions to production, quality control and packaging for a wide range of various products and processes.

Turnkey supplies

A finished concept and a specification are not necessary to start a partnership with us. We have a lot of experience regarding exactly this part of the process and are happy to help in defining the solution. We take full responsibility and take charge of the project management from specification to delivery of the turnkey project, which will be customized for your particular needs.

People and machines

Our machines must be easy to operate. The process operator must be able to take care of change-overs and fault conditions himself to the greatest extent possible. Safety is always our first priority both in terms of operation and maintenance.

Dedicated employees

We have an ambitious goal – all solutions must work 24/7. Our team of dedicated employees have specialized knowledge of automation. This knowledge is always updated and at our customers’ disposal. We are the competent business partner who takes you into the future with expert advice on new technology specifically for your business. PLASTICS

-

At KILDE we have more than 40 years of experience and we pride ourselves on a strong position as a leading automation supplier for the thermoforming industry. Our team of specialists is dedicated to thermoforming automation. Working closely with each business we create a solution that optimises specific processes. We use our experience to create solutions ensuring the future production of our customers.

Flexible automation for thermoformed trays and lids

KILDE supplies solutions that automate all processes after thermoforming of the parts. Our customized solutions are developed in close dialogue with our customers and are based on special modules developed specifically for the thermoforming industry. We also offer a range of other standard machines, for example a machine for insertion of absorption pads.

Large product program for optimisation of your packaging process

Based on our modular product program we offer unique solutions for optimisation of packaging processes. We look for the optimum solution depending on the specific products and needs. We continuously develop our program in order to ensure the best solutions. All solutions are based on standardized software and proven technology.

Higher profit with automation

Automation is connected to optimisation of the production. Automated production lines have higher output, less discarding of items and yield a higher profit. Optimisation is a process, and so is the introduction of automation. We work together with our customers on a long-term basis and want the individual investments to fit into the long-term optimisation of the production but also to result in immediate cost reductions in the short term.

Dedicated employees

We have an ambitious goal – all solutions must work 24/7. Our team of dedicated employees have specialized knowledge of automation within the thermoforming industry. This knowledge is always updated and at our customers’ disposal. We are the competent business partner who takes you into the future with expert advice on new technology specifically for your business. MEDICO & PHARMA

-

KILDE has a strong position within medico and pharma. We have more than 40 years of experience as turnkey supplier of customized production and packaging solutions. Our team of specialists is dedicated to medico and pharma and we are your strategic partner, when it comes to development of production solutions for new products and optimisation of your processes. Together with you we create a solution based on new technology and our experience, thus future-proofing your production.

Turnkey supplies

We take full responsibility and take charge of the project management from specification to delivery of the turnkey project, which will be customized for your particular needs. KILDE has supplied solutions for production processes, quality control and packaging for a wide range of various products within medico and pharma.

Dedicated employees

Our team of dedicated employees has specialized knowledge of automation within the thermoforming industry. This knowledge is always updated and at our customers’ disposal. We want you to see us as a competent business partner. A partner, who helps you into the future through expert and critical advice on new technology, and has the goal that all solutions must work 24/7.